Detecting Signal Fluctuations with Schmitt Trigger Efficiency

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Schmitt Trigger Technology Background and Objectives

The Schmitt trigger, first introduced by Otto Schmitt in 1937, represents a fundamental electronic circuit design that has evolved significantly over the decades. Originally developed to mimic the biological neural systems' hysteresis behavior, this comparator circuit with positive feedback has become an essential component in signal processing applications across numerous industries. The technology's evolution has been marked by continuous improvements in speed, power efficiency, and integration capabilities, particularly with the advent of semiconductor technologies.

In modern electronic systems, signal integrity remains a critical challenge, especially in environments prone to noise and interference. The Schmitt trigger's unique hysteresis characteristic—providing different threshold voltages for rising and falling input signals—offers a robust solution for clean signal detection and restoration in fluctuating conditions. This capability has positioned the technology as a cornerstone in digital systems, industrial automation, automotive electronics, and emerging IoT applications.

The current technological landscape demands increasingly efficient signal detection mechanisms capable of operating reliably in complex electromagnetic environments while minimizing power consumption. Market trends indicate a growing need for miniaturized, high-performance signal conditioning solutions that can maintain accuracy across wider temperature ranges and voltage variations. These requirements have pushed Schmitt trigger technology toward more sophisticated implementations and novel applications.

The primary objective of this technical research is to comprehensively evaluate the efficiency of Schmitt trigger technology in detecting and managing signal fluctuations across diverse operating conditions. This includes analyzing the optimal hysteresis window configurations for various application scenarios, investigating advanced implementation architectures, and identifying potential innovations that could enhance performance metrics such as propagation delay, power consumption, and noise immunity.

Additionally, this research aims to explore emerging applications where Schmitt trigger technology could provide significant advantages, particularly in low-power sensor interfaces, high-speed data communication systems, and precision measurement equipment. By understanding the fundamental limitations of current implementations and identifying promising research directions, we seek to establish a technological roadmap that aligns with future market requirements and emerging electronic design paradigms.

The findings from this investigation will serve as a foundation for strategic decision-making regarding technology investments, product development initiatives, and potential intellectual property opportunities in the signal processing domain. This comprehensive approach will ensure that our organization maintains technological leadership in this critical area while addressing evolving customer needs for reliable signal detection solutions.

In modern electronic systems, signal integrity remains a critical challenge, especially in environments prone to noise and interference. The Schmitt trigger's unique hysteresis characteristic—providing different threshold voltages for rising and falling input signals—offers a robust solution for clean signal detection and restoration in fluctuating conditions. This capability has positioned the technology as a cornerstone in digital systems, industrial automation, automotive electronics, and emerging IoT applications.

The current technological landscape demands increasingly efficient signal detection mechanisms capable of operating reliably in complex electromagnetic environments while minimizing power consumption. Market trends indicate a growing need for miniaturized, high-performance signal conditioning solutions that can maintain accuracy across wider temperature ranges and voltage variations. These requirements have pushed Schmitt trigger technology toward more sophisticated implementations and novel applications.

The primary objective of this technical research is to comprehensively evaluate the efficiency of Schmitt trigger technology in detecting and managing signal fluctuations across diverse operating conditions. This includes analyzing the optimal hysteresis window configurations for various application scenarios, investigating advanced implementation architectures, and identifying potential innovations that could enhance performance metrics such as propagation delay, power consumption, and noise immunity.

Additionally, this research aims to explore emerging applications where Schmitt trigger technology could provide significant advantages, particularly in low-power sensor interfaces, high-speed data communication systems, and precision measurement equipment. By understanding the fundamental limitations of current implementations and identifying promising research directions, we seek to establish a technological roadmap that aligns with future market requirements and emerging electronic design paradigms.

The findings from this investigation will serve as a foundation for strategic decision-making regarding technology investments, product development initiatives, and potential intellectual property opportunities in the signal processing domain. This comprehensive approach will ensure that our organization maintains technological leadership in this critical area while addressing evolving customer needs for reliable signal detection solutions.

Market Applications and Demand Analysis

The Schmitt trigger technology market is experiencing significant growth driven by the increasing demand for reliable signal processing solutions across multiple industries. The global market for signal conditioning components, including Schmitt triggers, is projected to reach $2.1 billion by 2026, with a compound annual growth rate of 6.8% from 2021. This growth is primarily fueled by the expanding electronics industry and the rising need for noise-resistant signal detection systems.

