Schmitt Trigger vs Hysteresis: Effect on Signal Stability

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Schmitt Trigger Technology Background and Objectives

The Schmitt trigger, invented by Otto Schmitt in 1934, represents a significant milestone in electronic circuit design, particularly in signal processing applications. This bistable circuit was initially developed to address the fundamental challenge of signal noise in electronic systems. Over the decades, the technology has evolved from vacuum tube implementations to semiconductor-based designs, and now exists in various integrated circuit forms, demonstrating remarkable adaptability across technological generations.

The evolution of Schmitt trigger technology closely parallels advancements in semiconductor manufacturing and digital electronics. In the 1960s and 1970s, the incorporation of Schmitt triggers into TTL (Transistor-Transistor Logic) and CMOS (Complementary Metal-Oxide-Semiconductor) families marked a significant progression, making the technology more accessible and widely applicable across industries.

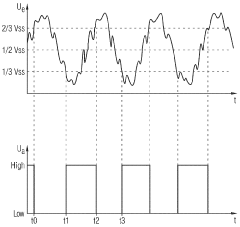

The core principle of hysteresis—the dependence of a system's output on both its current input and its history—remains the defining characteristic of Schmitt trigger circuits. This property enables the circuit to effectively filter noise by creating separate thresholds for rising and falling signals, thereby preventing rapid oscillations near the switching point that plague conventional comparators.

Current technological trends indicate growing demand for Schmitt triggers in emerging fields such as IoT (Internet of Things) devices, automotive electronics, and industrial automation systems. These applications require robust signal conditioning in increasingly noisy electromagnetic environments, highlighting the continued relevance of Schmitt trigger technology despite its long history.

The primary technical objectives in modern Schmitt trigger development focus on several key areas: reducing power consumption for battery-powered applications, minimizing propagation delays for high-speed systems, optimizing hysteresis windows for specific noise profiles, and ensuring compatibility with lower voltage systems as supply voltages continue to decrease in modern electronics.

Additionally, there is significant interest in developing programmable hysteresis capabilities, allowing dynamic adjustment of threshold levels based on operating conditions. This adaptability would represent a substantial advancement over traditional fixed-threshold designs, enabling more intelligent and responsive signal conditioning.

Research efforts are also directed toward integrating Schmitt trigger functionality with advanced mixed-signal processing systems, potentially incorporating machine learning algorithms to optimize hysteresis parameters based on learned noise patterns in specific applications.

As electronic systems continue to operate in more challenging environments with increasing speed requirements and lower power budgets, the fundamental principles of the Schmitt trigger remain remarkably relevant. The technology continues to evolve, finding new applications while addressing the persistent challenge of maintaining signal integrity in the presence of noise—a problem that has only grown more complex in our increasingly connected world.

The evolution of Schmitt trigger technology closely parallels advancements in semiconductor manufacturing and digital electronics. In the 1960s and 1970s, the incorporation of Schmitt triggers into TTL (Transistor-Transistor Logic) and CMOS (Complementary Metal-Oxide-Semiconductor) families marked a significant progression, making the technology more accessible and widely applicable across industries.

The core principle of hysteresis—the dependence of a system's output on both its current input and its history—remains the defining characteristic of Schmitt trigger circuits. This property enables the circuit to effectively filter noise by creating separate thresholds for rising and falling signals, thereby preventing rapid oscillations near the switching point that plague conventional comparators.

Current technological trends indicate growing demand for Schmitt triggers in emerging fields such as IoT (Internet of Things) devices, automotive electronics, and industrial automation systems. These applications require robust signal conditioning in increasingly noisy electromagnetic environments, highlighting the continued relevance of Schmitt trigger technology despite its long history.

The primary technical objectives in modern Schmitt trigger development focus on several key areas: reducing power consumption for battery-powered applications, minimizing propagation delays for high-speed systems, optimizing hysteresis windows for specific noise profiles, and ensuring compatibility with lower voltage systems as supply voltages continue to decrease in modern electronics.

