Design Tactics for Reliable Schmitt Trigger Circuit Applications

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Schmitt Trigger Technology Background and Objectives

The Schmitt trigger circuit, first introduced by Otto Schmitt in 1934, represents a fundamental advancement in electronic circuit design, particularly in signal conditioning and noise immunity applications. This bistable multivibrator circuit has evolved from vacuum tube implementations to modern semiconductor-based designs, establishing itself as an essential component in digital and analog systems across multiple industries.

The evolution of Schmitt trigger technology has been closely aligned with broader semiconductor advancements. Early implementations utilized discrete components, while integration into standard logic families like TTL (Transistor-Transistor Logic) and CMOS (Complementary Metal-Oxide-Semiconductor) in the 1970s and 1980s significantly expanded their application scope. Recent developments have focused on optimizing performance parameters such as power consumption, switching speed, and noise immunity for specialized applications.

Current technological trends indicate a growing demand for Schmitt triggers in emerging fields including IoT devices, automotive electronics, and medical instrumentation, where signal integrity under varying environmental conditions is paramount. The miniaturization trend in electronics has simultaneously driven research toward more compact and energy-efficient Schmitt trigger implementations, particularly for battery-powered and portable applications.

The primary technical objective in Schmitt trigger design is achieving reliable hysteresis behavior—the defining characteristic that provides immunity to noise and prevents oscillation near threshold voltages. Modern design goals focus on optimizing the hysteresis window for specific application requirements while maintaining consistent performance across temperature variations, supply voltage fluctuations, and manufacturing process variations.

Another critical objective is reducing power consumption without compromising switching performance, particularly for applications in mobile and IoT devices. This has led to exploration of sub-threshold operation techniques and novel circuit topologies that maintain robust hysteresis characteristics while operating at lower supply voltages.

Integration capabilities represent another significant goal, with designers seeking to incorporate Schmitt triggers into complex mixed-signal systems while minimizing interference with adjacent circuits. This includes addressing challenges related to ground bounce, power supply noise, and electromagnetic compatibility in densely packed electronic systems.

The advancement of Schmitt trigger technology also aims to extend operational frequency ranges to accommodate high-speed digital interfaces and communication protocols. This requires careful consideration of parasitic capacitances and propagation delays that become increasingly significant at higher frequencies.

Looking forward, research objectives include developing adaptive Schmitt trigger circuits capable of dynamically adjusting hysteresis thresholds based on environmental conditions or signal characteristics, potentially opening new application domains where traditional fixed-threshold designs prove inadequate.

The evolution of Schmitt trigger technology has been closely aligned with broader semiconductor advancements. Early implementations utilized discrete components, while integration into standard logic families like TTL (Transistor-Transistor Logic) and CMOS (Complementary Metal-Oxide-Semiconductor) in the 1970s and 1980s significantly expanded their application scope. Recent developments have focused on optimizing performance parameters such as power consumption, switching speed, and noise immunity for specialized applications.

Current technological trends indicate a growing demand for Schmitt triggers in emerging fields including IoT devices, automotive electronics, and medical instrumentation, where signal integrity under varying environmental conditions is paramount. The miniaturization trend in electronics has simultaneously driven research toward more compact and energy-efficient Schmitt trigger implementations, particularly for battery-powered and portable applications.

The primary technical objective in Schmitt trigger design is achieving reliable hysteresis behavior—the defining characteristic that provides immunity to noise and prevents oscillation near threshold voltages. Modern design goals focus on optimizing the hysteresis window for specific application requirements while maintaining consistent performance across temperature variations, supply voltage fluctuations, and manufacturing process variations.

Another critical objective is reducing power consumption without compromising switching performance, particularly for applications in mobile and IoT devices. This has led to exploration of sub-threshold operation techniques and novel circuit topologies that maintain robust hysteresis characteristics while operating at lower supply voltages.

Integration capabilities represent another significant goal, with designers seeking to incorporate Schmitt triggers into complex mixed-signal systems while minimizing interference with adjacent circuits. This includes addressing challenges related to ground bounce, power supply noise, and electromagnetic compatibility in densely packed electronic systems.

