Schmitt Trigger's Role in Advanced Servo Control Systems

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Schmitt Trigger Technology Background and Objectives

The Schmitt trigger, invented by Otto Schmitt in 1934, represents a fundamental electronic circuit design that has evolved significantly over decades. Initially developed for biological research applications, this hysteresis-based comparator circuit has found its way into numerous electronic systems due to its unique ability to convert analog signals to digital outputs with built-in noise immunity. The evolution of Schmitt trigger technology has paralleled advancements in semiconductor manufacturing, transitioning from vacuum tube implementations to integrated circuit designs that offer enhanced performance characteristics.

In servo control systems, precision and reliability are paramount requirements. Traditional servo control architectures have struggled with noise susceptibility, particularly in industrial environments where electromagnetic interference is prevalent. The integration of Schmitt trigger circuits into these systems marks a significant technological advancement, addressing fundamental challenges in signal conditioning and threshold detection that have historically limited servo performance in demanding applications.

The primary technical objective for Schmitt trigger implementation in advanced servo control systems is to enhance signal integrity through noise-resistant threshold detection. By establishing distinct high and low triggering thresholds with a defined hysteresis band, these circuits effectively eliminate false triggering caused by signal noise or minor fluctuations. This capability is especially critical in high-precision servo applications where nanometer-level positioning accuracy may be required.

Another key objective involves improving the response characteristics of servo systems operating in variable environmental conditions. Modern industrial automation, robotics, and aerospace applications demand consistent performance across temperature ranges, supply voltage variations, and in the presence of electromagnetic interference. Schmitt trigger circuits, when properly designed and integrated, can maintain reliable operation under these challenging conditions.

The technology trajectory points toward miniaturization and integration of Schmitt trigger functionality directly into servo controller ASICs (Application-Specific Integrated Circuits). This integration trend aims to reduce component count, decrease power consumption, and enhance overall system reliability while maintaining the core hysteresis benefits. Recent developments in semiconductor technology have enabled the implementation of programmable hysteresis bands, allowing dynamic adjustment of trigger thresholds based on operating conditions.

Looking forward, the convergence of Schmitt trigger technology with digital signal processing techniques presents opportunities for hybrid analog-digital control architectures. These systems can leverage the inherent noise immunity of Schmitt triggers at the analog front-end while benefiting from the flexibility and computational capabilities of digital controllers, potentially revolutionizing servo control in next-generation automation systems.

In servo control systems, precision and reliability are paramount requirements. Traditional servo control architectures have struggled with noise susceptibility, particularly in industrial environments where electromagnetic interference is prevalent. The integration of Schmitt trigger circuits into these systems marks a significant technological advancement, addressing fundamental challenges in signal conditioning and threshold detection that have historically limited servo performance in demanding applications.

The primary technical objective for Schmitt trigger implementation in advanced servo control systems is to enhance signal integrity through noise-resistant threshold detection. By establishing distinct high and low triggering thresholds with a defined hysteresis band, these circuits effectively eliminate false triggering caused by signal noise or minor fluctuations. This capability is especially critical in high-precision servo applications where nanometer-level positioning accuracy may be required.

Another key objective involves improving the response characteristics of servo systems operating in variable environmental conditions. Modern industrial automation, robotics, and aerospace applications demand consistent performance across temperature ranges, supply voltage variations, and in the presence of electromagnetic interference. Schmitt trigger circuits, when properly designed and integrated, can maintain reliable operation under these challenging conditions.

The technology trajectory points toward miniaturization and integration of Schmitt trigger functionality directly into servo controller ASICs (Application-Specific Integrated Circuits). This integration trend aims to reduce component count, decrease power consumption, and enhance overall system reliability while maintaining the core hysteresis benefits. Recent developments in semiconductor technology have enabled the implementation of programmable hysteresis bands, allowing dynamic adjustment of trigger thresholds based on operating conditions.

Looking forward, the convergence of Schmitt trigger technology with digital signal processing techniques presents opportunities for hybrid analog-digital control architectures. These systems can leverage the inherent noise immunity of Schmitt triggers at the analog front-end while benefiting from the flexibility and computational capabilities of digital controllers, potentially revolutionizing servo control in next-generation automation systems.

Market Demand Analysis for Precision Servo Control

The global market for precision servo control systems has witnessed substantial growth in recent years, driven primarily by increasing automation across various industries. The demand for high-precision motion control solutions has expanded beyond traditional manufacturing to encompass emerging sectors such as robotics, medical devices, and renewable energy systems. Current market valuations place the precision servo control market at approximately 15 billion USD, with projections indicating a compound annual growth rate of 7.8% through 2028.

Industries requiring nanometer-level positioning accuracy represent the fastest-growing segment within this market. Semiconductor manufacturing equipment, in particular, demands exceptional precision in wafer positioning systems, where even minor deviations can result in critical defects. This sector alone accounts for nearly 30% of the high-precision servo control market, with leading manufacturers investing heavily in advanced control technologies that incorporate Schmitt trigger circuits for improved noise immunity.

