Optimizing DC Signal Handling Using Schmitt Trigger

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Schmitt Trigger DC Signal Optimization Background and Objectives

The Schmitt trigger, first introduced by Otto Schmitt in 1934, represents a significant milestone in electronic circuit design for signal processing. This hysteresis-based comparator has evolved from vacuum tube implementations to modern integrated circuit designs, demonstrating remarkable versatility across decades of technological advancement. The fundamental principle of providing different switching thresholds for rising and falling signals has remained consistent, while implementation technologies have dramatically transformed.

Recent technological trends show increasing integration of Schmitt triggers in mixed-signal environments, particularly in industrial automation, automotive systems, and IoT devices where reliable DC signal handling is critical. The miniaturization of electronic components and the rise of low-power applications have pushed Schmitt trigger designs toward greater efficiency and reduced footprint, while maintaining robust noise immunity characteristics.

The primary objective of optimizing DC signal handling using Schmitt triggers is to enhance signal integrity in environments with significant noise, slow signal transitions, or multiple crossing points. This optimization aims to eliminate false triggering events that plague conventional comparators when processing real-world analog signals with superimposed noise components or slow transition rates.

Secondary objectives include reducing power consumption in battery-operated devices, minimizing propagation delays for time-critical applications, and ensuring consistent performance across varying temperature and voltage conditions. These goals align with broader industry trends toward more efficient, reliable electronic systems capable of operating in increasingly demanding environments.

The technical evolution path suggests that future Schmitt trigger implementations will likely focus on programmable hysteresis thresholds, allowing dynamic adaptation to changing signal conditions. This adaptability represents a significant advancement over traditional fixed-threshold designs, potentially opening new application domains where signal characteristics vary widely during operation.

From a historical perspective, the progression from discrete component implementations to integrated solutions has dramatically reduced cost and improved performance. Current research indicates potential for further improvements through novel semiconductor materials and advanced circuit topologies that could enhance temperature stability and reduce power requirements by orders of magnitude.

The intersection of Schmitt trigger technology with emerging fields such as edge computing and autonomous systems presents new challenges and opportunities, driving innovation toward more sophisticated implementations that maintain the fundamental advantages of hysteresis-based signal conditioning while addressing increasingly complex signal processing requirements.

Recent technological trends show increasing integration of Schmitt triggers in mixed-signal environments, particularly in industrial automation, automotive systems, and IoT devices where reliable DC signal handling is critical. The miniaturization of electronic components and the rise of low-power applications have pushed Schmitt trigger designs toward greater efficiency and reduced footprint, while maintaining robust noise immunity characteristics.

The primary objective of optimizing DC signal handling using Schmitt triggers is to enhance signal integrity in environments with significant noise, slow signal transitions, or multiple crossing points. This optimization aims to eliminate false triggering events that plague conventional comparators when processing real-world analog signals with superimposed noise components or slow transition rates.

Secondary objectives include reducing power consumption in battery-operated devices, minimizing propagation delays for time-critical applications, and ensuring consistent performance across varying temperature and voltage conditions. These goals align with broader industry trends toward more efficient, reliable electronic systems capable of operating in increasingly demanding environments.

The technical evolution path suggests that future Schmitt trigger implementations will likely focus on programmable hysteresis thresholds, allowing dynamic adaptation to changing signal conditions. This adaptability represents a significant advancement over traditional fixed-threshold designs, potentially opening new application domains where signal characteristics vary widely during operation.

From a historical perspective, the progression from discrete component implementations to integrated solutions has dramatically reduced cost and improved performance. Current research indicates potential for further improvements through novel semiconductor materials and advanced circuit topologies that could enhance temperature stability and reduce power requirements by orders of magnitude.

The intersection of Schmitt trigger technology with emerging fields such as edge computing and autonomous systems presents new challenges and opportunities, driving innovation toward more sophisticated implementations that maintain the fundamental advantages of hysteresis-based signal conditioning while addressing increasingly complex signal processing requirements.

Market Applications and Demand Analysis for Schmitt Trigger Solutions

The Schmitt trigger technology has witnessed significant market expansion across multiple industries due to its unique ability to handle DC signals with hysteresis, providing noise immunity and clean signal conversion. The global market for Schmitt trigger solutions is currently valued at approximately 3.2 billion USD, with a projected annual growth rate of 5.7% through 2028, driven primarily by increasing demand in automotive electronics, industrial automation, and consumer electronics sectors.

