Minimize Crosstalk in Circuitry Using Schmitt Trigger

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Schmitt Trigger Technology Background and Objectives

The Schmitt trigger, invented by Otto Schmitt in 1934, represents a significant milestone in electronic circuit design, particularly for noise immunity applications. This hysteresis-based comparator circuit has evolved from vacuum tube implementations to modern semiconductor designs, becoming a fundamental building block in digital and analog systems. The technology's evolution has been driven by the increasing demand for reliable signal processing in noisy environments, especially as electronic devices have become more compact and complex.

In contemporary electronic systems, crosstalk has emerged as a critical challenge that threatens signal integrity. As circuit densities increase and operating frequencies rise, the electromagnetic interference between adjacent signal paths can cause false triggering, data corruption, and system instability. Traditional threshold detection circuits often fail to provide adequate noise immunity in these environments, necessitating more robust solutions.

The Schmitt trigger's unique hysteresis characteristic offers a promising approach to mitigating crosstalk effects. By implementing different thresholds for rising and falling signals, the circuit creates a "dead zone" that prevents noise-induced oscillations and false triggering. This fundamental property makes Schmitt triggers particularly valuable in mixed-signal environments where digital and analog circuits must coexist.

Recent technological advancements have expanded the application scope of Schmitt triggers beyond simple noise filtering. Modern implementations incorporate adaptive threshold adjustment, reduced power consumption, and enhanced switching speeds. These improvements have positioned Schmitt triggers as essential components in high-speed data transmission systems, sensor interfaces, and power management circuits.

The primary objective of this technical research is to comprehensively evaluate how Schmitt trigger technology can be optimized specifically for crosstalk mitigation in contemporary circuit designs. This includes investigating advanced implementation techniques, analyzing performance metrics under various noise conditions, and identifying optimal design parameters for different application scenarios.

Additionally, this research aims to explore emerging Schmitt trigger architectures that address the challenges of ultra-low power applications and high-frequency operations. By examining both traditional CMOS implementations and novel approaches using alternative semiconductor technologies, we seek to establish design guidelines that maximize crosstalk immunity while minimizing power consumption and circuit complexity.

The ultimate goal is to develop a technical framework that enables engineers to systematically implement Schmitt trigger-based solutions for crosstalk problems across diverse electronic systems, from consumer electronics to industrial control systems and telecommunications infrastructure. This framework will incorporate both theoretical models and practical design considerations to bridge the gap between academic research and industrial applications.

In contemporary electronic systems, crosstalk has emerged as a critical challenge that threatens signal integrity. As circuit densities increase and operating frequencies rise, the electromagnetic interference between adjacent signal paths can cause false triggering, data corruption, and system instability. Traditional threshold detection circuits often fail to provide adequate noise immunity in these environments, necessitating more robust solutions.

The Schmitt trigger's unique hysteresis characteristic offers a promising approach to mitigating crosstalk effects. By implementing different thresholds for rising and falling signals, the circuit creates a "dead zone" that prevents noise-induced oscillations and false triggering. This fundamental property makes Schmitt triggers particularly valuable in mixed-signal environments where digital and analog circuits must coexist.

Recent technological advancements have expanded the application scope of Schmitt triggers beyond simple noise filtering. Modern implementations incorporate adaptive threshold adjustment, reduced power consumption, and enhanced switching speeds. These improvements have positioned Schmitt triggers as essential components in high-speed data transmission systems, sensor interfaces, and power management circuits.

The primary objective of this technical research is to comprehensively evaluate how Schmitt trigger technology can be optimized specifically for crosstalk mitigation in contemporary circuit designs. This includes investigating advanced implementation techniques, analyzing performance metrics under various noise conditions, and identifying optimal design parameters for different application scenarios.

Additionally, this research aims to explore emerging Schmitt trigger architectures that address the challenges of ultra-low power applications and high-frequency operations. By examining both traditional CMOS implementations and novel approaches using alternative semiconductor technologies, we seek to establish design guidelines that maximize crosstalk immunity while minimizing power consumption and circuit complexity.

The ultimate goal is to develop a technical framework that enables engineers to systematically implement Schmitt trigger-based solutions for crosstalk problems across diverse electronic systems, from consumer electronics to industrial control systems and telecommunications infrastructure. This framework will incorporate both theoretical models and practical design considerations to bridge the gap between academic research and industrial applications.