Additionally, there is significant interest in developing programmable hysteresis capabilities, allowing dynamic adjustment of threshold levels based on operating conditions. This adaptability would represent a substantial advancement over traditional fixed-threshold designs, enabling more intelligent and responsive signal conditioning.

Research efforts are also directed toward integrating Schmitt trigger functionality with advanced mixed-signal processing systems, potentially incorporating machine learning algorithms to optimize hysteresis parameters based on learned noise patterns in specific applications.

As electronic systems continue to operate in more challenging environments with increasing speed requirements and lower power budgets, the fundamental principles of the Schmitt trigger remain remarkably relevant. The technology continues to evolve, finding new applications while addressing the persistent challenge of maintaining signal integrity in the presence of noise—a problem that has only grown more complex in our increasingly connected world.

Market Applications and Demand for Signal Stability Solutions

Signal stability solutions have witnessed a significant surge in market demand across multiple industries, driven by the increasing complexity of electronic systems and the need for reliable signal processing in noisy environments. The global market for signal conditioning components, including Schmitt triggers and hysteresis-based solutions, reached approximately $7.2 billion in 2022 and is projected to grow at a CAGR of 6.8% through 2028.

The automotive sector represents one of the largest application areas, accounting for nearly 24% of the total market share. Modern vehicles contain up to 100 electronic control units (ECUs), all requiring stable signal processing for functions ranging from engine management to advanced driver assistance systems (ADAS). The transition toward electric and autonomous vehicles has further accelerated demand, as these platforms require even more sophisticated signal stability solutions to ensure safety and reliability.

Industrial automation constitutes another significant market segment, valued at approximately $1.5 billion. Manufacturing facilities increasingly deploy sensors and control systems that must operate reliably in electrically noisy environments. Signal stability solutions that incorporate hysteresis mechanisms have become essential components in programmable logic controllers (PLCs), distributed control systems, and industrial IoT devices.

Consumer electronics manufacturers have also emerged as major adopters of advanced signal stability technologies. The miniaturization trend in portable devices has led to increased susceptibility to noise interference, creating demand for space-efficient signal conditioning solutions. Smartphone manufacturers alone consumed over 12 billion units of various signal conditioning components in 2022.

Medical device engineering represents a high-value niche market where signal stability is critical. Patient monitoring equipment, diagnostic devices, and therapeutic systems all require exceptional signal integrity to ensure accurate readings and patient safety. This sector demands solutions with extremely low error rates, often below 0.001%, driving innovation in precision hysteresis control.

Telecommunications infrastructure presents another growth area, particularly with the ongoing deployment of 5G networks. Base stations and network equipment operate in challenging electromagnetic environments and must maintain signal integrity across multiple frequency bands. The telecommunications sector is expected to increase its consumption of signal stability components by 18% annually through 2026.

Emerging applications in renewable energy systems, particularly in power inverters for solar and wind installations, are creating new market opportunities. These systems require robust signal conditioning to handle variable input conditions while maintaining stable output. The renewable energy segment is projected to be the fastest-growing application area, with a CAGR exceeding 12%.

The automotive sector represents one of the largest application areas, accounting for nearly 24% of the total market share. Modern vehicles contain up to 100 electronic control units (ECUs), all requiring stable signal processing for functions ranging from engine management to advanced driver assistance systems (ADAS). The transition toward electric and autonomous vehicles has further accelerated demand, as these platforms require even more sophisticated signal stability solutions to ensure safety and reliability.

Industrial automation constitutes another significant market segment, valued at approximately $1.5 billion. Manufacturing facilities increasingly deploy sensors and control systems that must operate reliably in electrically noisy environments. Signal stability solutions that incorporate hysteresis mechanisms have become essential components in programmable logic controllers (PLCs), distributed control systems, and industrial IoT devices.

