How Schmitt Trigger Adapts to Voltage Varying Conditions

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Schmitt Trigger Evolution and Design Objectives

The Schmitt trigger, first introduced by Otto Schmitt in 1937, represents a significant milestone in electronic circuit design. Originally developed to study nerve propagation in squid nerves, this ingenious circuit has evolved into a fundamental component in modern electronics. The evolution of Schmitt triggers has been characterized by continuous refinement to address increasingly complex voltage environments, transitioning from vacuum tube implementations to solid-state designs utilizing transistors and eventually integrated circuits.

Throughout the 1950s and 1960s, the adoption of semiconductor technology revolutionized Schmitt trigger designs, making them more compact, reliable, and energy-efficient. By the 1970s, Schmitt triggers became standard components in integrated circuit families like the 7414 hex inverter, marking their transition from specialized to ubiquitous electronic elements.

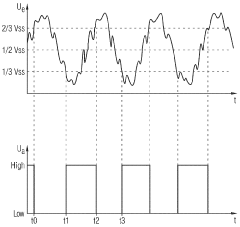

The primary technical objective of Schmitt triggers is to provide robust signal conditioning in environments with fluctuating voltage levels. Unlike conventional comparators, Schmitt triggers incorporate hysteresis—a deliberate difference between rising and falling threshold voltages—which prevents rapid oscillations when input signals contain noise or slow transitions. This hysteresis window creates a "memory effect" that stabilizes output despite input variations.

Modern Schmitt trigger design objectives focus on optimizing several critical parameters: minimizing power consumption for battery-powered applications, reducing propagation delays for high-speed systems, ensuring consistent hysteresis across temperature variations, and maintaining reliable operation across wide supply voltage ranges. These objectives have become increasingly important as electronic devices operate in more diverse and challenging environments.

The trend toward lower supply voltages in modern electronics has presented new challenges for Schmitt trigger design. As supply voltages decrease from traditional 5V to 3.3V, 1.8V, or even lower, maintaining adequate noise margins and hysteresis windows becomes technically demanding. This has driven innovation in circuit topologies that can maintain robust operation even with reduced voltage headroom.

Another significant evolution trend is the integration of Schmitt triggers with programmable hysteresis, allowing dynamic adaptation to changing noise conditions. This adaptive capability represents a paradigm shift from static to dynamic threshold management, enabling more intelligent signal conditioning that can respond to environmental changes.

Looking forward, the technical objectives for Schmitt trigger development include further miniaturization for nanoscale applications, integration with machine learning algorithms for predictive threshold adjustment, and development of ultra-low-power variants for energy harvesting systems and Internet of Things (IoT) devices.

Throughout the 1950s and 1960s, the adoption of semiconductor technology revolutionized Schmitt trigger designs, making them more compact, reliable, and energy-efficient. By the 1970s, Schmitt triggers became standard components in integrated circuit families like the 7414 hex inverter, marking their transition from specialized to ubiquitous electronic elements.

The primary technical objective of Schmitt triggers is to provide robust signal conditioning in environments with fluctuating voltage levels. Unlike conventional comparators, Schmitt triggers incorporate hysteresis—a deliberate difference between rising and falling threshold voltages—which prevents rapid oscillations when input signals contain noise or slow transitions. This hysteresis window creates a "memory effect" that stabilizes output despite input variations.

Modern Schmitt trigger design objectives focus on optimizing several critical parameters: minimizing power consumption for battery-powered applications, reducing propagation delays for high-speed systems, ensuring consistent hysteresis across temperature variations, and maintaining reliable operation across wide supply voltage ranges. These objectives have become increasingly important as electronic devices operate in more diverse and challenging environments.

The trend toward lower supply voltages in modern electronics has presented new challenges for Schmitt trigger design. As supply voltages decrease from traditional 5V to 3.3V, 1.8V, or even lower, maintaining adequate noise margins and hysteresis windows becomes technically demanding. This has driven innovation in circuit topologies that can maintain robust operation even with reduced voltage headroom.

Another significant evolution trend is the integration of Schmitt triggers with programmable hysteresis, allowing dynamic adaptation to changing noise conditions. This adaptive capability represents a paradigm shift from static to dynamic threshold management, enabling more intelligent signal conditioning that can respond to environmental changes.