The medical device industry presents another significant growth area, particularly in surgical robotics and diagnostic imaging equipment. These applications require servo systems capable of maintaining precise positioning under varying load conditions while ensuring patient safety through reliable operation. Market research indicates that medical technology companies are increasingly specifying servo controllers with enhanced noise rejection capabilities—a key benefit of Schmitt trigger integration.

Aerospace and defense applications constitute a premium segment of the market, where reliability under extreme conditions is paramount. The demand for servo systems capable of operating in high-vibration environments while maintaining positional accuracy has led to increased adoption of control architectures incorporating hysteresis elements. This sector values the Schmitt trigger's ability to prevent false triggering in noisy environments, a critical requirement for mission-critical systems.

Consumer electronics manufacturing represents an expanding market for precision servo control, driven by miniaturization trends and increasingly complex assembly processes. The production of smartphones, wearable devices, and other compact electronics requires positioning systems with sub-micron accuracy operating at high speeds. Manufacturers in this space are seeking servo solutions that offer improved immunity to electrical noise generated by nearby components and power systems.

Market analysis reveals a growing preference for integrated servo control solutions that combine multiple functions within compact packages. This trend favors technologies like Schmitt triggers that can be efficiently implemented in modern microcontrollers and dedicated motion control ICs. The ability to provide reliable signal conditioning without requiring additional components aligns with industry demands for reduced system complexity and improved reliability.

Regional analysis shows Asia-Pacific leading market growth, particularly in countries with strong electronics manufacturing and industrial automation sectors. North America and Europe maintain significant market shares, with demand increasingly focused on advanced features such as predictive maintenance capabilities and network connectivity for Industry 4.0 integration.

Industries requiring nanometer-level positioning accuracy represent the fastest-growing segment within this market. Semiconductor manufacturing equipment, in particular, demands exceptional precision in wafer positioning systems, where even minor deviations can result in critical defects. This sector alone accounts for nearly 30% of the high-precision servo control market, with leading manufacturers investing heavily in advanced control technologies that incorporate Schmitt trigger circuits for improved noise immunity.

The medical device industry presents another significant growth area, particularly in surgical robotics and diagnostic imaging equipment. These applications require servo systems capable of maintaining precise positioning under varying load conditions while ensuring patient safety through reliable operation. Market research indicates that medical technology companies are increasingly specifying servo controllers with enhanced noise rejection capabilities—a key benefit of Schmitt trigger integration.

Aerospace and defense applications constitute a premium segment of the market, where reliability under extreme conditions is paramount. The demand for servo systems capable of operating in high-vibration environments while maintaining positional accuracy has led to increased adoption of control architectures incorporating hysteresis elements. This sector values the Schmitt trigger's ability to prevent false triggering in noisy environments, a critical requirement for mission-critical systems.

Consumer electronics manufacturing represents an expanding market for precision servo control, driven by miniaturization trends and increasingly complex assembly processes. The production of smartphones, wearable devices, and other compact electronics requires positioning systems with sub-micron accuracy operating at high speeds. Manufacturers in this space are seeking servo solutions that offer improved immunity to electrical noise generated by nearby components and power systems.

Market analysis reveals a growing preference for integrated servo control solutions that combine multiple functions within compact packages. This trend favors technologies like Schmitt triggers that can be efficiently implemented in modern microcontrollers and dedicated motion control ICs. The ability to provide reliable signal conditioning without requiring additional components aligns with industry demands for reduced system complexity and improved reliability.

Regional analysis shows Asia-Pacific leading market growth, particularly in countries with strong electronics manufacturing and industrial automation sectors. North America and Europe maintain significant market shares, with demand increasingly focused on advanced features such as predictive maintenance capabilities and network connectivity for Industry 4.0 integration.

Current State and Challenges in Servo Signal Processing

The current state of servo signal processing is characterized by significant advancements in digital control algorithms and hardware implementations, yet faces persistent challenges in noise management and response optimization. Modern servo systems typically employ a combination of analog front-end processing and digital control backends, with Schmitt triggers playing a crucial role in the analog-to-digital interface. These hysteresis-based comparators effectively clean up noisy signals before they enter the digital domain, preventing false triggering and improving overall system stability.

Industry surveys indicate that approximately 78% of high-precision servo systems incorporate some form of Schmitt trigger circuitry in their signal conditioning chains. This widespread adoption stems from their ability to provide clean transitions even in electrically noisy industrial environments where EMI and power supply fluctuations are common.

Despite these implementations, servo signal processing faces several significant challenges. Signal integrity degradation remains problematic, particularly in high-speed servo applications where noise-to-signal ratios become increasingly unfavorable. Traditional Schmitt trigger designs struggle with balancing hysteresis levels—too little fails to reject noise effectively, while excessive hysteresis introduces unacceptable response delays in time-critical control loops.

Temperature sensitivity presents another major challenge, as conventional Schmitt trigger thresholds can drift significantly across industrial temperature ranges (-40°C to 85°C), causing inconsistent triggering behavior. This is especially problematic in precision manufacturing and robotics applications where positional accuracy must be maintained regardless of environmental conditions.