Market Demand for Crosstalk Reduction Solutions

The global market for crosstalk reduction solutions has experienced significant growth in recent years, driven primarily by the increasing complexity of electronic systems and the continuous miniaturization of circuit components. As device dimensions shrink and operating frequencies increase, the problem of signal interference between adjacent conductors has become more pronounced, creating substantial demand for effective crosstalk mitigation technologies.

The telecommunications sector represents one of the largest markets for crosstalk reduction solutions, with high-speed data transmission systems requiring exceptional signal integrity. According to industry analyses, this sector alone accounts for approximately 35% of the total market demand. The rapid deployment of 5G infrastructure worldwide has further accelerated this demand, as these networks operate at significantly higher frequencies where crosstalk issues are more severe.

Consumer electronics manufacturers constitute another major market segment, particularly as devices become smaller while incorporating more functionality. The trend toward thinner smartphones, tablets, and laptops has resulted in circuit boards with densely packed traces, creating ideal conditions for crosstalk. This segment has shown consistent annual growth rates exceeding the overall electronics market by 3-4 percentage points.

The automotive industry has emerged as a rapidly expanding market for crosstalk reduction technologies. Modern vehicles contain numerous electronic control units and advanced driver assistance systems that rely on precise signal processing. The transition toward electric and autonomous vehicles has intensified this demand, as these platforms incorporate substantially more electronic components operating at higher frequencies than traditional vehicles.

Medical device manufacturers represent a premium segment of the market, where signal integrity is critical for diagnostic accuracy and patient safety. This sector demands highly reliable solutions and shows willingness to adopt advanced technologies like Schmitt triggers despite potentially higher implementation costs.

Industrial automation and aerospace/defense sectors also contribute significantly to market demand, with both requiring robust solutions that can operate reliably in harsh environments. These sectors value long-term reliability over initial cost considerations, making them ideal targets for advanced crosstalk reduction technologies.

Market forecasts indicate that the global crosstalk reduction solutions market will continue to expand at a compound annual growth rate of approximately 8% through 2028, reaching a market value significantly higher than current levels. This growth trajectory is supported by the accelerating digitalization across industries and the increasing adoption of high-frequency applications in consumer and industrial products.

The telecommunications sector represents one of the largest markets for crosstalk reduction solutions, with high-speed data transmission systems requiring exceptional signal integrity. According to industry analyses, this sector alone accounts for approximately 35% of the total market demand. The rapid deployment of 5G infrastructure worldwide has further accelerated this demand, as these networks operate at significantly higher frequencies where crosstalk issues are more severe.

Consumer electronics manufacturers constitute another major market segment, particularly as devices become smaller while incorporating more functionality. The trend toward thinner smartphones, tablets, and laptops has resulted in circuit boards with densely packed traces, creating ideal conditions for crosstalk. This segment has shown consistent annual growth rates exceeding the overall electronics market by 3-4 percentage points.

The automotive industry has emerged as a rapidly expanding market for crosstalk reduction technologies. Modern vehicles contain numerous electronic control units and advanced driver assistance systems that rely on precise signal processing. The transition toward electric and autonomous vehicles has intensified this demand, as these platforms incorporate substantially more electronic components operating at higher frequencies than traditional vehicles.

Medical device manufacturers represent a premium segment of the market, where signal integrity is critical for diagnostic accuracy and patient safety. This sector demands highly reliable solutions and shows willingness to adopt advanced technologies like Schmitt triggers despite potentially higher implementation costs.

Industrial automation and aerospace/defense sectors also contribute significantly to market demand, with both requiring robust solutions that can operate reliably in harsh environments. These sectors value long-term reliability over initial cost considerations, making them ideal targets for advanced crosstalk reduction technologies.

Market forecasts indicate that the global crosstalk reduction solutions market will continue to expand at a compound annual growth rate of approximately 8% through 2028, reaching a market value significantly higher than current levels. This growth trajectory is supported by the accelerating digitalization across industries and the increasing adoption of high-frequency applications in consumer and industrial products.

