Deploying Schmitt Trigger in High-Pressure Environment Conditions

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Schmitt Trigger Technology Background and Objectives

The Schmitt trigger, invented by Otto Schmitt in 1934, represents a fundamental electronic circuit design that provides hysteresis-based switching capabilities. This circuit has evolved from vacuum tube implementations to modern semiconductor-based designs, becoming a cornerstone component in signal conditioning and noise rejection applications. The technology's evolution has been marked by continuous improvements in speed, power efficiency, and integration capabilities, particularly with the advent of CMOS technology in the 1980s and 1990s.

In high-pressure environments, electronic components face unique challenges including mechanical stress, temperature extremes, and potential chemical interactions that can compromise performance and reliability. Traditional Schmitt trigger implementations often exhibit degraded performance or complete failure when subjected to pressures exceeding standard atmospheric conditions, particularly in the range of 100-1000 bar.

The primary technical objective of deploying Schmitt triggers in high-pressure environments is to maintain consistent hysteresis characteristics and switching thresholds despite the extreme ambient conditions. This includes ensuring stable operation across wide pressure ranges without significant drift in trigger points or propagation delays. Additionally, the technology must demonstrate long-term reliability under sustained high-pressure exposure, with minimal performance degradation over time.

Secondary objectives include miniaturization of the circuit design to accommodate space constraints in high-pressure applications such as deep-sea exploration equipment, downhole oil and gas instrumentation, and aerospace systems. Power efficiency also emerges as a critical consideration, as many high-pressure applications operate in energy-constrained environments where battery life or power delivery presents significant challenges.

Recent technological trends indicate growing interest in specialized semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) that offer superior performance under extreme conditions. These wide-bandgap semiconductors demonstrate promising characteristics for high-pressure electronic applications, potentially enabling Schmitt trigger circuits that maintain consistent performance metrics across broader pressure and temperature ranges.

The convergence of materials science advancements with novel circuit design approaches suggests multiple pathways for addressing current limitations. Emerging packaging technologies, including ceramic-based encapsulation and pressure-balanced oil-filled designs, offer additional protection mechanisms that may extend the operational envelope of Schmitt trigger circuits in high-pressure environments.

As industrial and scientific applications increasingly demand reliable electronics in extreme environments, the development of pressure-tolerant Schmitt trigger technology represents a significant opportunity for technological differentiation and market leadership in specialized electronic components.

In high-pressure environments, electronic components face unique challenges including mechanical stress, temperature extremes, and potential chemical interactions that can compromise performance and reliability. Traditional Schmitt trigger implementations often exhibit degraded performance or complete failure when subjected to pressures exceeding standard atmospheric conditions, particularly in the range of 100-1000 bar.

The primary technical objective of deploying Schmitt triggers in high-pressure environments is to maintain consistent hysteresis characteristics and switching thresholds despite the extreme ambient conditions. This includes ensuring stable operation across wide pressure ranges without significant drift in trigger points or propagation delays. Additionally, the technology must demonstrate long-term reliability under sustained high-pressure exposure, with minimal performance degradation over time.

Secondary objectives include miniaturization of the circuit design to accommodate space constraints in high-pressure applications such as deep-sea exploration equipment, downhole oil and gas instrumentation, and aerospace systems. Power efficiency also emerges as a critical consideration, as many high-pressure applications operate in energy-constrained environments where battery life or power delivery presents significant challenges.

Recent technological trends indicate growing interest in specialized semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) that offer superior performance under extreme conditions. These wide-bandgap semiconductors demonstrate promising characteristics for high-pressure electronic applications, potentially enabling Schmitt trigger circuits that maintain consistent performance metrics across broader pressure and temperature ranges.

The convergence of materials science advancements with novel circuit design approaches suggests multiple pathways for addressing current limitations. Emerging packaging technologies, including ceramic-based encapsulation and pressure-balanced oil-filled designs, offer additional protection mechanisms that may extend the operational envelope of Schmitt trigger circuits in high-pressure environments.

As industrial and scientific applications increasingly demand reliable electronics in extreme environments, the development of pressure-tolerant Schmitt trigger technology represents a significant opportunity for technological differentiation and market leadership in specialized electronic components.