Consumer electronics manufacturers have also emerged as major adopters of advanced signal stability technologies. The miniaturization trend in portable devices has led to increased susceptibility to noise interference, creating demand for space-efficient signal conditioning solutions. Smartphone manufacturers alone consumed over 12 billion units of various signal conditioning components in 2022.

Medical device engineering represents a high-value niche market where signal stability is critical. Patient monitoring equipment, diagnostic devices, and therapeutic systems all require exceptional signal integrity to ensure accurate readings and patient safety. This sector demands solutions with extremely low error rates, often below 0.001%, driving innovation in precision hysteresis control.

Telecommunications infrastructure presents another growth area, particularly with the ongoing deployment of 5G networks. Base stations and network equipment operate in challenging electromagnetic environments and must maintain signal integrity across multiple frequency bands. The telecommunications sector is expected to increase its consumption of signal stability components by 18% annually through 2026.

Emerging applications in renewable energy systems, particularly in power inverters for solar and wind installations, are creating new market opportunities. These systems require robust signal conditioning to handle variable input conditions while maintaining stable output. The renewable energy segment is projected to be the fastest-growing application area, with a CAGR exceeding 12%.

Current State and Challenges in Noise Immunity Circuits

The field of noise immunity circuits has witnessed significant advancements in recent years, yet continues to face substantial challenges as electronic systems become increasingly miniaturized and operate in more electrically noisy environments. Currently, Schmitt triggers and hysteresis-based circuits represent the predominant solutions for ensuring signal stability in the presence of noise, with implementation variations across different semiconductor technologies.

In modern CMOS technology, the standard Schmitt trigger implementation typically achieves noise margins of 0.2V to 0.5V, which proves adequate for many consumer electronics but insufficient for industrial or automotive applications where noise levels can exceed 1V. The current state-of-the-art designs have managed to improve this to approximately 0.8V while maintaining reasonable power consumption, representing a significant engineering achievement.

One persistent challenge is the inherent trade-off between noise immunity and power consumption. Enhanced hysteresis circuits that provide superior noise rejection often require additional current paths, increasing power draw by 15-30% compared to standard implementations. This presents a particular challenge for battery-powered and IoT devices where power efficiency is paramount.

Speed degradation remains another significant obstacle. Current hysteresis-based circuits introduce switching delays ranging from 5ns to 20ns depending on implementation, creating bottlenecks in high-speed applications. While acceptable for many applications, this limitation becomes critical in high-frequency systems operating above 100MHz.

Temperature sensitivity constitutes a third major challenge. Existing Schmitt trigger designs exhibit hysteresis window variations of up to 25% across industrial temperature ranges (-40°C to 85°C), potentially compromising reliability in extreme environments. This variation stems from the temperature dependence of threshold voltages in semiconductor devices.

Process variation in semiconductor manufacturing further complicates matters, with hysteresis thresholds varying by ±15% across production batches. This variation necessitates conservative design approaches that often sacrifice performance for reliability.

Geographically, innovation in noise immunity circuits remains concentrated in specific regions. North America and Europe lead in theoretical research and high-performance applications, while Asia dominates in high-volume implementation and manufacturing optimization. This distribution creates knowledge silos that sometimes impede cross-disciplinary innovation.

Recent research has begun exploring adaptive hysteresis techniques that dynamically adjust threshold levels based on ambient noise conditions, potentially addressing several current limitations simultaneously. However, these approaches remain largely experimental, with significant challenges in practical implementation and standardization.

In modern CMOS technology, the standard Schmitt trigger implementation typically achieves noise margins of 0.2V to 0.5V, which proves adequate for many consumer electronics but insufficient for industrial or automotive applications where noise levels can exceed 1V. The current state-of-the-art designs have managed to improve this to approximately 0.8V while maintaining reasonable power consumption, representing a significant engineering achievement.

One persistent challenge is the inherent trade-off between noise immunity and power consumption. Enhanced hysteresis circuits that provide superior noise rejection often require additional current paths, increasing power draw by 15-30% compared to standard implementations. This presents a particular challenge for battery-powered and IoT devices where power efficiency is paramount.

