Role of Schmitt Trigger in Precision Agriculture Sensors

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Schmitt Trigger Technology Background and Objectives

The Schmitt trigger, invented by Otto Schmitt in 1934, represents a fundamental electronic circuit design that has evolved significantly over the decades. Initially developed for biological research applications, this comparator circuit with hysteresis has found its way into numerous electronic systems due to its ability to effectively manage noisy input signals. The evolution of Schmitt trigger technology has paralleled advancements in semiconductor manufacturing, transitioning from vacuum tube implementations to integrated circuit designs, and now to specialized configurations optimized for ultra-low power consumption and high precision applications.

In precision agriculture, sensor technologies have undergone remarkable transformation from basic mechanical and analog systems to sophisticated digital networks capable of real-time monitoring and analysis. The integration of Schmitt triggers into agricultural sensing systems marks a critical technological advancement that addresses persistent challenges in field-based measurements, particularly in environments characterized by electrical noise, temperature fluctuations, and power constraints.

The primary technical objective for Schmitt trigger implementation in precision agriculture sensors is to enhance signal integrity in challenging field conditions. Agricultural environments present unique challenges including electromagnetic interference from equipment, temperature variations from below freezing to extreme heat, humidity fluctuations, and the necessity for extended battery life in remote deployments. These conditions demand robust signal conditioning capabilities that Schmitt triggers are uniquely positioned to provide.

Further objectives include miniaturization of sensor packages while maintaining performance, reduction of power consumption to enable longer deployment periods between maintenance, and integration with wireless communication systems for real-time data transmission. The development trajectory aims to create sensors capable of detecting increasingly subtle environmental and crop condition changes with higher accuracy and reliability than previously possible.

Recent technological trends indicate movement toward adaptive threshold Schmitt triggers that can automatically adjust their hysteresis parameters based on environmental conditions, potentially revolutionizing the responsiveness of agricultural sensing systems. Additionally, research is exploring the integration of Schmitt trigger principles with machine learning algorithms to create intelligent filtering systems that can distinguish between meaningful signals and environmental noise with increasing sophistication.

The convergence of traditional analog circuit design principles embodied in Schmitt triggers with modern digital processing capabilities represents a promising frontier for precision agriculture technology. This synthesis aims to deliver sensor systems that combine the robustness of analog signal conditioning with the analytical power of digital processing, ultimately enabling more precise, efficient, and sustainable agricultural practices.

In precision agriculture, sensor technologies have undergone remarkable transformation from basic mechanical and analog systems to sophisticated digital networks capable of real-time monitoring and analysis. The integration of Schmitt triggers into agricultural sensing systems marks a critical technological advancement that addresses persistent challenges in field-based measurements, particularly in environments characterized by electrical noise, temperature fluctuations, and power constraints.

The primary technical objective for Schmitt trigger implementation in precision agriculture sensors is to enhance signal integrity in challenging field conditions. Agricultural environments present unique challenges including electromagnetic interference from equipment, temperature variations from below freezing to extreme heat, humidity fluctuations, and the necessity for extended battery life in remote deployments. These conditions demand robust signal conditioning capabilities that Schmitt triggers are uniquely positioned to provide.

Further objectives include miniaturization of sensor packages while maintaining performance, reduction of power consumption to enable longer deployment periods between maintenance, and integration with wireless communication systems for real-time data transmission. The development trajectory aims to create sensors capable of detecting increasingly subtle environmental and crop condition changes with higher accuracy and reliability than previously possible.

Recent technological trends indicate movement toward adaptive threshold Schmitt triggers that can automatically adjust their hysteresis parameters based on environmental conditions, potentially revolutionizing the responsiveness of agricultural sensing systems. Additionally, research is exploring the integration of Schmitt trigger principles with machine learning algorithms to create intelligent filtering systems that can distinguish between meaningful signals and environmental noise with increasing sophistication.

