Enhancing Output Waveform Uniformity with Schmitt Trigger

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Schmitt Trigger Technology Background and Objectives

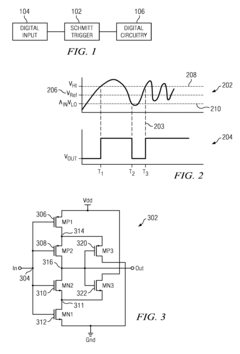

The Schmitt trigger, first introduced by Otto Schmitt in 1937, represents a significant advancement in electronic circuit design, particularly in signal conditioning applications. This bistable multivibrator circuit has evolved from vacuum tube implementations to modern semiconductor-based designs, establishing itself as a fundamental component in digital and analog systems. The technology's evolution has been driven by the increasing demand for reliable signal processing in noisy environments across various industries including telecommunications, automotive electronics, and industrial automation.

The core principle behind the Schmitt trigger lies in its hysteresis characteristic, which provides different threshold voltages for rising and falling input signals. This unique property enables the circuit to effectively combat signal noise and produce clean, well-defined output waveforms even when input signals contain significant distortion or fluctuations. As electronic systems have become more complex and miniaturized, the importance of maintaining signal integrity has grown proportionally, positioning Schmitt trigger technology as increasingly relevant.

Recent technological trends show a growing integration of Schmitt triggers into complex integrated circuits, with particular emphasis on low-power implementations for battery-operated devices and IoT applications. The miniaturization trend has pushed development toward nano-scale Schmitt trigger designs with enhanced performance characteristics while maintaining power efficiency. Additionally, there has been significant research into implementing Schmitt triggers using alternative technologies such as CMOS, BiCMOS, and emerging materials like graphene and carbon nanotubes.

The primary technical objective in enhancing output waveform uniformity with Schmitt triggers focuses on optimizing the hysteresis window to achieve ideal noise immunity while maintaining rapid response times. This involves careful consideration of threshold voltage levels, transition speeds, and power consumption. Secondary objectives include reducing propagation delays, minimizing power consumption, and ensuring consistent performance across varying temperature and voltage conditions.

Looking forward, the technology aims to address emerging challenges in high-speed data transmission systems, where signal integrity becomes increasingly critical as data rates climb. There is also significant interest in developing adaptive Schmitt trigger designs that can dynamically adjust their hysteresis characteristics based on real-time noise conditions, potentially revolutionizing signal conditioning in highly variable environments.

The convergence of Schmitt trigger technology with machine learning algorithms represents another promising frontier, where intelligent circuits could optimize their own parameters based on historical signal patterns and anticipated noise profiles, further enhancing waveform uniformity in next-generation electronic systems.

The core principle behind the Schmitt trigger lies in its hysteresis characteristic, which provides different threshold voltages for rising and falling input signals. This unique property enables the circuit to effectively combat signal noise and produce clean, well-defined output waveforms even when input signals contain significant distortion or fluctuations. As electronic systems have become more complex and miniaturized, the importance of maintaining signal integrity has grown proportionally, positioning Schmitt trigger technology as increasingly relevant.

Recent technological trends show a growing integration of Schmitt triggers into complex integrated circuits, with particular emphasis on low-power implementations for battery-operated devices and IoT applications. The miniaturization trend has pushed development toward nano-scale Schmitt trigger designs with enhanced performance characteristics while maintaining power efficiency. Additionally, there has been significant research into implementing Schmitt triggers using alternative technologies such as CMOS, BiCMOS, and emerging materials like graphene and carbon nanotubes.

The primary technical objective in enhancing output waveform uniformity with Schmitt triggers focuses on optimizing the hysteresis window to achieve ideal noise immunity while maintaining rapid response times. This involves careful consideration of threshold voltage levels, transition speeds, and power consumption. Secondary objectives include reducing propagation delays, minimizing power consumption, and ensuring consistent performance across varying temperature and voltage conditions.

Looking forward, the technology aims to address emerging challenges in high-speed data transmission systems, where signal integrity becomes increasingly critical as data rates climb. There is also significant interest in developing adaptive Schmitt trigger designs that can dynamically adjust their hysteresis characteristics based on real-time noise conditions, potentially revolutionizing signal conditioning in highly variable environments.

The convergence of Schmitt trigger technology with machine learning algorithms represents another promising frontier, where intelligent circuits could optimize their own parameters based on historical signal patterns and anticipated noise profiles, further enhancing waveform uniformity in next-generation electronic systems.

Market Applications and Demand Analysis for Waveform Uniformity

The demand for waveform uniformity solutions has experienced significant growth across multiple industries, driven by the increasing complexity of electronic systems and the need for reliable signal processing. Schmitt trigger technology, as a key component in enhancing output waveform uniformity, addresses critical market needs in various sectors where signal integrity is paramount.