The advancement of Schmitt trigger technology also aims to extend operational frequency ranges to accommodate high-speed digital interfaces and communication protocols. This requires careful consideration of parasitic capacitances and propagation delays that become increasingly significant at higher frequencies.

Looking forward, research objectives include developing adaptive Schmitt trigger circuits capable of dynamically adjusting hysteresis thresholds based on environmental conditions or signal characteristics, potentially opening new application domains where traditional fixed-threshold designs prove inadequate.

Market Applications and Demand Analysis

The Schmitt trigger circuit market is experiencing significant growth driven by the increasing demand for reliable signal conditioning and noise immunity in various electronic applications. The global market for analog comparators, which includes Schmitt triggers, is projected to reach $2.1 billion by 2026, with a compound annual growth rate of 5.8% from 2021. This growth is primarily fueled by the expanding electronics industry and the rising need for precision in signal processing applications.

Industrial automation represents one of the largest application segments for Schmitt trigger circuits, accounting for approximately 28% of the total market share. In this sector, Schmitt triggers are essential components in control systems, sensors, and feedback mechanisms where noise immunity and precise threshold detection are critical for operational reliability. The industrial IoT revolution has further accelerated demand, as factories increasingly implement smart sensors requiring robust signal conditioning.

The automotive electronics sector constitutes another significant market for Schmitt trigger applications, growing at 7.2% annually. Modern vehicles contain numerous electronic control units that rely on Schmitt triggers for clean signal processing in harsh electromagnetic environments. Advanced driver assistance systems (ADAS) and autonomous driving technologies have particularly stringent requirements for signal integrity, further driving demand for high-performance Schmitt trigger designs.

Consumer electronics represents the fastest-growing application segment, with demand increasing at 8.5% annually. Smartphones, wearables, and smart home devices all utilize Schmitt triggers in various subsystems including touch interfaces, power management, and sensor interfaces. The miniaturization trend in consumer electronics has created specific market demand for low-power, space-efficient Schmitt trigger implementations.

Medical device manufacturers constitute a premium market segment for high-reliability Schmitt trigger circuits, with particular emphasis on precision and long-term stability. Patient monitoring equipment, diagnostic devices, and implantable medical devices all require exceptional signal integrity in environments with significant electromagnetic interference, creating demand for specialized Schmitt trigger designs with enhanced reliability features.

Telecommunications infrastructure represents another substantial market, particularly with the ongoing 5G network deployment. Signal integrity in high-frequency applications has become increasingly critical, driving demand for advanced Schmitt trigger designs capable of operating reliably at higher frequencies while maintaining precise hysteresis characteristics.

Market analysis indicates a growing preference for integrated Schmitt trigger solutions that combine multiple functions in single packages, reducing board space and improving system reliability. This trend aligns with the broader industry movement toward higher integration and system-on-chip solutions.

Industrial automation represents one of the largest application segments for Schmitt trigger circuits, accounting for approximately 28% of the total market share. In this sector, Schmitt triggers are essential components in control systems, sensors, and feedback mechanisms where noise immunity and precise threshold detection are critical for operational reliability. The industrial IoT revolution has further accelerated demand, as factories increasingly implement smart sensors requiring robust signal conditioning.

The automotive electronics sector constitutes another significant market for Schmitt trigger applications, growing at 7.2% annually. Modern vehicles contain numerous electronic control units that rely on Schmitt triggers for clean signal processing in harsh electromagnetic environments. Advanced driver assistance systems (ADAS) and autonomous driving technologies have particularly stringent requirements for signal integrity, further driving demand for high-performance Schmitt trigger designs.

Consumer electronics represents the fastest-growing application segment, with demand increasing at 8.5% annually. Smartphones, wearables, and smart home devices all utilize Schmitt triggers in various subsystems including touch interfaces, power management, and sensor interfaces. The miniaturization trend in consumer electronics has created specific market demand for low-power, space-efficient Schmitt trigger implementations.

Medical device manufacturers constitute a premium market segment for high-reliability Schmitt trigger circuits, with particular emphasis on precision and long-term stability. Patient monitoring equipment, diagnostic devices, and implantable medical devices all require exceptional signal integrity in environments with significant electromagnetic interference, creating demand for specialized Schmitt trigger designs with enhanced reliability features.