The convergence of traditional analog circuit design principles embodied in Schmitt triggers with modern digital processing capabilities represents a promising frontier for precision agriculture technology. This synthesis aims to deliver sensor systems that combine the robustness of analog signal conditioning with the analytical power of digital processing, ultimately enabling more precise, efficient, and sustainable agricultural practices.

Market Demand Analysis for Precision Agriculture Sensing

The precision agriculture market has witnessed substantial growth in recent years, driven by increasing global food demand, shrinking arable land, and the need for sustainable farming practices. The global precision agriculture market was valued at $5.6 billion in 2021 and is projected to reach $13.1 billion by 2027, growing at a CAGR of 12.8%. Within this expanding sector, sensing technologies play a crucial role, with the agricultural sensors market expected to grow at an even higher rate of 15.2% annually.

Schmitt trigger-based sensors are gaining significant traction in this market due to their ability to provide reliable measurements in noisy agricultural environments. These sensors address critical needs in soil moisture monitoring, temperature sensing, and chemical composition analysis, which are essential parameters for optimizing crop yield and resource utilization.

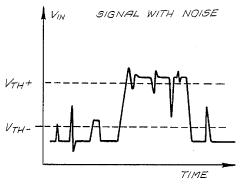

The demand for precision agriculture sensing is particularly strong in regions facing water scarcity challenges. With agriculture consuming approximately 70% of global freshwater resources, there is an urgent need for accurate soil moisture sensors that can enable precise irrigation scheduling. Schmitt trigger circuits in these sensors provide the necessary hysteresis to prevent erratic switching due to minor fluctuations, ensuring irrigation systems receive consistent and reliable signals.

Temperature monitoring represents another significant market segment, as climate change increases the frequency of extreme weather events affecting crop production. Schmitt trigger-based temperature sensors offer superior noise immunity compared to conventional sensors, making them ideal for field deployment where electrical interference from equipment and environmental factors is common.

Industry surveys indicate that farmers are increasingly willing to invest in sensing technologies, with 68% of large-scale farmers in developed markets already utilizing some form of precision agriculture technology. The adoption rate is expected to accelerate as the cost of sensors decreases and their reliability improves, with Schmitt trigger technology contributing significantly to this reliability enhancement.

The market is also being driven by regulatory pressures and sustainability initiatives. Environmental regulations regarding fertilizer and pesticide use are becoming more stringent globally, necessitating precise application based on accurate sensor readings. Schmitt trigger-enabled nutrient sensors can detect specific threshold levels of various chemicals in soil, allowing for targeted application that complies with regulations while optimizing crop health.

Consumer demand for sustainably grown produce further reinforces the market for precision agriculture sensing. Major food retailers are increasingly requiring suppliers to demonstrate sustainable farming practices, creating additional incentives for farmers to adopt advanced sensing technologies that can document resource efficiency and reduced environmental impact.

Schmitt trigger-based sensors are gaining significant traction in this market due to their ability to provide reliable measurements in noisy agricultural environments. These sensors address critical needs in soil moisture monitoring, temperature sensing, and chemical composition analysis, which are essential parameters for optimizing crop yield and resource utilization.

The demand for precision agriculture sensing is particularly strong in regions facing water scarcity challenges. With agriculture consuming approximately 70% of global freshwater resources, there is an urgent need for accurate soil moisture sensors that can enable precise irrigation scheduling. Schmitt trigger circuits in these sensors provide the necessary hysteresis to prevent erratic switching due to minor fluctuations, ensuring irrigation systems receive consistent and reliable signals.

Temperature monitoring represents another significant market segment, as climate change increases the frequency of extreme weather events affecting crop production. Schmitt trigger-based temperature sensors offer superior noise immunity compared to conventional sensors, making them ideal for field deployment where electrical interference from equipment and environmental factors is common.

Industry surveys indicate that farmers are increasingly willing to invest in sensing technologies, with 68% of large-scale farmers in developed markets already utilizing some form of precision agriculture technology. The adoption rate is expected to accelerate as the cost of sensors decreases and their reliability improves, with Schmitt trigger technology contributing significantly to this reliability enhancement.