In the automotive industry, Schmitt triggers are extensively utilized in engine control units, safety systems, and advanced driver-assistance systems (ADAS). The automotive electronics market, valued at 248 billion USD in 2022, represents a substantial opportunity for Schmitt trigger applications, particularly as vehicles incorporate more sensors requiring reliable signal conditioning in electrically noisy environments.

Industrial automation represents another significant market segment, where Schmitt triggers are essential components in programmable logic controllers (PLCs), motor drives, and factory automation systems. The industrial control and factory automation market is expected to reach 269 billion USD by 2026, with signal conditioning components like Schmitt triggers playing a critical role in ensuring reliable operation in harsh industrial environments.

Consumer electronics constitutes the largest application segment, with Schmitt triggers found in smartphones, laptops, gaming consoles, and smart home devices. Their ability to provide clean digital signals from analog inputs makes them invaluable in touch interfaces, power management circuits, and sensor interfaces. The consumer electronics market, valued at 1.1 trillion USD, continues to drive innovation in miniaturized, low-power Schmitt trigger implementations.

Medical equipment represents an emerging high-value market for precision Schmitt trigger solutions, particularly in patient monitoring systems, diagnostic equipment, and medical imaging devices. The medical electronics market is projected to grow at 6.9% annually through 2027, with increasing demands for reliable signal processing in life-critical applications.

Regional analysis indicates that Asia-Pacific dominates the Schmitt trigger market with approximately 42% market share, followed by North America (28%) and Europe (21%). China, Japan, South Korea, and Taiwan lead in production volume, while specialized high-performance variants are predominantly developed in the United States and Germany.

Customer requirements are evolving toward lower power consumption, higher operating frequencies, and greater integration density. Market research indicates that 76% of design engineers prioritize noise immunity in signal conditioning circuits, while 68% seek solutions with configurable hysteresis thresholds to optimize performance across varying operating conditions.

In the automotive industry, Schmitt triggers are extensively utilized in engine control units, safety systems, and advanced driver-assistance systems (ADAS). The automotive electronics market, valued at 248 billion USD in 2022, represents a substantial opportunity for Schmitt trigger applications, particularly as vehicles incorporate more sensors requiring reliable signal conditioning in electrically noisy environments.

Industrial automation represents another significant market segment, where Schmitt triggers are essential components in programmable logic controllers (PLCs), motor drives, and factory automation systems. The industrial control and factory automation market is expected to reach 269 billion USD by 2026, with signal conditioning components like Schmitt triggers playing a critical role in ensuring reliable operation in harsh industrial environments.

Consumer electronics constitutes the largest application segment, with Schmitt triggers found in smartphones, laptops, gaming consoles, and smart home devices. Their ability to provide clean digital signals from analog inputs makes them invaluable in touch interfaces, power management circuits, and sensor interfaces. The consumer electronics market, valued at 1.1 trillion USD, continues to drive innovation in miniaturized, low-power Schmitt trigger implementations.

Medical equipment represents an emerging high-value market for precision Schmitt trigger solutions, particularly in patient monitoring systems, diagnostic equipment, and medical imaging devices. The medical electronics market is projected to grow at 6.9% annually through 2027, with increasing demands for reliable signal processing in life-critical applications.

Regional analysis indicates that Asia-Pacific dominates the Schmitt trigger market with approximately 42% market share, followed by North America (28%) and Europe (21%). China, Japan, South Korea, and Taiwan lead in production volume, while specialized high-performance variants are predominantly developed in the United States and Germany.

Customer requirements are evolving toward lower power consumption, higher operating frequencies, and greater integration density. Market research indicates that 76% of design engineers prioritize noise immunity in signal conditioning circuits, while 68% seek solutions with configurable hysteresis thresholds to optimize performance across varying operating conditions.

Current Challenges in DC Signal Handling Technologies

DC signal handling technologies face several significant challenges in today's electronic systems, particularly in environments with high noise levels, varying input impedances, and demanding precision requirements. One of the most persistent issues is signal integrity degradation due to noise interference, which becomes especially problematic in low-voltage DC applications where the signal-to-noise ratio is inherently lower. Industrial settings with high electromagnetic interference (EMI) and radio frequency interference (RFI) exacerbate these challenges, making reliable signal detection increasingly difficult.