Current Challenges in Crosstalk Minimization

Crosstalk in electronic circuits represents one of the most persistent challenges in modern circuit design, particularly as device dimensions continue to shrink and operating frequencies increase. The fundamental issue stems from unwanted electromagnetic coupling between adjacent signal paths, creating signal integrity problems that can compromise system reliability. In high-density circuit boards and integrated circuits, the proximity of conductors creates parasitic capacitive and inductive coupling, allowing signals from one trace to interfere with neighboring traces.

The severity of crosstalk issues has intensified with the industry's push toward higher clock speeds and reduced form factors. As signal rise and fall times decrease to support faster data rates, the higher-frequency components of these signals couple more efficiently to adjacent conductors. This creates a technical paradox where improvements in one area of performance (speed) directly exacerbate challenges in another (signal integrity).

Current mitigation techniques such as guard traces, increased spacing, and differential signaling provide partial solutions but introduce trade-offs in terms of board space, design complexity, and manufacturing cost. Traditional threshold-based receivers remain vulnerable to noise near the switching threshold, creating a critical weakness in high-noise environments. This vulnerability becomes particularly problematic in industrial applications, automotive systems, and other environments with significant electromagnetic interference.

The implementation of filtering techniques to reduce crosstalk often introduces unacceptable signal delays or bandwidth limitations. While sophisticated signal processing algorithms can help identify and remove crosstalk effects in digital systems, they typically require significant computational resources and introduce latency that may be unacceptable for real-time applications.

Power consumption presents another significant challenge, as many existing crosstalk mitigation techniques require active components that increase the overall energy footprint of the system. This becomes particularly problematic in battery-powered devices and energy-efficient designs where power budgets are strictly limited.

The lack of standardized testing methodologies for crosstalk characterization further complicates the development of effective solutions. Engineers often rely on proprietary testing approaches or simplified models that may not accurately represent real-world conditions, leading to unexpected performance issues when designs are deployed in actual applications.

Schmitt trigger circuits offer promising capabilities for addressing these challenges through their inherent hysteresis properties, but their traditional implementations face limitations in terms of speed, power consumption, and adaptability to varying noise environments. The fixed hysteresis thresholds in conventional Schmitt trigger designs may be insufficient for environments where noise characteristics change dynamically, necessitating more sophisticated approaches that can adjust to changing conditions.

The severity of crosstalk issues has intensified with the industry's push toward higher clock speeds and reduced form factors. As signal rise and fall times decrease to support faster data rates, the higher-frequency components of these signals couple more efficiently to adjacent conductors. This creates a technical paradox where improvements in one area of performance (speed) directly exacerbate challenges in another (signal integrity).

Current mitigation techniques such as guard traces, increased spacing, and differential signaling provide partial solutions but introduce trade-offs in terms of board space, design complexity, and manufacturing cost. Traditional threshold-based receivers remain vulnerable to noise near the switching threshold, creating a critical weakness in high-noise environments. This vulnerability becomes particularly problematic in industrial applications, automotive systems, and other environments with significant electromagnetic interference.

The implementation of filtering techniques to reduce crosstalk often introduces unacceptable signal delays or bandwidth limitations. While sophisticated signal processing algorithms can help identify and remove crosstalk effects in digital systems, they typically require significant computational resources and introduce latency that may be unacceptable for real-time applications.

Power consumption presents another significant challenge, as many existing crosstalk mitigation techniques require active components that increase the overall energy footprint of the system. This becomes particularly problematic in battery-powered devices and energy-efficient designs where power budgets are strictly limited.

The lack of standardized testing methodologies for crosstalk characterization further complicates the development of effective solutions. Engineers often rely on proprietary testing approaches or simplified models that may not accurately represent real-world conditions, leading to unexpected performance issues when designs are deployed in actual applications.

Schmitt trigger circuits offer promising capabilities for addressing these challenges through their inherent hysteresis properties, but their traditional implementations face limitations in terms of speed, power consumption, and adaptability to varying noise environments. The fixed hysteresis thresholds in conventional Schmitt trigger designs may be insufficient for environments where noise characteristics change dynamically, necessitating more sophisticated approaches that can adjust to changing conditions.