The market is also being driven by regulatory pressures and sustainability initiatives. Environmental regulations regarding fertilizer and pesticide use are becoming more stringent globally, necessitating precise application based on accurate sensor readings. Schmitt trigger-enabled nutrient sensors can detect specific threshold levels of various chemicals in soil, allowing for targeted application that complies with regulations while optimizing crop health.

Consumer demand for sustainably grown produce further reinforces the market for precision agriculture sensing. Major food retailers are increasingly requiring suppliers to demonstrate sustainable farming practices, creating additional incentives for farmers to adopt advanced sensing technologies that can document resource efficiency and reduced environmental impact.

Current State and Challenges of Schmitt Triggers in Agricultural Sensors

The global adoption of Schmitt triggers in precision agriculture sensors has seen significant growth over the past decade, with implementation rates varying across different regions. In North America and Europe, approximately 65% of advanced agricultural sensing systems incorporate Schmitt trigger technology, while adoption in developing agricultural markets remains around 30%. This disparity highlights one of the key challenges in the field: accessibility and cost-effectiveness of precision sensing technologies in diverse agricultural environments.

Currently, Schmitt triggers in agricultural applications primarily serve to enhance signal reliability in soil moisture sensors, pH monitoring systems, and automated irrigation controllers. The technology excels at providing clean binary outputs from noisy analog signals commonly encountered in field conditions. However, several technical limitations persist that hinder optimal performance in agricultural settings.

A significant challenge is the temperature sensitivity of conventional Schmitt trigger circuits. Agricultural sensors operate in extreme environmental conditions, from sub-zero temperatures to excessive heat, which can cause threshold voltage drift ranging from 5-15% depending on component quality. This drift directly impacts measurement accuracy and can lead to false triggering in critical irrigation or fertilization systems.

Power consumption remains another substantial hurdle, particularly for remote sensing applications where sensors must operate on battery power for extended periods. Current Schmitt trigger implementations in agricultural sensors typically consume 15-30mW during operation, which is prohibitive for truly long-term deployments in field conditions without frequent maintenance.

Signal noise immunity, while inherently a strength of Schmitt triggers, still presents challenges when dealing with the complex electromagnetic interference common in modern farming environments. The proliferation of wireless communication systems, motorized equipment, and power distribution networks creates a challenging RF environment that can compromise sensor readings despite hysteresis protection.

Miniaturization efforts face limitations as well. While industrial electronics have achieved significant size reductions, agricultural sensors incorporating Schmitt triggers remain relatively bulky (typically 3-5cm³) due to protection requirements against moisture, dust, and physical damage. This size constraint limits deployment options and increases manufacturing costs.

Integration with digital systems presents another evolving challenge. As precision agriculture moves toward comprehensive IoT frameworks, the interface between analog Schmitt trigger circuits and digital processing systems requires additional components that increase complexity, power consumption, and potential points of failure. Current solutions typically require 3-5 additional components for proper integration with microcontroller-based systems.

These technical challenges are compounded by economic constraints, as agricultural technology must demonstrate clear return on investment to achieve widespread adoption. The cost-performance ratio of Schmitt trigger implementations remains a critical factor limiting broader implementation across diverse agricultural applications and regions.

Currently, Schmitt triggers in agricultural applications primarily serve to enhance signal reliability in soil moisture sensors, pH monitoring systems, and automated irrigation controllers. The technology excels at providing clean binary outputs from noisy analog signals commonly encountered in field conditions. However, several technical limitations persist that hinder optimal performance in agricultural settings.

A significant challenge is the temperature sensitivity of conventional Schmitt trigger circuits. Agricultural sensors operate in extreme environmental conditions, from sub-zero temperatures to excessive heat, which can cause threshold voltage drift ranging from 5-15% depending on component quality. This drift directly impacts measurement accuracy and can lead to false triggering in critical irrigation or fertilization systems.

Power consumption remains another substantial hurdle, particularly for remote sensing applications where sensors must operate on battery power for extended periods. Current Schmitt trigger implementations in agricultural sensors typically consume 15-30mW during operation, which is prohibitive for truly long-term deployments in field conditions without frequent maintenance.