Temperature drift presents another substantial obstacle, as DC signal handling circuits often exhibit sensitivity to ambient temperature variations. This thermal dependency can cause threshold voltage shifts, resulting in inconsistent triggering points and potential system failures in applications requiring precise timing or measurement. The problem is particularly acute in automotive and outdoor industrial applications where temperature ranges can be extreme.

Power consumption considerations have also become increasingly critical, especially in battery-powered and IoT devices. Traditional DC signal handling approaches often require continuous power for monitoring and processing, which conflicts with the energy efficiency demands of modern portable electronics. This creates a technical dilemma between maintaining signal monitoring accuracy and extending battery life.

Hysteresis control represents a significant technical hurdle in conventional comparator circuits. Without proper hysteresis, these circuits can experience rapid oscillations when input signals hover near the threshold voltage, leading to chattering outputs and unpredictable system behavior. This becomes particularly problematic in slowly changing signals or those with superimposed noise.

Component tolerance and aging effects further complicate DC signal handling. Manufacturing variations in resistors and capacitors can shift threshold voltages, while semiconductor aging can gradually alter circuit characteristics over time. These factors make it difficult to maintain consistent performance across production batches and throughout a product's lifecycle.

The increasing miniaturization of electronic devices has created spatial constraints that limit the implementation of robust DC signal handling solutions. Complex filtering networks and precision components often require significant board space, forcing engineers to make compromises between signal quality and form factor.

Finally, there is a growing demand for adaptive threshold capabilities in modern applications. Fixed-threshold DC signal handling technologies struggle to accommodate varying input conditions, creating a need for more sophisticated approaches that can dynamically adjust to changing signal characteristics while maintaining reliable operation across diverse operating environments.

Temperature drift presents another substantial obstacle, as DC signal handling circuits often exhibit sensitivity to ambient temperature variations. This thermal dependency can cause threshold voltage shifts, resulting in inconsistent triggering points and potential system failures in applications requiring precise timing or measurement. The problem is particularly acute in automotive and outdoor industrial applications where temperature ranges can be extreme.

Power consumption considerations have also become increasingly critical, especially in battery-powered and IoT devices. Traditional DC signal handling approaches often require continuous power for monitoring and processing, which conflicts with the energy efficiency demands of modern portable electronics. This creates a technical dilemma between maintaining signal monitoring accuracy and extending battery life.

Hysteresis control represents a significant technical hurdle in conventional comparator circuits. Without proper hysteresis, these circuits can experience rapid oscillations when input signals hover near the threshold voltage, leading to chattering outputs and unpredictable system behavior. This becomes particularly problematic in slowly changing signals or those with superimposed noise.

Component tolerance and aging effects further complicate DC signal handling. Manufacturing variations in resistors and capacitors can shift threshold voltages, while semiconductor aging can gradually alter circuit characteristics over time. These factors make it difficult to maintain consistent performance across production batches and throughout a product's lifecycle.

The increasing miniaturization of electronic devices has created spatial constraints that limit the implementation of robust DC signal handling solutions. Complex filtering networks and precision components often require significant board space, forcing engineers to make compromises between signal quality and form factor.

Finally, there is a growing demand for adaptive threshold capabilities in modern applications. Fixed-threshold DC signal handling technologies struggle to accommodate varying input conditions, creating a need for more sophisticated approaches that can dynamically adjust to changing signal characteristics while maintaining reliable operation across diverse operating environments.