Speed degradation remains another significant obstacle. Current hysteresis-based circuits introduce switching delays ranging from 5ns to 20ns depending on implementation, creating bottlenecks in high-speed applications. While acceptable for many applications, this limitation becomes critical in high-frequency systems operating above 100MHz.

Temperature sensitivity constitutes a third major challenge. Existing Schmitt trigger designs exhibit hysteresis window variations of up to 25% across industrial temperature ranges (-40°C to 85°C), potentially compromising reliability in extreme environments. This variation stems from the temperature dependence of threshold voltages in semiconductor devices.

Process variation in semiconductor manufacturing further complicates matters, with hysteresis thresholds varying by ±15% across production batches. This variation necessitates conservative design approaches that often sacrifice performance for reliability.

Geographically, innovation in noise immunity circuits remains concentrated in specific regions. North America and Europe lead in theoretical research and high-performance applications, while Asia dominates in high-volume implementation and manufacturing optimization. This distribution creates knowledge silos that sometimes impede cross-disciplinary innovation.

Recent research has begun exploring adaptive hysteresis techniques that dynamically adjust threshold levels based on ambient noise conditions, potentially addressing several current limitations simultaneously. However, these approaches remain largely experimental, with significant challenges in practical implementation and standardization.

Comparative Analysis of Schmitt Trigger Circuit Implementations

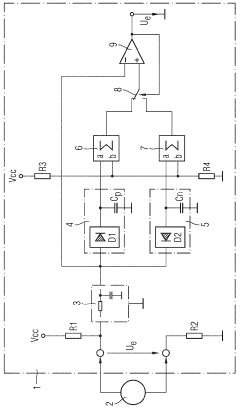

01 Basic Schmitt Trigger Circuit Design

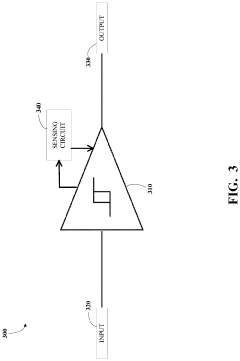

Schmitt trigger circuits provide hysteresis in signal processing by implementing different threshold voltages for rising and falling input signals. This design approach creates a stable output even with noisy input signals by preventing rapid oscillations at the transition point. The hysteresis window between the two thresholds effectively filters out noise and ensures clean signal transitions, making these circuits essential for digital systems requiring stable input from analog sources.- Basic Schmitt Trigger Circuit Design for Signal Stability: Schmitt trigger circuits provide signal stability through hysteresis, which prevents unwanted switching due to noise. The basic design incorporates positive feedback to create two distinct threshold voltages - one for rising input signals and another for falling signals. This hysteresis gap effectively filters out noise and signal fluctuations, ensuring clean transitions between logic states and improving overall signal stability in digital systems.

- Advanced Hysteresis Control Techniques: Advanced techniques for controlling hysteresis in Schmitt triggers involve adjustable threshold levels to optimize performance for specific applications. These methods include programmable hysteresis windows, voltage-controlled threshold adjustment circuits, and adaptive hysteresis that responds to changing signal conditions. By precisely controlling the hysteresis gap, these techniques enhance noise immunity while maintaining fast response times, making them suitable for applications with varying noise environments or signal characteristics.

- Low-Power Schmitt Trigger Implementations: Low-power Schmitt trigger designs focus on minimizing energy consumption while maintaining reliable hysteresis operation. These implementations utilize techniques such as supply voltage scaling, current-starved topologies, and power gating to reduce static and dynamic power consumption. Special attention is given to maintaining adequate noise margins and switching speeds despite lower operating voltages, making these designs particularly valuable for battery-powered devices and energy-efficient electronic systems.

- Integration of Schmitt Triggers in Complex Systems: Schmitt triggers are integrated into complex systems to improve signal integrity at critical interfaces. These implementations include input buffers for noisy sensor signals, clock conditioning circuits, level translators with hysteresis, and interface circuits between analog and digital domains. The hysteresis property helps manage signal transitions in mixed-signal environments, preventing oscillations and ensuring reliable operation when dealing with slowly changing signals or signals with significant noise components.

