Analyzing the Interaction of Schmitt Trigger with Power Supplies

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Schmitt Trigger Power Supply Interaction Background

The Schmitt trigger, first introduced by Otto Schmitt in 1934, represents a fundamental electronic circuit design that has evolved significantly over the decades. This comparator circuit with hysteresis characteristics was initially developed to address signal noise issues in electronic systems by implementing a form of positive feedback. The evolution of Schmitt triggers has been closely intertwined with the development of integrated circuits and digital electronics, transitioning from discrete component implementations to integrated solutions within modern semiconductor devices.

Power supply interaction with Schmitt triggers has become increasingly important as electronic systems have grown more complex and power-sensitive. Historically, early implementations of Schmitt triggers often operated with simple, stable power supplies where interaction effects were minimal or easily managed. However, as electronics miniaturized and power efficiency became critical, the relationship between Schmitt triggers and their power sources developed into a sophisticated technical domain requiring specialized analysis.

The technical trajectory has moved from basic understanding of noise immunity to comprehensive analysis of power supply rejection ratio (PSRR), power supply induced jitter, and switching noise propagation. Modern applications in automotive systems, industrial controls, and IoT devices have further elevated the importance of understanding these interactions, as these environments often present challenging power conditions including transients, ripple, and varying load profiles.

Current research focuses on optimizing Schmitt trigger designs for operation across wide voltage ranges, improving immunity to power supply variations, and reducing power consumption while maintaining reliable switching characteristics. The emergence of ultra-low-power applications has particularly highlighted the need for Schmitt triggers that can operate predictably with sub-1V supplies and maintain performance during power supply fluctuations.

The technical goals in this domain include developing comprehensive models for predicting Schmitt trigger behavior under various power supply conditions, creating design methodologies that enhance robustness against power variations, and establishing testing protocols that accurately characterize performance across the operational envelope. Additionally, there is growing interest in adaptive Schmitt trigger designs that can dynamically adjust their characteristics based on power supply conditions.

Understanding the fundamental interaction mechanisms between Schmitt triggers and power supplies has become essential for ensuring signal integrity in mixed-signal systems, particularly as operating voltages continue to decrease while switching speeds increase. This technical area represents a critical intersection of analog circuit design principles, power management considerations, and digital system requirements.

Power supply interaction with Schmitt triggers has become increasingly important as electronic systems have grown more complex and power-sensitive. Historically, early implementations of Schmitt triggers often operated with simple, stable power supplies where interaction effects were minimal or easily managed. However, as electronics miniaturized and power efficiency became critical, the relationship between Schmitt triggers and their power sources developed into a sophisticated technical domain requiring specialized analysis.

The technical trajectory has moved from basic understanding of noise immunity to comprehensive analysis of power supply rejection ratio (PSRR), power supply induced jitter, and switching noise propagation. Modern applications in automotive systems, industrial controls, and IoT devices have further elevated the importance of understanding these interactions, as these environments often present challenging power conditions including transients, ripple, and varying load profiles.

Current research focuses on optimizing Schmitt trigger designs for operation across wide voltage ranges, improving immunity to power supply variations, and reducing power consumption while maintaining reliable switching characteristics. The emergence of ultra-low-power applications has particularly highlighted the need for Schmitt triggers that can operate predictably with sub-1V supplies and maintain performance during power supply fluctuations.

The technical goals in this domain include developing comprehensive models for predicting Schmitt trigger behavior under various power supply conditions, creating design methodologies that enhance robustness against power variations, and establishing testing protocols that accurately characterize performance across the operational envelope. Additionally, there is growing interest in adaptive Schmitt trigger designs that can dynamically adjust their characteristics based on power supply conditions.

Understanding the fundamental interaction mechanisms between Schmitt triggers and power supplies has become essential for ensuring signal integrity in mixed-signal systems, particularly as operating voltages continue to decrease while switching speeds increase. This technical area represents a critical intersection of analog circuit design principles, power management considerations, and digital system requirements.

