What feedstocks offer highest yields in biomass upgrading

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biomass Feedstock Evolution and Research Objectives

Biomass conversion technologies have evolved significantly over the past decades, transitioning from simple combustion methods to sophisticated biochemical and thermochemical processes. The historical trajectory began with traditional direct combustion for heat and power generation, which offered limited efficiency and substantial emissions. The 1970s energy crisis catalyzed research into alternative energy sources, marking the first significant wave of modern biomass utilization research. By the 1990s, first-generation biofuels emerged, primarily derived from food crops such as corn and sugarcane, raising concerns about food security and land use.

The 2000s witnessed the development of second-generation technologies focusing on lignocellulosic feedstocks, including agricultural residues, forestry waste, and dedicated energy crops. This shift addressed many sustainability concerns while introducing new technical challenges in breaking down recalcitrant plant cell walls. The current third-generation approaches explore algal biomass and other novel feedstocks, promising higher yields and reduced environmental footprints.

Recent technological advancements have significantly expanded the range of viable feedstocks for biomass upgrading. Genetic engineering and advanced breeding techniques have created crop varieties with enhanced characteristics for bioenergy production, including increased biomass yield, improved sugar content, and reduced lignin complexity. Concurrently, pretreatment technologies have evolved to handle diverse feedstock types more efficiently, enabling higher conversion rates and product yields.

The primary objective of current biomass feedstock research is to identify and develop sources that maximize conversion efficiency while minimizing environmental impact and production costs. This involves comprehensive characterization of feedstock properties, including cellulose, hemicellulose, and lignin content, as these components directly influence conversion pathways and product yields. Research aims to establish standardized metrics for evaluating feedstock quality and predicting conversion performance across different upgrading technologies.

Another critical research goal is developing feedstocks with reduced recalcitrance to enzymatic and chemical breakdown, as this represents a significant barrier to efficient conversion. This includes exploring natural genetic diversity, applying precision breeding techniques, and developing novel pretreatment methods tailored to specific feedstock characteristics. Additionally, research focuses on feedstocks that can be cultivated on marginal lands unsuitable for food production, thereby minimizing competition with agricultural resources while providing economic opportunities for rural communities.

The ultimate technical objective remains developing an integrated biomass value chain that optimizes feedstock selection, cultivation practices, harvesting methods, and conversion technologies to achieve maximum energy and material yields with minimal environmental footprint and economic investment.

The 2000s witnessed the development of second-generation technologies focusing on lignocellulosic feedstocks, including agricultural residues, forestry waste, and dedicated energy crops. This shift addressed many sustainability concerns while introducing new technical challenges in breaking down recalcitrant plant cell walls. The current third-generation approaches explore algal biomass and other novel feedstocks, promising higher yields and reduced environmental footprints.

Recent technological advancements have significantly expanded the range of viable feedstocks for biomass upgrading. Genetic engineering and advanced breeding techniques have created crop varieties with enhanced characteristics for bioenergy production, including increased biomass yield, improved sugar content, and reduced lignin complexity. Concurrently, pretreatment technologies have evolved to handle diverse feedstock types more efficiently, enabling higher conversion rates and product yields.

The primary objective of current biomass feedstock research is to identify and develop sources that maximize conversion efficiency while minimizing environmental impact and production costs. This involves comprehensive characterization of feedstock properties, including cellulose, hemicellulose, and lignin content, as these components directly influence conversion pathways and product yields. Research aims to establish standardized metrics for evaluating feedstock quality and predicting conversion performance across different upgrading technologies.

Another critical research goal is developing feedstocks with reduced recalcitrance to enzymatic and chemical breakdown, as this represents a significant barrier to efficient conversion. This includes exploring natural genetic diversity, applying precision breeding techniques, and developing novel pretreatment methods tailored to specific feedstock characteristics. Additionally, research focuses on feedstocks that can be cultivated on marginal lands unsuitable for food production, thereby minimizing competition with agricultural resources while providing economic opportunities for rural communities.

The ultimate technical objective remains developing an integrated biomass value chain that optimizes feedstock selection, cultivation practices, harvesting methods, and conversion technologies to achieve maximum energy and material yields with minimal environmental footprint and economic investment.