Existing Schmitt Trigger Implementation Methods

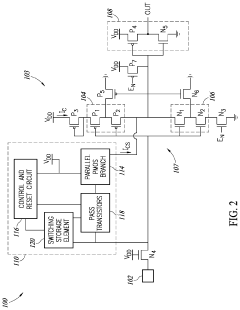

01 Schmitt trigger circuit designs to reduce crosstalk

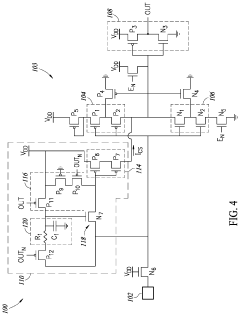

Various circuit designs for Schmitt triggers that specifically address crosstalk issues. These designs include modified input stages, specialized feedback mechanisms, and optimized hysteresis control to minimize the effects of noise and crosstalk from adjacent signal lines. These circuit configurations help maintain signal integrity in high-density electronic environments where crosstalk is a significant concern.- Schmitt trigger circuit designs to reduce crosstalk: Various circuit designs for Schmitt triggers that specifically address crosstalk issues. These designs include modified input stages, specialized feedback mechanisms, and optimized hysteresis control to minimize the effects of noise and crosstalk from adjacent signal lines. These circuit configurations help maintain reliable switching thresholds even in the presence of electromagnetic interference from neighboring circuits.

- Noise immunity techniques in Schmitt trigger applications: Implementation of noise immunity techniques in Schmitt trigger circuits to prevent false triggering caused by crosstalk. These techniques include differential input structures, balanced signal paths, and specialized filtering components that can distinguish between actual input signals and noise induced by crosstalk. The enhanced noise immunity helps maintain signal integrity in dense circuit environments where crosstalk is prevalent.

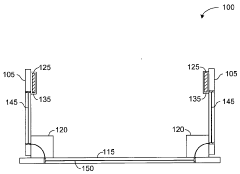

- Isolation methods for Schmitt trigger circuits: Methods for isolating Schmitt trigger circuits from crosstalk effects through physical layout techniques, shielding, and specialized grounding schemes. These isolation methods include guard rings, strategic component placement, and optimized trace routing to minimize capacitive and inductive coupling between signal lines. Proper isolation ensures that the Schmitt trigger operates according to design specifications without interference from adjacent circuits.

- Power supply decoupling for Schmitt trigger stability: Techniques for power supply decoupling and stabilization to prevent crosstalk-induced noise from affecting Schmitt trigger operation. These include specialized filtering networks, local decoupling capacitors, and power distribution strategies that maintain clean supply voltages. Stable power supplies ensure that the switching thresholds of Schmitt triggers remain consistent even when other circuit elements experience transient current demands that could otherwise cause crosstalk.

- Advanced Schmitt trigger architectures for high-speed applications: Advanced Schmitt trigger architectures designed specifically for high-speed applications where crosstalk becomes more problematic. These designs incorporate specialized compensation techniques, impedance matching networks, and optimized transistor configurations to maintain signal integrity at higher frequencies. The architectures address both input and output stages to minimize crosstalk generation and susceptibility throughout the signal path.

02 Noise immunity techniques in Schmitt trigger applications

Implementation of specific noise immunity techniques in Schmitt trigger circuits to prevent false triggering caused by crosstalk. These techniques include differential input structures, balanced threshold control, and specialized filtering components that can distinguish between actual signals and noise induced by crosstalk from neighboring circuits. These approaches significantly improve the reliability of Schmitt triggers in noisy environments.Expand Specific Solutions03 Shielding and isolation methods for Schmitt trigger circuits

Methods for physically and electrically isolating Schmitt trigger circuits to prevent crosstalk. These include specialized layout techniques, guard rings, shielding structures, and isolation barriers that minimize electromagnetic interference between adjacent circuit elements. The implementation of these methods helps maintain the intended switching thresholds of Schmitt triggers by preventing unwanted signal coupling.Expand Specific Solutions04 Advanced Schmitt trigger designs for high-speed applications

Specialized Schmitt trigger designs optimized for high-speed applications where crosstalk becomes more problematic due to faster signal transitions. These designs incorporate advanced features such as adaptive threshold adjustment, frequency-dependent compensation, and specialized input buffering to maintain clean switching characteristics even when operating at high frequencies in dense circuit environments.Expand Specific Solutions05 Power and ground management for crosstalk reduction