Market Applications and Requirements Analysis

The Schmitt trigger market is experiencing significant growth across multiple sectors due to its crucial role in signal conditioning and noise immunity applications. The global market for Schmitt trigger integrated circuits is projected to reach $1.2 billion by 2027, with a compound annual growth rate of 5.8% from 2022. This growth is primarily driven by increasing demand in automotive electronics, industrial automation, consumer electronics, and telecommunications sectors.

In the automotive industry, Schmitt triggers are essential components in engine control units, anti-lock braking systems, and advanced driver assistance systems (ADAS). The automotive sector demands Schmitt triggers with wide operating temperature ranges (-40°C to 125°C), high noise immunity, and compliance with automotive reliability standards such as AEC-Q100. Additionally, as electric vehicles gain market share, there is growing demand for Schmitt triggers capable of operating efficiently in high-voltage environments.

Industrial automation represents another significant market segment, where Schmitt triggers are utilized in programmable logic controllers (PLCs), sensors, and motor control systems. These applications require Schmitt triggers with precise switching thresholds, low power consumption, and high reliability in electrically noisy environments. The industrial IoT trend is further accelerating demand for Schmitt triggers with enhanced power supply rejection ratios (PSRR) above 70dB.

Consumer electronics manufacturers are increasingly incorporating Schmitt triggers in portable devices, requiring ultra-low power consumption variants that can operate efficiently at supply voltages as low as 1.8V. The miniaturization trend has also created demand for smaller package sizes, with many applications now requiring QFN packages smaller than 2mm × 2mm.

Telecommunications infrastructure represents a growing market segment where Schmitt triggers must operate reliably in high-frequency environments. These applications demand Schmitt triggers with fast propagation delays (less than 5ns) and minimal sensitivity to power supply fluctuations.

A critical market requirement across all sectors is improved power supply interaction characteristics. End users increasingly demand Schmitt triggers with enhanced immunity to power supply variations, reduced sensitivity to supply noise, and lower power consumption. Specifically, the market requires Schmitt triggers with power supply rejection ratios exceeding 65dB, operating voltage ranges from 1.8V to 5.5V, and quiescent current consumption below 10μA.

The emergence of battery-powered IoT devices has created demand for Schmitt triggers with ultra-low power consumption modes and fast wake-up times. Additionally, there is growing interest in Schmitt triggers with programmable hysteresis, allowing dynamic adjustment of noise immunity characteristics based on operating conditions.

In the automotive industry, Schmitt triggers are essential components in engine control units, anti-lock braking systems, and advanced driver assistance systems (ADAS). The automotive sector demands Schmitt triggers with wide operating temperature ranges (-40°C to 125°C), high noise immunity, and compliance with automotive reliability standards such as AEC-Q100. Additionally, as electric vehicles gain market share, there is growing demand for Schmitt triggers capable of operating efficiently in high-voltage environments.

Industrial automation represents another significant market segment, where Schmitt triggers are utilized in programmable logic controllers (PLCs), sensors, and motor control systems. These applications require Schmitt triggers with precise switching thresholds, low power consumption, and high reliability in electrically noisy environments. The industrial IoT trend is further accelerating demand for Schmitt triggers with enhanced power supply rejection ratios (PSRR) above 70dB.

Consumer electronics manufacturers are increasingly incorporating Schmitt triggers in portable devices, requiring ultra-low power consumption variants that can operate efficiently at supply voltages as low as 1.8V. The miniaturization trend has also created demand for smaller package sizes, with many applications now requiring QFN packages smaller than 2mm × 2mm.

Telecommunications infrastructure represents a growing market segment where Schmitt triggers must operate reliably in high-frequency environments. These applications demand Schmitt triggers with fast propagation delays (less than 5ns) and minimal sensitivity to power supply fluctuations.