Market Analysis for High-Yield Biomass Products

The global biomass upgrading market is experiencing significant growth, driven by increasing demand for renewable energy sources and sustainable materials. As of 2023, the market is valued at approximately 120 billion USD, with projections indicating a compound annual growth rate of 7.8% through 2030. This growth trajectory is supported by stringent environmental regulations, particularly in Europe and North America, which incentivize the adoption of biomass-derived products.

The demand for high-yield biomass feedstocks is particularly strong in the biofuels sector, which accounts for nearly 60% of the total biomass upgrading market. Within this segment, advanced biofuels derived from non-food crops and agricultural residues are witnessing the fastest growth, as they address concerns related to food security and land use changes associated with first-generation biofuels.

Biochemicals represent another rapidly expanding market segment, currently valued at 45 billion USD. Major chemical companies are increasingly investing in bio-based alternatives to petroleum-derived products, driven by consumer preference for sustainable goods and corporate sustainability commitments. High-yield biomass feedstocks capable of producing multiple value-added chemicals are especially sought after in this segment.

Geographically, North America leads the market with a 35% share, followed closely by Europe at 30%. However, the Asia-Pacific region is expected to exhibit the highest growth rate in the coming years, primarily due to rapid industrialization, increasing energy demands, and government initiatives promoting renewable energy sources in countries like China and India.

The market for biomass-derived materials in construction and packaging industries is also expanding rapidly, with a current market size of 25 billion USD. This growth is fueled by the increasing adoption of green building practices and regulations limiting single-use plastics in various countries.

Consumer willingness to pay premium prices for sustainable products has created a favorable market environment for biomass-derived goods. Recent surveys indicate that 68% of consumers are willing to pay more for products made from renewable resources, particularly in developed economies.

Investment in biomass upgrading technologies has seen a substantial increase, with venture capital funding in this sector reaching 8.5 billion USD in 2022, a 15% increase from the previous year. This influx of capital is accelerating the commercialization of novel biomass conversion technologies and expanding the range of viable feedstocks.

The demand for high-yield biomass feedstocks is particularly strong in the biofuels sector, which accounts for nearly 60% of the total biomass upgrading market. Within this segment, advanced biofuels derived from non-food crops and agricultural residues are witnessing the fastest growth, as they address concerns related to food security and land use changes associated with first-generation biofuels.

Biochemicals represent another rapidly expanding market segment, currently valued at 45 billion USD. Major chemical companies are increasingly investing in bio-based alternatives to petroleum-derived products, driven by consumer preference for sustainable goods and corporate sustainability commitments. High-yield biomass feedstocks capable of producing multiple value-added chemicals are especially sought after in this segment.

Geographically, North America leads the market with a 35% share, followed closely by Europe at 30%. However, the Asia-Pacific region is expected to exhibit the highest growth rate in the coming years, primarily due to rapid industrialization, increasing energy demands, and government initiatives promoting renewable energy sources in countries like China and India.

The market for biomass-derived materials in construction and packaging industries is also expanding rapidly, with a current market size of 25 billion USD. This growth is fueled by the increasing adoption of green building practices and regulations limiting single-use plastics in various countries.

Consumer willingness to pay premium prices for sustainable products has created a favorable market environment for biomass-derived goods. Recent surveys indicate that 68% of consumers are willing to pay more for products made from renewable resources, particularly in developed economies.

Investment in biomass upgrading technologies has seen a substantial increase, with venture capital funding in this sector reaching 8.5 billion USD in 2022, a 15% increase from the previous year. This influx of capital is accelerating the commercialization of novel biomass conversion technologies and expanding the range of viable feedstocks.

Global Biomass Upgrading Technology Assessment

Biomass upgrading technologies have evolved significantly over the past decades, transitioning from basic combustion methods to sophisticated biochemical and thermochemical conversion processes. This evolution has been driven by increasing global energy demands, environmental concerns, and the need for sustainable alternatives to fossil fuels. The technological trajectory shows a clear shift towards more efficient, cost-effective, and environmentally friendly processes that maximize energy recovery and minimize waste production.