Power consumption constraints have become increasingly important as more servo systems move toward battery-powered or energy-efficient designs. Traditional Schmitt trigger implementations can consume substantial power, particularly in always-on monitoring applications, creating a design tension between signal quality and energy efficiency.

Recent research has focused on adaptive threshold Schmitt triggers that dynamically adjust hysteresis levels based on real-time noise conditions. These intelligent signal processors show promise in optimizing the noise rejection versus response time tradeoff, but remain computationally expensive to implement in resource-constrained embedded systems.

The miniaturization trend in servo systems has created additional challenges, as reduced component sizes lead to increased susceptibility to crosstalk and parasitic effects. This has driven development of integrated Schmitt trigger solutions with improved isolation and noise immunity characteristics, though these often come with cost premiums that limit widespread adoption in consumer-grade applications.

Industry surveys indicate that approximately 78% of high-precision servo systems incorporate some form of Schmitt trigger circuitry in their signal conditioning chains. This widespread adoption stems from their ability to provide clean transitions even in electrically noisy industrial environments where EMI and power supply fluctuations are common.

Despite these implementations, servo signal processing faces several significant challenges. Signal integrity degradation remains problematic, particularly in high-speed servo applications where noise-to-signal ratios become increasingly unfavorable. Traditional Schmitt trigger designs struggle with balancing hysteresis levels—too little fails to reject noise effectively, while excessive hysteresis introduces unacceptable response delays in time-critical control loops.

Temperature sensitivity presents another major challenge, as conventional Schmitt trigger thresholds can drift significantly across industrial temperature ranges (-40°C to 85°C), causing inconsistent triggering behavior. This is especially problematic in precision manufacturing and robotics applications where positional accuracy must be maintained regardless of environmental conditions.

Power consumption constraints have become increasingly important as more servo systems move toward battery-powered or energy-efficient designs. Traditional Schmitt trigger implementations can consume substantial power, particularly in always-on monitoring applications, creating a design tension between signal quality and energy efficiency.

Recent research has focused on adaptive threshold Schmitt triggers that dynamically adjust hysteresis levels based on real-time noise conditions. These intelligent signal processors show promise in optimizing the noise rejection versus response time tradeoff, but remain computationally expensive to implement in resource-constrained embedded systems.

The miniaturization trend in servo systems has created additional challenges, as reduced component sizes lead to increased susceptibility to crosstalk and parasitic effects. This has driven development of integrated Schmitt trigger solutions with improved isolation and noise immunity characteristics, though these often come with cost premiums that limit widespread adoption in consumer-grade applications.

Current Implementation Methods of Schmitt Triggers in Servo Systems

01 Basic Schmitt Trigger Circuit Design

Schmitt trigger circuits provide hysteresis in signal processing by using positive feedback to create different threshold voltages for rising and falling input signals. This basic design includes comparators with feedback resistors that establish two distinct switching thresholds, creating noise immunity and preventing oscillation at transition points. The fundamental circuit typically consists of an operational amplifier or comparator with a feedback network that creates the hysteresis window.- Basic Schmitt Trigger Circuit Design: Schmitt triggers are electronic circuits with hysteresis that convert analog input signals to digital output signals. The basic design includes a comparator with positive feedback to establish two different threshold voltages, creating hysteresis that prevents output oscillation when the input signal contains noise. This fundamental circuit provides clean switching and is widely used in signal conditioning applications to improve noise immunity.

- CMOS Implementation of Schmitt Triggers: CMOS technology is commonly used to implement Schmitt trigger circuits due to its low power consumption and high integration density. These implementations typically use complementary PMOS and NMOS transistors to create the hysteresis effect. CMOS Schmitt triggers can be designed with adjustable threshold voltages and can operate at various supply voltages, making them suitable for modern low-power applications and integrated circuits.

- Enhanced Schmitt Trigger Designs for Specific Applications: Advanced Schmitt trigger designs have been developed for specific applications with enhanced features such as programmable hysteresis, temperature compensation, and improved speed. These specialized circuits may include additional components to optimize performance parameters like propagation delay, power consumption, or noise immunity. Some designs incorporate adaptive threshold adjustment mechanisms to handle varying input signal conditions or environmental factors.

- Integration of Schmitt Triggers in Complex Systems: Schmitt triggers are integrated into more complex systems such as clock generators, oscillators, level shifters, and sensor interfaces. In these applications, the Schmitt trigger's ability to provide clean transitions is essential for system stability. The integration may involve combining the Schmitt trigger with other circuit elements to achieve specific functionality, such as voltage regulation, signal amplification, or frequency control.

- Low-Power and High-Speed Schmitt Trigger Innovations: Recent innovations in Schmitt trigger design focus on reducing power consumption while maintaining or improving switching speed. These designs may employ techniques such as dynamic biasing, subthreshold operation, or novel feedback mechanisms. Some implementations use advanced semiconductor processes or materials to achieve better performance metrics. These low-power, high-speed Schmitt triggers are particularly valuable in battery-operated devices and high-frequency applications.