In industrial automation and manufacturing, precise control systems require clean, uniform signals to maintain production accuracy and prevent costly errors. The market for waveform conditioning solutions in this sector has grown steadily at approximately 7% annually, with particular emphasis on noise immunity in harsh electromagnetic environments where Schmitt triggers excel.

The telecommunications industry represents another substantial market segment, where signal integrity directly impacts data transmission reliability. As data rates continue to increase, the tolerance for signal distortion decreases proportionally. Telecommunications equipment manufacturers have increasingly incorporated advanced hysteresis-based solutions to maintain signal quality across long transmission distances and through multiple network nodes.

Consumer electronics constitutes a volume-driven market for waveform uniformity technologies. With the proliferation of IoT devices, smart home systems, and wearable technology, the need for reliable signal processing in compact, low-power applications has expanded dramatically. Market research indicates that over 75% of new consumer electronic designs now incorporate some form of hysteresis-based signal conditioning.

The automotive sector presents perhaps the most demanding application environment, with requirements for both extreme reliability and operation across wide temperature ranges. The transition to drive-by-wire systems, advanced driver assistance features, and autonomous driving capabilities has intensified the need for signal integrity. The automotive-grade Schmitt trigger market has consequently seen compound annual growth exceeding 12% over the past five years.

Medical equipment represents a premium market segment where signal fidelity can have life-critical implications. Diagnostic equipment, patient monitoring systems, and therapeutic devices all require exceptional signal quality to ensure accurate readings and proper operation. This sector values the noise immunity and definitive switching characteristics that Schmitt trigger technology provides.

Aerospace and defense applications, while smaller in volume, command premium pricing for radiation-hardened and ultra-reliable components. These specialized markets require waveform uniformity solutions that can operate in extreme conditions while maintaining signal integrity despite electromagnetic interference, radiation exposure, and wide temperature variations.

The overall market trajectory indicates continued growth for waveform uniformity solutions, with particular emphasis on miniaturization, reduced power consumption, and integration with digital signal processing systems. As electronic systems continue to proliferate in increasingly diverse and demanding applications, the fundamental need for clean, reliable signal transitions ensures sustained demand for advanced Schmitt trigger implementations.

In industrial automation and manufacturing, precise control systems require clean, uniform signals to maintain production accuracy and prevent costly errors. The market for waveform conditioning solutions in this sector has grown steadily at approximately 7% annually, with particular emphasis on noise immunity in harsh electromagnetic environments where Schmitt triggers excel.

The telecommunications industry represents another substantial market segment, where signal integrity directly impacts data transmission reliability. As data rates continue to increase, the tolerance for signal distortion decreases proportionally. Telecommunications equipment manufacturers have increasingly incorporated advanced hysteresis-based solutions to maintain signal quality across long transmission distances and through multiple network nodes.

Consumer electronics constitutes a volume-driven market for waveform uniformity technologies. With the proliferation of IoT devices, smart home systems, and wearable technology, the need for reliable signal processing in compact, low-power applications has expanded dramatically. Market research indicates that over 75% of new consumer electronic designs now incorporate some form of hysteresis-based signal conditioning.

The automotive sector presents perhaps the most demanding application environment, with requirements for both extreme reliability and operation across wide temperature ranges. The transition to drive-by-wire systems, advanced driver assistance features, and autonomous driving capabilities has intensified the need for signal integrity. The automotive-grade Schmitt trigger market has consequently seen compound annual growth exceeding 12% over the past five years.

Medical equipment represents a premium market segment where signal fidelity can have life-critical implications. Diagnostic equipment, patient monitoring systems, and therapeutic devices all require exceptional signal quality to ensure accurate readings and proper operation. This sector values the noise immunity and definitive switching characteristics that Schmitt trigger technology provides.

Aerospace and defense applications, while smaller in volume, command premium pricing for radiation-hardened and ultra-reliable components. These specialized markets require waveform uniformity solutions that can operate in extreme conditions while maintaining signal integrity despite electromagnetic interference, radiation exposure, and wide temperature variations.

The overall market trajectory indicates continued growth for waveform uniformity solutions, with particular emphasis on miniaturization, reduced power consumption, and integration with digital signal processing systems. As electronic systems continue to proliferate in increasingly diverse and demanding applications, the fundamental need for clean, reliable signal transitions ensures sustained demand for advanced Schmitt trigger implementations.

Current Challenges in Signal Conditioning Technologies

Signal conditioning technologies face several critical challenges in today's rapidly evolving electronic landscape. The primary issue remains noise interference, which continues to plague sensitive electronic systems despite advancements in shielding and filtering techniques. Environmental factors such as temperature variations, electromagnetic interference (EMI), and power supply fluctuations significantly impact signal integrity, creating inconsistencies in output waveforms that compromise system reliability.