Looking forward, the technical objectives for Schmitt trigger development include further miniaturization for nanoscale applications, integration with machine learning algorithms for predictive threshold adjustment, and development of ultra-low-power variants for energy harvesting systems and Internet of Things (IoT) devices.

Market Applications and Industry Requirements

The Schmitt trigger's ability to adapt to varying voltage conditions has positioned it as a critical component across multiple industries where signal integrity and noise immunity are paramount. In power management systems, Schmitt triggers are extensively utilized for voltage monitoring and protection circuits, with the market for such applications growing at a steady rate due to increasing deployment of smart grid technologies and renewable energy systems. These applications require Schmitt triggers that can reliably operate across wide voltage ranges from 1.8V to 15V while maintaining consistent hysteresis characteristics.

In the automotive sector, the demand for Schmitt triggers has seen significant growth with the expansion of electronic control units (ECUs) in modern vehicles. The automotive electronics market, valued at over $300 billion globally, requires components that can function reliably in harsh environments with voltage fluctuations. Industry specifications mandate that these components must operate across temperature ranges from -40°C to 125°C while handling supply voltage variations of ±10% without performance degradation.

The industrial automation sector presents another substantial market, where Schmitt triggers are essential in sensor interfaces and control systems. These applications demand devices that can adapt to both analog signal variations and power supply fluctuations in factory environments. The industry requires Schmitt triggers with programmable hysteresis that can be adjusted based on the noise profile of specific industrial settings.

Consumer electronics manufacturers have increasingly stringent requirements for power efficiency, driving demand for Schmitt triggers that can operate at lower voltage levels while maintaining noise immunity. The trend toward battery-powered IoT devices has created a market segment specifically for ultra-low voltage Schmitt triggers that can function reliably at supply voltages as low as 0.9V.

Medical equipment represents a specialized but growing application area, where precision and reliability are non-negotiable. Devices such as patient monitors and diagnostic equipment require Schmitt triggers that maintain consistent performance despite variations in operating conditions. Industry standards in this sector mandate extensive validation testing across voltage ranges with failure rates below 1 part per million.

Telecommunications infrastructure relies heavily on Schmitt triggers for signal conditioning in data transmission systems. With the ongoing deployment of 5G networks, there is increasing demand for components that can handle the higher frequencies and maintain signal integrity across varying power conditions. The market requirements specify Schmitt triggers with propagation delays under 5ns and the ability to operate across multiple voltage domains.

In the automotive sector, the demand for Schmitt triggers has seen significant growth with the expansion of electronic control units (ECUs) in modern vehicles. The automotive electronics market, valued at over $300 billion globally, requires components that can function reliably in harsh environments with voltage fluctuations. Industry specifications mandate that these components must operate across temperature ranges from -40°C to 125°C while handling supply voltage variations of ±10% without performance degradation.

The industrial automation sector presents another substantial market, where Schmitt triggers are essential in sensor interfaces and control systems. These applications demand devices that can adapt to both analog signal variations and power supply fluctuations in factory environments. The industry requires Schmitt triggers with programmable hysteresis that can be adjusted based on the noise profile of specific industrial settings.

Consumer electronics manufacturers have increasingly stringent requirements for power efficiency, driving demand for Schmitt triggers that can operate at lower voltage levels while maintaining noise immunity. The trend toward battery-powered IoT devices has created a market segment specifically for ultra-low voltage Schmitt triggers that can function reliably at supply voltages as low as 0.9V.

Medical equipment represents a specialized but growing application area, where precision and reliability are non-negotiable. Devices such as patient monitors and diagnostic equipment require Schmitt triggers that maintain consistent performance despite variations in operating conditions. Industry standards in this sector mandate extensive validation testing across voltage ranges with failure rates below 1 part per million.

Telecommunications infrastructure relies heavily on Schmitt triggers for signal conditioning in data transmission systems. With the ongoing deployment of 5G networks, there is increasing demand for components that can handle the higher frequencies and maintain signal integrity across varying power conditions. The market requirements specify Schmitt triggers with propagation delays under 5ns and the ability to operate across multiple voltage domains.