Telecommunications infrastructure represents another substantial market, particularly with the ongoing 5G network deployment. Signal integrity in high-frequency applications has become increasingly critical, driving demand for advanced Schmitt trigger designs capable of operating reliably at higher frequencies while maintaining precise hysteresis characteristics.

Market analysis indicates a growing preference for integrated Schmitt trigger solutions that combine multiple functions in single packages, reducing board space and improving system reliability. This trend aligns with the broader industry movement toward higher integration and system-on-chip solutions.

Current Challenges in Schmitt Trigger Design

Despite significant advancements in Schmitt trigger design over the decades, several persistent challenges continue to impede optimal performance in modern applications. One of the primary obstacles is achieving consistent hysteresis width across varying operating conditions. Temperature fluctuations, supply voltage variations, and process corners significantly affect the threshold voltages, causing unpredictable behavior in critical applications where precise switching points are essential.

Power consumption remains a substantial concern, particularly in battery-operated and IoT devices. Traditional Schmitt trigger designs often require continuous current flow to maintain hysteresis characteristics, creating an inherent trade-off between power efficiency and noise immunity. This challenge becomes more pronounced as supply voltages continue to decrease in modern semiconductor processes.

Noise susceptibility at the transition points presents another significant hurdle. While Schmitt triggers are designed specifically to combat noise, their effectiveness diminishes in environments with high-frequency noise components or when operating near their threshold limits. Engineers must constantly balance noise immunity against switching speed requirements.

The increasing demand for miniaturization creates layout and area constraints that complicate Schmitt trigger implementation. As circuit dimensions shrink, maintaining consistent performance becomes more difficult due to increased susceptibility to manufacturing variations and parasitic effects. This challenge is particularly evident in nanometer-scale processes where device matching is increasingly problematic.

Process variation across semiconductor manufacturing batches introduces significant threshold voltage inconsistencies. These variations can cause substantial differences in hysteresis width between supposedly identical circuits, creating reliability issues in volume production. Compensation techniques often increase complexity and cost.

Integration challenges arise when incorporating Schmitt triggers into complex mixed-signal systems. Interference from adjacent digital circuits can compromise the analog performance of Schmitt triggers, while the triggers themselves may introduce noise into sensitive analog sections. Careful isolation techniques are required but add design complexity.

Speed limitations present obstacles in high-frequency applications. The inherent feedback mechanism that creates hysteresis introduces propagation delays that can be problematic in timing-critical circuits. Designers must carefully balance noise immunity against switching speed requirements, often resulting in application-specific compromises.

Finally, simulation accuracy remains challenging. Accurately modeling Schmitt trigger behavior across all operating conditions requires sophisticated simulation models that account for temperature effects, process variations, and dynamic behavior. The gap between simulation and real-world performance often necessitates multiple design iterations and extensive testing.

Power consumption remains a substantial concern, particularly in battery-operated and IoT devices. Traditional Schmitt trigger designs often require continuous current flow to maintain hysteresis characteristics, creating an inherent trade-off between power efficiency and noise immunity. This challenge becomes more pronounced as supply voltages continue to decrease in modern semiconductor processes.

Noise susceptibility at the transition points presents another significant hurdle. While Schmitt triggers are designed specifically to combat noise, their effectiveness diminishes in environments with high-frequency noise components or when operating near their threshold limits. Engineers must constantly balance noise immunity against switching speed requirements.

The increasing demand for miniaturization creates layout and area constraints that complicate Schmitt trigger implementation. As circuit dimensions shrink, maintaining consistent performance becomes more difficult due to increased susceptibility to manufacturing variations and parasitic effects. This challenge is particularly evident in nanometer-scale processes where device matching is increasingly problematic.

Process variation across semiconductor manufacturing batches introduces significant threshold voltage inconsistencies. These variations can cause substantial differences in hysteresis width between supposedly identical circuits, creating reliability issues in volume production. Compensation techniques often increase complexity and cost.

Integration challenges arise when incorporating Schmitt triggers into complex mixed-signal systems. Interference from adjacent digital circuits can compromise the analog performance of Schmitt triggers, while the triggers themselves may introduce noise into sensitive analog sections. Careful isolation techniques are required but add design complexity.

