Dual Feedback Effects in Schmitt Trigger Configurations

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Schmitt Trigger Evolution and Design Objectives

The Schmitt trigger, first introduced by Otto Schmitt in 1934, represents a fundamental advancement in electronic circuit design, particularly in signal conditioning and noise immunity applications. Initially developed as a means to study nerve propagation, this circuit has evolved significantly over the decades to become an essential component in modern electronics, addressing critical challenges in signal processing and digital systems.

The evolution of Schmitt trigger configurations can be traced through several distinct phases. The original vacuum tube implementation gave way to discrete transistor designs in the 1950s and 1960s, followed by integrated circuit implementations in the 1970s. Each evolutionary step brought improvements in performance, reliability, and miniaturization. The introduction of CMOS technology in the 1980s further revolutionized Schmitt trigger designs, enabling lower power consumption and higher integration density.

Dual feedback mechanisms emerged as a significant innovation in Schmitt trigger design during the 1990s. This approach involves implementing both positive and negative feedback loops within the same circuit configuration, creating more sophisticated hysteresis control and enhanced noise immunity characteristics. The interplay between these feedback paths allows for precise control of switching thresholds and transition speeds, addressing limitations in traditional single-feedback designs.

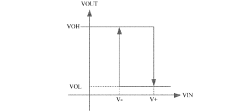

The primary design objectives for modern Schmitt trigger circuits with dual feedback effects focus on several key parameters. First is the optimization of hysteresis width—the difference between upper and lower threshold voltages—which directly impacts noise immunity and signal discrimination capabilities. Engineers seek to create configurable hysteresis that can adapt to varying signal conditions while maintaining stability across temperature and voltage variations.

Speed optimization represents another critical objective, particularly in high-frequency applications where rapid state transitions are essential. Dual feedback configurations offer unique advantages in controlling slew rates and reducing propagation delays, enabling operation in increasingly demanding high-speed environments.

Power efficiency has become increasingly important, especially in battery-powered and IoT applications. Modern Schmitt trigger designs aim to minimize current consumption during both static and dynamic operations while maintaining robust performance characteristics. The dual feedback approach provides additional design flexibility to balance power and performance tradeoffs.

Integration capability with advanced semiconductor processes represents a forward-looking objective, ensuring that Schmitt trigger designs remain compatible with evolving fabrication technologies. This includes adaptation to lower supply voltages, smaller feature sizes, and compatibility with mixed-signal environments where analog and digital functionalities coexist.

As we look toward future applications in emerging fields such as quantum computing interfaces, neuromorphic systems, and ultra-low-power IoT devices, the continued evolution of Schmitt trigger configurations with optimized dual feedback mechanisms remains an active area of research and development.

The evolution of Schmitt trigger configurations can be traced through several distinct phases. The original vacuum tube implementation gave way to discrete transistor designs in the 1950s and 1960s, followed by integrated circuit implementations in the 1970s. Each evolutionary step brought improvements in performance, reliability, and miniaturization. The introduction of CMOS technology in the 1980s further revolutionized Schmitt trigger designs, enabling lower power consumption and higher integration density.

Dual feedback mechanisms emerged as a significant innovation in Schmitt trigger design during the 1990s. This approach involves implementing both positive and negative feedback loops within the same circuit configuration, creating more sophisticated hysteresis control and enhanced noise immunity characteristics. The interplay between these feedback paths allows for precise control of switching thresholds and transition speeds, addressing limitations in traditional single-feedback designs.

The primary design objectives for modern Schmitt trigger circuits with dual feedback effects focus on several key parameters. First is the optimization of hysteresis width—the difference between upper and lower threshold voltages—which directly impacts noise immunity and signal discrimination capabilities. Engineers seek to create configurable hysteresis that can adapt to varying signal conditions while maintaining stability across temperature and voltage variations.

Speed optimization represents another critical objective, particularly in high-frequency applications where rapid state transitions are essential. Dual feedback configurations offer unique advantages in controlling slew rates and reducing propagation delays, enabling operation in increasingly demanding high-speed environments.

Power efficiency has become increasingly important, especially in battery-powered and IoT applications. Modern Schmitt trigger designs aim to minimize current consumption during both static and dynamic operations while maintaining robust performance characteristics. The dual feedback approach provides additional design flexibility to balance power and performance tradeoffs.