Current Challenges in Voltage Varying Environments

Despite significant advancements in Schmitt trigger technology, several critical challenges persist when these circuits operate in environments with fluctuating voltage conditions. The primary challenge lies in maintaining consistent hysteresis thresholds across varying supply voltages. As supply voltage changes, the threshold voltages typically shift proportionally, which can lead to unpredictable triggering behavior in applications requiring precise threshold control.

Temperature-induced variations compound this challenge, as the temperature coefficients of components within the Schmitt trigger circuit can cause threshold drift independent of voltage changes. This creates a complex interdependency between voltage variations and temperature effects that is difficult to model and compensate for in practical applications.

Power consumption optimization presents another significant hurdle. Traditional Schmitt trigger designs often exhibit increased current draw during transition states, which becomes problematic in battery-powered or energy-harvesting applications where voltage naturally varies throughout operation. The trade-off between power efficiency and switching performance becomes more pronounced as operating voltages fluctuate.

Noise immunity, a key advantage of Schmitt triggers, becomes compromised in varying voltage environments. The noise margin—typically defined as a percentage of supply voltage—changes in absolute terms as the supply voltage changes, potentially allowing noise to trigger false state transitions in low-voltage conditions.

Integration challenges emerge when implementing Schmitt triggers in modern mixed-signal ICs. As system-on-chip designs incorporate both digital and analog components operating at different voltage domains, maintaining consistent Schmitt trigger performance across these domains requires sophisticated level-shifting techniques and careful consideration of interface requirements.

Manufacturing process variations introduce additional complications, as component tolerances affect threshold voltages and hysteresis windows. These variations become more significant at lower operating voltages, where the ratio of threshold uncertainty to operating voltage increases substantially.

Response time consistency represents another critical challenge. As supply voltage varies, the charging and discharging rates of capacitive elements within the circuit change, affecting the speed at which the Schmitt trigger can respond to input transitions. This variable response time can disrupt timing-sensitive applications such as oscillators or pulse-width modulators.

Finally, the lack of standardized design methodologies for voltage-adaptive Schmitt triggers hampers widespread implementation of robust solutions. While various compensation techniques exist, they often require application-specific optimizations that increase design complexity and development time.

Temperature-induced variations compound this challenge, as the temperature coefficients of components within the Schmitt trigger circuit can cause threshold drift independent of voltage changes. This creates a complex interdependency between voltage variations and temperature effects that is difficult to model and compensate for in practical applications.

Power consumption optimization presents another significant hurdle. Traditional Schmitt trigger designs often exhibit increased current draw during transition states, which becomes problematic in battery-powered or energy-harvesting applications where voltage naturally varies throughout operation. The trade-off between power efficiency and switching performance becomes more pronounced as operating voltages fluctuate.

Noise immunity, a key advantage of Schmitt triggers, becomes compromised in varying voltage environments. The noise margin—typically defined as a percentage of supply voltage—changes in absolute terms as the supply voltage changes, potentially allowing noise to trigger false state transitions in low-voltage conditions.

Integration challenges emerge when implementing Schmitt triggers in modern mixed-signal ICs. As system-on-chip designs incorporate both digital and analog components operating at different voltage domains, maintaining consistent Schmitt trigger performance across these domains requires sophisticated level-shifting techniques and careful consideration of interface requirements.

Manufacturing process variations introduce additional complications, as component tolerances affect threshold voltages and hysteresis windows. These variations become more significant at lower operating voltages, where the ratio of threshold uncertainty to operating voltage increases substantially.

Response time consistency represents another critical challenge. As supply voltage varies, the charging and discharging rates of capacitive elements within the circuit change, affecting the speed at which the Schmitt trigger can respond to input transitions. This variable response time can disrupt timing-sensitive applications such as oscillators or pulse-width modulators.

Finally, the lack of standardized design methodologies for voltage-adaptive Schmitt triggers hampers widespread implementation of robust solutions. While various compensation techniques exist, they often require application-specific optimizations that increase design complexity and development time.