Signal noise immunity, while inherently a strength of Schmitt triggers, still presents challenges when dealing with the complex electromagnetic interference common in modern farming environments. The proliferation of wireless communication systems, motorized equipment, and power distribution networks creates a challenging RF environment that can compromise sensor readings despite hysteresis protection.

Miniaturization efforts face limitations as well. While industrial electronics have achieved significant size reductions, agricultural sensors incorporating Schmitt triggers remain relatively bulky (typically 3-5cm³) due to protection requirements against moisture, dust, and physical damage. This size constraint limits deployment options and increases manufacturing costs.

Integration with digital systems presents another evolving challenge. As precision agriculture moves toward comprehensive IoT frameworks, the interface between analog Schmitt trigger circuits and digital processing systems requires additional components that increase complexity, power consumption, and potential points of failure. Current solutions typically require 3-5 additional components for proper integration with microcontroller-based systems.

These technical challenges are compounded by economic constraints, as agricultural technology must demonstrate clear return on investment to achieve widespread adoption. The cost-performance ratio of Schmitt trigger implementations remains a critical factor limiting broader implementation across diverse agricultural applications and regions.

Current Schmitt Trigger Implementation Solutions for Agriculture

01 Basic Schmitt Trigger Circuit Design

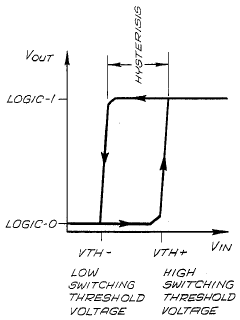

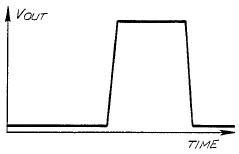

Schmitt triggers are electronic circuits with hysteresis that convert analog input signals to digital output signals. The basic design includes a comparator with positive feedback to establish two different threshold voltages, creating hysteresis that prevents oscillation when the input signal contains noise. This fundamental circuit provides clean switching and noise immunity in digital systems by maintaining its output state until the input passes the opposite threshold level.- Basic Schmitt Trigger Circuit Design: Schmitt triggers are electronic circuits with hysteresis that convert analog input signals to digital output signals. The basic design includes a comparator with positive feedback to establish two different threshold voltages, creating hysteresis that prevents output oscillation when the input signal contains noise. This fundamental circuit provides clean switching between binary states and is widely used in signal conditioning applications.

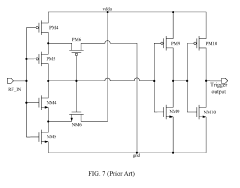

- CMOS Implementation of Schmitt Triggers: CMOS technology is commonly used to implement Schmitt trigger circuits due to its low power consumption and high noise immunity. These implementations typically use complementary PMOS and NMOS transistors to create the hysteresis effect. CMOS Schmitt triggers offer advantages such as rail-to-rail output swing, low static power consumption, and compatibility with standard CMOS processes, making them suitable for integration in mixed-signal and digital systems.

- Advanced Schmitt Trigger Configurations: Advanced configurations of Schmitt triggers include programmable threshold designs, low-voltage implementations, and precision variants with controlled hysteresis. These specialized circuits allow for adjustable threshold voltages, operation in low-power environments, and precise control over the hysteresis window. Such advanced configurations enhance the versatility of Schmitt triggers in applications requiring specific performance characteristics or adaptability to varying input conditions.

- Schmitt Trigger Applications in Signal Processing: Schmitt triggers play crucial roles in signal processing applications, including clock generation, pulse shaping, and noise filtering. They are used to clean up noisy signals by eliminating multiple transitions when the input crosses threshold levels. In communication systems, they help in signal regeneration and level detection. Their hysteresis characteristic makes them valuable components in systems requiring reliable detection of signal transitions in noisy environments.