Contemporary Schmitt Trigger Implementation Methodologies

01 Schmitt Trigger Circuits for DC Signal Conditioning

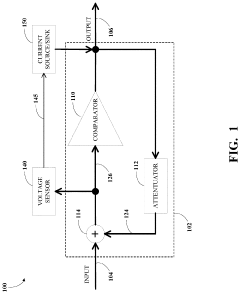

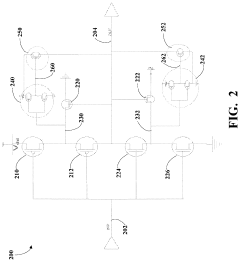

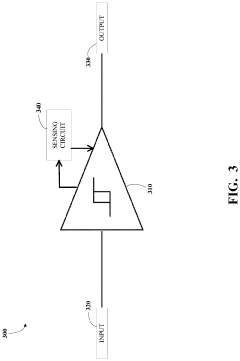

Schmitt trigger circuits are designed to handle DC signals by providing hysteresis, which helps eliminate noise and ensure clean switching between logic states. These circuits typically incorporate feedback mechanisms to establish different threshold voltages for rising and falling input signals, making them ideal for DC signal conditioning applications where stable operation is required despite noisy input conditions.- Schmitt Trigger Circuits for DC Signal Conditioning: Schmitt trigger circuits are designed to handle DC signals by providing hysteresis, which helps eliminate noise and ensure clean switching between states. These circuits typically incorporate feedback mechanisms that establish different threshold levels for rising and falling input signals, making them ideal for DC signal conditioning applications where stable switching is required despite signal fluctuations or noise.

- Noise Immunity and Threshold Control in DC Applications: Schmitt triggers provide enhanced noise immunity for DC signals through adjustable threshold control mechanisms. By implementing variable threshold levels, these circuits can be optimized for specific DC signal characteristics, preventing false triggering due to noise or small signal variations. Advanced designs incorporate precision voltage references and temperature compensation to maintain consistent threshold levels across operating conditions.

- Low Power Schmitt Trigger Implementations for DC Processing: Power-efficient Schmitt trigger designs are crucial for battery-operated devices processing DC signals. These implementations utilize techniques such as dynamic biasing, reduced supply voltage operation, and optimized transistor sizing to minimize power consumption while maintaining reliable DC signal handling capabilities. Some designs incorporate power-down modes that activate only when signal transitions occur, further reducing energy requirements.

- Integration of Schmitt Triggers in Complex DC Signal Processing Systems: Schmitt triggers are integrated into larger DC signal processing systems to provide clean digital representations of analog DC inputs. These integrated solutions combine the Schmitt trigger with additional components such as filters, level shifters, and digital interfaces to create complete signal conditioning chains. Modern implementations often include programmable hysteresis and threshold levels to accommodate various DC signal characteristics within a single system.

- Advanced Schmitt Trigger Architectures for Precision DC Applications: Advanced Schmitt trigger architectures employ specialized circuit topologies to achieve high precision in DC signal handling. These designs may utilize differential inputs, rail-to-rail operation, and precision reference voltages to accurately process DC signals across wide voltage ranges. Some implementations incorporate calibration mechanisms to compensate for manufacturing variations and aging effects, ensuring consistent performance in critical applications requiring precise DC signal detection thresholds.

02 Hysteresis Control in Schmitt Trigger Designs

Advanced Schmitt trigger designs feature adjustable hysteresis control mechanisms that allow for precise tuning of threshold voltages. These implementations enable optimization of DC signal handling characteristics based on specific application requirements. By controlling the hysteresis width, these circuits can be tailored to accommodate various DC signal levels and noise environments, improving overall system reliability and performance.Expand Specific Solutions03 Low Power Schmitt Trigger Implementations

Energy-efficient Schmitt trigger designs focus on minimizing power consumption while maintaining reliable DC signal handling capabilities. These implementations utilize various techniques such as voltage scaling, current limiting, and optimized transistor sizing to reduce power requirements. Low power Schmitt triggers are particularly valuable in battery-operated devices and energy-conscious applications where DC signal conditioning is needed with minimal power overhead.Expand Specific Solutions04 Integrated Schmitt Trigger Solutions for Mixed-Signal Processing

Integrated Schmitt trigger solutions combine DC signal handling capabilities with additional signal processing functionalities. These designs incorporate Schmitt triggers within larger mixed-signal systems to provide clean digital outputs from analog DC inputs. The integration enables efficient interfacing between analog and digital domains, with the Schmitt trigger serving as a robust front-end for processing DC signals before further digital manipulation.Expand Specific Solutions05 Noise-Immune Schmitt Trigger Architectures