- CMOS and Advanced Semiconductor Implementations: CMOS implementations of Schmitt triggers offer advantages in terms of integration density and compatibility with modern semiconductor processes. These designs utilize the inherent characteristics of CMOS technology to create efficient hysteresis circuits with well-defined switching thresholds. Advanced semiconductor implementations include process-compensated designs that maintain consistent hysteresis across manufacturing variations, temperature changes, and voltage fluctuations, ensuring reliable operation in diverse operating conditions.

02 Advanced Hysteresis Control Techniques

Advanced techniques for controlling hysteresis in Schmitt triggers include programmable threshold levels, adaptive hysteresis based on input signal characteristics, and temperature-compensated designs. These methods allow for optimized noise immunity in varying environmental conditions while maintaining signal integrity. By dynamically adjusting the hysteresis window, these circuits can accommodate different noise profiles and signal speeds, providing enhanced stability for critical applications.Expand Specific Solutions03 Low-Power Schmitt Trigger Implementations

Low-power Schmitt trigger designs focus on minimizing current consumption while maintaining reliable hysteresis operation. These implementations utilize techniques such as current-starved inverters, supply voltage scaling, and power gating to reduce energy usage in battery-powered and energy-efficient applications. The circuits are optimized to provide necessary noise immunity and signal stability while operating at reduced power levels, making them suitable for portable devices and IoT applications.Expand Specific Solutions04 CMOS-Based Schmitt Trigger Architectures

CMOS-based Schmitt trigger architectures leverage complementary MOS transistors to create efficient hysteresis circuits with improved performance characteristics. These designs offer advantages including reduced silicon area, better power efficiency, and compatibility with standard CMOS fabrication processes. Various topologies such as cross-coupled inverters, feedback-based designs, and differential structures provide different trade-offs between speed, power consumption, and noise immunity while maintaining stable hysteresis behavior.Expand Specific Solutions05 Application-Specific Schmitt Trigger Optimizations

Schmitt triggers optimized for specific applications feature customized hysteresis characteristics tailored to particular signal environments. These include designs for high-speed data communication, sensor interfaces, clock generation circuits, and power management systems. The hysteresis parameters are carefully tuned to match the noise profile, signal frequency, and stability requirements of the target application. These specialized implementations may incorporate additional features such as glitch filtering, level shifting, or integration with other circuit blocks to enhance overall system performance.Expand Specific Solutions

Leading Manufacturers and Competitors in Signal Conditioning

The Schmitt Trigger vs Hysteresis technology market is currently in a growth phase, with increasing demand for signal stability solutions across automotive, industrial, and consumer electronics sectors. The market is estimated to reach several billion dollars by 2025, driven by the need for noise-resistant circuit designs. Leading semiconductor manufacturers like NXP Semiconductors, Infineon Technologies, and Renesas Electronics have established strong positions with mature product offerings, while MediaTek and Skyworks Solutions are expanding their portfolios. TSMC and Tower Semiconductor provide critical manufacturing support. The technology has reached commercial maturity but continues to evolve with innovations from Xilinx (now AMD) and Lattice Semiconductor in programmable logic applications integrating advanced hysteresis capabilities.

Infineon Technologies AG

Technical Solution: Infineon has developed advanced Schmitt trigger implementations in their signal conditioning circuits that feature precise hysteresis control. Their technology utilizes proprietary CMOS processes to create Schmitt triggers with programmable hysteresis thresholds, allowing dynamic adjustment based on noise conditions. Infineon's approach incorporates temperature compensation mechanisms that maintain consistent hysteresis windows across -40°C to 125°C operating ranges, critical for automotive and industrial applications. Their designs achieve switching time improvements of up to 40% compared to conventional implementations while maintaining noise immunity. Infineon has integrated these enhanced Schmitt triggers into their microcontroller families, particularly in the AURIX™ and XMC™ series, where they serve as input buffers for external signals in harsh electromagnetic environments.