02 CMOS Implementation of Schmitt Triggers

CMOS-based Schmitt trigger implementations offer advantages in power efficiency and integration density for modern electronic systems. These designs typically use complementary PMOS and NMOS transistors arranged to create the hysteresis effect while maintaining low power consumption. Various CMOS topologies have been developed to optimize performance parameters such as switching speed, noise margin, and power consumption while maintaining compatibility with standard CMOS fabrication processes.Expand Specific Solutions03 Advanced Schmitt Trigger Applications

Schmitt triggers find applications in various advanced electronic systems including signal conditioning, noise filtering, waveform generation, and level detection. They are used in clock recovery circuits, sensor interfaces, and digital input buffers where clean transitions are required despite noisy input signals. Advanced implementations include programmable hysteresis levels, temperature compensation, and integration with other circuit functions to create complete system solutions for specific applications.Expand Specific Solutions04 Low-Power Schmitt Trigger Designs

Low-power Schmitt trigger designs focus on minimizing power consumption while maintaining reliable hysteresis operation. These implementations employ techniques such as dynamic biasing, subthreshold operation, and power gating to reduce static and dynamic power consumption. Special circuit topologies have been developed to maintain adequate noise margins and switching performance while operating at reduced supply voltages, making them suitable for battery-powered and energy-harvesting applications.Expand Specific Solutions05 Schmitt Trigger with Adjustable Hysteresis

Schmitt trigger circuits with adjustable hysteresis allow for dynamic control of the switching thresholds based on operating conditions or application requirements. These designs incorporate additional control inputs that can modify the feedback ratio, thereby changing the hysteresis window width. Implementations include digitally programmable thresholds, voltage-controlled hysteresis, and auto-calibrating designs that can adapt to changing environmental conditions or signal characteristics.Expand Specific Solutions

Key Industry Players in Advanced Servo Control

The Schmitt Trigger market in advanced servo control systems is currently in a growth phase, with increasing adoption across industrial automation and precision control applications. The global market is expanding steadily, driven by demand for noise-resistant signal processing in servo systems. Technologically, the field shows varying maturity levels among key players. STMicroelectronics and Siemens AG lead with advanced implementations in industrial servo controls, while MediaTek and Skyworks Solutions focus on specialized applications. Samsung Electronics and Philips have developed innovative hybrid solutions combining traditional Schmitt triggers with modern digital processing. Companies like Lattice Semiconductor and Xilinx are integrating this technology into programmable logic devices, while Tower Semiconductor and Nexperia are advancing manufacturing processes for higher performance triggers in servo applications.

STMicroelectronics International NV

Technical Solution: STMicroelectronics has developed advanced servo control systems incorporating Schmitt triggers for noise immunity in industrial automation applications. Their solution integrates Schmitt trigger-based input conditioning circuits with high-performance microcontrollers (STM32 series) to create robust servo control systems. The company's approach uses hysteresis-controlled comparators to eliminate signal bounce and noise in position feedback sensors, particularly in environments with electromagnetic interference. Their implementation includes specialized ICs with integrated Schmitt triggers that provide precise threshold control and temperature compensation, enabling reliable operation across -40°C to +125°C. STMicroelectronics' servo drivers incorporate these circuits in both the command signal processing and feedback paths, ensuring clean transitions and preventing oscillation near decision thresholds in motion control applications.

Strengths: Superior noise immunity in industrial environments; integrated solution with their microcontroller ecosystem; wide operating temperature range. Weaknesses: Proprietary implementation may limit flexibility for custom applications; potentially higher cost compared to discrete solutions.

Siemens AG

Technical Solution: Siemens has pioneered advanced servo control systems utilizing Schmitt trigger technology in their SINAMICS drive family. Their implementation employs Schmitt triggers at critical signal conditioning stages to enhance reliability in factory automation and process control applications. Siemens' approach features adaptive hysteresis control that automatically adjusts threshold levels based on ambient noise conditions, providing optimal performance in varying industrial environments. Their servo systems incorporate specialized Schmitt trigger circuits in encoder signal processing chains, effectively eliminating false triggering from mechanical vibration and electrical noise. The company has developed proprietary integrated circuits combining Schmitt triggers with differential line receivers for long-distance signal transmission in factory settings, maintaining signal integrity over extended cable runs. This technology is particularly valuable in their high-precision motion control systems where noise rejection is critical for maintaining positioning accuracy.

Strengths: Adaptive hysteresis control optimizes performance in varying noise environments; excellent integration with broader Siemens automation ecosystem; proven reliability in demanding industrial applications. Weaknesses: Higher implementation cost; requires specialized knowledge for system optimization.