Industrial automation represents one of the largest application segments for Schmitt trigger technology, accounting for approximately 28% of the total market share. In this sector, Schmitt triggers are essential for ensuring accurate sensor readings in electrically noisy environments, preventing false triggering in control systems, and maintaining operational reliability in manufacturing processes. The industrial IoT revolution has further accelerated demand, as factories increasingly implement sensor networks requiring robust signal conditioning.

The automotive industry constitutes another significant market segment, representing about 23% of global demand. Modern vehicles contain numerous electronic control units that rely on Schmitt triggers for clean signal processing in applications ranging from engine management systems to advanced driver assistance systems (ADAS). The transition toward electric and autonomous vehicles is expected to drive a 9.2% annual increase in demand for high-efficiency Schmitt trigger implementations through 2025.

Consumer electronics applications account for approximately 19% of the market, with Schmitt triggers being integral components in power management circuits, input devices, and signal conversion systems. The miniaturization trend in consumer devices has created demand for more efficient, low-power Schmitt trigger designs that can operate reliably while consuming minimal energy.

Medical device manufacturers represent a growing market segment with particular requirements for signal stability and reliability. Applications include patient monitoring systems, diagnostic equipment, and therapeutic devices where signal integrity is critical for accurate diagnosis and treatment. This segment is expected to grow at 7.5% annually through 2026.

Telecommunications and networking equipment manufacturers utilize Schmitt triggers in signal repeaters, line drivers, and interface circuits. With the ongoing deployment of 5G infrastructure, demand for high-speed, noise-resistant signal conditioning components is projected to increase by 8.3% annually over the next five years.

The market analysis reveals a clear trend toward integration, with customers increasingly preferring Schmitt trigger functionality embedded within larger system-on-chip solutions rather than as discrete components. This shift is driving innovation in more efficient implementations that can maintain performance while reducing power consumption and silicon area requirements.

Industrial automation represents one of the largest application segments for Schmitt trigger technology, accounting for approximately 28% of the total market share. In this sector, Schmitt triggers are essential for ensuring accurate sensor readings in electrically noisy environments, preventing false triggering in control systems, and maintaining operational reliability in manufacturing processes. The industrial IoT revolution has further accelerated demand, as factories increasingly implement sensor networks requiring robust signal conditioning.

The automotive industry constitutes another significant market segment, representing about 23% of global demand. Modern vehicles contain numerous electronic control units that rely on Schmitt triggers for clean signal processing in applications ranging from engine management systems to advanced driver assistance systems (ADAS). The transition toward electric and autonomous vehicles is expected to drive a 9.2% annual increase in demand for high-efficiency Schmitt trigger implementations through 2025.

Consumer electronics applications account for approximately 19% of the market, with Schmitt triggers being integral components in power management circuits, input devices, and signal conversion systems. The miniaturization trend in consumer devices has created demand for more efficient, low-power Schmitt trigger designs that can operate reliably while consuming minimal energy.

Medical device manufacturers represent a growing market segment with particular requirements for signal stability and reliability. Applications include patient monitoring systems, diagnostic equipment, and therapeutic devices where signal integrity is critical for accurate diagnosis and treatment. This segment is expected to grow at 7.5% annually through 2026.

Telecommunications and networking equipment manufacturers utilize Schmitt triggers in signal repeaters, line drivers, and interface circuits. With the ongoing deployment of 5G infrastructure, demand for high-speed, noise-resistant signal conditioning components is projected to increase by 8.3% annually over the next five years.

The market analysis reveals a clear trend toward integration, with customers increasingly preferring Schmitt trigger functionality embedded within larger system-on-chip solutions rather than as discrete components. This shift is driving innovation in more efficient implementations that can maintain performance while reducing power consumption and silicon area requirements.

Current Challenges in Signal Fluctuation Detection

Signal fluctuation detection faces significant challenges in today's rapidly evolving technological landscape. The primary obstacle lies in distinguishing genuine signals from noise in environments with decreasing signal-to-noise ratios (SNR). As electronic devices continue to miniaturize while operating at higher frequencies, the boundary between valid signals and background noise becomes increasingly blurred, making accurate detection more difficult.