The global biomass upgrading market is projected to grow at a CAGR of approximately 6.2% between 2021 and 2026, reaching a market value of USD 168.9 billion by 2026. This growth is primarily fueled by supportive government policies, increasing investments in renewable energy, and growing awareness about the environmental benefits of biomass-derived products. Regions like Europe and North America currently lead in technology adoption, while Asia-Pacific represents the fastest-growing market due to rapid industrialization and urbanization.

Current biomass upgrading technologies face several challenges, including feedstock variability, process efficiency limitations, and economic viability concerns. The heterogeneous nature of biomass feedstocks presents significant processing challenges, as different types require specific pretreatment methods and conversion technologies. Additionally, the energy density of biomass is generally lower than fossil fuels, necessitating more efficient conversion processes to achieve comparable energy outputs.

Geographically, biomass upgrading technology development is concentrated in North America, Europe, and increasingly in Asia. The United States leads in research and development of advanced biofuels and biochemicals, while European countries like Germany, Denmark, and Sweden excel in biogas production and integrated biorefinery concepts. China and India are emerging as significant players, particularly in the development of cost-effective technologies suitable for agricultural residues abundant in these regions.

Recent technological breakthroughs include the development of more efficient catalysts for thermochemical conversion, advanced enzyme systems for biochemical processes, and innovative reactor designs that improve process economics. These advancements are gradually addressing the technical barriers that have historically limited the widespread adoption of biomass upgrading technologies.

The integration of digital technologies, such as artificial intelligence and machine learning, is beginning to transform biomass upgrading operations by optimizing process parameters, predicting maintenance needs, and enhancing overall system efficiency. This digital transformation represents a significant trend that is expected to accelerate in the coming years, potentially revolutionizing how biomass resources are converted into valuable products.

The global biomass upgrading market is projected to grow at a CAGR of approximately 6.2% between 2021 and 2026, reaching a market value of USD 168.9 billion by 2026. This growth is primarily fueled by supportive government policies, increasing investments in renewable energy, and growing awareness about the environmental benefits of biomass-derived products. Regions like Europe and North America currently lead in technology adoption, while Asia-Pacific represents the fastest-growing market due to rapid industrialization and urbanization.

Current biomass upgrading technologies face several challenges, including feedstock variability, process efficiency limitations, and economic viability concerns. The heterogeneous nature of biomass feedstocks presents significant processing challenges, as different types require specific pretreatment methods and conversion technologies. Additionally, the energy density of biomass is generally lower than fossil fuels, necessitating more efficient conversion processes to achieve comparable energy outputs.

Geographically, biomass upgrading technology development is concentrated in North America, Europe, and increasingly in Asia. The United States leads in research and development of advanced biofuels and biochemicals, while European countries like Germany, Denmark, and Sweden excel in biogas production and integrated biorefinery concepts. China and India are emerging as significant players, particularly in the development of cost-effective technologies suitable for agricultural residues abundant in these regions.

Recent technological breakthroughs include the development of more efficient catalysts for thermochemical conversion, advanced enzyme systems for biochemical processes, and innovative reactor designs that improve process economics. These advancements are gradually addressing the technical barriers that have historically limited the widespread adoption of biomass upgrading technologies.

The integration of digital technologies, such as artificial intelligence and machine learning, is beginning to transform biomass upgrading operations by optimizing process parameters, predicting maintenance needs, and enhancing overall system efficiency. This digital transformation represents a significant trend that is expected to accelerate in the coming years, potentially revolutionizing how biomass resources are converted into valuable products.

Current High-Yield Feedstock Processing Methods

01 Genetic modification for enhanced biomass yield

Genetic engineering techniques can be applied to modify plants and microorganisms to increase biomass production. These modifications target specific genes that control growth rate, photosynthetic efficiency, and stress tolerance. By enhancing these traits, the overall biomass yield can be significantly improved, making feedstocks more economically viable for biofuel and biochemical production.- Genetic modification for improved biomass yield: Genetic engineering techniques are used to modify plants and microorganisms to enhance biomass production. These modifications target specific traits such as increased photosynthetic efficiency, improved stress tolerance, and enhanced carbon fixation. By altering gene expression or introducing new genetic material, researchers can develop feedstock varieties with significantly higher biomass yields, making them more efficient for biofuel and bioproduct production.