Specialized Schmitt trigger architectures focus on enhanced noise immunity for handling DC signals in electrically noisy environments. These designs incorporate additional filtering stages, differential input structures, or advanced feedback mechanisms to reject common-mode noise while preserving the desired DC signal characteristics. Such noise-immune implementations are critical in industrial applications, automotive systems, and other environments where reliable DC signal handling is required despite significant electrical interference.Expand Specific Solutions

Leading Manufacturers and Competitors in Signal Processing Industry

The Schmitt Trigger DC signal handling optimization market is currently in a growth phase, with increasing demand across automotive, consumer electronics, and industrial automation sectors. The competitive landscape is dominated by established semiconductor manufacturers like STMicroelectronics, which leads with comprehensive analog solutions, and Cirrus Logic, known for high-precision signal processing components. Other significant players include Skyworks Solutions, MediaTek, and SG Micro Corp, each leveraging their specialized expertise in analog circuit design. The technology has reached moderate maturity but continues to evolve with innovations from companies like Samsung Electronics and LG Electronics focusing on noise immunity improvements and power efficiency. Siemens and IBM are expanding applications through integration with digital systems, while smaller players like Faraday Technology and Tower Semiconductor offer specialized niche solutions.

STMicroelectronics International NV

Technical Solution: STMicroelectronics has developed advanced Schmitt trigger implementations for DC signal handling in their microcontroller and analog product lines. Their approach integrates programmable hysteresis thresholds that can be dynamically adjusted based on environmental conditions and signal characteristics. The company's STM32 series incorporates enhanced Schmitt trigger input buffers that provide superior noise immunity while maintaining fast transition times. Their implementation includes specialized low-power modes where the Schmitt trigger circuitry can operate with reduced current consumption during standby states while still monitoring critical DC signals. STMicroelectronics has also developed temperature-compensated Schmitt trigger designs that maintain consistent hysteresis windows across industrial temperature ranges (-40°C to +125°C), ensuring reliable operation in harsh environments. Their integrated solutions often combine Schmitt triggers with programmable filtering capabilities to optimize both noise rejection and response time based on application requirements.

Strengths: Industry-leading noise immunity with programmable hysteresis thresholds; excellent temperature stability across wide operating ranges; integrated power management features for low-power applications. Weaknesses: Higher cost compared to basic implementations; requires more complex configuration in some applications; slightly increased propagation delay in certain operating modes.

Cirrus Logic, Inc.

Technical Solution: Cirrus Logic has pioneered precision Schmitt trigger implementations specifically optimized for audio and mixed-signal applications. Their approach focuses on ultra-low noise performance while maintaining precise hysteresis control. The company's proprietary design incorporates adaptive threshold technology that automatically adjusts trigger points based on ambient noise conditions, particularly valuable in audio signal processing chains. Cirrus Logic's implementation features sub-microvolt precision for handling extremely small DC signal variations while maintaining immunity to noise. Their architecture includes specialized input stages with matched differential pairs to minimize offset errors that could affect trigger point accuracy. For audio applications, they've developed Schmitt trigger variants with controlled slew rates to reduce harmonic distortion during signal level transitions. The company has also integrated these optimized Schmitt triggers into their audio codec and amplifier products, providing consistent performance across their product ecosystem.

Strengths: Exceptional precision for handling small-signal DC variations; industry-leading noise performance; adaptive threshold technology for varying environmental conditions. Weaknesses: Higher power consumption than simpler implementations; primarily optimized for audio applications which may limit versatility in other domains; premium pricing reflecting specialized performance characteristics.

Critical Patents and Technical Innovations in Hysteresis Control

Low-swing schmitt triggers

PatentActiveUS20220200586A1

Innovation

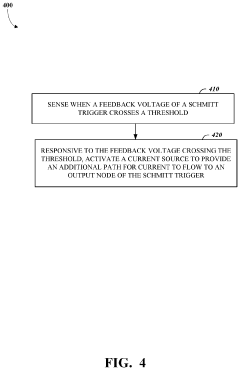

- The implementation of a low-swing Schmitt trigger circuit with additional parallel paths for current sourcing and sinking, utilizing transistors and voltage sensors to enhance state transitions even when input voltages are near threshold levels, thereby reducing delay and increasing switching speed.

Schmitt trigger with threshold voltage close to rail voltage

PatentActiveGB2545335A

Innovation

- A Schmitt trigger circuit with a voltage level shifter configured to shift the threshold voltage close to rail voltage by using a combination of switching devices with different strengths and a voltage level shifter circuit, allowing precise control of the switching process in class-D amplifiers.