Threshold determination presents another major challenge. Traditional fixed-threshold detection methods often fail when signal amplitudes vary significantly or when noise characteristics change dynamically. This limitation becomes particularly problematic in applications such as industrial automation, medical devices, and automotive systems where environmental conditions fluctuate unpredictably.

Power consumption constraints further complicate signal detection systems. With the proliferation of battery-powered and energy-harvesting devices, detection circuits must maintain high accuracy while minimizing energy usage. This creates a fundamental design tension between detection sensitivity and power efficiency that engineers must constantly balance.

Temperature sensitivity introduces additional complications. Many detection circuits exhibit performance drift across temperature ranges, leading to inconsistent triggering points. This thermal dependency can cause false positives in hot environments or missed detections in cold conditions, reducing overall system reliability.

Timing precision represents another critical challenge. Modern high-speed applications require detection circuits to respond within nanoseconds while maintaining accuracy. However, achieving this speed without introducing timing jitter or propagation delays remains difficult, especially when processing signals with rapid fluctuations or irregular patterns.

Component tolerance and aging effects further undermine detection reliability. Manufacturing variations in electronic components can cause detection thresholds to deviate from design specifications. Additionally, these components degrade over time, gradually shifting detection parameters and potentially causing system failures without warning.

Integration challenges arise when implementing detection circuits within complex systems. Signal integrity can be compromised by electromagnetic interference from nearby components, power supply fluctuations, or ground plane noise. These integration issues often manifest only after system assembly, making them particularly difficult to diagnose and resolve.

Finally, adaptability to varying signal characteristics presents an ongoing challenge. Many applications require detection systems to handle signals with widely different amplitudes, frequencies, and duty cycles. Creating detection circuits versatile enough to accommodate this range while maintaining accuracy demands sophisticated design approaches beyond simple threshold detection.

Threshold determination presents another major challenge. Traditional fixed-threshold detection methods often fail when signal amplitudes vary significantly or when noise characteristics change dynamically. This limitation becomes particularly problematic in applications such as industrial automation, medical devices, and automotive systems where environmental conditions fluctuate unpredictably.

Power consumption constraints further complicate signal detection systems. With the proliferation of battery-powered and energy-harvesting devices, detection circuits must maintain high accuracy while minimizing energy usage. This creates a fundamental design tension between detection sensitivity and power efficiency that engineers must constantly balance.

Temperature sensitivity introduces additional complications. Many detection circuits exhibit performance drift across temperature ranges, leading to inconsistent triggering points. This thermal dependency can cause false positives in hot environments or missed detections in cold conditions, reducing overall system reliability.

Timing precision represents another critical challenge. Modern high-speed applications require detection circuits to respond within nanoseconds while maintaining accuracy. However, achieving this speed without introducing timing jitter or propagation delays remains difficult, especially when processing signals with rapid fluctuations or irregular patterns.

Component tolerance and aging effects further undermine detection reliability. Manufacturing variations in electronic components can cause detection thresholds to deviate from design specifications. Additionally, these components degrade over time, gradually shifting detection parameters and potentially causing system failures without warning.

Integration challenges arise when implementing detection circuits within complex systems. Signal integrity can be compromised by electromagnetic interference from nearby components, power supply fluctuations, or ground plane noise. These integration issues often manifest only after system assembly, making them particularly difficult to diagnose and resolve.

Finally, adaptability to varying signal characteristics presents an ongoing challenge. Many applications require detection systems to handle signals with widely different amplitudes, frequencies, and duty cycles. Creating detection circuits versatile enough to accommodate this range while maintaining accuracy demands sophisticated design approaches beyond simple threshold detection.

Current Implementation Methods for Schmitt Triggers

01 Hysteresis control in Schmitt trigger circuits

Schmitt trigger circuits can be designed with controllable hysteresis to effectively detect signal fluctuations while rejecting noise. By adjusting the hysteresis window, these circuits can be optimized to ignore small signal variations while responding to genuine transitions. This approach improves detection efficiency by preventing false triggering from noise or small signal fluctuations, making the circuit more reliable in noisy environments.- Hysteresis control in Schmitt trigger circuits: Schmitt trigger circuits can be designed with adjustable hysteresis to effectively detect signal fluctuations while rejecting noise. By controlling the threshold voltage difference between the high and low switching points, these circuits can be optimized for specific signal conditions. Advanced hysteresis control techniques improve detection efficiency by preventing false triggering from small signal fluctuations while maintaining sensitivity to genuine state changes.