A critical market requirement across all sectors is improved power supply interaction characteristics. End users increasingly demand Schmitt triggers with enhanced immunity to power supply variations, reduced sensitivity to supply noise, and lower power consumption. Specifically, the market requires Schmitt triggers with power supply rejection ratios exceeding 65dB, operating voltage ranges from 1.8V to 5.5V, and quiescent current consumption below 10μA.

The emergence of battery-powered IoT devices has created demand for Schmitt triggers with ultra-low power consumption modes and fast wake-up times. Additionally, there is growing interest in Schmitt triggers with programmable hysteresis, allowing dynamic adjustment of noise immunity characteristics based on operating conditions.

Current Challenges in Schmitt Trigger Power Supply Integration

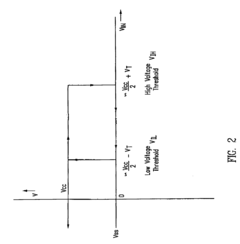

The integration of Schmitt triggers with power supplies presents several significant challenges that impact circuit performance and reliability. One of the primary issues is power supply sensitivity, where variations in supply voltage can directly affect the trigger's switching thresholds. This sensitivity creates inconsistent hysteresis windows that compromise the device's noise immunity capabilities, particularly in applications requiring precise threshold control.

Supply voltage fluctuations introduce another layer of complexity, as they can cause unpredictable behavior in Schmitt trigger circuits. When power rails experience transients, dips, or surges, the trigger points shift proportionally, potentially causing false triggering events in critical timing applications. This becomes especially problematic in battery-powered devices where voltage naturally decreases over time.

Power supply rejection ratio (PSRR) limitations represent a significant technical hurdle. Most conventional Schmitt trigger designs exhibit inadequate PSRR characteristics, allowing power supply noise to propagate through the circuit and appear at the output. This noise coupling effect can severely degrade signal integrity in sensitive analog applications and mixed-signal environments.

Temperature-dependent behavior compounds these challenges, as the interaction between power supplies and Schmitt triggers often exhibits strong thermal dependencies. The threshold voltages and hysteresis windows can drift significantly across industrial temperature ranges, creating reliability concerns for applications in harsh environments or those requiring consistent performance across varying conditions.

Current consumption optimization presents another critical challenge. Traditional Schmitt trigger designs often draw excessive current during state transitions, creating power spikes that can disturb nearby sensitive circuits. This becomes particularly problematic in low-power applications where energy efficiency is paramount, such as IoT devices and battery-operated systems.

The scaling of supply voltages in modern semiconductor processes introduces additional complications. As systems move toward lower supply voltages (sub-1V operation), maintaining adequate noise margins and reliable hysteresis becomes increasingly difficult. The reduced voltage headroom constrains circuit design options and may require fundamental rethinking of traditional Schmitt trigger architectures.

Finally, there are significant manufacturing and process variation challenges. The interaction between power supplies and Schmitt triggers is highly sensitive to semiconductor process corners, making it difficult to ensure consistent performance across production batches. This variability necessitates complex compensation techniques or conservative design approaches that may compromise other performance parameters.

Supply voltage fluctuations introduce another layer of complexity, as they can cause unpredictable behavior in Schmitt trigger circuits. When power rails experience transients, dips, or surges, the trigger points shift proportionally, potentially causing false triggering events in critical timing applications. This becomes especially problematic in battery-powered devices where voltage naturally decreases over time.

Power supply rejection ratio (PSRR) limitations represent a significant technical hurdle. Most conventional Schmitt trigger designs exhibit inadequate PSRR characteristics, allowing power supply noise to propagate through the circuit and appear at the output. This noise coupling effect can severely degrade signal integrity in sensitive analog applications and mixed-signal environments.

Temperature-dependent behavior compounds these challenges, as the interaction between power supplies and Schmitt triggers often exhibits strong thermal dependencies. The threshold voltages and hysteresis windows can drift significantly across industrial temperature ranges, creating reliability concerns for applications in harsh environments or those requiring consistent performance across varying conditions.