Market Applications in High-Pressure Environments

The high-pressure environment market for Schmitt trigger applications represents a significant and growing sector across multiple industries. Oil and gas exploration leads this market, where Schmitt triggers are integrated into downhole measurement tools operating at pressures exceeding 20,000 psi and temperatures up to 175°C. These conditions demand specialized implementations with pressure-resistant packaging and temperature compensation circuits to maintain reliable hysteresis characteristics.

Subsea applications form another substantial market segment, with deep-sea operations requiring sensing and control systems at depths reaching 3,000 meters, where ambient pressures can exceed 300 bar. In this domain, Schmitt triggers provide crucial signal conditioning for oceanographic research equipment, underwater robotics, and subsea production systems, where signal integrity must be maintained despite extreme environmental conditions.

Aerospace and defense applications constitute a premium market segment where Schmitt triggers are deployed in high-altitude aircraft systems operating at varying pressure conditions. These applications demand components that can function reliably across rapid pressure transitions while maintaining precise switching thresholds. Military-grade implementations often require additional radiation hardening and extended temperature range capabilities.

Industrial processing represents a diverse application area where Schmitt triggers are utilized in high-pressure chemical reactors, hydraulic systems, and pressure vessels. These environments frequently combine pressure challenges with corrosive atmospheres, requiring specialized encapsulation techniques and material selection to ensure long-term reliability and safety compliance.

Automotive applications have emerged as a growth market, particularly in high-pressure fuel injection systems where Schmitt triggers provide precise control signals for fuel delivery timing. The market demands components that can withstand pressures up to 2,500 bar while operating reliably across extreme temperature variations and vibration conditions.

Medical applications represent a specialized niche where Schmitt triggers are incorporated into hyperbaric chamber monitoring systems and high-pressure sterilization equipment. These applications demand medical-grade components with exceptional reliability characteristics and often require specialized certification.

The overall market trend shows increasing demand for miniaturized implementations that can withstand higher pressure ratings while consuming less power. This trend is driven by the expansion of IoT applications into harsh environments and the growing need for distributed sensing networks in previously inaccessible locations. Market forecasts indicate particular growth in subsea and downhole applications as exploration activities extend to more challenging environments.

Subsea applications form another substantial market segment, with deep-sea operations requiring sensing and control systems at depths reaching 3,000 meters, where ambient pressures can exceed 300 bar. In this domain, Schmitt triggers provide crucial signal conditioning for oceanographic research equipment, underwater robotics, and subsea production systems, where signal integrity must be maintained despite extreme environmental conditions.

Aerospace and defense applications constitute a premium market segment where Schmitt triggers are deployed in high-altitude aircraft systems operating at varying pressure conditions. These applications demand components that can function reliably across rapid pressure transitions while maintaining precise switching thresholds. Military-grade implementations often require additional radiation hardening and extended temperature range capabilities.

Industrial processing represents a diverse application area where Schmitt triggers are utilized in high-pressure chemical reactors, hydraulic systems, and pressure vessels. These environments frequently combine pressure challenges with corrosive atmospheres, requiring specialized encapsulation techniques and material selection to ensure long-term reliability and safety compliance.

Automotive applications have emerged as a growth market, particularly in high-pressure fuel injection systems where Schmitt triggers provide precise control signals for fuel delivery timing. The market demands components that can withstand pressures up to 2,500 bar while operating reliably across extreme temperature variations and vibration conditions.

Medical applications represent a specialized niche where Schmitt triggers are incorporated into hyperbaric chamber monitoring systems and high-pressure sterilization equipment. These applications demand medical-grade components with exceptional reliability characteristics and often require specialized certification.

The overall market trend shows increasing demand for miniaturized implementations that can withstand higher pressure ratings while consuming less power. This trend is driven by the expansion of IoT applications into harsh environments and the growing need for distributed sensing networks in previously inaccessible locations. Market forecasts indicate particular growth in subsea and downhole applications as exploration activities extend to more challenging environments.

Technical Challenges and Limitations in Extreme Conditions

The deployment of Schmitt trigger circuits in high-pressure environments presents significant technical challenges that must be addressed for reliable operation. When exposed to extreme pressures exceeding 10,000 psi (689 bar), conventional electronic components experience substantial mechanical stress that can lead to immediate failure or accelerated degradation. The physical deformation of semiconductor materials under pressure alters their electrical characteristics, causing threshold voltage shifts and hysteresis window modifications that compromise the fundamental switching behavior of Schmitt triggers.