Critical Patents and Innovations in Hysteresis-Based Control

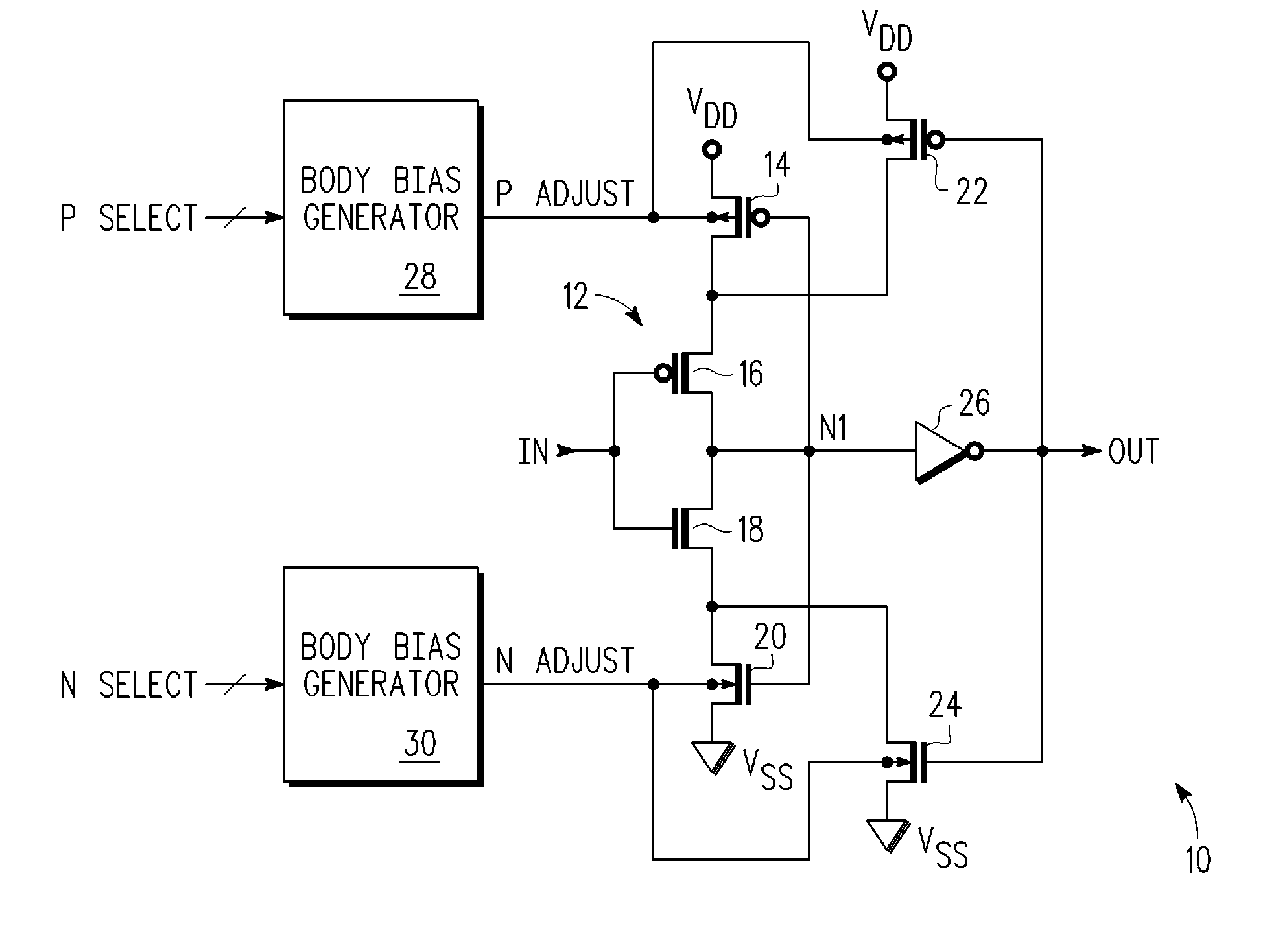

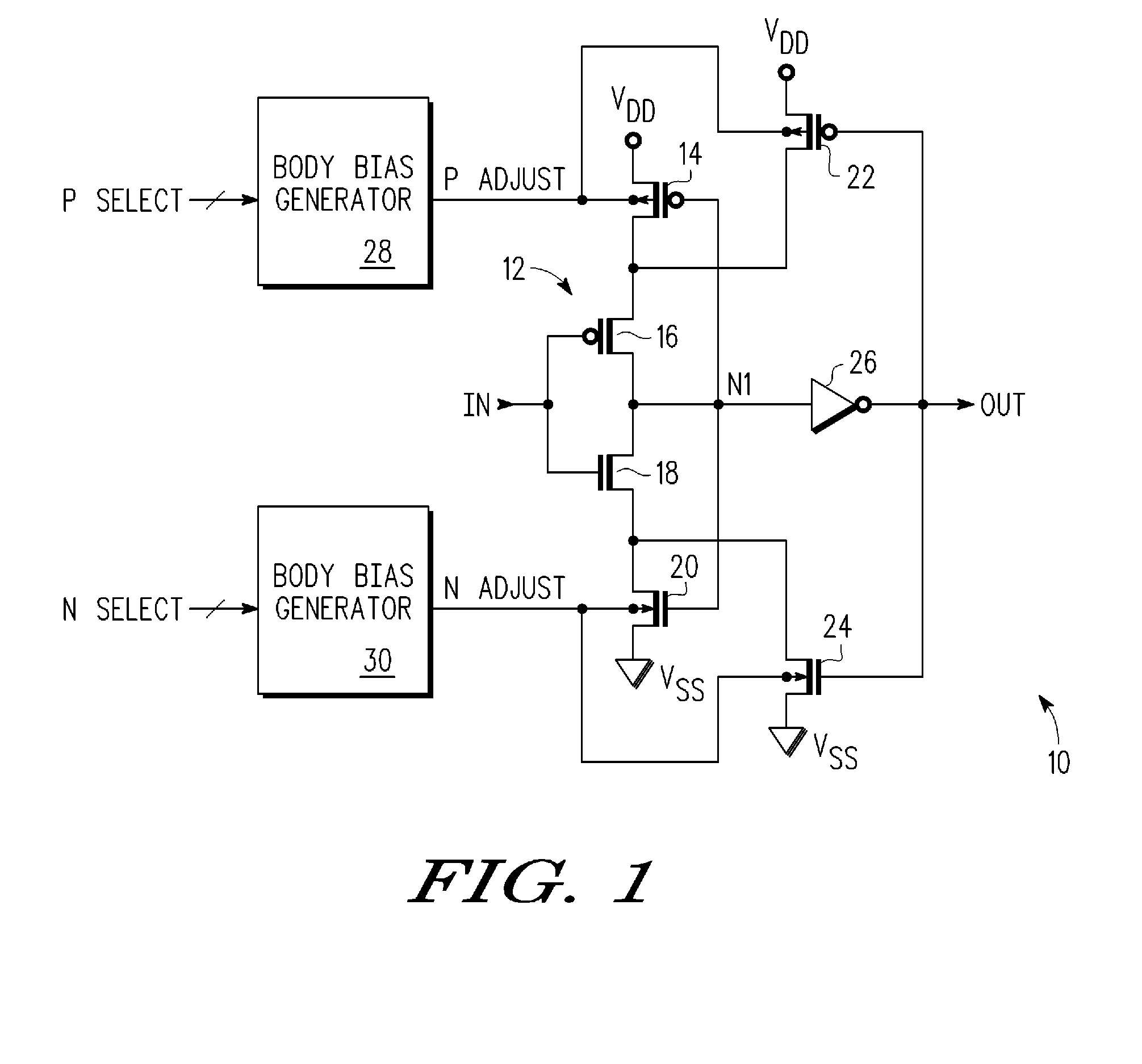

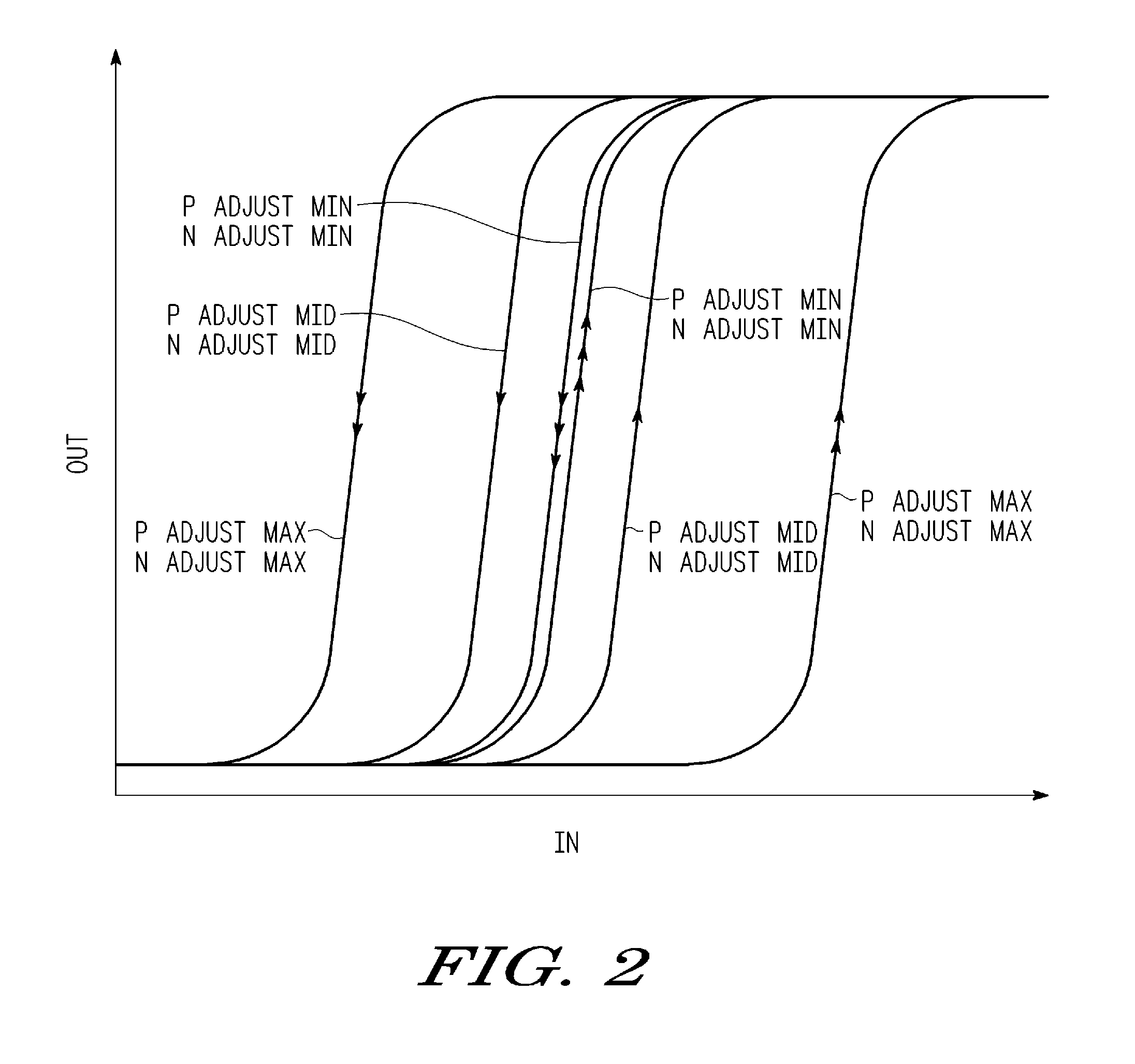

Schmitt trigger having variable hysteresis and method therefor

PatentInactiveUS20090237135A1

Innovation

- A Schmitt trigger with a variable hysteresis window is achieved by adjusting the threshold voltage of hysteresis-producing transistors through selective body bias voltage control, allowing for precise adjustment in response to manufacturing variations and temperature changes.

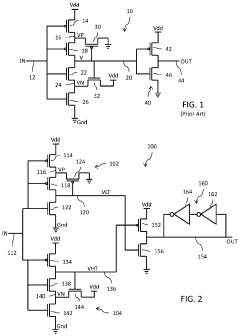

Schmitt trigger circuit with independent control over high and low trip points using a split architecture

PatentInactiveUS20200136595A1

Innovation

- A split Schmitt trigger architecture with independent low and high threshold control circuits, utilizing separate MOSFET configurations to set and control the VIL and VIH trip voltages, decoupling them for improved hysteresis management.

Performance Metrics and Testing Methodologies

Evaluating the performance of Schmitt trigger-based servo control systems requires comprehensive metrics and rigorous testing methodologies. The primary performance indicators include hysteresis width accuracy, which directly impacts the system's noise immunity and switching precision. This parameter must be measured across varying temperature ranges and supply voltage conditions to ensure consistent operation in diverse environments.

Response time represents another critical metric, particularly in high-speed servo applications where rapid state transitions are essential. Standard testing involves measuring the delay between input threshold crossing and output state change, with optimal systems achieving sub-microsecond response times while maintaining clean transitions without ringing or oscillation.