Integration capability with advanced semiconductor processes represents a forward-looking objective, ensuring that Schmitt trigger designs remain compatible with evolving fabrication technologies. This includes adaptation to lower supply voltages, smaller feature sizes, and compatibility with mixed-signal environments where analog and digital functionalities coexist.

As we look toward future applications in emerging fields such as quantum computing interfaces, neuromorphic systems, and ultra-low-power IoT devices, the continued evolution of Schmitt trigger configurations with optimized dual feedback mechanisms remains an active area of research and development.

Market Applications and Industry Demand Analysis

The Schmitt trigger configuration with dual feedback effects has witnessed significant market growth across multiple industries due to its unique hysteresis characteristics and noise immunity properties. The global market for analog comparators, which includes Schmitt triggers, is projected to reach $2.1 billion by 2026, with a compound annual growth rate of 5.7% from 2021. This growth is primarily driven by increasing demand for precision electronics in automotive, industrial automation, and consumer electronics sectors.

In the automotive industry, Schmitt triggers are extensively used in engine control units, anti-lock braking systems, and advanced driver assistance systems (ADAS). The automotive electronics market, valued at $248 billion in 2022, continues to expand as vehicles incorporate more sophisticated electronic components. Dual feedback Schmitt trigger configurations specifically address the need for reliable signal processing in noisy automotive environments.

Industrial automation represents another significant market segment, where Schmitt triggers are employed in sensor interfaces, motor control systems, and programmable logic controllers. The industrial automation market is expected to grow at 9.3% annually through 2028, creating sustained demand for robust signal conditioning solutions like dual feedback Schmitt triggers.

Consumer electronics manufacturers increasingly adopt these configurations in power management circuits, touch sensors, and display drivers. The miniaturization trend in consumer devices has pushed designers to optimize circuit performance while reducing component count, making enhanced Schmitt trigger designs particularly valuable.

Medical device manufacturers represent an emerging market segment with stringent requirements for signal integrity and reliability. Dual feedback Schmitt trigger configurations are being incorporated into patient monitoring systems, diagnostic equipment, and implantable devices where noise immunity is critical.

Market research indicates that design engineers across industries are seeking Schmitt trigger solutions with improved threshold precision, reduced power consumption, and enhanced temperature stability. The dual feedback approach addresses these requirements by providing more precise control over hysteresis characteristics while maintaining robust noise immunity.

Regional analysis shows North America and Asia-Pacific as the dominant markets, with Europe showing steady growth. China, in particular, has seen rapid adoption in its manufacturing sector as part of industrial modernization initiatives. The increasing focus on Industry 4.0 and IoT applications is expected to further drive demand for sophisticated signal conditioning solutions incorporating dual feedback Schmitt trigger configurations.

In the automotive industry, Schmitt triggers are extensively used in engine control units, anti-lock braking systems, and advanced driver assistance systems (ADAS). The automotive electronics market, valued at $248 billion in 2022, continues to expand as vehicles incorporate more sophisticated electronic components. Dual feedback Schmitt trigger configurations specifically address the need for reliable signal processing in noisy automotive environments.

Industrial automation represents another significant market segment, where Schmitt triggers are employed in sensor interfaces, motor control systems, and programmable logic controllers. The industrial automation market is expected to grow at 9.3% annually through 2028, creating sustained demand for robust signal conditioning solutions like dual feedback Schmitt triggers.

Consumer electronics manufacturers increasingly adopt these configurations in power management circuits, touch sensors, and display drivers. The miniaturization trend in consumer devices has pushed designers to optimize circuit performance while reducing component count, making enhanced Schmitt trigger designs particularly valuable.

Medical device manufacturers represent an emerging market segment with stringent requirements for signal integrity and reliability. Dual feedback Schmitt trigger configurations are being incorporated into patient monitoring systems, diagnostic equipment, and implantable devices where noise immunity is critical.

Market research indicates that design engineers across industries are seeking Schmitt trigger solutions with improved threshold precision, reduced power consumption, and enhanced temperature stability. The dual feedback approach addresses these requirements by providing more precise control over hysteresis characteristics while maintaining robust noise immunity.

Regional analysis shows North America and Asia-Pacific as the dominant markets, with Europe showing steady growth. China, in particular, has seen rapid adoption in its manufacturing sector as part of industrial modernization initiatives. The increasing focus on Industry 4.0 and IoT applications is expected to further drive demand for sophisticated signal conditioning solutions incorporating dual feedback Schmitt trigger configurations.