Current consumption optimization presents another critical challenge. Traditional Schmitt trigger designs often draw excessive current during state transitions, creating power spikes that can disturb nearby sensitive circuits. This becomes particularly problematic in low-power applications where energy efficiency is paramount, such as IoT devices and battery-operated systems.

The scaling of supply voltages in modern semiconductor processes introduces additional complications. As systems move toward lower supply voltages (sub-1V operation), maintaining adequate noise margins and reliable hysteresis becomes increasingly difficult. The reduced voltage headroom constrains circuit design options and may require fundamental rethinking of traditional Schmitt trigger architectures.

Finally, there are significant manufacturing and process variation challenges. The interaction between power supplies and Schmitt triggers is highly sensitive to semiconductor process corners, making it difficult to ensure consistent performance across production batches. This variability necessitates complex compensation techniques or conservative design approaches that may compromise other performance parameters.

Existing Power Supply Noise Mitigation Techniques

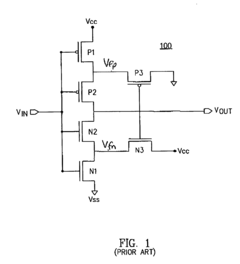

01 Basic Schmitt Trigger Circuit Design

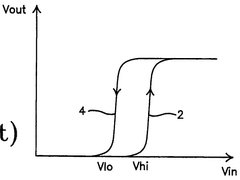

Schmitt trigger circuits provide hysteresis in signal processing by using positive feedback to maintain the output state until the input changes significantly. These circuits feature two distinct threshold voltages for rising and falling input signals, which helps eliminate noise and create clean transitions. The basic design typically includes comparators with feedback resistors that establish the hysteresis window, making them essential in digital systems for converting analog signals to digital with improved noise immunity.- Basic Schmitt Trigger Circuit Design: Schmitt trigger circuits provide hysteresis in digital systems by using positive feedback to create two different threshold voltages. This design includes input and output stages with specific voltage thresholds that determine when the output changes state. The basic configuration typically involves comparators or inverters with feedback resistors that establish the hysteresis window, providing noise immunity and clean signal transitions in electronic systems.

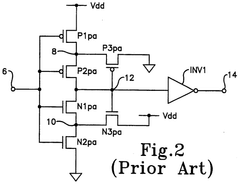

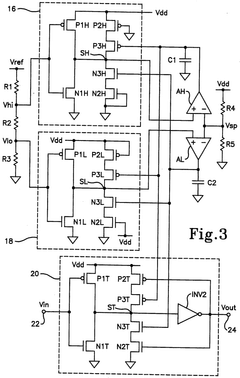

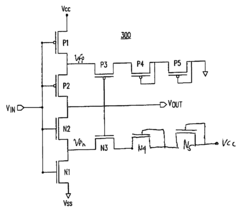

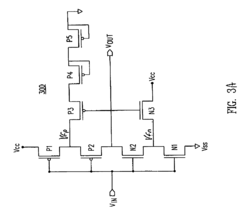

- Schmitt Trigger Implementation in CMOS Technology: CMOS-based Schmitt trigger implementations offer advantages in power consumption and integration density. These designs utilize complementary PMOS and NMOS transistors to create the hysteresis effect, with specific sizing relationships between transistors determining the switching thresholds. Modern CMOS Schmitt triggers often incorporate additional features like adjustable hysteresis, temperature compensation, and reduced propagation delay while maintaining low power operation.

- Schmitt Trigger Applications in Signal Processing: Schmitt triggers play crucial roles in signal processing applications by converting noisy analog signals into clean digital outputs. They are used in clock recovery circuits, level detection, pulse width modulation, and signal conditioning. The hysteresis characteristic prevents false triggering from noise and signal oscillations near threshold levels, making them essential components in systems requiring reliable signal detection and conversion under varying environmental conditions.