Speed limitations present obstacles in high-frequency applications. The inherent feedback mechanism that creates hysteresis introduces propagation delays that can be problematic in timing-critical circuits. Designers must carefully balance noise immunity against switching speed requirements, often resulting in application-specific compromises.

Finally, simulation accuracy remains challenging. Accurately modeling Schmitt trigger behavior across all operating conditions requires sophisticated simulation models that account for temperature effects, process variations, and dynamic behavior. The gap between simulation and real-world performance often necessitates multiple design iterations and extensive testing.

Contemporary Design Solutions and Implementations

01 Noise immunity and hysteresis optimization

Schmitt trigger circuits can be designed with optimized hysteresis characteristics to improve reliability in noisy environments. By carefully selecting threshold voltages and implementing proper feedback mechanisms, these circuits can effectively filter out unwanted noise signals and prevent false triggering. This approach enhances the circuit's stability and ensures consistent operation even when input signals contain significant noise components.- Noise immunity and hysteresis optimization: Schmitt trigger circuits can be designed with optimized hysteresis characteristics to improve reliability in noisy environments. By carefully selecting threshold voltages and implementing proper feedback mechanisms, these circuits can effectively filter out unwanted noise signals and prevent false triggering. Enhanced noise immunity ensures stable operation in industrial and automotive applications where electrical noise is prevalent, making the circuit more reliable under varying operating conditions.

- Temperature compensation techniques: Temperature variations can significantly affect Schmitt trigger reliability. Implementing temperature compensation techniques such as bandgap reference circuits, differential designs, and thermally balanced layouts helps maintain consistent threshold voltages across wide temperature ranges. These approaches minimize drift in switching points and ensure predictable operation in extreme environments, enhancing overall circuit reliability in applications requiring stable performance under varying thermal conditions.

- Power supply variation tolerance: Reliable Schmitt trigger circuits incorporate design elements that maintain consistent operation despite power supply fluctuations. Techniques include internal voltage regulation, reference-based designs, and proportional threshold scaling. These approaches ensure that switching thresholds maintain appropriate relationships to input signals even when supply voltage varies, preventing erratic behavior and improving circuit reliability in systems with unstable power sources or battery-powered applications.

- Enhanced output stability and drive capability: Improving the output stage of Schmitt trigger circuits enhances overall reliability. Implementing push-pull output configurations, buffer stages, and controlled slew rates reduces susceptibility to load variations and transmission line effects. These enhancements ensure clean transitions, minimize ringing, and provide sufficient drive capability for downstream circuits, resulting in more reliable system operation especially in applications requiring long signal traces or driving multiple loads.

- Process variation compensation: Manufacturing process variations can impact Schmitt trigger reliability. Advanced designs incorporate self-calibration circuits, trimming capabilities, and adaptive threshold adjustment to compensate for these variations. Some implementations use digital calibration or analog feedback mechanisms to maintain consistent performance across different manufacturing batches. These techniques ensure predictable operation despite semiconductor process variations, improving yield and long-term reliability in high-volume applications.

02 Temperature compensation techniques

Temperature variations can significantly affect Schmitt trigger reliability. Implementing temperature compensation techniques, such as using complementary semiconductor materials with opposing temperature coefficients or adding dedicated compensation circuits, helps maintain consistent threshold voltages across a wide temperature range. These methods ensure stable operation in varying environmental conditions and improve overall circuit reliability.Expand Specific Solutions03 Power supply variation tolerance

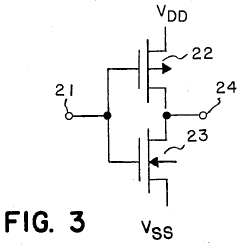

Enhancing Schmitt trigger circuits to maintain reliable operation despite power supply fluctuations involves implementing voltage reference circuits, regulated bias networks, or proportional threshold designs. These approaches ensure that the trigger points maintain their relative positions regardless of supply voltage changes, preventing erratic behavior and improving circuit reliability in applications where power supply stability cannot be guaranteed.Expand Specific Solutions04 Advanced semiconductor implementation