- Pretreatment methods for biomass conversion: Various pretreatment technologies are employed to break down the complex structure of lignocellulosic biomass, making it more accessible for conversion processes. These methods include physical (milling, grinding), chemical (acid, alkali, solvent-based), physicochemical (steam explosion, ammonia fiber expansion), and biological (enzymatic) approaches. Effective pretreatment significantly increases the yield of fermentable sugars and other valuable compounds from biomass feedstocks.

- Optimization of cultivation and harvesting techniques: Advanced cultivation strategies and harvesting methods are developed to maximize biomass yield from various feedstocks. These include optimized planting density, nutrient management, irrigation scheduling, and precise timing of harvest. Specialized equipment and techniques are designed for efficient collection and processing of different biomass types, reducing losses and maintaining quality. These approaches significantly increase the overall yield of usable biomass per unit area.

- Microbial conversion and fermentation processes: Engineered microorganisms and optimized fermentation processes are used to convert biomass into valuable products with higher yields. These biological systems can efficiently break down complex carbohydrates and convert them into biofuels, biochemicals, and other high-value products. Advanced bioreactor designs, process control strategies, and microbial strain improvements contribute to increased product yields from various biomass feedstocks.

- Feedstock selection and diversification: Strategic selection and diversification of biomass feedstocks are employed to optimize yield and sustainability. This includes evaluating and utilizing various sources such as agricultural residues, energy crops, forestry waste, algae, and municipal solid waste. Each feedstock type offers unique advantages in terms of growth rate, composition, and conversion efficiency. Blending different feedstocks can also enhance overall process yields and reduce dependence on single biomass sources.

02 Pretreatment methods for biomass conversion efficiency

Various pretreatment technologies can be applied to biomass feedstocks to break down complex structures and improve accessibility to enzymes. These methods include physical (grinding, milling), chemical (acid, alkali, solvent), and biological (enzymatic) approaches. Effective pretreatment increases the conversion efficiency of biomass to fermentable sugars, ultimately enhancing the yield of biofuels and bioproducts.Expand Specific Solutions03 Optimization of cultivation conditions for biomass feedstocks

The yield of biomass feedstocks can be significantly improved by optimizing cultivation conditions. This includes controlling factors such as nutrient availability, water management, light exposure, temperature, and CO2 concentration. Advanced cultivation systems like precision agriculture and controlled environment agriculture can be implemented to maximize biomass production while minimizing resource inputs.Expand Specific Solutions04 Novel biomass feedstock selection and development

Identifying and developing high-yielding biomass feedstocks is crucial for sustainable bioenergy production. This includes selecting naturally productive species, breeding for improved traits, and developing dedicated energy crops. Characteristics such as rapid growth, high biomass density, low water requirements, and resistance to pests and diseases are prioritized to ensure maximum yield under various environmental conditions.Expand Specific Solutions05 Microbial conversion systems for biomass processing

Advanced microbial systems can be engineered to efficiently convert biomass into valuable products. These systems utilize specialized microorganisms that can break down complex biomass components and transform them into biofuels, biochemicals, or other high-value products. By optimizing the microbial consortia and fermentation conditions, the overall yield from biomass feedstocks can be substantially increased.Expand Specific Solutions

Leading Organizations in Biomass Upgrading Research

The biomass upgrading market is currently in a growth phase, with increasing demand for sustainable feedstock solutions driven by environmental concerns and energy security. The market size is expanding rapidly, projected to reach significant scale as industries seek alternatives to fossil fuels. Technologically, the field shows varying maturity levels across different conversion pathways. Leading players like Shell, ExxonMobil, and BASF are advancing commercial-scale technologies, while specialized firms such as Xyleco, Virent, and Anellotech focus on innovative processing methods for higher yields. Academic institutions including Zhejiang University and research organizations like the Korean Research Institute of Chemical Technology are developing next-generation feedstock optimization techniques. The competitive landscape features both established energy companies leveraging existing infrastructure and agile startups pioneering novel conversion technologies for maximizing biomass yields.

Xyleco, Inc.