Existing Adaptation Mechanisms for Voltage Fluctuations

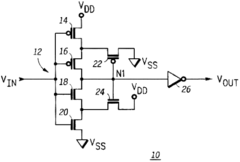

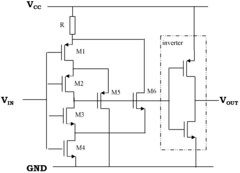

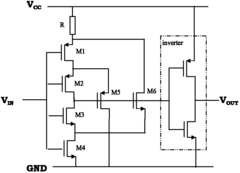

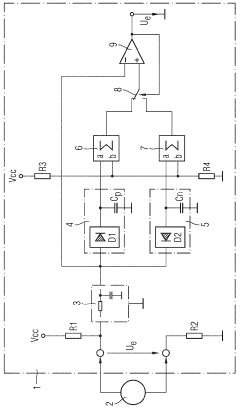

01 Adjustable threshold voltage techniques

Various methods for adapting the threshold voltage levels in Schmitt trigger circuits to achieve desired hysteresis characteristics. These techniques involve modifying circuit components or parameters to adjust the switching thresholds, allowing for customization based on specific application requirements. Adjustable threshold designs enable optimization for noise immunity, power consumption, and switching speed in different operating environments.- Adjustable threshold voltage techniques: Various methods for adjusting the threshold voltages of Schmitt triggers to adapt to different operating conditions. These techniques include using resistor networks, voltage dividers, or programmable reference voltages to modify the hysteresis window. By adjusting threshold voltages, the Schmitt trigger can be optimized for specific noise immunity requirements or signal characteristics in different applications.

- Temperature compensation mechanisms: Implementation of temperature compensation circuits in Schmitt triggers to maintain consistent voltage thresholds across varying temperatures. These designs incorporate temperature-dependent components or feedback mechanisms that automatically adjust threshold voltages to counteract temperature-induced variations, ensuring stable operation in changing environmental conditions.

- Power supply voltage adaptation: Techniques for adapting Schmitt trigger thresholds based on power supply voltage variations. These circuits automatically adjust their switching thresholds proportionally to the supply voltage, maintaining consistent hysteresis ratios. This approach ensures reliable operation across different supply voltages or in systems with fluctuating power conditions.

- Digitally programmable threshold control: Implementation of digital control interfaces that allow precise programming of Schmitt trigger threshold voltages. These designs incorporate digital-to-analog converters, digital control registers, or microcontroller interfaces to dynamically adjust threshold voltages during operation. This enables adaptive behavior based on system requirements or signal conditions.

- Low-power and high-speed adaptation techniques: Specialized circuit designs that optimize Schmitt triggers for either low power consumption or high-speed operation while maintaining adaptable threshold voltages. These implementations use techniques such as current-mode sensing, dynamic biasing, or advanced CMOS structures to achieve power efficiency or high-frequency operation while preserving the ability to adjust threshold voltages.

02 Voltage reference integration for threshold control

Implementation of voltage reference circuits within Schmitt trigger designs to provide stable and precise threshold voltage control. These configurations incorporate reference voltage generators that maintain consistent threshold levels despite variations in supply voltage or temperature. The integration of voltage references enables adaptive behavior where thresholds can be dynamically adjusted based on operating conditions or external control signals.Expand Specific Solutions03 Temperature and process variation compensation

Circuit designs that adapt Schmitt trigger threshold voltages to compensate for temperature fluctuations and manufacturing process variations. These approaches maintain consistent hysteresis characteristics across different operating conditions by employing feedback mechanisms or complementary components that adjust threshold voltages proportionally to environmental changes. Such compensation techniques improve reliability in extreme environments and ensure consistent performance across manufactured devices.Expand Specific Solutions04 Programmable hysteresis control

Methods for dynamically adjusting the hysteresis window of Schmitt trigger circuits through programmable control inputs. These designs allow for runtime modification of threshold voltages based on system requirements or operating conditions. Programmable hysteresis enables adaptive noise immunity, optimized power consumption, and application-specific performance tuning without requiring hardware modifications.Expand Specific Solutions05 Low-voltage and power-efficient adaptation techniques

Specialized circuit configurations that enable Schmitt trigger operation with adaptive thresholds in low-voltage or power-constrained applications. These designs modify traditional Schmitt trigger architectures to maintain reliable hysteresis characteristics while operating at reduced supply voltages or consuming minimal power. Techniques include modified feedback paths, current-mode designs, and specialized biasing schemes that preserve functionality while adapting to power constraints.Expand Specific Solutions