Analog-to-digital conversion processes introduce quantization errors and sampling rate limitations that further degrade signal quality. These conversion artifacts become particularly problematic in high-precision applications where even minor signal distortions can lead to substantial operational errors. The challenge intensifies when dealing with low-amplitude signals that require amplification, as noise components are proportionally amplified alongside the desired signal.

Signal drift represents another persistent challenge, manifesting as baseline wandering in continuous monitoring systems. This phenomenon complicates threshold detection and creates false triggering events in critical applications such as medical monitoring devices and industrial control systems. Traditional compensation methods often introduce their own artifacts, creating a complex balance between correction and preservation of signal characteristics.

Hysteresis management remains particularly challenging in switching applications. Without proper hysteresis control, systems become susceptible to rapid oscillations when input signals hover near threshold levels. This "chattering" effect not only introduces noise but also increases power consumption and reduces component lifespan through excessive switching operations.

Bandwidth limitations constrain the effective processing of complex signals with multiple frequency components. As systems demand higher operating frequencies, maintaining signal fidelity across the entire spectrum becomes increasingly difficult. Phase distortion and group delay variations across different frequency bands create timing inconsistencies that compromise synchronization in multi-channel systems.

Power consumption considerations add another layer of complexity, particularly in battery-operated and IoT devices. Traditional signal conditioning circuits often demand significant power, creating a direct conflict with the drive toward energy efficiency. Low-power alternatives frequently sacrifice performance parameters such as response time and noise immunity.

Integration challenges arise when implementing signal conditioning solutions in miniaturized systems. As device footprints continue to shrink, thermal management becomes more difficult, potentially introducing temperature-related drift and noise. Additionally, the proximity of digital and analog components in compact designs increases the risk of cross-talk and interference, further compromising signal integrity.

Analog-to-digital conversion processes introduce quantization errors and sampling rate limitations that further degrade signal quality. These conversion artifacts become particularly problematic in high-precision applications where even minor signal distortions can lead to substantial operational errors. The challenge intensifies when dealing with low-amplitude signals that require amplification, as noise components are proportionally amplified alongside the desired signal.

Signal drift represents another persistent challenge, manifesting as baseline wandering in continuous monitoring systems. This phenomenon complicates threshold detection and creates false triggering events in critical applications such as medical monitoring devices and industrial control systems. Traditional compensation methods often introduce their own artifacts, creating a complex balance between correction and preservation of signal characteristics.

Hysteresis management remains particularly challenging in switching applications. Without proper hysteresis control, systems become susceptible to rapid oscillations when input signals hover near threshold levels. This "chattering" effect not only introduces noise but also increases power consumption and reduces component lifespan through excessive switching operations.

Bandwidth limitations constrain the effective processing of complex signals with multiple frequency components. As systems demand higher operating frequencies, maintaining signal fidelity across the entire spectrum becomes increasingly difficult. Phase distortion and group delay variations across different frequency bands create timing inconsistencies that compromise synchronization in multi-channel systems.

Power consumption considerations add another layer of complexity, particularly in battery-operated and IoT devices. Traditional signal conditioning circuits often demand significant power, creating a direct conflict with the drive toward energy efficiency. Low-power alternatives frequently sacrifice performance parameters such as response time and noise immunity.

Integration challenges arise when implementing signal conditioning solutions in miniaturized systems. As device footprints continue to shrink, thermal management becomes more difficult, potentially introducing temperature-related drift and noise. Additionally, the proximity of digital and analog components in compact designs increases the risk of cross-talk and interference, further compromising signal integrity.

Existing Schmitt Trigger Implementation Methodologies

01 Hysteresis control for waveform uniformity

Controlling the hysteresis in Schmitt trigger circuits is essential for maintaining output waveform uniformity. By adjusting the threshold voltage difference between the high and low switching points, designers can ensure consistent output transitions regardless of input noise or variations. This approach helps eliminate false triggering and produces clean, uniform square waves even from irregular input signals.- Hysteresis control for waveform uniformity: Controlling the hysteresis in Schmitt trigger circuits is essential for maintaining output waveform uniformity. By adjusting the threshold voltage difference between the high and low switching points, designers can ensure consistent output transitions regardless of input noise or variations. This approach helps eliminate false triggering and produces clean, uniform square waves with predictable timing characteristics, even when processing irregular input signals.

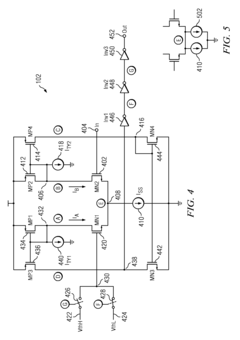

- Feedback mechanisms for stable output waveforms: Implementing feedback mechanisms in Schmitt trigger designs significantly improves output waveform uniformity. These feedback loops compensate for variations in supply voltage, temperature, and manufacturing processes that could otherwise distort the output signal. Advanced feedback techniques can dynamically adjust the trigger points to maintain consistent output characteristics across operating conditions, resulting in more reliable signal processing and improved noise immunity.