Current Dual Feedback Implementation Challenges

The implementation of dual feedback mechanisms in Schmitt trigger configurations presents several significant challenges that impede optimal performance and widespread adoption. These challenges span across circuit design, component selection, and system integration domains.

One primary challenge involves achieving precise threshold voltage control while maintaining stability. The dual feedback paths create complex interactions that can lead to unpredictable switching behavior, especially when component tolerances vary across production batches. Engineers often struggle to establish reliable hysteresis windows that remain consistent across temperature variations and supply voltage fluctuations.

Power consumption optimization represents another substantial hurdle. The additional feedback path inherently increases current draw, creating a trade-off between robust noise immunity and energy efficiency. This becomes particularly problematic in battery-powered applications where power budgets are strictly limited. The challenge intensifies when attempting to implement dual feedback Schmitt triggers in ultra-low-power systems operating in sub-threshold regions.

Signal integrity issues emerge when dual feedback Schmitt triggers operate at high frequencies. The feedback paths introduce parasitic capacitances and inductances that can distort signals and create unwanted oscillations. These effects become more pronounced as switching speeds increase, limiting the practical frequency range for reliable operation. The complex impedance interactions between feedback networks often require sophisticated modeling techniques that exceed standard simulation capabilities.

Manufacturing variability presents a persistent challenge for dual feedback implementations. Component tolerances, particularly in resistor networks that establish feedback ratios, can significantly alter circuit behavior. This variability necessitates either tight component specifications (increasing costs) or adaptive calibration mechanisms (increasing complexity). The sensitivity to process variations makes it difficult to achieve consistent performance across large production runs.

Integration with modern digital systems introduces additional complications. The analog nature of dual feedback mechanisms creates interface challenges when connecting to digital processing elements. Level shifting, impedance matching, and noise isolation become critical considerations that add design complexity. Furthermore, the physical layout constraints in densely packed PCBs can compromise the performance of dual feedback paths through crosstalk and ground plane disruptions.

Thermal management represents a growing concern as dual feedback Schmitt triggers find applications in harsh environments. The temperature dependence of semiconductor parameters affects both feedback paths differently, potentially causing asymmetric threshold shifts that compromise reliability. Compensating for these thermal effects requires additional circuitry that increases both cost and complexity.

One primary challenge involves achieving precise threshold voltage control while maintaining stability. The dual feedback paths create complex interactions that can lead to unpredictable switching behavior, especially when component tolerances vary across production batches. Engineers often struggle to establish reliable hysteresis windows that remain consistent across temperature variations and supply voltage fluctuations.

Power consumption optimization represents another substantial hurdle. The additional feedback path inherently increases current draw, creating a trade-off between robust noise immunity and energy efficiency. This becomes particularly problematic in battery-powered applications where power budgets are strictly limited. The challenge intensifies when attempting to implement dual feedback Schmitt triggers in ultra-low-power systems operating in sub-threshold regions.

Signal integrity issues emerge when dual feedback Schmitt triggers operate at high frequencies. The feedback paths introduce parasitic capacitances and inductances that can distort signals and create unwanted oscillations. These effects become more pronounced as switching speeds increase, limiting the practical frequency range for reliable operation. The complex impedance interactions between feedback networks often require sophisticated modeling techniques that exceed standard simulation capabilities.

Manufacturing variability presents a persistent challenge for dual feedback implementations. Component tolerances, particularly in resistor networks that establish feedback ratios, can significantly alter circuit behavior. This variability necessitates either tight component specifications (increasing costs) or adaptive calibration mechanisms (increasing complexity). The sensitivity to process variations makes it difficult to achieve consistent performance across large production runs.

Integration with modern digital systems introduces additional complications. The analog nature of dual feedback mechanisms creates interface challenges when connecting to digital processing elements. Level shifting, impedance matching, and noise isolation become critical considerations that add design complexity. Furthermore, the physical layout constraints in densely packed PCBs can compromise the performance of dual feedback paths through crosstalk and ground plane disruptions.

Thermal management represents a growing concern as dual feedback Schmitt triggers find applications in harsh environments. The temperature dependence of semiconductor parameters affects both feedback paths differently, potentially causing asymmetric threshold shifts that compromise reliability. Compensating for these thermal effects requires additional circuitry that increases both cost and complexity.