- Noise immunity enhancement techniques: Various techniques can be implemented to enhance the noise immunity of Schmitt trigger circuits for more efficient signal fluctuation detection. These include differential input structures, filtering components, and specialized feedback mechanisms. By incorporating these noise immunity enhancements, Schmitt triggers can operate reliably in environments with significant electromagnetic interference or signal degradation, improving overall detection efficiency and reducing error rates.

- High-speed response optimization: Optimizing Schmitt trigger circuits for high-speed response enables more efficient detection of rapid signal fluctuations. This involves careful design of transistor sizing, reduction of parasitic capacitances, and implementation of advanced switching techniques. High-speed Schmitt triggers can accurately detect fast transient signals and provide quick state changes, making them suitable for applications requiring real-time signal processing and detection of brief fluctuation events.

- Power efficiency improvements: Power-efficient Schmitt trigger designs enable effective signal fluctuation detection while minimizing energy consumption. These implementations utilize techniques such as dynamic biasing, power gating, and low-voltage operation to reduce power requirements without compromising detection performance. Energy-efficient Schmitt triggers are particularly valuable in battery-powered applications and systems where power constraints are significant while still requiring reliable signal fluctuation detection.

- Integration with signal processing systems: Integrating Schmitt triggers with advanced signal processing systems enhances overall fluctuation detection efficiency. These integrated solutions may include pre-processing filters, digital post-processing, adaptive threshold adjustment, and statistical analysis capabilities. By combining Schmitt trigger functionality with complementary signal processing techniques, these systems can achieve higher detection accuracy across varying signal conditions and automatically adapt to changing noise environments.

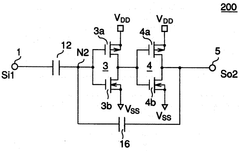

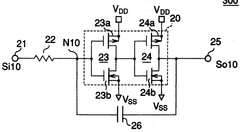

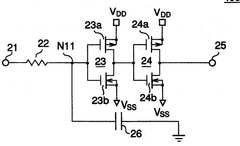

02 Advanced Schmitt trigger architectures for signal processing

Various specialized Schmitt trigger architectures have been developed to enhance signal fluctuation detection efficiency. These include differential Schmitt triggers, complementary Schmitt triggers, and programmable threshold Schmitt triggers. These advanced designs offer improved performance characteristics such as faster response times, better noise immunity, and more precise threshold control, making them suitable for applications requiring high-speed and accurate signal detection.Expand Specific Solutions03 Low-power Schmitt trigger implementations

Energy-efficient Schmitt trigger designs focus on maintaining detection efficiency while minimizing power consumption. These implementations utilize techniques such as dynamic biasing, power gating, and supply voltage scaling to reduce power requirements without compromising performance. Low-power Schmitt triggers are particularly valuable in battery-operated devices and IoT applications where energy efficiency is critical while maintaining reliable signal fluctuation detection.Expand Specific Solutions04 Integration of Schmitt triggers in complex signal processing systems

Schmitt triggers can be integrated into larger signal processing systems to enhance overall detection efficiency. These implementations combine Schmitt triggers with additional circuitry such as filters, amplifiers, and digital processing elements to create comprehensive signal detection solutions. The integration allows for pre-processing of signals before triggering, post-processing of detection results, and adaptation to varying signal conditions, significantly improving the system's ability to detect meaningful fluctuations.Expand Specific Solutions05 High-speed Schmitt trigger designs for rapid fluctuation detection