Noise Immunity Performance Metrics and Testing Standards

Noise immunity represents a critical performance metric for Schmitt trigger circuits in DC signal handling applications. The quantification of noise immunity is typically measured through the hysteresis voltage, which defines the difference between the upper and lower threshold voltages. Standard testing methodologies include the Common-Mode Rejection Ratio (CMRR) test, which evaluates the circuit's ability to reject noise common to both input terminals, and the Power Supply Rejection Ratio (PSRR) test, which measures immunity to power supply fluctuations.

Industry standards for noise immunity testing of Schmitt triggers include IEC 61000-4-4 for electrical fast transient immunity and IEC 61000-4-5 for surge immunity. These standards provide structured test procedures involving the application of controlled noise signals while monitoring the circuit's output for unwanted transitions. The JEDEC JESD22-A114 standard specifically addresses the latch-up immunity testing relevant to Schmitt trigger implementations in integrated circuits.

Performance metrics for Schmitt trigger noise immunity include the Noise Margin (NM), which quantifies the maximum amplitude of noise that can be superimposed on a valid input signal without causing an erroneous output. This metric is typically expressed in volts and should be at least 20% of the logic swing for robust industrial applications. The Noise Immunity Factor (NIF), calculated as the ratio of the hysteresis voltage to the peak noise amplitude, provides a dimensionless measure of noise rejection capability.

Temporal metrics are equally important in assessing Schmitt trigger performance. The Noise Pulse Width Immunity (NPWI) measures the minimum duration of a noise pulse required to trigger an unwanted state change. The Maximum Noise Energy (MNE) metric, expressed in joules, represents the maximum noise energy the circuit can absorb without malfunction.

Testing standards also specify environmental conditions for comprehensive evaluation. Temperature range testing (typically -40°C to +125°C for industrial applications) ensures consistent noise immunity across operating environments. Accelerated stress testing, including Temperature Cycling (TC) and Highly Accelerated Stress Test (HAST), evaluates long-term reliability of the noise immunity characteristics.

Statistical analysis methods, including Six Sigma and Design of Experiments (DoE), are increasingly employed to characterize noise immunity performance across manufacturing variations. Monte Carlo simulation techniques help predict the distribution of noise immunity parameters in mass-produced Schmitt trigger circuits, enabling manufacturers to establish realistic specification limits and quality control procedures.

Industry standards for noise immunity testing of Schmitt triggers include IEC 61000-4-4 for electrical fast transient immunity and IEC 61000-4-5 for surge immunity. These standards provide structured test procedures involving the application of controlled noise signals while monitoring the circuit's output for unwanted transitions. The JEDEC JESD22-A114 standard specifically addresses the latch-up immunity testing relevant to Schmitt trigger implementations in integrated circuits.

Performance metrics for Schmitt trigger noise immunity include the Noise Margin (NM), which quantifies the maximum amplitude of noise that can be superimposed on a valid input signal without causing an erroneous output. This metric is typically expressed in volts and should be at least 20% of the logic swing for robust industrial applications. The Noise Immunity Factor (NIF), calculated as the ratio of the hysteresis voltage to the peak noise amplitude, provides a dimensionless measure of noise rejection capability.

Temporal metrics are equally important in assessing Schmitt trigger performance. The Noise Pulse Width Immunity (NPWI) measures the minimum duration of a noise pulse required to trigger an unwanted state change. The Maximum Noise Energy (MNE) metric, expressed in joules, represents the maximum noise energy the circuit can absorb without malfunction.

Testing standards also specify environmental conditions for comprehensive evaluation. Temperature range testing (typically -40°C to +125°C for industrial applications) ensures consistent noise immunity across operating environments. Accelerated stress testing, including Temperature Cycling (TC) and Highly Accelerated Stress Test (HAST), evaluates long-term reliability of the noise immunity characteristics.

Statistical analysis methods, including Six Sigma and Design of Experiments (DoE), are increasingly employed to characterize noise immunity performance across manufacturing variations. Monte Carlo simulation techniques help predict the distribution of noise immunity parameters in mass-produced Schmitt trigger circuits, enabling manufacturers to establish realistic specification limits and quality control procedures.