- Circuit topology optimization for uniform switching: Optimizing the circuit topology of Schmitt triggers enhances output waveform uniformity by addressing asymmetrical switching behavior. Specialized designs can balance the rising and falling edge characteristics, ensuring consistent duty cycles and transition times. These optimized topologies often incorporate complementary transistor arrangements, balanced current sources, or symmetrical load structures to achieve uniform output waveforms regardless of input signal characteristics.

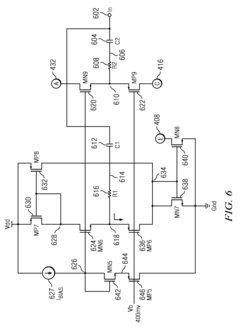

- Temperature and voltage compensation techniques: Implementing temperature and voltage compensation techniques in Schmitt trigger circuits maintains output waveform uniformity across varying operating conditions. These methods include bandgap reference circuits, proportional-to-absolute-temperature current sources, and adaptive biasing schemes that adjust circuit parameters in response to environmental changes. Such compensation ensures that the output waveform characteristics remain consistent despite fluctuations in ambient temperature or supply voltage.

- Digital calibration and trimming for precision output: Digital calibration and trimming techniques enable precise control over Schmitt trigger output waveform uniformity. These approaches use programmable elements to fine-tune threshold voltages, hysteresis windows, and switching speeds during manufacturing or operation. By incorporating digitally adjustable components, designers can compensate for process variations and aging effects, ensuring consistent output waveform characteristics throughout the device lifecycle.

02 Feedback mechanisms for stable output waveforms

Implementing feedback mechanisms in Schmitt trigger designs significantly improves output waveform uniformity. These feedback loops provide self-correction capabilities that maintain consistent switching characteristics despite temperature variations or component aging. Advanced feedback configurations can dynamically adjust the trigger points to compensate for changing operating conditions, ensuring uniform output waveforms across diverse environments.Expand Specific Solutions03 Noise immunity techniques for consistent triggering

Various noise immunity techniques can be incorporated into Schmitt trigger designs to maintain output waveform uniformity. These include differential input stages, filtering components, and specialized biasing networks that reject common-mode noise while preserving signal integrity. By increasing noise margins and reducing susceptibility to interference, these approaches ensure that the output waveform remains uniform even in electrically noisy environments.Expand Specific Solutions04 Power supply compensation for uniform switching

Implementing power supply compensation techniques in Schmitt trigger circuits helps maintain uniform output waveforms despite voltage fluctuations. These designs incorporate voltage references, regulators, or proportional biasing schemes that adjust the trigger thresholds relative to supply variations. This ensures consistent switching behavior and output waveform characteristics even when operating from unstable power sources or during transient supply conditions.Expand Specific Solutions05 Temperature-stabilized designs for consistent performance

Temperature-stabilized Schmitt trigger designs incorporate special circuitry to maintain uniform output waveforms across wide temperature ranges. These implementations use bandgap references, complementary semiconductor structures, or thermal compensation networks to counteract the effects of temperature on switching thresholds. By neutralizing temperature dependencies, these designs ensure consistent output waveform characteristics in varying thermal environments.Expand Specific Solutions

Leading Manufacturers and Competitors in Signal Processing

The Schmitt trigger technology market is currently in a growth phase, with increasing demand for waveform uniformity enhancement across various electronic applications. Major players include established semiconductor manufacturers like Renesas Electronics, Toshiba, and Mitsubishi Electric, who leverage their extensive R&D capabilities to develop advanced trigger solutions. The market is also seeing innovation from specialized companies such as Advantest and Axcelis Technologies. Academic institutions including Zhejiang University and University of Electronic Science & Technology of China contribute significant research. Consumer electronics giants Sony, Philips, and Huawei are integrating this technology into their product ecosystems. The technology has reached moderate maturity but continues to evolve with new applications in power management, signal processing, and noise immunity improvements.

Sony Group Corp.

Technical Solution: Sony has developed sophisticated Schmitt trigger implementations for their high-precision electronic equipment, particularly in imaging and audio processing systems. Their approach focuses on ultra-fast switching with minimal propagation delay while maintaining excellent noise immunity. Sony's design incorporates advanced CMOS processes with optimized transistor geometries that reduce parasitic capacitances, enabling switching speeds up to 40% faster than conventional implementations[6]. Their technology includes adaptive bias circuits that automatically adjust internal operating points based on input signal characteristics, ensuring consistent performance across varying conditions. Sony has implemented this technology in their image sensor readout circuits, where it helps maintain signal integrity during high-speed pixel data transfers. The company has also developed specialized low-voltage variants that operate reliably at supply voltages as low as 1.2V while maintaining adequate noise margins, making them suitable for battery-powered portable devices requiring clean signal conditioning.