Modern semiconductor technologies offer improved reliability for Schmitt trigger circuits through enhanced manufacturing processes and materials. Utilizing CMOS, BiCMOS, or other advanced semiconductor technologies provides better matching characteristics, reduced leakage currents, and improved resistance to aging effects. These implementations result in more consistent performance over the device lifetime and better reliability in critical applications.Expand Specific Solutions05 Feedback and stabilization mechanisms

Implementing specialized feedback networks and stabilization mechanisms in Schmitt trigger designs can significantly improve circuit reliability. These include capacitive feedback for improved transient response, resistive networks for precise threshold control, and additional stabilization components to prevent oscillations. Such enhancements ensure consistent triggering behavior and improve immunity to component variations and aging effects.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The Schmitt trigger circuit market is currently in a growth phase, driven by increasing demand for reliable signal conditioning in various electronic applications. The market size is estimated to be expanding at a CAGR of 5-7%, with major semiconductor manufacturers actively developing enhanced solutions. Technologically, the field has reached moderate maturity but continues to evolve with innovations in power efficiency and noise immunity. Key players include established semiconductor giants like Texas Instruments, STMicroelectronics, and NXP Semiconductors, who lead with comprehensive product portfolios. Taiwan Semiconductor Manufacturing Co. provides foundry services for many specialized designs, while companies like SG Micro Corp. and MXTronics focus on application-specific implementations. Research institutions such as Shenzhen University and Case Western Reserve University contribute to advancing theoretical frameworks and novel applications.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has developed specialized process technologies optimized for high-performance analog circuits including Schmitt triggers. Their advanced 28nm analog/mixed-signal process features precision-matched transistors with minimal threshold voltage variation (σVth < 2mV), enabling the fabrication of Schmitt trigger circuits with tightly controlled hysteresis windows. TSMC's platform incorporates specialized metal-insulator-metal (MIM) capacitors and high-precision resistors that allow for stable reference voltage generation critical to reliable Schmitt trigger operation. Their process technology enables integration of Schmitt triggers with complex digital logic while maintaining isolation between noisy digital sections and sensitive analog components. TSMC's manufacturing capabilities support implementation of radiation-hardened Schmitt trigger variants using their specialized RHBD (Radiation Hardened By Design) process technology, making these circuits suitable for aerospace and military applications where reliability under radiation exposure is critical.

Strengths: Industry-leading manufacturing precision enabling tight threshold tolerances; excellent scalability from discrete components to highly integrated SoCs; superior process control resulting in minimal device-to-device variation. Weaknesses: As a foundry, TSMC provides manufacturing technology rather than complete circuit solutions; requires customers to develop their own circuit designs; higher cost for specialized process nodes.

STMicroelectronics International NV

Technical Solution: STMicroelectronics has pioneered robust Schmitt trigger designs featuring advanced CMOS technology with rail-to-rail input capability for maximum operational range. Their approach incorporates precision-matched transistor pairs fabricated using their proprietary BCD (Bipolar-CMOS-DMOS) process technology, enabling exceptional threshold accuracy and temperature stability. ST's implementation includes specialized input protection structures that guard against electrostatic discharge and voltage transients up to ±8kV, making them suitable for harsh industrial environments. Their designs feature optimized propagation delay characteristics (typically <15ns) while maintaining well-controlled hysteresis windows that can be externally adjusted through simple resistor networks. ST has also developed ultra-low-power variants operating down to 1.8V with current consumption below 10μA, specifically targeting battery-powered and energy-harvesting applications.

Strengths: Excellent manufacturing consistency across production batches; superior ESD protection; wide operating voltage range from 1.8V to 5.5V. Weaknesses: Slightly higher cost than basic implementations; requires careful PCB layout to maintain noise immunity; some variants have limited high-frequency performance.

Key Patents and Technical Innovations

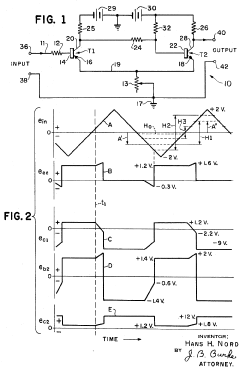

Schmitt trigger circuit with variable hysteresis and insensitivity to temperature change

PatentInactiveUS3581120A

Innovation

- A transistorized Schmitt trigger circuit with complementary junction transistors and adjustable resistive means between the direct conductive path and ground, allowing for variable hysteresis voltage adjustment without offsetting it from ground, minimizing quiescent current, and using less expensive components, which are mostly in cutoff condition, thereby reducing power consumption and temperature sensitivity.