Techniques focused on power supply and ground management to reduce crosstalk in Schmitt trigger circuits. These include dedicated power filtering, separate power domains, strategic decoupling capacitor placement, and specialized ground plane designs. By ensuring clean power delivery and proper grounding, these methods minimize the propagation of noise and crosstalk through power distribution networks that could otherwise affect Schmitt trigger operation.Expand Specific Solutions

Leading Manufacturers and Circuit Design Companies

The Schmitt trigger technology for minimizing crosstalk in circuitry is currently in a mature growth phase, with an estimated global market size of $3.5-4 billion. Major semiconductor players like Intel, Qualcomm, and NXP USA have established strong positions through advanced implementations, while specialized firms such as Rambus and Analog Devices offer innovative solutions with enhanced noise immunity. The technology demonstrates high maturity with companies like ROHM, STMicroelectronics, and Taiwan Semiconductor Manufacturing Co. incorporating Schmitt triggers into standard product lines. Recent advancements from Socionext and Himax Technologies focus on reducing power consumption and increasing switching speed, indicating continued evolution despite the technology's established status in signal integrity applications.

Intel Corp.

Technical Solution: Intel has developed a sophisticated approach to minimizing crosstalk using enhanced Schmitt trigger circuits in their high-speed processor interconnects and memory interfaces. Their implementation features a multi-threshold detection system that dynamically adjusts hysteresis levels based on real-time signal integrity measurements. Intel's proprietary "Signal Integrity Protection" architecture incorporates Schmitt triggers with programmable threshold voltages that can be calibrated during system initialization to account for manufacturing variations and operating conditions. This technology has been crucial in enabling reliable operation of their high-speed data buses operating at multi-gigahertz frequencies. Intel has further enhanced their Schmitt trigger designs with advanced power management features that reduce current consumption during idle states while maintaining rapid response times when needed.

Strengths: Programmable thresholds allow for post-manufacturing calibration to optimize performance. Integration with Intel's power management systems reduces overall system power consumption. Weaknesses: Complex implementation requires significant design expertise and characterization effort, making it challenging to implement in simpler systems.

QUALCOMM, Inc.

Technical Solution: Qualcomm has developed innovative Schmitt trigger implementations specifically optimized for mobile and IoT applications where power efficiency and signal integrity are equally critical. Their "UltraLow Power Schmitt" architecture incorporates adaptive biasing techniques that dynamically adjust current consumption based on input signal activity while maintaining robust noise immunity. Qualcomm's implementation features specialized layout techniques that physically separate sensitive analog paths from noisy digital circuits, with dedicated power domains and ground isolation to minimize coupling. Their Schmitt trigger designs include programmable hysteresis levels that can be adjusted based on the operating environment, allowing systems to optimize for either maximum noise immunity or minimum power consumption. This technology has been integrated into Qualcomm's Snapdragon mobile platforms, where it helps maintain signal integrity in densely packed mobile devices operating across multiple wireless standards.

Strengths: Exceptional power efficiency makes it ideal for battery-powered devices. Programmable hysteresis levels allow dynamic optimization for changing environmental conditions. Weaknesses: Performance optimization requires sophisticated power management control systems, increasing implementation complexity in simpler designs.

Key Patents and Innovations in Hysteresis Circuits

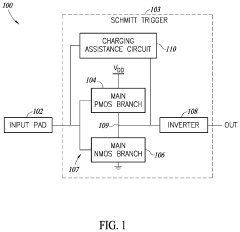

Schmitt trigger with current assistance circuit

PatentActiveUS11901900B2

Innovation

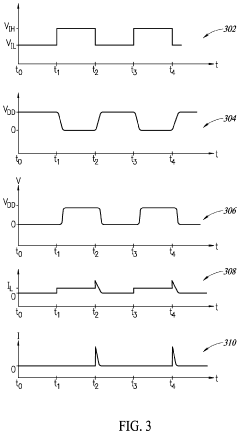

- Incorporating a charging assistance circuit that provides supplemental charging currents during transitions, contributing no static current consumption between transitions, thus enabling fast operation with minimal additional area consumption.