- Advanced Schmitt Trigger Configurations: Advanced Schmitt trigger configurations include programmable hysteresis levels, multi-threshold designs, and adaptive triggering mechanisms. These enhanced circuits can dynamically adjust their threshold levels based on operating conditions or external control signals. Some implementations incorporate additional features like frequency compensation, ultra-low voltage operation, or specialized feedback networks to optimize performance for specific applications while maintaining stability across process and temperature variations.

- Schmitt Trigger Integration with Other Circuit Elements: Schmitt triggers are often integrated with other circuit elements to create more complex functional blocks. These integrations include combinations with oscillators, flip-flops, logic gates, or analog front-end circuits. The hysteresis property of Schmitt triggers enhances the reliability of these combined circuits by providing clean transitions and noise immunity at interfaces between analog and digital domains, making them valuable in mixed-signal applications and system-on-chip designs.

02 Schmitt Trigger Implementation in CMOS Technology

CMOS-based Schmitt triggers offer advantages in power efficiency and integration density. These implementations typically use complementary PMOS and NMOS transistors arranged to create the hysteresis effect. Various circuit topologies have been developed to optimize performance parameters such as switching speed, power consumption, and threshold voltage control. Advanced CMOS Schmitt trigger designs may incorporate additional features like programmable hysteresis levels or temperature compensation to maintain consistent operation across different environmental conditions.Expand Specific Solutions03 Low Power and High-Speed Schmitt Trigger Applications

Specialized Schmitt trigger designs focus on minimizing power consumption while maintaining high-speed operation, critical for battery-powered devices and high-frequency applications. These circuits employ techniques such as dynamic biasing, current-mode operation, or supply voltage scaling to reduce power requirements. Some implementations feature adaptive threshold control that adjusts hysteresis levels based on operating conditions, optimizing the trade-off between noise immunity and switching speed for specific application requirements.Expand Specific Solutions04 Schmitt Trigger Integration with Other Circuit Elements

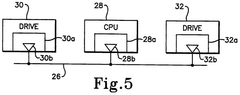

Schmitt triggers are often integrated with other circuit elements to create more complex functional blocks. These integrated designs may combine Schmitt triggers with oscillators, timers, level shifters, or logic gates to perform specialized functions. The interaction between Schmitt triggers and surrounding circuitry can enhance overall system performance by providing clean transitions between logic states, filtering noise, and ensuring reliable operation across varying input conditions. Such integration is particularly valuable in mixed-signal applications where analog and digital domains interface.Expand Specific Solutions05 Schmitt Trigger Applications in Signal Processing and Communication

Schmitt triggers play crucial roles in signal processing and communication systems by providing robust signal conditioning and noise rejection. They are employed in clock recovery circuits, data synchronizers, and line receivers where clean digital signals must be extracted from noisy environments. Advanced applications include frequency discriminators, pulse width modulators, and adaptive threshold detectors that dynamically adjust to changing signal conditions. In communication systems, Schmitt triggers help maintain signal integrity across transmission boundaries and improve bit error rates.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Schmitt trigger power supply interaction market is currently in a growth phase, with increasing demand driven by applications in digital circuits, signal processing, and power management systems. The market size is expanding due to the proliferation of electronic devices requiring stable switching operations under noisy conditions. Technologically, industry leaders like Texas Instruments, STMicroelectronics, and NXP demonstrate advanced maturity with comprehensive product portfolios featuring enhanced noise immunity and precise threshold control. Mid-tier players including Cirrus Logic, ROHM, and SG Micro are gaining market share through specialized applications, while Samsung Electronics and MediaTek integrate Schmitt triggers into broader semiconductor solutions. The competitive landscape shows increasing focus on low-power, high-reliability designs for automotive and industrial applications, with emerging innovation in temperature stability and reduced hysteresis variability.