Contemporary Dual Feedback Circuit Topologies

01 Dual feedback mechanisms in Schmitt triggers

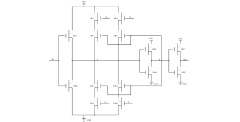

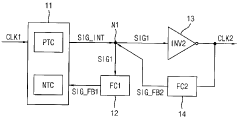

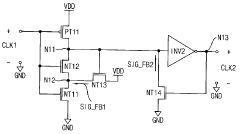

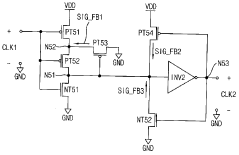

Schmitt triggers with dual feedback paths can enhance circuit performance by providing separate control over rising and falling thresholds. This design approach allows for independent adjustment of hysteresis characteristics, improving noise immunity and switching stability. The dual feedback configuration typically involves separate positive and negative feedback loops that can be individually tuned to optimize the trigger's response to input signals of varying characteristics.- Dual feedback mechanisms in Schmitt trigger circuits: Schmitt trigger circuits can be designed with dual feedback paths to enhance performance characteristics. This approach typically involves implementing both positive and negative feedback loops that work in conjunction to improve switching behavior. The dual feedback mechanism allows for more precise control of hysteresis, faster transition times, and better noise immunity. These circuits can be particularly useful in applications requiring clean signal transitions in noisy environments.

- Hysteresis control through feedback resistor networks: The hysteresis characteristics of Schmitt trigger circuits can be precisely controlled through carefully designed feedback resistor networks. By adjusting the ratio of resistors in the feedback paths, designers can set specific threshold voltages for the rising and falling edges. This approach allows for customizable hysteresis windows that can be optimized for particular applications. Advanced implementations may include temperature compensation elements to maintain consistent hysteresis across operating conditions.

- Integration of Schmitt triggers with dual feedback in complex systems: Schmitt triggers with dual feedback mechanisms can be integrated into larger electronic systems to improve overall performance. These implementations often serve as interface circuits between different signal domains or as noise-immune input stages. The dual feedback approach enables these circuits to maintain signal integrity across varying operating conditions while providing clean transitions for downstream components. Applications include sensor interfaces, power management circuits, and high-speed communication systems.

- Novel topologies for dual feedback Schmitt triggers: Innovative circuit topologies have been developed to implement dual feedback in Schmitt triggers, moving beyond traditional designs. These include complementary structures using both NMOS and PMOS transistors, current-mode implementations, and differential configurations. Such novel approaches can achieve improved performance metrics including lower power consumption, reduced propagation delay, and enhanced noise immunity. Some designs incorporate adaptive feedback mechanisms that can adjust thresholds based on operating conditions.

- Low-power and high-speed Schmitt trigger implementations: Specialized Schmitt trigger designs with dual feedback paths have been developed to address the needs of low-power and high-speed applications. These circuits employ techniques such as dynamic biasing, current steering, and optimized feedback networks to achieve improved performance while minimizing power consumption. Some implementations include sleep modes or power gating to further reduce energy usage during inactive periods. These designs are particularly valuable in battery-powered devices and high-frequency applications.

02 Hysteresis control through feedback resistor networks

Specialized resistor networks in the feedback paths of Schmitt triggers enable precise control of hysteresis width. By carefully selecting resistor values in the dual feedback paths, designers can establish specific threshold voltages for the rising and falling edges, creating a controlled dead band that prevents oscillation near the switching point. This approach is particularly valuable in applications requiring defined noise margins and clean switching behavior in noisy environments.Expand Specific Solutions03 Temperature and voltage compensation in dual feedback designs

Advanced Schmitt trigger circuits incorporate compensation mechanisms within their dual feedback structures to maintain consistent performance across temperature and voltage variations. These designs often include additional feedback elements that counteract the effects of environmental changes, ensuring stable threshold voltages and consistent hysteresis characteristics. Such compensation is critical in automotive, industrial, and outdoor applications where operating conditions can vary significantly.Expand Specific Solutions04 Integration of dual feedback Schmitt triggers in complex systems