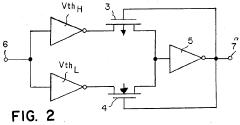

Schmitt trigger circuit with stable operation

PatentInactiveUS4603264A

Innovation

- A Schmitt trigger circuit design utilizing CMOS type inverters with high and low threshold voltage inverters, where switches control the turn-on and turn-off levels independently of output impedances, allowing for adjustment through threshold voltage manipulation, such as changing channel lengths or gate insulator thickness.

Noise Immunity and Performance Optimization Strategies

Noise immunity represents a critical factor in Schmitt trigger circuit design, directly impacting reliability in real-world applications. Enhanced noise immunity can be achieved through strategic hysteresis width adjustment—increasing the gap between threshold voltages creates greater noise tolerance but may compromise switching speed. This trade-off necessitates application-specific optimization, with high-noise environments requiring wider hysteresis and speed-critical applications demanding narrower margins.

Power supply rejection ratio (PSRR) optimization serves as another essential strategy, particularly in battery-powered or automotive applications where voltage fluctuations are common. Implementing voltage reference circuits independent of supply variations and incorporating decoupling capacitors at strategic nodes significantly improves PSRR performance. Advanced designs may utilize differential architectures to further enhance common-mode noise rejection.

Temperature compensation techniques address the challenge of threshold voltage drift across operating temperature ranges. Bandgap reference integration provides stable voltage references regardless of temperature variations, while complementary temperature coefficient components can effectively cancel thermal drift effects. For precision applications, digital calibration mechanisms may be implemented to dynamically adjust threshold voltages based on temperature feedback.

Frequency response optimization ensures reliable operation across the intended bandwidth. Careful consideration of parasitic capacitances and strategic placement of speed-up capacitors can enhance high-frequency performance. In applications requiring consistent performance across wide frequency ranges, pole-zero compensation techniques prove valuable for maintaining stable hysteresis characteristics.

Layout considerations significantly impact noise immunity and overall performance. Guard rings around sensitive analog components isolate them from digital noise sources, while symmetrical differential layouts minimize mismatch-induced errors. Star-ground configurations reduce ground bounce effects, and strategic metal routing minimizes parasitic inductances that could compromise high-frequency performance.

Advanced simulation techniques, including Monte Carlo analysis and corner simulations, enable comprehensive performance verification across process, voltage, and temperature variations. These methodologies identify potential reliability issues before physical implementation, allowing designers to implement appropriate countermeasures. Post-silicon validation through statistical characterization further ensures that manufactured circuits meet noise immunity specifications across all operating conditions.

Power supply rejection ratio (PSRR) optimization serves as another essential strategy, particularly in battery-powered or automotive applications where voltage fluctuations are common. Implementing voltage reference circuits independent of supply variations and incorporating decoupling capacitors at strategic nodes significantly improves PSRR performance. Advanced designs may utilize differential architectures to further enhance common-mode noise rejection.

Temperature compensation techniques address the challenge of threshold voltage drift across operating temperature ranges. Bandgap reference integration provides stable voltage references regardless of temperature variations, while complementary temperature coefficient components can effectively cancel thermal drift effects. For precision applications, digital calibration mechanisms may be implemented to dynamically adjust threshold voltages based on temperature feedback.

Frequency response optimization ensures reliable operation across the intended bandwidth. Careful consideration of parasitic capacitances and strategic placement of speed-up capacitors can enhance high-frequency performance. In applications requiring consistent performance across wide frequency ranges, pole-zero compensation techniques prove valuable for maintaining stable hysteresis characteristics.

Layout considerations significantly impact noise immunity and overall performance. Guard rings around sensitive analog components isolate them from digital noise sources, while symmetrical differential layouts minimize mismatch-induced errors. Star-ground configurations reduce ground bounce effects, and strategic metal routing minimizes parasitic inductances that could compromise high-frequency performance.