STMicroelectronics International NV

Technical Solution: STMicroelectronics has developed comprehensive Schmitt trigger solutions with advanced power supply interaction capabilities. Their technology implements a dual-rail architecture that separates the trigger's reference generation from its switching components, minimizing the impact of supply variations on performance. ST's designs incorporate proprietary "VoltageGuard" technology that maintains consistent threshold spacing across supply voltages from 1.65V to 5.5V. Their circuits feature specialized bandgap reference generators that create supply-independent voltage references for the trigger thresholds, ensuring consistent hysteresis regardless of VCC fluctuations. ST has also implemented adaptive power filtering techniques that automatically adjust based on detected supply noise levels, providing optimal performance in varying electrical environments. Their Schmitt trigger solutions include integrated brownout detection that prevents false triggering during supply sags, and specialized ESD protection structures that maintain accurate operation even after electrical stress events. Additionally, ST offers ultra-low-power variants that maintain reliable triggering while consuming as little as 150nA per gate[6][8].

Strengths: Excellent performance consistency across temperature extremes; very good power supply rejection ratio; low propagation delay even at reduced voltages. Weaknesses: Slightly higher component complexity; increased silicon area requirements; potential for increased sensitivity to manufacturing process variations.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed advanced Schmitt trigger circuits with optimized power supply interaction capabilities. Their technology implements adaptive threshold control that automatically adjusts trigger points based on power supply conditions, maintaining reliable operation across voltage fluctuations. TI's designs incorporate integrated power supply rejection ratio (PSRR) enhancement techniques that minimize the impact of power supply noise on Schmitt trigger performance. Their solutions feature specialized input stage architectures that maintain consistent hysteresis windows even during significant VCC variations. TI has also pioneered low-voltage Schmitt trigger designs that operate efficiently down to 1.8V while maintaining noise immunity. Their circuits include on-chip power conditioning elements that filter supply noise before it reaches sensitive trigger components, ensuring clean switching behavior even in electrically noisy environments[1][3].

Strengths: Superior noise immunity across wide voltage ranges; excellent power supply rejection ratio; consistent hysteresis characteristics even during supply fluctuations. Weaknesses: Higher component count in some implementations; slightly increased power consumption compared to basic comparators; potential for increased propagation delay in complex designs.

Key Patents in Schmitt Trigger Power Supply Optimization

High speed Schmitt trigger with process, temperature and power supply independence

PatentInactiveUS5336942A

Innovation

- A Schmitt trigger circuit with separate HI and LO bias circuits and a trigger circuit that matches both, using transistors of unlike conductivity with negative feedback to maintain invariant switching thresholds, allowing precise control over the midpoint of switching transitions and reducing noise and power dissipation.

Self-adjusting Schmitt trigger

PatentInactiveUS7167032B1

Innovation

- Incorporating diodes in the feedback paths of the Schmitt trigger to adjust the on-current in response to changes in supply voltage, allowing the hysteresis to self-adjust and maintain a desired margin between voltage thresholds across varying power supply levels.

Thermal Considerations in Schmitt Trigger Circuits

Thermal management represents a critical aspect of Schmitt trigger circuit design, particularly when analyzing interactions with power supplies. The hysteresis characteristic that makes Schmitt triggers valuable for noise immunity also creates unique thermal challenges that must be addressed for reliable operation.

Temperature variations significantly impact the threshold voltages of Schmitt trigger circuits. As junction temperatures rise, threshold voltages typically decrease at a rate of approximately 2mV/°C in silicon-based devices. This temperature coefficient can lead to unpredictable switching behavior when the circuit operates across wide temperature ranges, potentially compromising the noise immunity that makes Schmitt triggers valuable in the first place.