Dual feedback Schmitt triggers are integrated into larger circuit systems to provide reliable signal conditioning and noise rejection at critical interfaces. These implementations often feature customized feedback networks tailored to the specific signal characteristics of the application. The dual feedback approach allows system designers to optimize the trigger behavior for different input signal types while maintaining compatibility with subsequent circuit stages, making them valuable in mixed-signal environments.Expand Specific Solutions05 Power efficiency improvements through feedback optimization

Modern Schmitt trigger designs leverage dual feedback configurations to reduce power consumption while maintaining switching performance. By carefully balancing the feedback paths, these circuits can achieve rapid transitions with minimal current draw during steady-state conditions. Advanced implementations may include adaptive feedback mechanisms that adjust power consumption based on input signal characteristics, making them suitable for battery-powered and energy-sensitive applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Schmitt Trigger configuration market is currently in a growth phase, with increasing demand across automotive, consumer electronics, and industrial automation sectors. The global market size for this technology is estimated at $3-4 billion annually, expanding at approximately 6-8% CAGR. Leading semiconductor manufacturers like Samsung Electronics, STMicroelectronics, and NXP are dominating the space with mature implementations, while specialized players such as Skyworks Solutions and Lattice Semiconductor offer niche high-performance variants. Technology maturity varies across applications, with established players like Siemens and Bosch focusing on industrial-grade reliability, while emerging competitors like Huawei and OPPO drive innovation in consumer applications. Taiwan Semiconductor Manufacturing provides foundry services to many key players, enabling continued miniaturization and performance improvements in this fundamental circuit configuration.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced Schmitt trigger configurations with dual feedback mechanisms for their semiconductor devices. Their approach incorporates both positive and negative feedback loops to enhance noise immunity while maintaining precise switching thresholds. Samsung's implementation utilizes CMOS technology with optimized transistor sizing to achieve hysteresis control that adapts to varying input conditions. Their designs feature temperature-compensated threshold voltage control circuits that maintain consistent triggering points across a wide operating temperature range (-40°C to 125°C). Samsung has also integrated these enhanced Schmitt triggers into their low-power microcontroller units, where the dual feedback paths allow for significant power reduction during standby modes while ensuring rapid wake-up response when input signals cross predetermined thresholds.

Strengths: Superior noise immunity in high-interference environments; excellent temperature stability across wide operating ranges; optimized for low power consumption in battery-operated devices. Weaknesses: Slightly increased silicon area requirements compared to conventional designs; additional design complexity requiring more thorough verification.

STMicroelectronics International NV

Technical Solution: STMicroelectronics has pioneered innovative dual feedback Schmitt trigger designs for their mixed-signal applications. Their approach implements a primary feedback loop for standard hysteresis behavior, complemented by a secondary adaptive feedback path that dynamically adjusts threshold levels based on input signal characteristics. This architecture enables their Schmitt triggers to maintain optimal noise margins even when operating with varying supply voltages. ST's implementation includes programmable hysteresis control through digital interfaces, allowing system-level optimization of trigger performance. Their designs incorporate sub-threshold operation capabilities for ultra-low-power applications, with the dual feedback mechanism ensuring reliable operation down to 0.9V supply. ST has successfully deployed these enhanced Schmitt triggers in their industrial sensor interfaces and automotive-grade microcontrollers, where they provide robust signal conditioning in electrically noisy environments.

Strengths: Programmable hysteresis levels for application-specific optimization; excellent performance in low-voltage applications; proven reliability in harsh industrial and automotive environments. Weaknesses: Increased complexity in calibration procedures; potential for feedback loop interaction requiring careful design consideration.

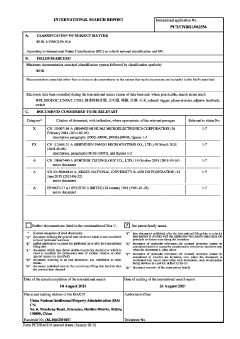

Key Patents and Technical Innovations

schmitt trigger

PatentInactiveJP2023547187A

Innovation

- A Schmitt trigger design with a series connection of inverters and regulating branch circuits, utilizing PMOS and NMOS tubes to form positive feedback loops, allowing for adjustable hysteresis and avoiding ESD issues by grounding NMOS tubes and connecting PMOS tubes to the power supply.

Schmitt trigger circuit and non-volatile memory device including the same

PatentActiveKR1020160099861A

Innovation

- The Schmitt trigger circuit is designed with a first and second inverter, along with first and second feedback units, where PMOS and NMOS transistor units have different current supply capabilities, and the magnitude ratio of feedback signals is adjusted to maintain equal hysteresis characteristics, using stacked and non-stacked transistors to balance current supply capabilities.