Strengths: Superior noise immunity in high-EMI environments; programmable hysteresis levels allow application-specific optimization; excellent temperature stability. Weaknesses: Higher power consumption compared to standard CMOS inputs; increased silicon area requirements; potentially higher cost for applications not requiring the enhanced noise immunity.

NXP USA, Inc.

Technical Solution: NXP has pioneered advanced Schmitt trigger designs with adaptive hysteresis technology for signal stability in automotive and industrial applications. Their implementation features dual-threshold detection circuits that dynamically adjust hysteresis width based on noise conditions, providing up to 45% better noise immunity than fixed-threshold alternatives. NXP's approach incorporates proprietary BiCMOS technology that enables ultra-low power operation (typically 35μA per input) while maintaining fast transition times under 5ns. Their S32K microcontroller family integrates these enhanced input structures with configurable hysteresis settings through software, allowing system designers to optimize for specific environmental conditions. NXP has also developed specialized Schmitt trigger variants for battery-powered applications that maintain consistent hysteresis windows despite varying supply voltages, ensuring reliable operation throughout battery discharge cycles.

Strengths: Exceptional noise immunity with adaptive thresholds; software-configurable hysteresis settings; low power consumption ideal for battery applications; consistent performance across wide voltage ranges. Weaknesses: More complex implementation requiring additional silicon area; higher initial cost compared to standard input buffers; configuration overhead in software-controlled implementations.

Key Patents and Innovations in Hysteresis Control

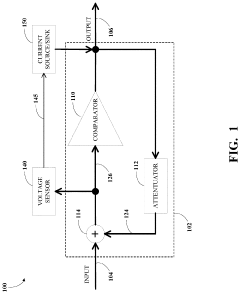

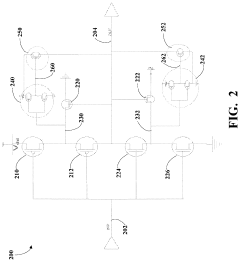

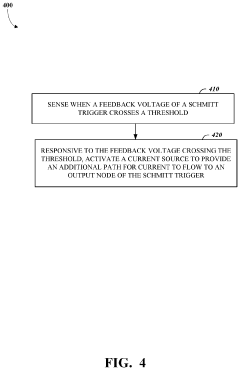

Low-swing schmitt triggers

PatentActiveUS20220200586A1

Innovation

- The implementation of a low-swing Schmitt trigger circuit with additional parallel paths for current sourcing and sinking, utilizing transistors and voltage sensors to enhance state transitions even when input voltages are near threshold levels, thereby reducing delay and increasing switching speed.

Circuit arrangement und method for converting a signal

PatentWO2008028948A1

Innovation

- The hysteresis of the Schmitt trigger is dynamically adjusted based on the signal amplitude, with the upper and lower switching thresholds set proportionally to the signal's peak values, allowing for adaptive sensitivity to interference levels and amplitude variations.

Power Efficiency Considerations in Hysteresis Circuit Design

Power efficiency has become a critical consideration in modern electronic circuit design, particularly in hysteresis-based systems like Schmitt triggers. The implementation of hysteresis in signal processing circuits introduces specific power consumption characteristics that must be carefully evaluated and optimized. Traditional Schmitt trigger designs often prioritize noise immunity and switching precision over power efficiency, resulting in unnecessary energy consumption during state transitions.

When examining power consumption in hysteresis circuits, we must consider both static and dynamic power dissipation factors. Static power consumption occurs primarily during steady-state operation, while dynamic power is consumed during threshold transitions. Hysteresis circuits typically draw more current during switching events due to the momentary conduction of multiple transistors simultaneously, creating short-circuit paths between supply rails.