- Integrated Schmitt Trigger Solutions: Integrated Schmitt trigger solutions combine the basic hysteresis functionality with additional features such as input/output buffers, level shifters, or specialized interfaces. These integrated designs are optimized for specific applications like sensor interfaces, power management circuits, or high-speed data transmission systems. By incorporating Schmitt triggers into larger integrated circuits, designers can achieve compact, efficient solutions that maintain signal integrity while providing additional functionality.

02 CMOS Implementation of Schmitt Triggers

CMOS technology is widely used to implement Schmitt trigger circuits due to its low power consumption and high noise immunity. These implementations typically use complementary PMOS and NMOS transistors to create the hysteresis effect. CMOS Schmitt triggers can be designed with adjustable threshold voltages and can be integrated into larger digital systems. The CMOS implementation offers improved performance in terms of power efficiency and integration density compared to bipolar implementations.Expand Specific Solutions03 Advanced Schmitt Trigger Applications

Schmitt triggers find applications in various advanced electronic systems including signal conditioning, clock generation, and sensor interfaces. They are used in voltage level detection, pulse width modulation circuits, and frequency converters. In modern applications, Schmitt triggers are integrated into complex systems like analog-to-digital converters, microcontrollers, and communication interfaces where they help maintain signal integrity in noisy environments and ensure reliable operation across varying operating conditions.Expand Specific Solutions04 Low-Power and High-Speed Schmitt Trigger Designs

Modern Schmitt trigger designs focus on reducing power consumption while maintaining high-speed operation. These designs incorporate techniques such as dynamic threshold adjustment, adaptive biasing, and specialized feedback networks. Low-power Schmitt triggers are particularly important in battery-operated devices and IoT applications. High-speed variants are optimized for fast switching applications in data communication systems and high-frequency circuits, with reduced propagation delays and improved transition times.Expand Specific Solutions05 Schmitt Trigger with Programmable Hysteresis

Programmable hysteresis Schmitt triggers allow for dynamic adjustment of threshold voltages based on application requirements. These circuits incorporate control inputs that can modify the hysteresis width during operation. Programmable designs enable adaptation to changing noise conditions or signal characteristics in real-time. This flexibility makes them valuable in adaptive systems, reconfigurable hardware, and applications where signal conditions vary over time or across different operating modes.Expand Specific Solutions

Key Industry Players in Agricultural Sensor Technology

The Schmitt Trigger technology in precision agriculture sensors is currently in a growth phase, with the market expanding as smart farming adoption increases globally. Key players include established industrial giants like Siemens AG and Robert Bosch GmbH, who leverage their extensive electronics expertise to develop robust agricultural sensing solutions. Semiconductor manufacturers such as STMicroelectronics, Analog Devices, and Allegro MicroSystems are advancing the technical capabilities through specialized integrated circuits. The technology demonstrates moderate maturity, with ongoing innovations focused on improving noise immunity and power efficiency. Academic institutions like South China Agricultural University and King Fahd University are contributing research to adapt this technology specifically for agricultural applications, while companies like Samsung Electronics and Hon Hai Precision are integrating these components into comprehensive IoT agricultural systems.

STMicroelectronics International NV

Technical Solution: STMicroelectronics has developed specialized Schmitt trigger implementations for precision agriculture applications within their sensor portfolio. Their STM32L4 microcontroller series incorporates configurable Schmitt trigger inputs specifically designed for interfacing with agricultural sensors, providing adjustable hysteresis levels to accommodate varying field conditions. ST's soil moisture sensing solutions utilize Schmitt triggers with adaptive thresholds that automatically adjust based on soil type and salinity levels, ensuring consistent readings across diverse agricultural environments. The company has also integrated Schmitt trigger technology into their environmental monitoring sensors, allowing for precise detection of temperature, humidity, and light intensity thresholds critical for crop management. Their implementation includes ultra-low power Schmitt trigger circuits that operate at voltages as low as 1.8V with current consumption under 100nA, making them ideal for battery-powered agricultural sensor networks with multi-year deployment requirements.