Advanced simulation techniques, including Monte Carlo analysis and corner simulations, enable comprehensive performance verification across process, voltage, and temperature variations. These methodologies identify potential reliability issues before physical implementation, allowing designers to implement appropriate countermeasures. Post-silicon validation through statistical characterization further ensures that manufactured circuits meet noise immunity specifications across all operating conditions.

Integration Considerations in Modern Electronic Systems

The integration of Schmitt trigger circuits into modern electronic systems presents unique challenges and opportunities that demand careful consideration. As system complexity increases and form factors shrink, designers must address multiple integration factors to ensure reliable operation. Power supply considerations become paramount, as Schmitt triggers must maintain consistent hysteresis characteristics across varying supply voltages. In low-power applications, designers must carefully evaluate the trade-off between noise immunity and power consumption, potentially implementing adaptive hysteresis techniques that adjust thresholds based on system power states.

Signal integrity across system boundaries requires particular attention when integrating Schmitt triggers. The interconnection between different voltage domains necessitates level-shifting techniques and appropriate interface design to preserve the noise immunity benefits of the Schmitt trigger. Additionally, designers must account for transmission line effects in high-speed applications, where signal reflections can potentially cause false triggering or compromise the intended hysteresis window.

Thermal management represents another critical integration consideration. The temperature coefficient of the threshold voltages in Schmitt trigger circuits can lead to operational variations across the system's temperature range. Implementing temperature compensation techniques or selecting components with minimal thermal drift becomes essential for maintaining consistent performance in environments with significant temperature fluctuations.

Electromagnetic compatibility (EMC) concerns must be addressed during integration, as Schmitt triggers are often employed at system interfaces where they may be exposed to external electromagnetic interference. Proper PCB layout techniques, including strategic component placement, ground plane design, and signal routing, can significantly enhance immunity to external noise sources while preventing the circuit itself from becoming a source of emissions.

Manufacturing and testability aspects also influence integration decisions. Design for testability features, such as accessible test points or built-in self-test capabilities, ensure that the Schmitt trigger's functionality can be verified after integration. Additionally, sensitivity analysis during the design phase helps identify critical parameters that may be affected by manufacturing variations, allowing for appropriate design margins to maintain reliable operation across production batches.

Finally, integration must consider the system's lifecycle requirements. Reliability factors such as aging effects, which can alter threshold voltages over time, must be evaluated against the expected operational lifetime. For mission-critical applications, redundancy schemes or monitoring circuits may be necessary to detect potential failures in Schmitt trigger functionality before they impact system performance.

Signal integrity across system boundaries requires particular attention when integrating Schmitt triggers. The interconnection between different voltage domains necessitates level-shifting techniques and appropriate interface design to preserve the noise immunity benefits of the Schmitt trigger. Additionally, designers must account for transmission line effects in high-speed applications, where signal reflections can potentially cause false triggering or compromise the intended hysteresis window.

Thermal management represents another critical integration consideration. The temperature coefficient of the threshold voltages in Schmitt trigger circuits can lead to operational variations across the system's temperature range. Implementing temperature compensation techniques or selecting components with minimal thermal drift becomes essential for maintaining consistent performance in environments with significant temperature fluctuations.

Electromagnetic compatibility (EMC) concerns must be addressed during integration, as Schmitt triggers are often employed at system interfaces where they may be exposed to external electromagnetic interference. Proper PCB layout techniques, including strategic component placement, ground plane design, and signal routing, can significantly enhance immunity to external noise sources while preventing the circuit itself from becoming a source of emissions.

Manufacturing and testability aspects also influence integration decisions. Design for testability features, such as accessible test points or built-in self-test capabilities, ensure that the Schmitt trigger's functionality can be verified after integration. Additionally, sensitivity analysis during the design phase helps identify critical parameters that may be affected by manufacturing variations, allowing for appropriate design margins to maintain reliable operation across production batches.

Finally, integration must consider the system's lifecycle requirements. Reliability factors such as aging effects, which can alter threshold voltages over time, must be evaluated against the expected operational lifetime. For mission-critical applications, redundancy schemes or monitoring circuits may be necessary to detect potential failures in Schmitt trigger functionality before they impact system performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!