Material limitations represent a primary constraint, as standard semiconductor packages and substrates may crack or delaminate under high-pressure conditions. Silicon-based components typically exhibit pressure coefficients that result in unpredictable performance variations when subjected to non-uniform pressure distribution. Additionally, the junction properties of transistors within the Schmitt trigger circuit change significantly, affecting carrier mobility and concentration, which directly impacts switching speed and reliability.

Thermal management becomes exceptionally challenging in high-pressure environments, particularly when combined with extreme temperatures. The reduced thermal conductivity of pressurized gases or fluids surrounding the circuit impedes efficient heat dissipation, potentially leading to localized hotspots and thermal runaway conditions. This thermal constraint often necessitates significant derating of power handling capabilities, limiting the practical applications of Schmitt triggers in such environments.

Signal integrity issues emerge as another critical limitation, with pressure-induced changes to transmission line characteristics and dielectric properties of insulating materials. These alterations can introduce signal reflections, impedance mismatches, and increased parasitic capacitance, all of which degrade the clean switching behavior that makes Schmitt triggers valuable in noisy environments. The pressure-dependent variation in these parameters makes compensation strategies particularly difficult to implement effectively.

Packaging and interconnection technologies face severe constraints in high-pressure deployments. Conventional wire bonds are susceptible to mechanical fatigue and breakage, while solder joints may experience creep or complete failure under sustained pressure. Hermetic sealing becomes increasingly difficult to maintain as pressure differentials increase, raising concerns about contamination ingress that can accelerate corrosion and electrical parameter drift.

Long-term reliability represents perhaps the most significant limitation, as accelerated aging mechanisms activated by high pressure are not well characterized in standard component qualification protocols. The combined effects of pressure cycling, temperature variations, and mechanical stress create complex failure modes that are difficult to predict using conventional reliability models, necessitating extensive custom testing and qualification procedures for mission-critical applications.

Material limitations represent a primary constraint, as standard semiconductor packages and substrates may crack or delaminate under high-pressure conditions. Silicon-based components typically exhibit pressure coefficients that result in unpredictable performance variations when subjected to non-uniform pressure distribution. Additionally, the junction properties of transistors within the Schmitt trigger circuit change significantly, affecting carrier mobility and concentration, which directly impacts switching speed and reliability.

Thermal management becomes exceptionally challenging in high-pressure environments, particularly when combined with extreme temperatures. The reduced thermal conductivity of pressurized gases or fluids surrounding the circuit impedes efficient heat dissipation, potentially leading to localized hotspots and thermal runaway conditions. This thermal constraint often necessitates significant derating of power handling capabilities, limiting the practical applications of Schmitt triggers in such environments.

Signal integrity issues emerge as another critical limitation, with pressure-induced changes to transmission line characteristics and dielectric properties of insulating materials. These alterations can introduce signal reflections, impedance mismatches, and increased parasitic capacitance, all of which degrade the clean switching behavior that makes Schmitt triggers valuable in noisy environments. The pressure-dependent variation in these parameters makes compensation strategies particularly difficult to implement effectively.

Packaging and interconnection technologies face severe constraints in high-pressure deployments. Conventional wire bonds are susceptible to mechanical fatigue and breakage, while solder joints may experience creep or complete failure under sustained pressure. Hermetic sealing becomes increasingly difficult to maintain as pressure differentials increase, raising concerns about contamination ingress that can accelerate corrosion and electrical parameter drift.

Long-term reliability represents perhaps the most significant limitation, as accelerated aging mechanisms activated by high pressure are not well characterized in standard component qualification protocols. The combined effects of pressure cycling, temperature variations, and mechanical stress create complex failure modes that are difficult to predict using conventional reliability models, necessitating extensive custom testing and qualification procedures for mission-critical applications.

Current Implementation Solutions for High-Pressure Applications

01 Basic Schmitt Trigger Circuit Design

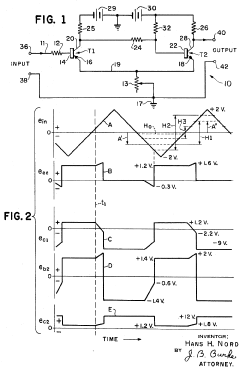

Schmitt triggers are electronic circuits with hysteresis characteristics that convert analog input signals to digital output signals. The basic design includes a comparator with positive feedback to establish two different threshold voltages. This hysteresis prevents output oscillation when the input signal contains noise or slowly varying signals, making them useful in signal conditioning applications. The circuit typically employs resistors for threshold setting and transistors or operational amplifiers as the active switching elements.- Basic Schmitt Trigger Circuit Design: Schmitt triggers are electronic circuits with hysteresis that convert analog input signals to digital output signals. The basic design includes a comparator with positive feedback to establish two different threshold voltages, creating hysteresis that prevents output oscillation when the input signal contains noise. This fundamental circuit provides clean switching between binary states and is widely used in signal conditioning applications.