Technical Solution: Xyleco has developed proprietary biomass processing technologies focused on cellulosic feedstocks. Their approach involves a unique combination of physical, chemical, and biological treatments to break down recalcitrant biomass structures. The company's technology platform enables the processing of diverse lignocellulosic materials including agricultural residues, woody biomass, and energy crops. Their patented biomass fractionation process separates cellulose, hemicellulose, and lignin components with high efficiency, allowing for targeted upgrading of each fraction. Xyleco's process reportedly achieves up to 30% higher sugar yields from cellulosic materials compared to conventional methods[1], with particular success using mixed hardwood feedstocks that can yield over 85% of theoretical maximum sugars. The company has also developed specialized enzyme cocktails that work synergistically with their pretreatment methods to maximize conversion rates of complex carbohydrates.

Strengths: Versatility in processing multiple feedstock types; proprietary enzyme systems optimized for specific biomass sources; reduced inhibitor formation during pretreatment. Weaknesses: Higher capital costs for specialized equipment; process complexity requiring precise control parameters; potential scalability challenges for distributed biomass collection.

Shell Oil Co.

Technical Solution: Shell has pioneered advanced biofuel production technologies focusing on non-food biomass feedstocks. Their research has identified specific high-yielding feedstocks including miscanthus, switchgrass, and agricultural residues like corn stover and wheat straw. Shell's approach combines thermochemical and biochemical conversion pathways to maximize carbon efficiency. Their IH² (Integrated Hydropyrolysis and Hydroconversion) technology has demonstrated particularly high yields with woody biomass, converting up to 70% of biomass carbon into liquid transportation fuels[2]. For biochemical pathways, Shell has developed specialized pretreatment processes that enhance sugar release from lignocellulosic materials while minimizing inhibitor formation. Their research indicates that purpose-grown energy crops like miscanthus can produce approximately 2.5 times more biofuel per hectare than conventional corn ethanol[3]. Shell has also explored algal biomass as a high-yield feedstock, with pilot projects demonstrating oil yields exceeding 5,000 gallons per acre annually under optimal conditions.

Strengths: Extensive experience in fuel production and distribution; integrated approach combining multiple conversion technologies; global supply chain expertise for feedstock sourcing and logistics. Weaknesses: High capital requirements for commercial-scale facilities; dependence on consistent biomass quality; sensitivity to feedstock price fluctuations affecting economic viability.

Key Patents and Breakthroughs in Feedstock Selection

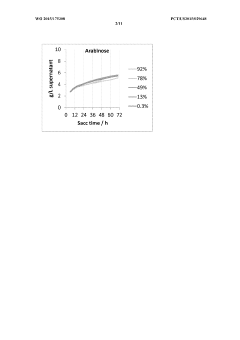

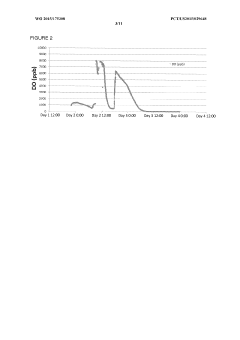

Improved enzymatic hydrolysis of biomass

PatentWO2015175308A1

Innovation

- A fed batch reactor system with controlled aeration maintains dissolved oxygen levels above 1.5% saturation during enzymatic hydrolysis, optimizing the saccharification process by ensuring sufficient oxygen for enzyme activity and biomass accessibility, using a combination of cellulases and hemicellulases with accessory enzymes.

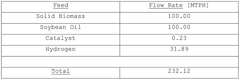

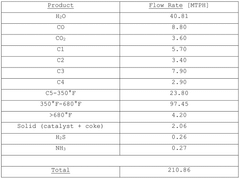

Slurry hydrocracking of renewable feedstocks

PatentWO2025014725A1

Innovation

- A slurry hydrocracking process is introduced, where solid biomass is mixed with a renewable liquid carrier and a slurry hydrocracking catalyst in the presence of hydrogen, under specific conditions to produce lighter hydrocarbonaceous products, which are then further upgraded through hydrotreating to produce high-quality naphtha and diesel range hydrocarbons.

Sustainability Metrics for Biomass Feedstock Evaluation

Evaluating the sustainability of biomass feedstocks requires comprehensive metrics that go beyond simple yield calculations. These metrics must consider environmental impacts, resource efficiency, and long-term viability across the entire biomass upgrading process. When assessing feedstocks for optimal yields, sustainability metrics provide critical decision-making frameworks that balance productivity with ecological responsibility.