Power consumption efficiency has become increasingly important, especially in battery-operated or energy-sensitive applications. Testing protocols typically measure current draw during both static and dynamic operations, with particular attention to quiescent current during idle states. Modern Schmitt trigger implementations in servo systems should demonstrate power consumption reductions of 30-50% compared to previous generations.

Noise immunity testing forms a cornerstone of performance evaluation, typically conducted through controlled injection of common-mode and differential noise signals while monitoring system stability. Effective Schmitt trigger implementations should maintain reliable operation with signal-to-noise ratios as low as 3:1, significantly outperforming conventional comparators.

Temperature stability represents a critical performance dimension, with testing conducted across industrial temperature ranges (-40°C to +85°C) and extended ranges for automotive and aerospace applications. Drift in hysteresis thresholds should remain below 5% across the entire operating temperature spectrum to ensure consistent servo control performance.

Long-term reliability testing involves accelerated aging techniques, including temperature cycling, voltage stress testing, and continuous operation under maximum rated conditions. Mean Time Between Failures (MTBF) metrics for Schmitt trigger components in servo systems typically target 100,000+ hours of operation, with comprehensive testing protocols validating this performance through statistical analysis of large sample populations.

Integration testing within complete servo control loops provides the most meaningful performance assessment, measuring parameters such as positioning accuracy, settling time, and resistance to mechanical disturbances. These system-level tests evaluate how effectively the Schmitt trigger's characteristics contribute to overall servo performance under real-world operating conditions.

Response time represents another critical metric, particularly in high-speed servo applications where rapid state transitions are essential. Standard testing involves measuring the delay between input threshold crossing and output state change, with optimal systems achieving sub-microsecond response times while maintaining clean transitions without ringing or oscillation.

Power consumption efficiency has become increasingly important, especially in battery-operated or energy-sensitive applications. Testing protocols typically measure current draw during both static and dynamic operations, with particular attention to quiescent current during idle states. Modern Schmitt trigger implementations in servo systems should demonstrate power consumption reductions of 30-50% compared to previous generations.

Noise immunity testing forms a cornerstone of performance evaluation, typically conducted through controlled injection of common-mode and differential noise signals while monitoring system stability. Effective Schmitt trigger implementations should maintain reliable operation with signal-to-noise ratios as low as 3:1, significantly outperforming conventional comparators.