High-speed Schmitt trigger circuits are specifically designed to detect rapid signal fluctuations with minimal delay. These designs employ techniques such as current-mode operation, reduced parasitic capacitance, and optimized transistor sizing to achieve faster response times. By minimizing propagation delay and improving slew rate, these circuits can efficiently detect high-frequency signal transitions and rapid fluctuations, making them suitable for applications requiring real-time signal processing.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The Schmitt Trigger efficiency market is currently in a growth phase, with increasing demand for signal fluctuation detection across multiple industries. The market size is expanding due to rising applications in automotive electronics, industrial automation, and consumer devices. Technologically, the field shows varying maturity levels among key players. Tektronix and Infineon Technologies lead with advanced trigger solutions, while semiconductor giants like Intel, Samsung, and STMicroelectronics offer integrated circuit implementations with enhanced noise immunity. Renesas Electronics and Fujitsu have developed specialized applications for automotive and industrial sectors. Research institutions like Osaka University contribute fundamental innovations, while test equipment manufacturers such as Anritsu provide measurement solutions for signal integrity verification. The competitive landscape reflects both established players and emerging specialists focusing on power efficiency and miniaturization.

Tektronix, Inc.

Technical Solution: Tektronix has incorporated advanced Schmitt trigger technology in their test and measurement equipment, particularly in their oscilloscopes and logic analyzers. Their implementation features proprietary "TekVPI" signal conditioning that combines Schmitt trigger functionality with sophisticated analog preprocessing. This approach delivers exceptional noise immunity while maintaining precise triggering thresholds. Tektronix's technology employs adaptive hysteresis that automatically adjusts based on signal characteristics and noise profiles, optimizing detection performance across diverse input conditions. Their latest implementations achieve trigger jitter below 1ps RMS, enabling precise timing measurements even with noisy signals. Tektronix has also developed specialized Schmitt trigger variants for specific applications, including their "FastAcq" technology that can process over 400,000 waveforms per second while maintaining reliable trigger operation.

Strengths: Exceptional precision and stability suitable for metrology applications; sophisticated integration with advanced signal analysis capabilities; industry-leading trigger sensitivity. Weaknesses: Primarily implemented in high-end test equipment rather than embedded systems; higher cost than general-purpose solutions.

Infineon Technologies AG

Technical Solution: Infineon has developed advanced Schmitt trigger implementations in their microcontroller and sensor product lines, particularly in their XENSIV™ sensor family. Their technology utilizes proprietary circuit designs that optimize the hysteresis window dynamically based on input signal characteristics. Infineon's approach incorporates adaptive threshold adjustment mechanisms that automatically calibrate to varying noise environments, making their Schmitt triggers particularly effective in automotive and industrial applications where signal integrity is critical. Their latest implementations feature ultra-low power consumption (as low as 10μA in standby mode) while maintaining fast response times (typically under 100ns). Infineon has also integrated their enhanced Schmitt trigger technology with digital filtering algorithms that further improve noise immunity without sacrificing detection speed.

Strengths: Superior noise immunity in harsh electromagnetic environments; extremely low power consumption suitable for battery-powered applications; high integration with other signal processing functions. Weaknesses: Higher cost compared to standard implementations; requires more complex configuration for optimal performance in specialized applications.

Core Patents and Technical Innovations

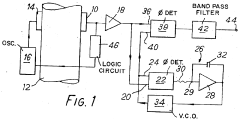

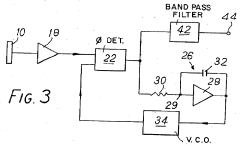

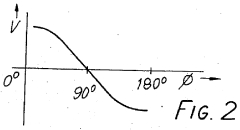

Circuits for detecting rapid fluctuations in the phase of an a.c. signal

PatentInactiveUS3860867A

Innovation

- A circuit using a phase detector with negative feedback and a voltage-controlled oscillator to stabilize the mean frequency, combined with a phase locked loop and band-pass filtering to isolate and amplify rapid phase fluctuations, ensuring that only rapid changes in phase are detected while maintaining stability against slow changes in the mean phase shift.

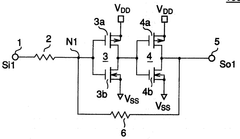

Schmitt trigger circuit with CMOS inverters and filtering means

PatentInactiveUS5438292A

Innovation

- A Schmitt trigger circuit design featuring an even number of MOS inverters connected in series, an input resistor, and a feedback capacitor, which acts as a low pass filter to reduce noise and current consumption, allowing proper operation in the direct current region and minimizing malfunctions from noise.