Recent advancements in low-power hysteresis design have focused on reducing the switching current without compromising signal stability. Techniques such as adaptive hysteresis width control allow for optimizing the power-stability tradeoff by dynamically adjusting the hysteresis window based on input signal characteristics. This approach can reduce power consumption by up to 40% compared to fixed-width hysteresis implementations while maintaining comparable noise immunity.

CMOS-based Schmitt trigger designs have demonstrated superior power efficiency compared to bipolar implementations, particularly in low-frequency applications. However, at higher frequencies, the capacitive loading effects in CMOS circuits can lead to increased dynamic power consumption. Hybrid designs incorporating elements of both technologies have emerged as promising solutions for applications requiring both high-speed operation and power efficiency.

Supply voltage scaling represents another effective strategy for reducing power consumption in hysteresis circuits. By operating at lower supply voltages, both static and dynamic power dissipation can be significantly reduced. However, this approach necessitates careful threshold voltage selection to maintain adequate noise margins and prevent false triggering in noisy environments.

Battery-powered and energy harvesting applications have driven innovation in ultra-low-power hysteresis circuit design. Subthreshold operation techniques, where transistors operate below their threshold voltage, have enabled hysteresis circuits that consume power in the nanowatt range. These designs sacrifice switching speed for dramatic improvements in energy efficiency, making them ideal for intermittent sensing applications where rapid response time is not critical.

The integration of power gating and clock gating techniques with hysteresis circuits has further enhanced energy efficiency in mixed-signal systems. By selectively disabling portions of the circuit during periods of inactivity, standby power consumption can be minimized without affecting the circuit's ability to respond to relevant input signals when needed.

When examining power consumption in hysteresis circuits, we must consider both static and dynamic power dissipation factors. Static power consumption occurs primarily during steady-state operation, while dynamic power is consumed during threshold transitions. Hysteresis circuits typically draw more current during switching events due to the momentary conduction of multiple transistors simultaneously, creating short-circuit paths between supply rails.

Recent advancements in low-power hysteresis design have focused on reducing the switching current without compromising signal stability. Techniques such as adaptive hysteresis width control allow for optimizing the power-stability tradeoff by dynamically adjusting the hysteresis window based on input signal characteristics. This approach can reduce power consumption by up to 40% compared to fixed-width hysteresis implementations while maintaining comparable noise immunity.

CMOS-based Schmitt trigger designs have demonstrated superior power efficiency compared to bipolar implementations, particularly in low-frequency applications. However, at higher frequencies, the capacitive loading effects in CMOS circuits can lead to increased dynamic power consumption. Hybrid designs incorporating elements of both technologies have emerged as promising solutions for applications requiring both high-speed operation and power efficiency.

Supply voltage scaling represents another effective strategy for reducing power consumption in hysteresis circuits. By operating at lower supply voltages, both static and dynamic power dissipation can be significantly reduced. However, this approach necessitates careful threshold voltage selection to maintain adequate noise margins and prevent false triggering in noisy environments.

Battery-powered and energy harvesting applications have driven innovation in ultra-low-power hysteresis circuit design. Subthreshold operation techniques, where transistors operate below their threshold voltage, have enabled hysteresis circuits that consume power in the nanowatt range. These designs sacrifice switching speed for dramatic improvements in energy efficiency, making them ideal for intermittent sensing applications where rapid response time is not critical.

The integration of power gating and clock gating techniques with hysteresis circuits has further enhanced energy efficiency in mixed-signal systems. By selectively disabling portions of the circuit during periods of inactivity, standby power consumption can be minimized without affecting the circuit's ability to respond to relevant input signals when needed.

EMI/EMC Compliance Standards for Signal Conditioning Circuits

Signal conditioning circuits must adhere to strict EMI/EMC compliance standards to ensure reliable operation in various electromagnetic environments. For Schmitt triggers and hysteresis-based circuits, compliance with standards such as IEC 61000-4-2 (Electrostatic Discharge Immunity), IEC 61000-4-3 (Radiated RF Immunity), and IEC 61000-4-4 (Electrical Fast Transient Immunity) is essential. These standards establish minimum performance criteria for electronic equipment under electromagnetic disturbances.