Power Efficiency Considerations in Schmitt Trigger Applications

Power efficiency has become a critical consideration in Schmitt trigger applications, particularly as electronic devices continue to trend toward miniaturization and battery operation. The inherent hysteresis characteristic of Schmitt triggers, while beneficial for noise immunity, introduces power consumption challenges that must be addressed through careful design optimization. Traditional Schmitt trigger circuits often consume significant static power due to their resistive feedback networks and constant current paths.

Modern design approaches focus on reducing this power consumption through several key strategies. Dynamic biasing techniques allow the circuit to adjust its operating point based on input signal conditions, significantly reducing power consumption during idle periods. When handling DC signals, this approach is particularly effective as the circuit can enter a low-power state during extended periods of signal stability.

Complementary MOS (CMOS) implementations of Schmitt triggers have revolutionized power efficiency by dramatically reducing static power consumption. These designs leverage the inherent characteristics of CMOS technology to minimize current flow when the circuit is in a stable state. Advanced CMOS Schmitt trigger designs can achieve power consumption in the nanowatt range, making them suitable for ultra-low-power applications such as IoT sensors and medical implants.

Supply voltage scaling represents another effective approach for power optimization. By designing Schmitt triggers to operate at lower supply voltages, power consumption can be reduced quadratically according to the P = CV²f relationship. Modern sub-threshold Schmitt trigger designs can operate effectively at voltages below 1V, though careful consideration must be given to maintaining adequate noise margins at these reduced voltage levels.

Process technology selection significantly impacts power efficiency in Schmitt trigger applications. Advanced semiconductor processes with smaller feature sizes generally offer reduced parasitic capacitances and lower leakage currents. However, designers must balance these benefits against increased manufacturing costs and potential reliability concerns in harsh environments.

For DC signal handling applications specifically, power gating and clock gating techniques can be implemented to disable portions of the circuit when not actively processing signal transitions. These approaches can reduce power consumption by up to 90% in applications where signal changes are infrequent, such as environmental monitoring systems or battery management circuits.

Temperature compensation mechanisms are increasingly important for maintaining consistent power efficiency across operating conditions. As leakage currents in semiconductor devices vary exponentially with temperature, adaptive biasing schemes that adjust circuit parameters based on ambient temperature can help maintain optimal power efficiency across a wide operating range.

Modern design approaches focus on reducing this power consumption through several key strategies. Dynamic biasing techniques allow the circuit to adjust its operating point based on input signal conditions, significantly reducing power consumption during idle periods. When handling DC signals, this approach is particularly effective as the circuit can enter a low-power state during extended periods of signal stability.

Complementary MOS (CMOS) implementations of Schmitt triggers have revolutionized power efficiency by dramatically reducing static power consumption. These designs leverage the inherent characteristics of CMOS technology to minimize current flow when the circuit is in a stable state. Advanced CMOS Schmitt trigger designs can achieve power consumption in the nanowatt range, making them suitable for ultra-low-power applications such as IoT sensors and medical implants.

Supply voltage scaling represents another effective approach for power optimization. By designing Schmitt triggers to operate at lower supply voltages, power consumption can be reduced quadratically according to the P = CV²f relationship. Modern sub-threshold Schmitt trigger designs can operate effectively at voltages below 1V, though careful consideration must be given to maintaining adequate noise margins at these reduced voltage levels.

Process technology selection significantly impacts power efficiency in Schmitt trigger applications. Advanced semiconductor processes with smaller feature sizes generally offer reduced parasitic capacitances and lower leakage currents. However, designers must balance these benefits against increased manufacturing costs and potential reliability concerns in harsh environments.

For DC signal handling applications specifically, power gating and clock gating techniques can be implemented to disable portions of the circuit when not actively processing signal transitions. These approaches can reduce power consumption by up to 90% in applications where signal changes are infrequent, such as environmental monitoring systems or battery management circuits.

Temperature compensation mechanisms are increasingly important for maintaining consistent power efficiency across operating conditions. As leakage currents in semiconductor devices vary exponentially with temperature, adaptive biasing schemes that adjust circuit parameters based on ambient temperature can help maintain optimal power efficiency across a wide operating range.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!