Leading Manufacturers and Circuit Design Houses

The Schmitt Trigger technology market is currently in a growth phase, characterized by increasing adoption across various voltage-sensitive applications. The market size is expanding steadily, driven by demand in automotive electronics, consumer devices, and industrial control systems. From a technical maturity perspective, the landscape shows varied development levels among key players. Industry leaders like STMicroelectronics, NXP, and Texas Instruments have established robust Schmitt Trigger portfolios, while companies such as SG Micro Corp, Skyworks Solutions, and MediaTek are advancing specialized implementations. Continental Automotive and Samsung are integrating this technology into broader automotive and consumer applications. Emerging players like Halo Microelectronics and DB HITEK are developing innovative adaptations for varying voltage conditions, particularly in mobile and IoT applications, indicating a technology that continues to evolve despite its fundamental principles being well-established.

STMicroelectronics International NV

Technical Solution: STMicroelectronics has developed advanced Schmitt trigger implementations that dynamically adapt to varying voltage conditions through their proprietary "adaptive threshold technology." This approach utilizes feedback mechanisms to automatically adjust trigger thresholds based on the ambient voltage environment. Their solutions incorporate temperature compensation circuits that maintain consistent hysteresis windows across wide temperature ranges (-40°C to +125°C), ensuring reliable operation in automotive and industrial applications. ST's implementation includes programmable hysteresis control that allows dynamic adjustment of noise immunity levels based on environmental conditions. Their latest generation of Schmitt triggers features ultra-low power consumption (as low as 100nA in standby mode) while maintaining fast response times (typically <10ns). ST has integrated these adaptive Schmitt triggers into their STM32 microcontroller families, providing robust input signal conditioning that automatically adjusts to battery voltage fluctuations in portable applications.

Strengths: Industry-leading noise immunity with programmable hysteresis levels; excellent temperature stability across extreme conditions; ultra-low power consumption suitable for battery-powered devices. Weaknesses: Higher cost compared to standard implementations; requires additional silicon area; slightly increased propagation delay when operating in adaptive mode.

ARM LIMITED

Technical Solution: ARM has developed an innovative approach to Schmitt trigger design for their low-power microcontroller input/output interfaces that adapts to varying voltage conditions. Their "Adaptive Input Threshold Technology" dynamically adjusts trigger thresholds based on both supply voltage and noise environment assessment. ARM's implementation utilizes a proportional biasing scheme that maintains consistent hysteresis ratios (typically 20-30% of VDD) across supply voltages ranging from 0.9V to 3.6V. This enables their Cortex-M series microcontrollers to operate reliably across wide voltage ranges while maintaining consistent input characteristics. The technology incorporates a noise sampling mechanism that periodically evaluates the signal environment and adjusts hysteresis windows accordingly, providing optimal noise rejection without sacrificing response time. ARM's adaptive Schmitt triggers feature ultra-low power operation, consuming less than 50nA per input in sleep modes while maintaining wake-up capability. This approach has been particularly valuable in IoT and wearable applications where battery voltage decreases significantly over the device lifetime.

Strengths: Exceptional low-voltage performance down to sub-1V operation; ultra-low power consumption ideal for battery-powered devices; intelligent noise adaptation that optimizes performance for the specific environment. Weaknesses: Additional complexity in IP implementation; slightly increased silicon area; requires periodic environment sampling that can impact power consumption in certain use cases.

Key Patents and Innovations in Hysteresis Control

Schmidt trigger having threshold voltage insensitive to power source voltage fluctuation

PatentInactiveCN202268858U

Innovation

- A resistor is introduced into the Schmitt trigger, and one end of the resistor is coupled to the first power supply voltage terminal to divide the power supply voltage fluctuation, reduce the sensitivity of the threshold to the power supply voltage fluctuation, and reduce the instantaneous current when the state flips.

Circuit arrangement und method for converting a signal

PatentWO2008028948A1

Innovation

- The hysteresis of the Schmitt trigger is dynamically adjusted based on the signal amplitude, with the upper and lower switching thresholds set proportionally to the signal's peak values, allowing for adaptive sensitivity to interference levels and amplitude variations.