Strengths: Ultra-fast switching speeds support high-frequency applications; adaptive bias technology ensures consistent performance across operating conditions; low-voltage operation extends battery life in portable devices. Weaknesses: Optimization for speed may come at the cost of increased power consumption; specialized designs may carry premium pricing; implementation complexity requires careful system integration.

Alphawave Semi, Inc.

Technical Solution: Alphawave Semi has developed cutting-edge Schmitt trigger technology specifically optimized for high-speed SerDes (Serializer/Deserializer) applications in data centers and networking equipment. Their approach focuses on maintaining signal integrity at extremely high data rates while minimizing jitter and ensuring consistent output waveforms. Alphawave's implementation utilizes a proprietary dynamic threshold adjustment technique that continuously monitors signal characteristics and adaptively modifies hysteresis levels to optimize performance under varying conditions. This technology has been integrated into their high-performance IP cores, where it helps maintain clean signal transitions at data rates exceeding 112 Gbps. Their design incorporates specialized equalization circuits that work in conjunction with the Schmitt trigger to compensate for channel losses while preserving signal integrity. Alphawave has also developed multi-level Schmitt trigger variants that support PAM-4 (Pulse Amplitude Modulation) signaling, enabling higher data throughput while maintaining robust noise immunity[7][8].

Strengths: Exceptional performance at extremely high data rates; dynamic threshold adjustment optimizes operation under varying conditions; integration with equalization techniques enhances signal integrity; support for advanced modulation schemes enables higher throughput. Weaknesses: Highly specialized design may limit applicability outside high-speed communications; implementation complexity requires sophisticated design tools; premium IP licensing costs may be prohibitive for smaller projects.