The carbon footprint represents a fundamental sustainability metric, measuring greenhouse gas emissions throughout the feedstock lifecycle. High-yielding feedstocks like miscanthus and switchgrass often demonstrate superior carbon sequestration capabilities compared to conventional crops, potentially offering negative carbon balances when properly managed. This metric directly correlates with climate change mitigation potential and regulatory compliance under emerging carbon pricing mechanisms.

Water usage efficiency constitutes another crucial metric, particularly as climate change intensifies water scarcity concerns. Feedstocks such as sorghum and certain perennial grasses demonstrate remarkable drought tolerance while maintaining high biomass yields. The water footprint calculation must include irrigation requirements, natural precipitation utilization efficiency, and impacts on local watershed dynamics to provide meaningful sustainability assessments.

Land use efficiency metrics evaluate biomass yield per hectare while considering land quality impacts. Ideal feedstocks maximize production on marginal lands unsuitable for food crops, minimizing competition with food production. Advanced metrics in this category include soil organic carbon changes, erosion prevention capabilities, and biodiversity impacts, providing a holistic view of land stewardship beyond simple productivity measures.

Energy return on investment (EROI) calculations determine the ratio of energy output from biomass conversion relative to fossil energy inputs throughout cultivation, harvesting, and processing. Feedstocks with high EROI values, such as certain woody biomass species and agricultural residues, offer superior sustainability profiles despite potentially lower absolute yields in some contexts.

Nutrient cycling efficiency measures how effectively feedstocks utilize applied fertilizers and return nutrients to soil systems. Leguminous energy crops that fix atmospheric nitrogen can significantly reduce fertilizer requirements while maintaining high yields. This metric connects directly to both economic sustainability through reduced input costs and environmental sustainability through decreased nutrient runoff and associated water pollution.

Socioeconomic sustainability metrics complete the evaluation framework, assessing how feedstock production affects local communities, creates employment opportunities, and contributes to rural development. These considerations ensure that high-yielding feedstock systems deliver benefits beyond environmental performance, creating truly sustainable biomass supply chains that support long-term industry viability.

The carbon footprint represents a fundamental sustainability metric, measuring greenhouse gas emissions throughout the feedstock lifecycle. High-yielding feedstocks like miscanthus and switchgrass often demonstrate superior carbon sequestration capabilities compared to conventional crops, potentially offering negative carbon balances when properly managed. This metric directly correlates with climate change mitigation potential and regulatory compliance under emerging carbon pricing mechanisms.

Water usage efficiency constitutes another crucial metric, particularly as climate change intensifies water scarcity concerns. Feedstocks such as sorghum and certain perennial grasses demonstrate remarkable drought tolerance while maintaining high biomass yields. The water footprint calculation must include irrigation requirements, natural precipitation utilization efficiency, and impacts on local watershed dynamics to provide meaningful sustainability assessments.

Land use efficiency metrics evaluate biomass yield per hectare while considering land quality impacts. Ideal feedstocks maximize production on marginal lands unsuitable for food crops, minimizing competition with food production. Advanced metrics in this category include soil organic carbon changes, erosion prevention capabilities, and biodiversity impacts, providing a holistic view of land stewardship beyond simple productivity measures.

Energy return on investment (EROI) calculations determine the ratio of energy output from biomass conversion relative to fossil energy inputs throughout cultivation, harvesting, and processing. Feedstocks with high EROI values, such as certain woody biomass species and agricultural residues, offer superior sustainability profiles despite potentially lower absolute yields in some contexts.

Nutrient cycling efficiency measures how effectively feedstocks utilize applied fertilizers and return nutrients to soil systems. Leguminous energy crops that fix atmospheric nitrogen can significantly reduce fertilizer requirements while maintaining high yields. This metric connects directly to both economic sustainability through reduced input costs and environmental sustainability through decreased nutrient runoff and associated water pollution.

Socioeconomic sustainability metrics complete the evaluation framework, assessing how feedstock production affects local communities, creates employment opportunities, and contributes to rural development. These considerations ensure that high-yielding feedstock systems deliver benefits beyond environmental performance, creating truly sustainable biomass supply chains that support long-term industry viability.