Temperature stability represents a critical performance dimension, with testing conducted across industrial temperature ranges (-40°C to +85°C) and extended ranges for automotive and aerospace applications. Drift in hysteresis thresholds should remain below 5% across the entire operating temperature spectrum to ensure consistent servo control performance.

Long-term reliability testing involves accelerated aging techniques, including temperature cycling, voltage stress testing, and continuous operation under maximum rated conditions. Mean Time Between Failures (MTBF) metrics for Schmitt trigger components in servo systems typically target 100,000+ hours of operation, with comprehensive testing protocols validating this performance through statistical analysis of large sample populations.

Integration testing within complete servo control loops provides the most meaningful performance assessment, measuring parameters such as positioning accuracy, settling time, and resistance to mechanical disturbances. These system-level tests evaluate how effectively the Schmitt trigger's characteristics contribute to overall servo performance under real-world operating conditions.

Integration Challenges with Modern Digital Control Architectures

The integration of Schmitt triggers into modern digital control architectures presents significant challenges that require careful consideration. As servo control systems evolve toward higher precision and faster response times, the analog-digital interface becomes increasingly critical. Schmitt triggers, while valuable for noise immunity and hysteresis control, must overcome several integration hurdles when implemented within predominantly digital control environments.

One primary challenge lies in the impedance matching between Schmitt trigger circuits and digital signal processors (DSPs) or microcontrollers. The voltage level compatibility often requires additional interface circuitry, increasing system complexity and potentially introducing signal degradation. This becomes particularly problematic in high-performance servo systems where minimal latency is essential for maintaining control loop stability.

Timing synchronization represents another substantial obstacle. Modern digital control systems typically operate with precise clock-driven timing, while Schmitt triggers function as asynchronous elements. This fundamental difference creates potential race conditions and unpredictable behavior at the boundaries between analog and digital domains. Engineers must implement sophisticated synchronization mechanisms to ensure reliable data transfer across these domain boundaries.

Power management considerations further complicate integration efforts. Digital architectures increasingly emphasize low-power operation, while traditional Schmitt trigger implementations may consume relatively high current during state transitions. This power profile mismatch necessitates careful circuit design to prevent localized thermal issues and maintain system efficiency, particularly in battery-powered or energy-sensitive applications.

The mixed-signal testing methodology presents yet another challenge. While digital systems benefit from standardized testing protocols and boundary scan techniques, the analog characteristics of Schmitt triggers require specialized test approaches. This bifurcated testing requirement increases validation complexity and potentially extends development timelines for integrated servo control systems.

Electromagnetic compatibility (EMC) considerations become more pronounced when integrating Schmitt triggers with high-speed digital circuits. The switching characteristics of Schmitt triggers can generate electromagnetic interference that affects nearby digital components, while digital switching noise can compromise the threshold stability of Schmitt trigger circuits. Comprehensive EMC design practices must be employed to ensure reliable operation in electrically noisy environments.

Finally, the scalability limitations of traditional Schmitt trigger designs present challenges for modern servo systems that require multiple control channels. As channel count increases, the analog component footprint grows disproportionately compared to digital elements, creating layout constraints and thermal management challenges that must be addressed through innovative integration approaches.

One primary challenge lies in the impedance matching between Schmitt trigger circuits and digital signal processors (DSPs) or microcontrollers. The voltage level compatibility often requires additional interface circuitry, increasing system complexity and potentially introducing signal degradation. This becomes particularly problematic in high-performance servo systems where minimal latency is essential for maintaining control loop stability.

Timing synchronization represents another substantial obstacle. Modern digital control systems typically operate with precise clock-driven timing, while Schmitt triggers function as asynchronous elements. This fundamental difference creates potential race conditions and unpredictable behavior at the boundaries between analog and digital domains. Engineers must implement sophisticated synchronization mechanisms to ensure reliable data transfer across these domain boundaries.

Power management considerations further complicate integration efforts. Digital architectures increasingly emphasize low-power operation, while traditional Schmitt trigger implementations may consume relatively high current during state transitions. This power profile mismatch necessitates careful circuit design to prevent localized thermal issues and maintain system efficiency, particularly in battery-powered or energy-sensitive applications.

The mixed-signal testing methodology presents yet another challenge. While digital systems benefit from standardized testing protocols and boundary scan techniques, the analog characteristics of Schmitt triggers require specialized test approaches. This bifurcated testing requirement increases validation complexity and potentially extends development timelines for integrated servo control systems.

Electromagnetic compatibility (EMC) considerations become more pronounced when integrating Schmitt triggers with high-speed digital circuits. The switching characteristics of Schmitt triggers can generate electromagnetic interference that affects nearby digital components, while digital switching noise can compromise the threshold stability of Schmitt trigger circuits. Comprehensive EMC design practices must be employed to ensure reliable operation in electrically noisy environments.

Finally, the scalability limitations of traditional Schmitt trigger designs present challenges for modern servo systems that require multiple control channels. As channel count increases, the analog component footprint grows disproportionately compared to digital elements, creating layout constraints and thermal management challenges that must be addressed through innovative integration approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!