Noise Immunity and Performance Metrics

Noise immunity represents a critical factor in the evaluation of Schmitt trigger performance for signal fluctuation detection. The inherent hysteresis characteristic of Schmitt triggers provides significant advantages in rejecting unwanted noise components while maintaining signal integrity. This noise immunity is quantified through several key metrics, including the noise margin, which defines the threshold between acceptable signal variations and those classified as noise disturbances.

Performance evaluation of Schmitt triggers necessitates comprehensive analysis across multiple dimensions. The switching threshold accuracy determines how precisely the circuit responds to input signals reaching predefined voltage levels. This parameter directly impacts the reliability of detection systems operating in environments with varying noise profiles. Additionally, response time metrics—including rise time, fall time, and propagation delay—provide crucial insights into the temporal efficiency of Schmitt trigger implementations.

Temperature stability constitutes another essential performance metric, particularly for applications deployed in environments with significant temperature variations. High-quality Schmitt trigger designs maintain consistent hysteresis windows across wide temperature ranges, ensuring reliable operation in automotive, industrial, and outdoor sensing applications. The temperature coefficient of the threshold voltages typically ranges from 50 to 200 ppm/°C, depending on the specific implementation technology.

Power consumption efficiency has emerged as an increasingly important metric, especially for battery-powered and energy-harvesting applications. Modern Schmitt trigger designs optimize the trade-off between noise immunity and power requirements, with advanced implementations achieving sub-microwatt operation while maintaining adequate noise rejection capabilities. This balance becomes particularly critical in IoT sensor nodes and wearable devices where power constraints are severe.

Frequency response characteristics define the operational bandwidth of Schmitt trigger circuits. While traditional implementations exhibit bandwidth limitations in the megahertz range, advanced designs incorporating current-mode techniques have extended operational frequencies into the gigahertz domain. The bandwidth-power product serves as a useful figure of merit when comparing different implementation approaches.

Quantitative assessment methodologies for Schmitt trigger performance typically involve specialized test benches that simulate real-world noise conditions. Signal-to-noise ratio (SNR) improvement measurements provide objective comparisons between different circuit topologies. Industry standards recommend minimum SNR improvements of 12-15 dB for general-purpose applications, with mission-critical systems often requiring 20+ dB enhancement.

Implementation technologies significantly impact achievable performance metrics. While discrete component implementations offer flexibility, integrated CMOS implementations provide superior matching characteristics and temperature stability. Recent advances in compound semiconductor technologies have enabled Schmitt triggers with exceptional speed-power performance, particularly suitable for high-frequency sensing applications.

Performance evaluation of Schmitt triggers necessitates comprehensive analysis across multiple dimensions. The switching threshold accuracy determines how precisely the circuit responds to input signals reaching predefined voltage levels. This parameter directly impacts the reliability of detection systems operating in environments with varying noise profiles. Additionally, response time metrics—including rise time, fall time, and propagation delay—provide crucial insights into the temporal efficiency of Schmitt trigger implementations.

Temperature stability constitutes another essential performance metric, particularly for applications deployed in environments with significant temperature variations. High-quality Schmitt trigger designs maintain consistent hysteresis windows across wide temperature ranges, ensuring reliable operation in automotive, industrial, and outdoor sensing applications. The temperature coefficient of the threshold voltages typically ranges from 50 to 200 ppm/°C, depending on the specific implementation technology.

Power consumption efficiency has emerged as an increasingly important metric, especially for battery-powered and energy-harvesting applications. Modern Schmitt trigger designs optimize the trade-off between noise immunity and power requirements, with advanced implementations achieving sub-microwatt operation while maintaining adequate noise rejection capabilities. This balance becomes particularly critical in IoT sensor nodes and wearable devices where power constraints are severe.

Frequency response characteristics define the operational bandwidth of Schmitt trigger circuits. While traditional implementations exhibit bandwidth limitations in the megahertz range, advanced designs incorporating current-mode techniques have extended operational frequencies into the gigahertz domain. The bandwidth-power product serves as a useful figure of merit when comparing different implementation approaches.

Quantitative assessment methodologies for Schmitt trigger performance typically involve specialized test benches that simulate real-world noise conditions. Signal-to-noise ratio (SNR) improvement measurements provide objective comparisons between different circuit topologies. Industry standards recommend minimum SNR improvements of 12-15 dB for general-purpose applications, with mission-critical systems often requiring 20+ dB enhancement.