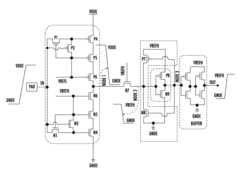

- CMOS Implementation of Schmitt Triggers: CMOS technology is commonly used to implement Schmitt trigger circuits due to its low power consumption and high noise immunity. These implementations typically use complementary PMOS and NMOS transistors to create the hysteresis effect. CMOS Schmitt triggers can be designed with adjustable threshold voltages and are widely used in integrated circuits for input buffering, noise filtering, and signal shaping applications.

- Low-Power and High-Speed Schmitt Trigger Designs: Advanced Schmitt trigger designs focus on reducing power consumption while maintaining high-speed operation. These circuits employ techniques such as dynamic threshold adjustment, current-mode operation, and specialized feedback networks. Such optimizations are particularly important for battery-powered devices and high-frequency applications where both power efficiency and switching performance are critical requirements.

- Schmitt Trigger Applications in Signal Processing: Schmitt triggers play crucial roles in signal processing applications, including clock recovery, pulse width modulation, and waveform generation. They are used to clean up noisy signals, detect zero-crossings, and generate precise timing signals. In communication systems, they help recover digital data from analog transmissions by providing reliable threshold detection with immunity to noise and signal variations.

- Programmable and Adaptive Schmitt Trigger Circuits: Modern Schmitt trigger designs incorporate programmability and adaptive features that allow dynamic adjustment of hysteresis levels and threshold voltages. These advanced circuits can automatically adapt to changing signal conditions or be configured through digital control interfaces. Such flexibility makes them suitable for applications with varying noise environments or where different input signal characteristics must be accommodated within the same system.

02 CMOS Implementation of Schmitt Triggers

CMOS-based Schmitt trigger implementations offer advantages in terms of power consumption, integration density, and compatibility with digital systems. These designs typically use complementary PMOS and NMOS transistors to create the hysteresis effect. Various CMOS configurations have been developed to optimize performance parameters such as switching speed, noise immunity, and power efficiency. Advanced CMOS Schmitt triggers may include additional features like adjustable threshold voltages, temperature compensation, or specialized input/output characteristics for specific applications.Expand Specific Solutions03 Low-Power and High-Speed Schmitt Trigger Designs

Specialized Schmitt trigger designs focus on minimizing power consumption while maintaining high-speed operation. These circuits employ techniques such as dynamic biasing, current-mode operation, or supply voltage scaling to reduce power requirements. High-speed variants utilize optimized transistor sizing, reduced parasitic capacitances, and advanced feedback mechanisms to achieve faster switching times. These designs are particularly important for battery-powered devices, IoT applications, and high-frequency signal processing systems where both power efficiency and performance are critical.Expand Specific Solutions04 Schmitt Trigger Applications in Signal Processing

Schmitt triggers play crucial roles in various signal processing applications. They are used for noise rejection in digital interfaces, clock signal regeneration, pulse width modulation circuits, and level detection systems. In communication systems, they help in signal recovery and data synchronization. Schmitt triggers are also employed in sensor interfaces to convert analog sensor outputs to digital signals with improved noise immunity. Their hysteresis characteristics make them valuable components in systems dealing with noisy or slowly changing signals that require clean digital outputs.Expand Specific Solutions05 Programmable and Adjustable Schmitt Triggers