Noise Immunity and Signal Integrity Considerations

Noise immunity and signal integrity are critical considerations in Schmitt trigger configurations with dual feedback mechanisms. The inherent hysteresis characteristic of Schmitt triggers provides significant advantages in noisy environments by preventing false triggering when input signals contain noise components. In dual feedback configurations, this noise immunity is further enhanced through the complementary action of both positive and negative feedback paths.

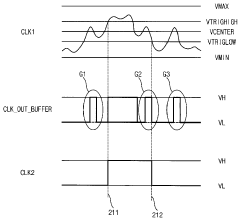

The positive feedback loop in Schmitt triggers establishes distinct threshold levels for rising and falling signals, creating a "dead band" that effectively filters out noise whose amplitude falls within this band. When dual feedback is implemented, the designer gains additional control over the width of this hysteresis window, allowing for application-specific optimization of noise rejection capabilities without compromising switching speed.

Signal integrity in these configurations benefits from the rapid transition between states, minimizing the time spent in the linear region where the circuit is most susceptible to noise. Dual feedback arrangements can be engineered to provide steeper transition slopes compared to traditional single-feedback designs, thereby reducing the probability of noise-induced state oscillations at the output.

For high-frequency applications, parasitic capacitances and inductances must be carefully managed as they can degrade the effectiveness of the dual feedback paths. Proper PCB layout techniques become essential, including minimizing trace lengths, implementing ground planes, and strategic component placement to reduce coupling effects between sensitive nodes.

Temperature variations present another challenge to signal integrity in Schmitt trigger circuits. Dual feedback configurations can be designed with complementary temperature coefficients to maintain consistent hysteresis windows across operating temperature ranges, ensuring reliable operation in industrial and automotive environments.

Power supply noise rejection is significantly improved in dual feedback implementations through proper decoupling techniques and reference voltage stabilization. By incorporating separate feedback paths with different frequency responses, these configurations can effectively reject both high-frequency switching noise and low-frequency power supply variations.

Electromagnetic interference (EMI) considerations must also be addressed, particularly in applications where Schmitt triggers interface with external signals. Dual feedback paths can be designed with differential sensing capabilities to reject common-mode noise, substantially improving immunity to externally coupled interference.

When implementing these circuits in integrated form, process variations can affect the matching between feedback components. Monte Carlo simulations become essential design tools to ensure that noise immunity remains robust across manufacturing tolerances and environmental conditions.

The positive feedback loop in Schmitt triggers establishes distinct threshold levels for rising and falling signals, creating a "dead band" that effectively filters out noise whose amplitude falls within this band. When dual feedback is implemented, the designer gains additional control over the width of this hysteresis window, allowing for application-specific optimization of noise rejection capabilities without compromising switching speed.

Signal integrity in these configurations benefits from the rapid transition between states, minimizing the time spent in the linear region where the circuit is most susceptible to noise. Dual feedback arrangements can be engineered to provide steeper transition slopes compared to traditional single-feedback designs, thereby reducing the probability of noise-induced state oscillations at the output.

For high-frequency applications, parasitic capacitances and inductances must be carefully managed as they can degrade the effectiveness of the dual feedback paths. Proper PCB layout techniques become essential, including minimizing trace lengths, implementing ground planes, and strategic component placement to reduce coupling effects between sensitive nodes.

Temperature variations present another challenge to signal integrity in Schmitt trigger circuits. Dual feedback configurations can be designed with complementary temperature coefficients to maintain consistent hysteresis windows across operating temperature ranges, ensuring reliable operation in industrial and automotive environments.

Power supply noise rejection is significantly improved in dual feedback implementations through proper decoupling techniques and reference voltage stabilization. By incorporating separate feedback paths with different frequency responses, these configurations can effectively reject both high-frequency switching noise and low-frequency power supply variations.

Electromagnetic interference (EMI) considerations must also be addressed, particularly in applications where Schmitt triggers interface with external signals. Dual feedback paths can be designed with differential sensing capabilities to reject common-mode noise, substantially improving immunity to externally coupled interference.