Economic Viability of Various Feedstock Options

The economic viability of biomass feedstocks represents a critical factor in determining the commercial feasibility of biomass upgrading processes. Different feedstock options present varying cost structures that significantly impact the overall economics of biofuel and biochemical production systems.

Agricultural residues such as corn stover, wheat straw, and rice husks offer competitive economics due to their abundance and relatively low acquisition costs. These materials, often considered waste products, typically range from $30-70 per dry ton. However, their seasonal availability and collection logistics can introduce additional costs of $15-25 per ton for transportation and preprocessing.

Dedicated energy crops like switchgrass, miscanthus, and poplar demonstrate promising economics when cultivated at scale. Production costs generally fall between $60-120 per dry ton depending on regional growing conditions, land costs, and cultivation practices. While initial establishment costs are higher, their perennial nature reduces annual planting expenses and provides more consistent supply chains.

Forest residues and woody biomass present moderate economic viability with costs ranging from $45-90 per dry ton. These feedstocks benefit from established harvesting infrastructure but face challenges related to transportation distances from forest sites to processing facilities, adding $20-40 per ton in logistical expenses.

Municipal solid waste (MSW) offers unique economic advantages with potential negative feedstock costs (-$20 to -$40 per ton) due to tipping fees paid for waste disposal. However, preprocessing requirements to remove contaminants can add $30-70 per ton, potentially offsetting these initial savings.

Algal biomass, while offering high theoretical yields, currently faces prohibitive economics with production costs of $500-2000 per dry ton. Significant technological advancements in cultivation and harvesting efficiency are required before economic viability can be achieved at commercial scale.

When evaluating overall economic performance, conversion efficiency becomes paramount. Feedstocks with higher carbohydrate or lipid content typically deliver superior product yields per unit cost. For example, sugar-rich crops may yield 2-3 times more biofuel per dollar invested compared to lignocellulosic alternatives, despite higher initial feedstock costs.

Regional factors further influence economic viability through variations in land availability, climate conditions, existing infrastructure, and proximity to markets. Integrated biorefinery approaches that capture value from multiple product streams can significantly improve overall economics, particularly for feedstocks with diverse biochemical compositions.

Agricultural residues such as corn stover, wheat straw, and rice husks offer competitive economics due to their abundance and relatively low acquisition costs. These materials, often considered waste products, typically range from $30-70 per dry ton. However, their seasonal availability and collection logistics can introduce additional costs of $15-25 per ton for transportation and preprocessing.

Dedicated energy crops like switchgrass, miscanthus, and poplar demonstrate promising economics when cultivated at scale. Production costs generally fall between $60-120 per dry ton depending on regional growing conditions, land costs, and cultivation practices. While initial establishment costs are higher, their perennial nature reduces annual planting expenses and provides more consistent supply chains.

Forest residues and woody biomass present moderate economic viability with costs ranging from $45-90 per dry ton. These feedstocks benefit from established harvesting infrastructure but face challenges related to transportation distances from forest sites to processing facilities, adding $20-40 per ton in logistical expenses.

Municipal solid waste (MSW) offers unique economic advantages with potential negative feedstock costs (-$20 to -$40 per ton) due to tipping fees paid for waste disposal. However, preprocessing requirements to remove contaminants can add $30-70 per ton, potentially offsetting these initial savings.

Algal biomass, while offering high theoretical yields, currently faces prohibitive economics with production costs of $500-2000 per dry ton. Significant technological advancements in cultivation and harvesting efficiency are required before economic viability can be achieved at commercial scale.

When evaluating overall economic performance, conversion efficiency becomes paramount. Feedstocks with higher carbohydrate or lipid content typically deliver superior product yields per unit cost. For example, sugar-rich crops may yield 2-3 times more biofuel per dollar invested compared to lignocellulosic alternatives, despite higher initial feedstock costs.

Regional factors further influence economic viability through variations in land availability, climate conditions, existing infrastructure, and proximity to markets. Integrated biorefinery approaches that capture value from multiple product streams can significantly improve overall economics, particularly for feedstocks with diverse biochemical compositions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!