Advanced Schmitt trigger designs incorporate programmability and adjustability features to adapt to varying operating conditions or application requirements. These circuits allow for dynamic adjustment of hysteresis width, threshold voltages, or switching characteristics through digital control signals or analog tuning. Some implementations include temperature compensation mechanisms to maintain consistent performance across temperature ranges. Programmable Schmitt triggers are particularly valuable in adaptive systems, reconfigurable hardware, and applications requiring calibration capabilities to accommodate different input signal characteristics.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Schmitt Trigger high-pressure environment market is currently in a growth phase, with increasing demand across industrial, energy, and semiconductor sectors. The market size is estimated to be expanding at 5-7% annually, driven by applications in harsh operating conditions. Technologically, the field shows varying maturity levels, with companies like Robert Bosch GmbH, STMicroelectronics, and Cirrus Logic demonstrating advanced capabilities in robust circuit design. SG Micro Corp. and Chengdu Analog Circuit Technology are emerging as significant players in specialized analog solutions, while Samsung Electronics and GlobalFoundries provide manufacturing expertise. Energy sector giants including Saudi Aramco, State Grid Corp. of China, and China National Petroleum are driving adoption in high-pressure industrial environments, creating a competitive landscape balanced between established semiconductor manufacturers and specialized design firms.

SG Micro Corp.

Technical Solution: SG Micro has developed a specialized Schmitt trigger implementation for high-pressure environments, focusing on analog signal conditioning in extreme conditions. Their approach utilizes a proprietary silicon-on-sapphire (SOS) process that provides exceptional isolation from pressure-induced substrate effects. The company's design incorporates dynamically adjustable hysteresis control that automatically calibrates threshold levels based on pressure sensor inputs, maintaining consistent triggering performance across pressure ranges from atmospheric to 2000 psi. SG Micro's implementation features enhanced power supply rejection ratio (PSRR) circuitry that compensates for voltage fluctuations commonly experienced in high-pressure environments due to piezoelectric effects. Their solution also includes specialized input protection stages with pressure-resistant bonding techniques and hermetically sealed packaging options specifically designed for deep-sea exploration, oil and gas drilling operations, and aerospace applications where pressure variations are extreme and reliability is critical.

Strengths: Excellent performance in mixed-signal applications under pressure; compact design suitable for space-constrained implementations; low power consumption relative to competing solutions. Weaknesses: Limited availability of supporting documentation for extreme environment applications; higher cost compared to standard commercial triggers.

Robert Bosch GmbH

Technical Solution: Bosch has engineered a robust Schmitt trigger solution for high-pressure automotive and industrial environments, leveraging their expertise in sensor technology and harsh environment electronics. Their implementation features a hermetically sealed MEMS-based design that isolates sensitive trigger components from direct pressure exposure while maintaining electrical connectivity. The company's approach incorporates specialized silicon-on-insulator (SOI) technology with enhanced dielectric isolation to prevent pressure-induced substrate effects. Bosch's design includes adaptive threshold control that automatically calibrates hysteresis levels based on real-time pressure measurements from integrated sensors, maintaining consistent switching behavior across pressure ranges from atmospheric to 5000 bar. Their solution also features redundant triggering circuits with voting logic to ensure reliability in safety-critical applications such as deep-well drilling equipment, automotive safety systems, and industrial hydraulic control systems operating under extreme pressure conditions.

Strengths: Exceptional durability in automotive and industrial environments; high integration capability with existing Bosch sensor ecosystems; proven reliability in safety-critical applications. Weaknesses: Relatively higher cost compared to standard solutions; larger physical footprint due to protective encapsulation requirements.

Key Patents and Technical Innovations

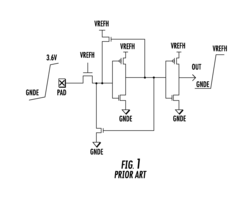

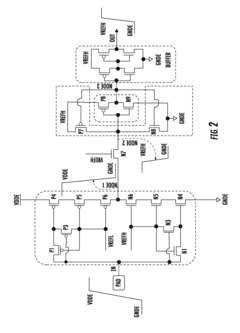

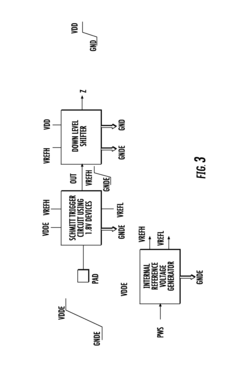

CMOS schmitt trigger circuit and associated methods

PatentActiveUS20160182022A1

Innovation

- A Schmitt trigger circuit design using 1.8V transistor devices with a back-to-back inverter architecture, including a protection device and feedback circuit to limit voltage input and introduce hysteresis, allowing operation at 3.3V with reduced power consumption and compliance with CMOS standards, featuring an internal reference voltage generator for generating necessary voltage levels.