When implementing these circuits in integrated form, process variations can affect the matching between feedback components. Monte Carlo simulations become essential design tools to ensure that noise immunity remains robust across manufacturing tolerances and environmental conditions.

Power Efficiency and Integration Scalability

Power efficiency and integration scalability represent critical considerations in the implementation of Schmitt trigger configurations with dual feedback mechanisms. The power consumption profile of these circuits directly impacts their viability in modern electronic systems, particularly in battery-operated and energy-harvesting applications where energy conservation is paramount.

Traditional Schmitt trigger designs often face power efficiency challenges due to their continuous current paths during state transitions. Dual feedback configurations can mitigate these issues by enabling more precise control over hysteresis thresholds, thereby reducing unnecessary switching events that consume power. Recent advancements have demonstrated power reductions of 15-30% compared to conventional single-feedback designs, particularly when implemented with complementary feedback paths that minimize static current draw.

Integration scalability presents both opportunities and challenges as semiconductor process nodes continue to shrink. At sub-28nm nodes, the implementation of dual feedback paths requires careful consideration of layout constraints and parasitic effects. The reduced supply voltages in advanced nodes (often below 1V) necessitate innovative approaches to maintain adequate noise margins while preserving the hysteresis characteristics that make Schmitt triggers valuable.

Thermal considerations become increasingly important as integration density increases. Dual feedback Schmitt triggers must be designed with thermal gradients in mind, as temperature variations across a die can alter threshold voltages and compromise circuit reliability. Self-heating effects can be particularly problematic in high-frequency applications where rapid switching occurs.

Area efficiency represents another dimension of integration scalability. While dual feedback mechanisms inherently require additional components compared to single-feedback designs, recent architectural innovations have demonstrated area-neutral implementations through clever reuse of existing circuit elements. For instance, capacitive coupling techniques can implement virtual feedback paths without dedicated transistors, preserving silicon area.

Process variation sensitivity must be addressed for successful integration at scale. Dual feedback paths can be designed to provide complementary compensation effects, where process-induced shifts in one path are counterbalanced by the other. This approach has shown promising results in maintaining consistent hysteresis windows across process corners, enhancing manufacturing yield and operational reliability.

Looking forward, emerging technologies such as FinFET and FDSOI processes offer new opportunities for implementing dual feedback Schmitt triggers with improved power-performance characteristics. These advanced processes provide better electrostatic control and reduced leakage, enabling more efficient implementations that maintain robust operation at lower supply voltages.

Traditional Schmitt trigger designs often face power efficiency challenges due to their continuous current paths during state transitions. Dual feedback configurations can mitigate these issues by enabling more precise control over hysteresis thresholds, thereby reducing unnecessary switching events that consume power. Recent advancements have demonstrated power reductions of 15-30% compared to conventional single-feedback designs, particularly when implemented with complementary feedback paths that minimize static current draw.

Integration scalability presents both opportunities and challenges as semiconductor process nodes continue to shrink. At sub-28nm nodes, the implementation of dual feedback paths requires careful consideration of layout constraints and parasitic effects. The reduced supply voltages in advanced nodes (often below 1V) necessitate innovative approaches to maintain adequate noise margins while preserving the hysteresis characteristics that make Schmitt triggers valuable.

Thermal considerations become increasingly important as integration density increases. Dual feedback Schmitt triggers must be designed with thermal gradients in mind, as temperature variations across a die can alter threshold voltages and compromise circuit reliability. Self-heating effects can be particularly problematic in high-frequency applications where rapid switching occurs.

Area efficiency represents another dimension of integration scalability. While dual feedback mechanisms inherently require additional components compared to single-feedback designs, recent architectural innovations have demonstrated area-neutral implementations through clever reuse of existing circuit elements. For instance, capacitive coupling techniques can implement virtual feedback paths without dedicated transistors, preserving silicon area.

Process variation sensitivity must be addressed for successful integration at scale. Dual feedback paths can be designed to provide complementary compensation effects, where process-induced shifts in one path are counterbalanced by the other. This approach has shown promising results in maintaining consistent hysteresis windows across process corners, enhancing manufacturing yield and operational reliability.

Looking forward, emerging technologies such as FinFET and FDSOI processes offer new opportunities for implementing dual feedback Schmitt triggers with improved power-performance characteristics. These advanced processes provide better electrostatic control and reduced leakage, enabling more efficient implementations that maintain robust operation at lower supply voltages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!