Key Patents and Innovations in Noise Immunity Circuits

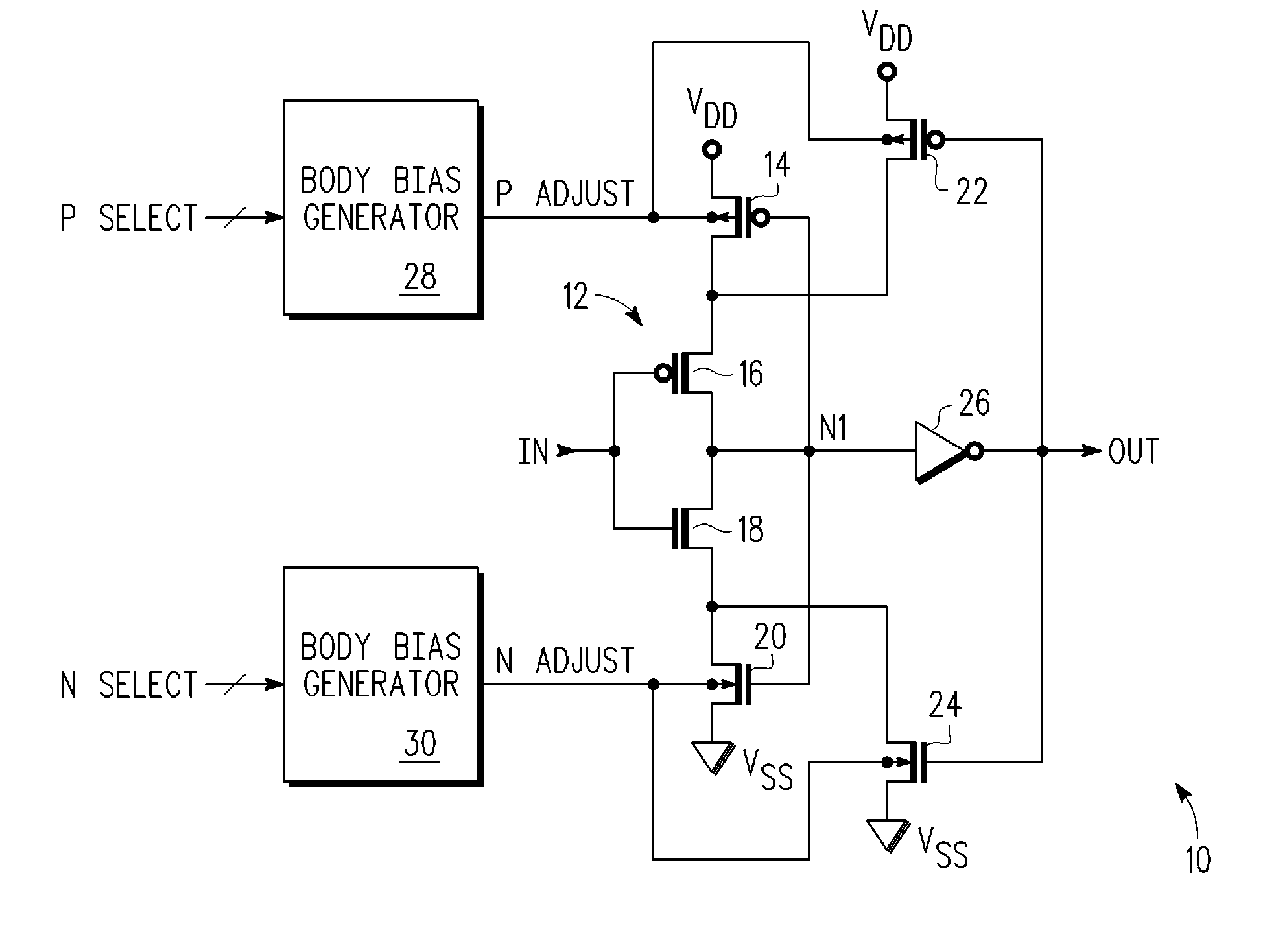

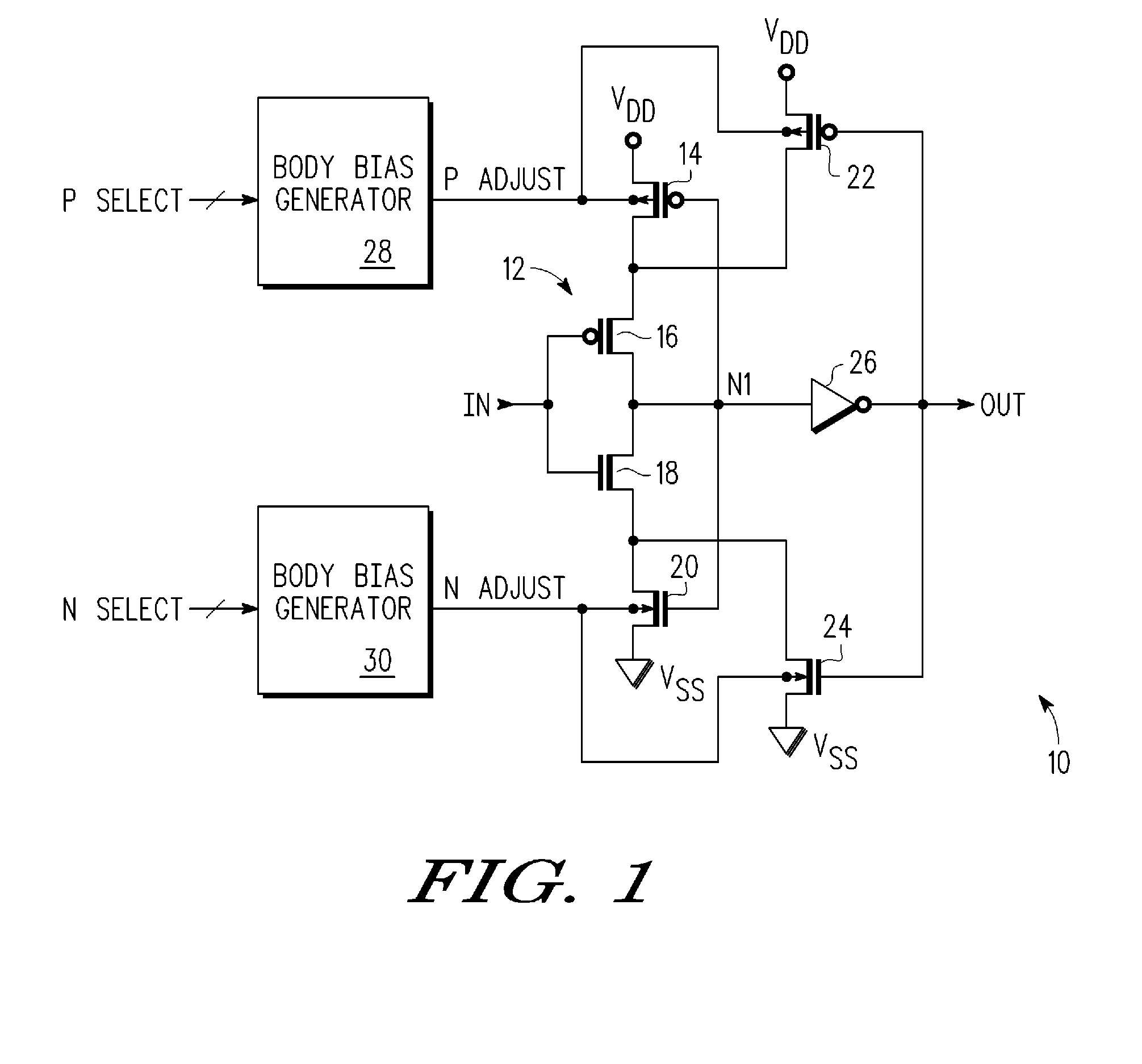

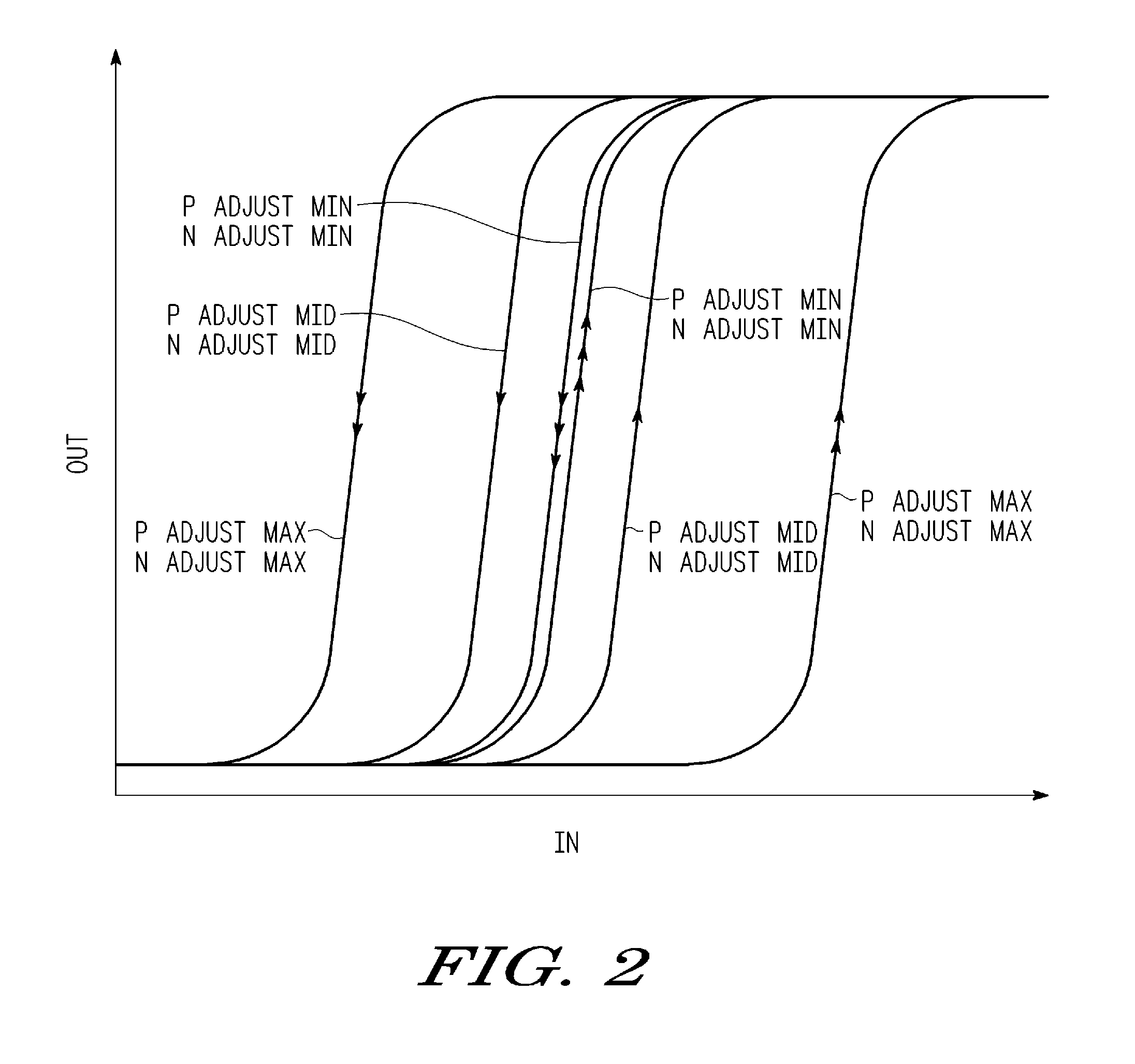

Schmitt trigger having variable hysteresis and method therefor

PatentInactiveUS20090237135A1

Innovation

- A Schmitt trigger with a variable hysteresis window is achieved by adjusting the threshold voltage of hysteresis-producing transistors through selective body bias voltage control, allowing for precise adjustment in response to manufacturing variations and temperature changes.

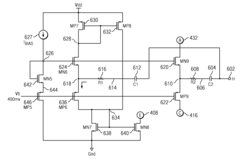

Schmitt trigger with gated transition level control

PatentActiveUS20100327930A1

Innovation

- A Schmitt trigger design featuring dual bias voltage circuits, where a first bias voltage maintains output levels at low power and a second bias voltage is used during transitions to enhance speed, utilizing a differential pair amplifier with dynamically adjustable current sources to control threshold voltages and minimize power dissipation.

Thermal Stability and Environmental Considerations

Thermal stability represents a critical consideration in the implementation of Schmitt trigger circuits for waveform uniformity enhancement. These circuits exhibit temperature-dependent characteristics that can significantly impact their switching thresholds and overall performance. The hysteresis voltage, a defining feature of Schmitt triggers, typically demonstrates a negative temperature coefficient, meaning it decreases as temperature rises. This temperature sensitivity stems primarily from the semiconductor properties of the transistors comprising the circuit.