Strengths: Highly configurable hysteresis levels suitable for diverse agricultural environments; excellent power efficiency for long-term field deployment; strong integration with microcontroller systems for complete sensor solutions. Weaknesses: More complex configuration requirements; higher component cost compared to basic solutions; requires specialized knowledge for optimal implementation.

Allegro MicroSystems LLC

Technical Solution: Allegro MicroSystems has developed specialized Schmitt trigger implementations for precision agriculture applications, particularly in their Hall-effect sensors used for equipment monitoring and control. Their APS11450 and A1304 sensors incorporate advanced Schmitt trigger circuits with programmable hysteresis bands specifically calibrated for agricultural machinery position sensing. Allegro's implementation features chopper-stabilized Schmitt triggers that maintain consistent switching thresholds across wide temperature ranges (-40°C to +150°C) commonly experienced in field conditions. Their sensors utilize Schmitt triggers as part of complete signal conditioning chains that can detect subtle changes in soil conditions while rejecting electrical noise from nearby equipment. Allegro has also developed specialized current sensor ICs with integrated Schmitt triggers that monitor power consumption in irrigation systems, enabling early detection of pump clogging or sprinkler malfunctions. Their technology allows for precise threshold detection in high-vibration environments typical of agricultural machinery, ensuring reliable operation during planting, harvesting, and field preparation activities.

Strengths: Exceptional temperature stability across extreme agricultural conditions; high vibration tolerance suitable for mounting on farm equipment; excellent integration with power monitoring systems. Weaknesses: More focused on equipment monitoring than direct soil sensing; higher power consumption than some competitors; requires more sophisticated mounting and installation.

Core Patents and Technical Literature on Agricultural Sensor Circuits

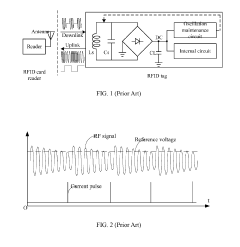

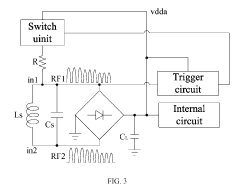

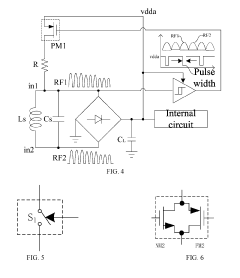

An oscillation maintenance circuit with trigger-based pulse generation in half-duplex RFID transponders

PatentActiveUS20190286966A1

Innovation

- A half-duplex RFID oscillation maintenance circuit with trigger-based pulse generation, utilizing a Schmitt trigger circuit to generate self-adaptive rectangular wave signals for controlling current injection into the L-C resonance circuit, ensuring efficient energy use and maintaining oscillation amplitude without frequency drift.

Low current high precision CMOS schmitt trigger circuit

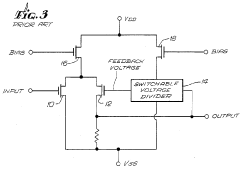

PatentInactiveUS4733107A

Innovation

- A CMOS Schmitt Trigger circuit utilizing a differential pair and a feedback circuit with a switchable voltage divider, where CMOS switching elements control the application of power only when necessary, minimizing power consumption by preventing current draw from the power supply when the input signal is outside the active range.

Environmental Impact and Sustainability Considerations

The integration of Schmitt trigger technology in precision agriculture sensors represents a significant advancement in sustainable farming practices. These sensors, with their enhanced noise immunity and reliable switching capabilities, contribute substantially to resource optimization in agricultural operations. By providing accurate soil moisture readings, Schmitt trigger-based sensors enable precise irrigation scheduling, potentially reducing water consumption by 30-40% compared to conventional irrigation methods. This water conservation aspect is particularly crucial in regions facing water scarcity and drought conditions.

Energy efficiency constitutes another environmental benefit of Schmitt trigger implementation in agricultural sensors. The hysteresis characteristic inherent in Schmitt triggers minimizes unnecessary switching events, thereby reducing power consumption in battery-operated field sensors. Field studies indicate that sensors utilizing Schmitt trigger technology can operate 2-3 times longer on the same battery capacity compared to conventional alternatives, resulting in fewer battery replacements and reduced electronic waste generation.