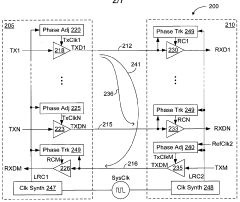

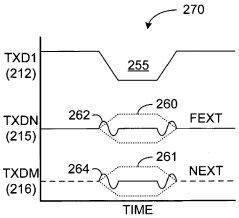

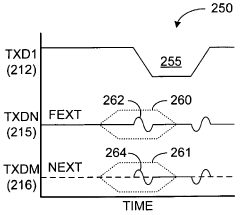

Crosstalk minimization in serial link systems

PatentWO2005117325A2

Innovation

- The implementation of phase-adjustment circuits in transceivers to dynamically alter the timing of aggressor data transitions, moving noise artifacts away from sensitive regions in victim channels, thereby reducing crosstalk effects by introducing static or dynamic timing offsets in aggressor and victim transmitters.

Signal Integrity Testing and Validation Methodologies

Effective signal integrity testing and validation methodologies are crucial when implementing Schmitt trigger solutions to minimize crosstalk in electronic circuits. The validation process typically begins with simulation-based testing using specialized electronic design automation (EDA) tools that can model signal behavior under various conditions. These simulations should specifically focus on threshold voltage transitions and hysteresis effects that are characteristic of Schmitt trigger implementations.

Laboratory validation requires a comprehensive approach using both time-domain and frequency-domain measurements. Time-domain reflectometry (TDR) serves as a primary method for detecting impedance discontinuities that may contribute to crosstalk, while vector network analyzers (VNAs) provide essential S-parameter measurements to quantify signal coupling between adjacent traces. When testing Schmitt trigger implementations, particular attention must be paid to the noise margin measurements at both high and low threshold points.

Eye diagram analysis represents another critical validation methodology, offering visual representation of signal quality and jitter performance. For Schmitt trigger circuits, the eye diagram should demonstrate improved noise immunity compared to conventional buffer implementations, with cleaner transitions and reduced susceptibility to spurious triggering. Quantitative metrics derived from eye diagrams include eye height, eye width, and jitter measurements, all of which should show improvement when Schmitt triggers are properly implemented.

Boundary scan testing (JTAG) can be employed to verify signal integrity at the integrated circuit level, particularly useful for complex systems where direct probing may be challenging. This approach allows for automated testing of interconnections between Schmitt trigger components and surrounding circuitry, helping to identify potential crosstalk issues at board interfaces.

Environmental testing constitutes an essential validation step, as temperature variations and power supply fluctuations can significantly impact Schmitt trigger performance. Validation protocols should include testing across the full operating temperature range and under various power supply conditions to ensure consistent hysteresis behavior and noise immunity across all expected operating scenarios.

Statistical analysis of test results provides valuable insights into design robustness. Monte Carlo simulations that account for manufacturing variations in component values can predict how production tolerances might affect crosstalk suppression performance in mass-produced circuits utilizing Schmitt triggers. This data informs design refinements and helps establish appropriate guard bands for reliable operation.

Laboratory validation requires a comprehensive approach using both time-domain and frequency-domain measurements. Time-domain reflectometry (TDR) serves as a primary method for detecting impedance discontinuities that may contribute to crosstalk, while vector network analyzers (VNAs) provide essential S-parameter measurements to quantify signal coupling between adjacent traces. When testing Schmitt trigger implementations, particular attention must be paid to the noise margin measurements at both high and low threshold points.

Eye diagram analysis represents another critical validation methodology, offering visual representation of signal quality and jitter performance. For Schmitt trigger circuits, the eye diagram should demonstrate improved noise immunity compared to conventional buffer implementations, with cleaner transitions and reduced susceptibility to spurious triggering. Quantitative metrics derived from eye diagrams include eye height, eye width, and jitter measurements, all of which should show improvement when Schmitt triggers are properly implemented.

Boundary scan testing (JTAG) can be employed to verify signal integrity at the integrated circuit level, particularly useful for complex systems where direct probing may be challenging. This approach allows for automated testing of interconnections between Schmitt trigger components and surrounding circuitry, helping to identify potential crosstalk issues at board interfaces.

Environmental testing constitutes an essential validation step, as temperature variations and power supply fluctuations can significantly impact Schmitt trigger performance. Validation protocols should include testing across the full operating temperature range and under various power supply conditions to ensure consistent hysteresis behavior and noise immunity across all expected operating scenarios.