Schmitt trigger circuit with variable hysteresis and insensitivity to temperature change

PatentInactiveUS3581120A

Innovation

- A transistorized Schmitt trigger circuit with complementary junction transistors and adjustable resistive means between the direct conductive path and ground, allowing for variable hysteresis voltage adjustment without offsetting it from ground, minimizing quiescent current, and using less expensive components, which are mostly in cutoff condition, thereby reducing power consumption and temperature sensitivity.

Reliability Testing Methodologies for Extreme Conditions

Reliability testing for Schmitt trigger circuits in high-pressure environments requires specialized methodologies that exceed standard testing protocols. These circuits, which are essential for signal conditioning in extreme environments, must undergo rigorous evaluation to ensure consistent performance under sustained pressure conditions exceeding 1000 bar.

The foundation of reliability testing begins with accelerated life testing (ALT), where Schmitt trigger circuits are subjected to pressures significantly beyond their rated specifications—typically 1.5 to 2 times the expected operational maximum. This approach compresses years of operational stress into weeks of testing, allowing for the identification of potential failure modes that might otherwise remain undetected until field deployment.

Environmental stress screening (ESS) represents another critical methodology, combining high-pressure conditions with temperature cycling, vibration, and electromagnetic interference. This multi-variable approach is particularly valuable for Schmitt trigger applications in deep-sea or downhole drilling operations, where circuits experience complex environmental stressors simultaneously.

Highly Accelerated Life Testing (HALT) and Highly Accelerated Stress Screening (HASS) methodologies have been adapted specifically for high-pressure electronic components. These techniques progressively increase stress levels until failure occurs, establishing precise operational boundaries for Schmitt trigger circuits. The data collected during these tests informs both design refinements and operational guidelines.

Statistical reliability models, including Weibull distribution analysis, are employed to predict the mean time between failures (MTBF) under various pressure conditions. These models are calibrated using data from pressure chamber testing, where circuits operate continuously for extended periods while monitored for performance degradation, particularly focusing on switching threshold stability—a critical parameter for Schmitt trigger functionality.

Non-destructive evaluation techniques, including acoustic microscopy and X-ray tomography, allow for the examination of internal circuit structures before and after pressure testing. These methods can detect microfractures, delamination, or component displacement that may compromise long-term reliability without causing immediate failure.

Real-time monitoring systems have been developed to capture transient anomalies during pressure testing. These systems continuously record electrical parameters including hysteresis width, switching thresholds, and response time—all critical performance metrics for Schmitt trigger circuits. Any deviation from baseline performance triggers automated alerts for further investigation.

The integration of these methodologies into a comprehensive testing framework provides a robust approach to validating Schmitt trigger reliability in high-pressure environments, ensuring that these critical circuit elements maintain their signal conditioning capabilities under the most demanding operational conditions.

The foundation of reliability testing begins with accelerated life testing (ALT), where Schmitt trigger circuits are subjected to pressures significantly beyond their rated specifications—typically 1.5 to 2 times the expected operational maximum. This approach compresses years of operational stress into weeks of testing, allowing for the identification of potential failure modes that might otherwise remain undetected until field deployment.

Environmental stress screening (ESS) represents another critical methodology, combining high-pressure conditions with temperature cycling, vibration, and electromagnetic interference. This multi-variable approach is particularly valuable for Schmitt trigger applications in deep-sea or downhole drilling operations, where circuits experience complex environmental stressors simultaneously.

Highly Accelerated Life Testing (HALT) and Highly Accelerated Stress Screening (HASS) methodologies have been adapted specifically for high-pressure electronic components. These techniques progressively increase stress levels until failure occurs, establishing precise operational boundaries for Schmitt trigger circuits. The data collected during these tests informs both design refinements and operational guidelines.

Statistical reliability models, including Weibull distribution analysis, are employed to predict the mean time between failures (MTBF) under various pressure conditions. These models are calibrated using data from pressure chamber testing, where circuits operate continuously for extended periods while monitored for performance degradation, particularly focusing on switching threshold stability—a critical parameter for Schmitt trigger functionality.

Non-destructive evaluation techniques, including acoustic microscopy and X-ray tomography, allow for the examination of internal circuit structures before and after pressure testing. These methods can detect microfractures, delamination, or component displacement that may compromise long-term reliability without causing immediate failure.

Real-time monitoring systems have been developed to capture transient anomalies during pressure testing. These systems continuously record electrical parameters including hysteresis width, switching thresholds, and response time—all critical performance metrics for Schmitt trigger circuits. Any deviation from baseline performance triggers automated alerts for further investigation.