Power supply interaction compounds these thermal challenges. When Schmitt triggers operate near power supply rails, the heat dissipation increases substantially during state transitions. This is particularly evident in CMOS implementations where both P and N-channel devices conduct simultaneously during switching, creating momentary current spikes that generate localized heating. These thermal transients can temporarily shift threshold voltages, introducing timing inconsistencies in high-frequency applications.

Self-heating effects become pronounced in high-speed applications where Schmitt triggers undergo frequent transitions. Thermal simulations reveal that junction temperatures can rise 15-20°C above ambient in poorly designed circuits, especially when multiple Schmitt trigger stages operate in close proximity on integrated circuits. This thermal coupling between adjacent circuits requires careful layout considerations to maintain consistent performance.

Power supply filtering plays a crucial role in thermal management. Inadequate decoupling capacitance can lead to power supply droop during switching events, causing increased power dissipation and consequent heating. Studies show that proper bypass capacitor implementation can reduce thermal hotspots by up to 30% in densely packed Schmitt trigger arrays.

Advanced packaging technologies offer promising solutions for thermal management in Schmitt trigger applications. Flip-chip designs with thermal vias and integrated heat spreaders have demonstrated superior performance in high-current applications where traditional packages would experience significant thermal resistance. These packaging innovations enable Schmitt triggers to maintain consistent hysteresis characteristics even when interfacing with noisy power supplies in challenging thermal environments.

Thermal simulation tools have become essential for predicting the behavior of Schmitt trigger circuits across operating conditions. Modern computational fluid dynamics (CFD) models can accurately predict temperature gradients across complex circuit boards, allowing designers to optimize component placement and thermal management strategies before physical prototyping.

Temperature variations significantly impact the threshold voltages of Schmitt trigger circuits. As junction temperatures rise, threshold voltages typically decrease at a rate of approximately 2mV/°C in silicon-based devices. This temperature coefficient can lead to unpredictable switching behavior when the circuit operates across wide temperature ranges, potentially compromising the noise immunity that makes Schmitt triggers valuable in the first place.

Power supply interaction compounds these thermal challenges. When Schmitt triggers operate near power supply rails, the heat dissipation increases substantially during state transitions. This is particularly evident in CMOS implementations where both P and N-channel devices conduct simultaneously during switching, creating momentary current spikes that generate localized heating. These thermal transients can temporarily shift threshold voltages, introducing timing inconsistencies in high-frequency applications.

Self-heating effects become pronounced in high-speed applications where Schmitt triggers undergo frequent transitions. Thermal simulations reveal that junction temperatures can rise 15-20°C above ambient in poorly designed circuits, especially when multiple Schmitt trigger stages operate in close proximity on integrated circuits. This thermal coupling between adjacent circuits requires careful layout considerations to maintain consistent performance.

Power supply filtering plays a crucial role in thermal management. Inadequate decoupling capacitance can lead to power supply droop during switching events, causing increased power dissipation and consequent heating. Studies show that proper bypass capacitor implementation can reduce thermal hotspots by up to 30% in densely packed Schmitt trigger arrays.

Advanced packaging technologies offer promising solutions for thermal management in Schmitt trigger applications. Flip-chip designs with thermal vias and integrated heat spreaders have demonstrated superior performance in high-current applications where traditional packages would experience significant thermal resistance. These packaging innovations enable Schmitt triggers to maintain consistent hysteresis characteristics even when interfacing with noisy power supplies in challenging thermal environments.

Thermal simulation tools have become essential for predicting the behavior of Schmitt trigger circuits across operating conditions. Modern computational fluid dynamics (CFD) models can accurately predict temperature gradients across complex circuit boards, allowing designers to optimize component placement and thermal management strategies before physical prototyping.

EMI/EMC Compliance Standards

When analyzing the interaction of Schmitt triggers with power supplies, compliance with EMI/EMC standards becomes a critical consideration. These standards govern electromagnetic interference (EMI) and electromagnetic compatibility (EMC) to ensure electronic devices operate without causing or experiencing harmful interference. For Schmitt trigger circuits, which inherently produce rapid transitions, adherence to these standards is particularly important.