Noise Immunity Enhancement Techniques

Schmitt triggers inherently possess superior noise immunity compared to conventional comparators due to their hysteresis characteristic. However, in environments with significant voltage variations, additional techniques can further enhance their noise rejection capabilities. One of the most effective approaches involves implementing adaptive threshold adjustment mechanisms that dynamically modify the hysteresis window based on detected noise levels or supply voltage fluctuations. These systems typically incorporate feedback loops that monitor ambient electrical conditions and automatically recalibrate trigger thresholds to maintain optimal noise margins.

Digital filtering techniques can be integrated with Schmitt trigger circuits to provide multi-stage noise suppression. By combining the analog hysteresis-based filtering of the Schmitt trigger with subsequent digital signal processing, systems can achieve remarkably high noise immunity even in harsh industrial environments. This hybrid approach is particularly valuable in applications where both high-frequency noise and slow voltage drifts must be simultaneously managed.

Frequency-selective noise immunity enhancement represents another sophisticated approach. By incorporating band-pass or notch filtering elements before the Schmitt trigger stage, specific noise frequencies can be attenuated while preserving the signal integrity. This technique proves especially valuable in environments with known noise sources operating at predictable frequencies, such as those near switching power supplies or wireless communication equipment.

Power supply conditioning forms a critical component of comprehensive noise immunity strategies. Implementing voltage regulators with high power supply rejection ratio (PSRR) characteristics can isolate Schmitt trigger circuits from power rail fluctuations. Additionally, strategic decoupling capacitor placement creates low-impedance paths for noise currents, preventing them from affecting the trigger's threshold voltages.

Advanced semiconductor fabrication techniques also contribute significantly to noise immunity. The development of specialized process technologies that reduce parasitic capacitances and leakage currents has enabled Schmitt triggers with inherently higher noise tolerance. These manufacturing improvements, combined with careful circuit layout practices that minimize coupling between signal paths, create robust designs capable of reliable operation even in electromagnetically noisy environments.

Statistical noise analysis and compensation techniques represent the cutting edge of noise immunity enhancement. By characterizing noise patterns through statistical methods, adaptive algorithms can dynamically adjust Schmitt trigger parameters to optimize performance under varying conditions. Machine learning approaches are increasingly being applied to predict noise characteristics and preemptively adjust circuit parameters before signal degradation occurs.

Digital filtering techniques can be integrated with Schmitt trigger circuits to provide multi-stage noise suppression. By combining the analog hysteresis-based filtering of the Schmitt trigger with subsequent digital signal processing, systems can achieve remarkably high noise immunity even in harsh industrial environments. This hybrid approach is particularly valuable in applications where both high-frequency noise and slow voltage drifts must be simultaneously managed.

Frequency-selective noise immunity enhancement represents another sophisticated approach. By incorporating band-pass or notch filtering elements before the Schmitt trigger stage, specific noise frequencies can be attenuated while preserving the signal integrity. This technique proves especially valuable in environments with known noise sources operating at predictable frequencies, such as those near switching power supplies or wireless communication equipment.

Power supply conditioning forms a critical component of comprehensive noise immunity strategies. Implementing voltage regulators with high power supply rejection ratio (PSRR) characteristics can isolate Schmitt trigger circuits from power rail fluctuations. Additionally, strategic decoupling capacitor placement creates low-impedance paths for noise currents, preventing them from affecting the trigger's threshold voltages.

Advanced semiconductor fabrication techniques also contribute significantly to noise immunity. The development of specialized process technologies that reduce parasitic capacitances and leakage currents has enabled Schmitt triggers with inherently higher noise tolerance. These manufacturing improvements, combined with careful circuit layout practices that minimize coupling between signal paths, create robust designs capable of reliable operation even in electromagnetically noisy environments.

Statistical noise analysis and compensation techniques represent the cutting edge of noise immunity enhancement. By characterizing noise patterns through statistical methods, adaptive algorithms can dynamically adjust Schmitt trigger parameters to optimize performance under varying conditions. Machine learning approaches are increasingly being applied to predict noise characteristics and preemptively adjust circuit parameters before signal degradation occurs.