Implementation technologies significantly impact achievable performance metrics. While discrete component implementations offer flexibility, integrated CMOS implementations provide superior matching characteristics and temperature stability. Recent advances in compound semiconductor technologies have enabled Schmitt triggers with exceptional speed-power performance, particularly suitable for high-frequency sensing applications.

Integration Strategies in Modern Circuit Design

The integration of Schmitt triggers into modern circuit designs represents a critical strategy for enhancing signal processing capabilities in noisy environments. When implementing Schmitt trigger circuits for detecting signal fluctuations, designers must consider several integration approaches that balance performance, power consumption, and spatial constraints. The most effective integration strategies typically involve embedding Schmitt triggers at critical signal transition points within larger systems, particularly in analog-to-digital interfaces where noise immunity is paramount.

Contemporary circuit design methodologies have evolved to incorporate Schmitt triggers through various architectural patterns. One prevalent approach utilizes distributed Schmitt trigger elements throughout signal paths, creating cascaded noise immunity zones that progressively clean signals as they propagate through the system. This distributed architecture proves particularly valuable in mixed-signal environments where digital noise can contaminate analog signals.

Miniaturization trends have driven the development of compact Schmitt trigger implementations that maintain hysteresis characteristics while reducing silicon footprint. Advanced CMOS processes now enable the integration of Schmitt triggers with adjustable hysteresis thresholds, allowing dynamic reconfiguration based on environmental conditions or signal characteristics. This adaptability significantly enhances the efficiency of signal fluctuation detection across varying operational scenarios.

System-on-chip (SoC) designs increasingly incorporate specialized Schmitt trigger blocks within standard cell libraries, facilitating seamless integration during automated place-and-route processes. These standardized cells are optimized for specific technology nodes and include comprehensive characterization data that enables accurate simulation and verification of hysteresis behavior under various temperature and voltage conditions.

Power-efficient integration strategies have become increasingly important, particularly for battery-operated devices. Modern approaches include power-gating techniques that selectively activate Schmitt trigger circuits only when signal monitoring is required, substantially reducing static power consumption. Additionally, adaptive biasing schemes adjust the operating point of Schmitt trigger circuits based on activity levels, optimizing the power-performance tradeoff.

Cross-domain integration represents another significant trend, where Schmitt triggers serve as robust interfaces between different voltage domains or between analog and digital subsystems. These interface circuits often incorporate level-shifting capabilities alongside hysteresis functions, providing comprehensive signal conditioning at domain boundaries while maintaining signal integrity through noise-immune transitions.

Contemporary circuit design methodologies have evolved to incorporate Schmitt triggers through various architectural patterns. One prevalent approach utilizes distributed Schmitt trigger elements throughout signal paths, creating cascaded noise immunity zones that progressively clean signals as they propagate through the system. This distributed architecture proves particularly valuable in mixed-signal environments where digital noise can contaminate analog signals.

Miniaturization trends have driven the development of compact Schmitt trigger implementations that maintain hysteresis characteristics while reducing silicon footprint. Advanced CMOS processes now enable the integration of Schmitt triggers with adjustable hysteresis thresholds, allowing dynamic reconfiguration based on environmental conditions or signal characteristics. This adaptability significantly enhances the efficiency of signal fluctuation detection across varying operational scenarios.

System-on-chip (SoC) designs increasingly incorporate specialized Schmitt trigger blocks within standard cell libraries, facilitating seamless integration during automated place-and-route processes. These standardized cells are optimized for specific technology nodes and include comprehensive characterization data that enables accurate simulation and verification of hysteresis behavior under various temperature and voltage conditions.

Power-efficient integration strategies have become increasingly important, particularly for battery-operated devices. Modern approaches include power-gating techniques that selectively activate Schmitt trigger circuits only when signal monitoring is required, substantially reducing static power consumption. Additionally, adaptive biasing schemes adjust the operating point of Schmitt trigger circuits based on activity levels, optimizing the power-performance tradeoff.

Cross-domain integration represents another significant trend, where Schmitt triggers serve as robust interfaces between different voltage domains or between analog and digital subsystems. These interface circuits often incorporate level-shifting capabilities alongside hysteresis functions, providing comprehensive signal conditioning at domain boundaries while maintaining signal integrity through noise-immune transitions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!