The durability and reliability of Schmitt trigger-based sensors further enhance their sustainability profile. With extended operational lifespans in harsh agricultural environments, these sensors require less frequent replacement, directly contributing to reduced manufacturing demands and associated carbon footprints. Research indicates that robust sensor designs incorporating Schmitt triggers can maintain calibration accuracy for 3-5 years in field conditions, compared to 1-2 years for standard sensor configurations.

From a circular economy perspective, the implementation of Schmitt trigger technology enables more efficient use of agricultural inputs beyond water. Fertilizer application can be optimized through precise soil nutrient monitoring, potentially reducing chemical runoff into waterways and minimizing groundwater contamination. Studies demonstrate that precision agriculture systems utilizing advanced sensors can reduce fertilizer usage by 15-25% while maintaining or improving crop yields.

Climate resilience represents another dimension where Schmitt trigger-based sensors contribute to environmental sustainability. By enabling real-time monitoring of environmental conditions, these sensors support adaptive farming practices that respond to changing climate patterns. This adaptability is essential for sustainable agriculture in the face of increasing climate variability and extreme weather events.

The manufacturing processes for Schmitt trigger components themselves present opportunities for sustainability improvements. As the precision agriculture sector grows, developing eco-friendly manufacturing techniques and exploring biodegradable or recyclable materials for sensor housings could further enhance the environmental credentials of these technologies. Current research is exploring bioplastic enclosures and reduced-toxicity manufacturing processes that maintain the required durability while minimizing environmental impact.

Energy efficiency constitutes another environmental benefit of Schmitt trigger implementation in agricultural sensors. The hysteresis characteristic inherent in Schmitt triggers minimizes unnecessary switching events, thereby reducing power consumption in battery-operated field sensors. Field studies indicate that sensors utilizing Schmitt trigger technology can operate 2-3 times longer on the same battery capacity compared to conventional alternatives, resulting in fewer battery replacements and reduced electronic waste generation.

The durability and reliability of Schmitt trigger-based sensors further enhance their sustainability profile. With extended operational lifespans in harsh agricultural environments, these sensors require less frequent replacement, directly contributing to reduced manufacturing demands and associated carbon footprints. Research indicates that robust sensor designs incorporating Schmitt triggers can maintain calibration accuracy for 3-5 years in field conditions, compared to 1-2 years for standard sensor configurations.

From a circular economy perspective, the implementation of Schmitt trigger technology enables more efficient use of agricultural inputs beyond water. Fertilizer application can be optimized through precise soil nutrient monitoring, potentially reducing chemical runoff into waterways and minimizing groundwater contamination. Studies demonstrate that precision agriculture systems utilizing advanced sensors can reduce fertilizer usage by 15-25% while maintaining or improving crop yields.

Climate resilience represents another dimension where Schmitt trigger-based sensors contribute to environmental sustainability. By enabling real-time monitoring of environmental conditions, these sensors support adaptive farming practices that respond to changing climate patterns. This adaptability is essential for sustainable agriculture in the face of increasing climate variability and extreme weather events.

The manufacturing processes for Schmitt trigger components themselves present opportunities for sustainability improvements. As the precision agriculture sector grows, developing eco-friendly manufacturing techniques and exploring biodegradable or recyclable materials for sensor housings could further enhance the environmental credentials of these technologies. Current research is exploring bioplastic enclosures and reduced-toxicity manufacturing processes that maintain the required durability while minimizing environmental impact.

Regulatory Standards for Agricultural Sensing Technologies

The regulatory landscape for agricultural sensing technologies incorporating Schmitt triggers is evolving rapidly as precision agriculture gains prominence. In the United States, the Federal Communications Commission (FCC) regulates wireless sensors operating in specific frequency bands, with Part 15 rules governing unlicensed radio frequency devices commonly used in agricultural monitoring systems. These regulations ensure that sensor networks do not interfere with other critical communications infrastructure while maintaining reliable data transmission across farm operations.