Power Efficiency Considerations in Trigger Circuits

Power efficiency has become a critical consideration in the design and implementation of Schmitt trigger circuits, particularly in environments where voltage conditions vary significantly. The power consumption of trigger circuits directly impacts the overall energy efficiency of electronic systems, making optimization essential for modern applications.

Traditional Schmitt trigger designs often prioritize reliability and noise immunity over power efficiency, resulting in constant current draw regardless of input state. This approach becomes problematic in battery-powered devices and energy-harvesting systems where power resources are limited. The static power consumption in conventional CMOS implementations of Schmitt triggers can account for a significant portion of the total system power budget.

Recent advancements have focused on developing adaptive biasing techniques that dynamically adjust the power consumption based on input signal characteristics. These techniques enable Schmitt triggers to operate with minimal power during steady-state conditions while maintaining robust performance during transitions. Implementations utilizing sleep modes and power gating have demonstrated power reductions of up to 70% compared to conventional designs.

The hysteresis characteristic of Schmitt triggers presents both challenges and opportunities for power optimization. While the dual-threshold operation inherently requires additional components compared to simple inverters, it also provides opportunities for intelligent power management. Modern designs leverage this hysteresis property to create energy-efficient circuits that consume power primarily during threshold transitions rather than continuously.

Supply voltage scaling has emerged as another effective strategy for reducing power consumption in Schmitt trigger circuits. By designing triggers capable of operating reliably at lower supply voltages, significant power savings can be achieved due to the quadratic relationship between voltage and power consumption. Sub-threshold operation of Schmitt triggers has been demonstrated in ultra-low-power applications, though with trade-offs in switching speed and noise margins.

Temperature compensation mechanisms have also been incorporated into energy-efficient Schmitt trigger designs to maintain consistent performance across varying environmental conditions without excessive power overhead. These adaptive circuits can adjust their operating parameters based on temperature fluctuations, ensuring reliable operation while minimizing unnecessary power consumption.

The integration of Schmitt triggers with energy harvesting systems represents a frontier in power-efficient design, where the circuit must not only minimize its own consumption but also effectively manage intermittent power sources. Self-powered Schmitt trigger implementations that can operate from harvested energy as low as 10-50 μW have been demonstrated in research settings, pointing toward future applications in autonomous sensor networks and IoT devices.

Traditional Schmitt trigger designs often prioritize reliability and noise immunity over power efficiency, resulting in constant current draw regardless of input state. This approach becomes problematic in battery-powered devices and energy-harvesting systems where power resources are limited. The static power consumption in conventional CMOS implementations of Schmitt triggers can account for a significant portion of the total system power budget.

Recent advancements have focused on developing adaptive biasing techniques that dynamically adjust the power consumption based on input signal characteristics. These techniques enable Schmitt triggers to operate with minimal power during steady-state conditions while maintaining robust performance during transitions. Implementations utilizing sleep modes and power gating have demonstrated power reductions of up to 70% compared to conventional designs.

The hysteresis characteristic of Schmitt triggers presents both challenges and opportunities for power optimization. While the dual-threshold operation inherently requires additional components compared to simple inverters, it also provides opportunities for intelligent power management. Modern designs leverage this hysteresis property to create energy-efficient circuits that consume power primarily during threshold transitions rather than continuously.

Supply voltage scaling has emerged as another effective strategy for reducing power consumption in Schmitt trigger circuits. By designing triggers capable of operating reliably at lower supply voltages, significant power savings can be achieved due to the quadratic relationship between voltage and power consumption. Sub-threshold operation of Schmitt triggers has been demonstrated in ultra-low-power applications, though with trade-offs in switching speed and noise margins.

Temperature compensation mechanisms have also been incorporated into energy-efficient Schmitt trigger designs to maintain consistent performance across varying environmental conditions without excessive power overhead. These adaptive circuits can adjust their operating parameters based on temperature fluctuations, ensuring reliable operation while minimizing unnecessary power consumption.

The integration of Schmitt triggers with energy harvesting systems represents a frontier in power-efficient design, where the circuit must not only minimize its own consumption but also effectively manage intermittent power sources. Self-powered Schmitt trigger implementations that can operate from harvested energy as low as 10-50 μW have been demonstrated in research settings, pointing toward future applications in autonomous sensor networks and IoT devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!