Statistical analysis of test results provides valuable insights into design robustness. Monte Carlo simulations that account for manufacturing variations in component values can predict how production tolerances might affect crosstalk suppression performance in mass-produced circuits utilizing Schmitt triggers. This data informs design refinements and helps establish appropriate guard bands for reliable operation.

EMI/EMC Compliance and Standards

Electromagnetic Interference (EMI) and Electromagnetic Compatibility (EMC) standards play a crucial role when implementing Schmitt trigger solutions to minimize crosstalk in electronic circuits. These standards ensure that electronic devices operate reliably in their intended electromagnetic environment without introducing intolerable electromagnetic disturbances to other systems. For circuits utilizing Schmitt triggers, compliance with standards such as IEC 61000, CISPR 22/32, and FCC Part 15 becomes essential to market products globally.

The implementation of Schmitt triggers must adhere to conducted and radiated emission limits specified in these standards. Schmitt triggers, with their hysteresis characteristics, inherently reduce high-frequency oscillations during signal transitions, which helps in limiting electromagnetic emissions. However, designers must still verify compliance through appropriate testing methodologies including GTEM cell measurements, anechoic chamber testing, and conducted emission analysis.

EMC testing for Schmitt trigger implementations typically focuses on measuring switching noise, which can be a significant source of EMI. The rapid voltage transitions in digital circuits create broadband noise that must be contained within regulatory limits. Schmitt triggers help mitigate this issue by controlling slew rates and reducing ringing, but proper PCB layout techniques must complement these benefits to achieve full compliance.

Immunity testing represents another critical aspect of EMC compliance. Circuits must demonstrate resilience against external electromagnetic disturbances without experiencing functional degradation. Schmitt triggers enhance immunity by providing noise margin through hysteresis, making them particularly valuable in industrial environments where electrical noise is prevalent. Standards like IEC 61000-4 series define specific immunity test methods that circuits incorporating Schmitt triggers must pass.

Regional variations in EMC standards present challenges for global product deployment. European CE marking requires compliance with the EMC Directive 2014/30/EU, while products for the US market must meet FCC requirements. Asian markets have their own standards, such as VCCI in Japan and CCC in China. Designers implementing Schmitt trigger solutions must consider these regional differences during the development phase to avoid costly redesigns.

Pre-compliance testing during development can significantly reduce the risk of EMC compliance failures. This involves using near-field probes, spectrum analyzers, and EMI receivers to identify potential emission hotspots in circuits utilizing Schmitt triggers. Such proactive measures help in addressing EMC issues early in the design cycle, reducing time-to-market and development costs.

The implementation of Schmitt triggers must adhere to conducted and radiated emission limits specified in these standards. Schmitt triggers, with their hysteresis characteristics, inherently reduce high-frequency oscillations during signal transitions, which helps in limiting electromagnetic emissions. However, designers must still verify compliance through appropriate testing methodologies including GTEM cell measurements, anechoic chamber testing, and conducted emission analysis.

EMC testing for Schmitt trigger implementations typically focuses on measuring switching noise, which can be a significant source of EMI. The rapid voltage transitions in digital circuits create broadband noise that must be contained within regulatory limits. Schmitt triggers help mitigate this issue by controlling slew rates and reducing ringing, but proper PCB layout techniques must complement these benefits to achieve full compliance.

Immunity testing represents another critical aspect of EMC compliance. Circuits must demonstrate resilience against external electromagnetic disturbances without experiencing functional degradation. Schmitt triggers enhance immunity by providing noise margin through hysteresis, making them particularly valuable in industrial environments where electrical noise is prevalent. Standards like IEC 61000-4 series define specific immunity test methods that circuits incorporating Schmitt triggers must pass.

Regional variations in EMC standards present challenges for global product deployment. European CE marking requires compliance with the EMC Directive 2014/30/EU, while products for the US market must meet FCC requirements. Asian markets have their own standards, such as VCCI in Japan and CCC in China. Designers implementing Schmitt trigger solutions must consider these regional differences during the development phase to avoid costly redesigns.

Pre-compliance testing during development can significantly reduce the risk of EMC compliance failures. This involves using near-field probes, spectrum analyzers, and EMI receivers to identify potential emission hotspots in circuits utilizing Schmitt triggers. Such proactive measures help in addressing EMC issues early in the design cycle, reducing time-to-market and development costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!