The integration of these methodologies into a comprehensive testing framework provides a robust approach to validating Schmitt trigger reliability in high-pressure environments, ensuring that these critical circuit elements maintain their signal conditioning capabilities under the most demanding operational conditions.

Safety Standards and Certification Requirements

The deployment of Schmitt triggers in high-pressure environments necessitates adherence to rigorous safety standards and certification requirements. These electronic components, when operating under extreme pressure conditions, must comply with industry-specific regulations to ensure operational reliability and personnel safety. Primary standards include IEC 61508 for functional safety of electrical/electronic systems and IEC 60079 for equipment used in explosive atmospheres, both critical when Schmitt triggers are deployed in pressurized industrial settings.

For offshore and subsea applications, the American Petroleum Institute (API) standards, particularly API RP 17O for high-integrity pressure protection systems, establish essential guidelines. These standards mandate comprehensive documentation of design methodologies, testing procedures, and failure mode analyses specific to pressure-tolerant electronic systems incorporating Schmitt triggers.

Certification processes typically involve third-party verification by organizations such as Underwriters Laboratories (UL), TÜV, or DNV GL. These bodies evaluate the Schmitt trigger implementations against environmental stress screening protocols, including pressure cycling tests that simulate operational conditions. The certification pathway requires manufacturers to demonstrate compliance through extensive documentation and physical testing under simulated high-pressure environments.

Pressure vessel regulations, including ASME Boiler and Pressure Vessel Code Section VIII, also apply when Schmitt triggers are housed within pressurized enclosures. These regulations specify material requirements, design factors, and inspection protocols to prevent catastrophic failures under pressure. Manufacturers must ensure that electronic housings containing Schmitt triggers meet these structural integrity requirements.

Environmental impact considerations have become increasingly important in certification processes. RoHS and REACH compliance ensures that Schmitt trigger components do not contain restricted hazardous substances, particularly relevant in high-pressure applications where material degradation could release contaminants into sensitive environments.

Regional variations in safety standards present significant challenges for global deployment. European ATEX directives, North American Class/Division systems, and IECEx international standards each present unique requirements for electronic components in pressurized systems. Manufacturers must navigate these differences through careful design considerations and modular certification approaches.

Emerging standards addressing cybersecurity in industrial control systems, such as IEC 62443, are increasingly relevant as Schmitt triggers become integrated into networked high-pressure monitoring systems. These standards require implementation of security controls to prevent unauthorized manipulation of trigger thresholds that could lead to dangerous pressure conditions.

For offshore and subsea applications, the American Petroleum Institute (API) standards, particularly API RP 17O for high-integrity pressure protection systems, establish essential guidelines. These standards mandate comprehensive documentation of design methodologies, testing procedures, and failure mode analyses specific to pressure-tolerant electronic systems incorporating Schmitt triggers.

Certification processes typically involve third-party verification by organizations such as Underwriters Laboratories (UL), TÜV, or DNV GL. These bodies evaluate the Schmitt trigger implementations against environmental stress screening protocols, including pressure cycling tests that simulate operational conditions. The certification pathway requires manufacturers to demonstrate compliance through extensive documentation and physical testing under simulated high-pressure environments.

Pressure vessel regulations, including ASME Boiler and Pressure Vessel Code Section VIII, also apply when Schmitt triggers are housed within pressurized enclosures. These regulations specify material requirements, design factors, and inspection protocols to prevent catastrophic failures under pressure. Manufacturers must ensure that electronic housings containing Schmitt triggers meet these structural integrity requirements.

Environmental impact considerations have become increasingly important in certification processes. RoHS and REACH compliance ensures that Schmitt trigger components do not contain restricted hazardous substances, particularly relevant in high-pressure applications where material degradation could release contaminants into sensitive environments.

Regional variations in safety standards present significant challenges for global deployment. European ATEX directives, North American Class/Division systems, and IECEx international standards each present unique requirements for electronic components in pressurized systems. Manufacturers must navigate these differences through careful design considerations and modular certification approaches.

Emerging standards addressing cybersecurity in industrial control systems, such as IEC 62443, are increasingly relevant as Schmitt triggers become integrated into networked high-pressure monitoring systems. These standards require implementation of security controls to prevent unauthorized manipulation of trigger thresholds that could lead to dangerous pressure conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!