The International Electrotechnical Commission (IEC) provides comprehensive frameworks through standards like IEC 61000 series that address various aspects of electromagnetic compatibility. Specifically, IEC 61000-4 details testing and measurement techniques for EMC, while IEC 61000-3 focuses on emission limits. When implementing Schmitt triggers in power supply designs, these standards establish the acceptable thresholds for conducted and radiated emissions.

In the United States, the Federal Communications Commission (FCC) regulates EMI/EMC compliance through Part 15 for digital devices. These regulations classify devices into Class A (industrial/commercial) and Class B (residential) categories, with Class B having more stringent requirements. Schmitt trigger circuits in consumer electronics must typically meet Class B specifications, which limit emissions across specified frequency ranges to prevent interference with communication systems.

European standards, consolidated under the CE marking requirements, incorporate the EN 55022 (CISPR 22) for information technology equipment. These standards specify limits and methods of measurement for radio disturbance characteristics. The fast switching characteristics of Schmitt triggers can generate high-frequency harmonics that must be contained within these regulatory limits.

Military and aerospace applications follow more rigorous standards such as MIL-STD-461, which addresses EMI characteristics of equipment and systems. These standards impose stricter control on both emissions and susceptibility, recognizing the critical nature of these applications and the potential consequences of electromagnetic interference.

Automotive electronics incorporating Schmitt triggers must comply with standards like CISPR 25 and ISO 7637, which address radio disturbance characteristics and electrical transients for vehicles. These standards are particularly relevant when Schmitt triggers are used in power management systems within automotive environments, where they must withstand significant electromagnetic challenges.

Testing methodologies for EMI/EMC compliance typically include conducted emission measurements, radiated emission tests, and immunity testing. For Schmitt trigger circuits, special attention must be paid to high-frequency emissions during state transitions, as these can be significant sources of electromagnetic interference if not properly managed through appropriate circuit design and shielding techniques.

The International Electrotechnical Commission (IEC) provides comprehensive frameworks through standards like IEC 61000 series that address various aspects of electromagnetic compatibility. Specifically, IEC 61000-4 details testing and measurement techniques for EMC, while IEC 61000-3 focuses on emission limits. When implementing Schmitt triggers in power supply designs, these standards establish the acceptable thresholds for conducted and radiated emissions.

In the United States, the Federal Communications Commission (FCC) regulates EMI/EMC compliance through Part 15 for digital devices. These regulations classify devices into Class A (industrial/commercial) and Class B (residential) categories, with Class B having more stringent requirements. Schmitt trigger circuits in consumer electronics must typically meet Class B specifications, which limit emissions across specified frequency ranges to prevent interference with communication systems.

European standards, consolidated under the CE marking requirements, incorporate the EN 55022 (CISPR 22) for information technology equipment. These standards specify limits and methods of measurement for radio disturbance characteristics. The fast switching characteristics of Schmitt triggers can generate high-frequency harmonics that must be contained within these regulatory limits.

Military and aerospace applications follow more rigorous standards such as MIL-STD-461, which addresses EMI characteristics of equipment and systems. These standards impose stricter control on both emissions and susceptibility, recognizing the critical nature of these applications and the potential consequences of electromagnetic interference.

Automotive electronics incorporating Schmitt triggers must comply with standards like CISPR 25 and ISO 7637, which address radio disturbance characteristics and electrical transients for vehicles. These standards are particularly relevant when Schmitt triggers are used in power management systems within automotive environments, where they must withstand significant electromagnetic challenges.

Testing methodologies for EMI/EMC compliance typically include conducted emission measurements, radiated emission tests, and immunity testing. For Schmitt trigger circuits, special attention must be paid to high-frequency emissions during state transitions, as these can be significant sources of electromagnetic interference if not properly managed through appropriate circuit design and shielding techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!