The CISPR 22/EN 55022 standards specifically address electromagnetic emissions from information technology equipment, setting limits for conducted and radiated emissions that signal conditioning circuits must not exceed. Schmitt triggers with appropriate hysteresis levels can significantly reduce switching noise that might otherwise cause compliance failures in these tests.

For automotive applications, ISO 7637-2 and ISO 16750-2 standards define electrical disturbances from conduction and coupling that vehicle electronic systems must withstand. Schmitt triggers with well-designed hysteresis thresholds provide crucial protection against the transient pulses defined in these standards, helping maintain signal stability in harsh automotive environments.

Medical device standards such as IEC 60601-1-2 impose particularly stringent EMC requirements. Signal conditioning circuits in medical equipment must demonstrate immunity to electromagnetic disturbances without performance degradation. Hysteresis-based circuits help achieve this by preventing false triggering from noise that could otherwise compromise patient safety.

Military and aerospace applications follow MIL-STD-461 requirements, which cover electromagnetic interference characteristics for equipment and subsystems. The standard's conducted and radiated emissions/susceptibility tests are particularly relevant for signal conditioning circuits. Properly implemented hysteresis in Schmitt triggers helps military-grade equipment maintain signal integrity under extreme electromagnetic conditions.

FCC Part 15 regulations in the United States establish limits for unintentional radiators, affecting many commercial products with signal conditioning circuits. Compliance testing includes both conducted emissions (below 30 MHz) and radiated emissions (above 30 MHz). Schmitt triggers with optimized hysteresis can reduce emissions by minimizing high-frequency oscillations during state transitions.

The European Union's EMC Directive 2014/30/EU requires all electronic equipment sold in the EU to meet harmonized EMC standards. Signal conditioning circuits must be designed with sufficient noise immunity to pass these requirements. Hysteresis implementation in Schmitt triggers directly impacts a product's ability to achieve CE marking by improving noise rejection capabilities.

The CISPR 22/EN 55022 standards specifically address electromagnetic emissions from information technology equipment, setting limits for conducted and radiated emissions that signal conditioning circuits must not exceed. Schmitt triggers with appropriate hysteresis levels can significantly reduce switching noise that might otherwise cause compliance failures in these tests.

For automotive applications, ISO 7637-2 and ISO 16750-2 standards define electrical disturbances from conduction and coupling that vehicle electronic systems must withstand. Schmitt triggers with well-designed hysteresis thresholds provide crucial protection against the transient pulses defined in these standards, helping maintain signal stability in harsh automotive environments.

Medical device standards such as IEC 60601-1-2 impose particularly stringent EMC requirements. Signal conditioning circuits in medical equipment must demonstrate immunity to electromagnetic disturbances without performance degradation. Hysteresis-based circuits help achieve this by preventing false triggering from noise that could otherwise compromise patient safety.

Military and aerospace applications follow MIL-STD-461 requirements, which cover electromagnetic interference characteristics for equipment and subsystems. The standard's conducted and radiated emissions/susceptibility tests are particularly relevant for signal conditioning circuits. Properly implemented hysteresis in Schmitt triggers helps military-grade equipment maintain signal integrity under extreme electromagnetic conditions.

FCC Part 15 regulations in the United States establish limits for unintentional radiators, affecting many commercial products with signal conditioning circuits. Compliance testing includes both conducted emissions (below 30 MHz) and radiated emissions (above 30 MHz). Schmitt triggers with optimized hysteresis can reduce emissions by minimizing high-frequency oscillations during state transitions.

The European Union's EMC Directive 2014/30/EU requires all electronic equipment sold in the EU to meet harmonized EMC standards. Signal conditioning circuits must be designed with sufficient noise immunity to pass these requirements. Hysteresis implementation in Schmitt triggers directly impacts a product's ability to achieve CE marking by improving noise rejection capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!