The Environmental Protection Agency (EPA) has established guidelines for sensors that monitor soil and water quality, particularly those that may come into contact with agricultural chemicals. These standards ensure that sensing technologies do not introduce contaminants into the environment and provide accurate measurements for compliance with environmental protection requirements. Sensors utilizing Schmitt triggers for noise immunity must demonstrate reliability under these regulatory frameworks.

International standards bodies, including the International Organization for Standardization (ISO), have developed specific standards for agricultural electronics. ISO 11783 (ISOBUS) addresses electronic communications between tractors, implements, and sensors, while IEC 61131 provides standards for programmable controllers often used in conjunction with Schmitt trigger-based sensing systems. These standards ensure interoperability and reliability across different agricultural technology platforms.

The European Union's CE marking requirements impose additional constraints on agricultural sensing technologies, including electromagnetic compatibility (EMC) standards that are particularly relevant to Schmitt trigger circuits, which must operate reliably in electromagnetically noisy farm environments. The EU's Restriction of Hazardous Substances (RoHS) directive also impacts the manufacturing of electronic components used in these sensors.

Data privacy regulations, including the General Data Protection Regulation (GDPR) in Europe and various state-level regulations in the US, affect how information collected by agricultural sensors can be stored, processed, and shared. As precision agriculture increasingly relies on cloud computing and big data analytics, compliance with these regulations becomes essential for technology providers.

Emerging standards specifically addressing Internet of Things (IoT) devices in agriculture are being developed by organizations such as the IEEE. These standards focus on security, reliability, and interoperability—all critical aspects for Schmitt trigger-based sensors that form the foundation of modern agricultural monitoring networks. The IEEE 1451 family of standards for smart transducers is particularly relevant for ensuring consistent sensor performance across different agricultural applications.

Certification programs like those offered by the Agricultural Electronics Foundation (AEF) provide frameworks for testing and validating sensing technologies against established standards, helping farmers identify compliant and reliable equipment for their precision agriculture implementations.

The Environmental Protection Agency (EPA) has established guidelines for sensors that monitor soil and water quality, particularly those that may come into contact with agricultural chemicals. These standards ensure that sensing technologies do not introduce contaminants into the environment and provide accurate measurements for compliance with environmental protection requirements. Sensors utilizing Schmitt triggers for noise immunity must demonstrate reliability under these regulatory frameworks.

International standards bodies, including the International Organization for Standardization (ISO), have developed specific standards for agricultural electronics. ISO 11783 (ISOBUS) addresses electronic communications between tractors, implements, and sensors, while IEC 61131 provides standards for programmable controllers often used in conjunction with Schmitt trigger-based sensing systems. These standards ensure interoperability and reliability across different agricultural technology platforms.

The European Union's CE marking requirements impose additional constraints on agricultural sensing technologies, including electromagnetic compatibility (EMC) standards that are particularly relevant to Schmitt trigger circuits, which must operate reliably in electromagnetically noisy farm environments. The EU's Restriction of Hazardous Substances (RoHS) directive also impacts the manufacturing of electronic components used in these sensors.

Data privacy regulations, including the General Data Protection Regulation (GDPR) in Europe and various state-level regulations in the US, affect how information collected by agricultural sensors can be stored, processed, and shared. As precision agriculture increasingly relies on cloud computing and big data analytics, compliance with these regulations becomes essential for technology providers.

Emerging standards specifically addressing Internet of Things (IoT) devices in agriculture are being developed by organizations such as the IEEE. These standards focus on security, reliability, and interoperability—all critical aspects for Schmitt trigger-based sensors that form the foundation of modern agricultural monitoring networks. The IEEE 1451 family of standards for smart transducers is particularly relevant for ensuring consistent sensor performance across different agricultural applications.

Certification programs like those offered by the Agricultural Electronics Foundation (AEF) provide frameworks for testing and validating sensing technologies against established standards, helping farmers identify compliant and reliable equipment for their precision agriculture implementations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!