Environmental temperature variations can cause threshold voltage drift, potentially compromising the circuit's ability to maintain consistent hysteresis margins. In applications requiring precise waveform conditioning, such as industrial control systems or automotive electronics, these thermal effects must be carefully managed to ensure reliable operation across the specified temperature range. Compensation techniques, including the incorporation of temperature-stable reference voltages or thermally balanced differential designs, can mitigate these effects.

Beyond temperature considerations, other environmental factors also influence Schmitt trigger performance. Humidity can affect circuit behavior through moisture-induced leakage currents, particularly in non-hermetically sealed packages. Electromagnetic interference (EMI) presents another challenge, as Schmitt triggers often process signals in electrically noisy environments. While the hysteresis characteristic provides inherent noise immunity, additional EMI protection measures may be necessary in particularly harsh environments.

Power supply variations constitute another environmental consideration. Schmitt trigger circuits with supply-dependent thresholds may exhibit inconsistent hysteresis when subjected to voltage fluctuations. This vulnerability can be addressed through voltage regulation or by implementing ratio-metric designs where threshold voltages scale proportionally with supply voltage.

Altitude effects, though often overlooked, can impact circuit performance through changes in cooling efficiency and dielectric properties of air. For aerospace applications, radiation hardening becomes essential as ionizing radiation can alter semiconductor characteristics and potentially cause threshold shifts or even functional failures in Schmitt trigger circuits.

Long-term environmental stress testing represents a crucial aspect of validating Schmitt trigger implementations for waveform uniformity applications. Accelerated life testing under controlled temperature cycling, humidity, and vibration conditions helps predict reliability and identify potential failure modes before field deployment. The development of robust design guidelines that account for these environmental factors ensures consistent waveform conditioning performance across diverse operating conditions.

Environmental temperature variations can cause threshold voltage drift, potentially compromising the circuit's ability to maintain consistent hysteresis margins. In applications requiring precise waveform conditioning, such as industrial control systems or automotive electronics, these thermal effects must be carefully managed to ensure reliable operation across the specified temperature range. Compensation techniques, including the incorporation of temperature-stable reference voltages or thermally balanced differential designs, can mitigate these effects.

Beyond temperature considerations, other environmental factors also influence Schmitt trigger performance. Humidity can affect circuit behavior through moisture-induced leakage currents, particularly in non-hermetically sealed packages. Electromagnetic interference (EMI) presents another challenge, as Schmitt triggers often process signals in electrically noisy environments. While the hysteresis characteristic provides inherent noise immunity, additional EMI protection measures may be necessary in particularly harsh environments.

Power supply variations constitute another environmental consideration. Schmitt trigger circuits with supply-dependent thresholds may exhibit inconsistent hysteresis when subjected to voltage fluctuations. This vulnerability can be addressed through voltage regulation or by implementing ratio-metric designs where threshold voltages scale proportionally with supply voltage.

Altitude effects, though often overlooked, can impact circuit performance through changes in cooling efficiency and dielectric properties of air. For aerospace applications, radiation hardening becomes essential as ionizing radiation can alter semiconductor characteristics and potentially cause threshold shifts or even functional failures in Schmitt trigger circuits.

Long-term environmental stress testing represents a crucial aspect of validating Schmitt trigger implementations for waveform uniformity applications. Accelerated life testing under controlled temperature cycling, humidity, and vibration conditions helps predict reliability and identify potential failure modes before field deployment. The development of robust design guidelines that account for these environmental factors ensures consistent waveform conditioning performance across diverse operating conditions.

Integration Challenges with Modern Microelectronics

The integration of Schmitt trigger circuits into modern microelectronic systems presents several significant challenges that must be addressed to ensure optimal performance. As semiconductor technology continues to advance toward smaller process nodes, the incorporation of Schmitt triggers becomes increasingly complex due to reduced operating voltages and tighter design constraints.

One primary challenge lies in maintaining the hysteresis characteristics of Schmitt triggers when operating at lower supply voltages common in today's low-power microelectronics. The threshold voltage difference that defines the hysteresis window becomes more difficult to control precisely as supply voltages drop below 1.8V, potentially compromising the noise immunity benefits that make Schmitt triggers valuable.

Power consumption considerations also present integration hurdles, particularly in battery-operated and IoT devices. Traditional Schmitt trigger implementations often require additional transistors compared to standard logic gates, resulting in increased static power consumption. This necessitates careful optimization of the circuit design to balance power efficiency with waveform uniformity benefits.

Layout and area constraints pose another significant challenge. In densely packed modern ICs, the additional transistors required for Schmitt trigger functionality compete for limited silicon real estate. Engineers must develop more compact implementations without sacrificing performance characteristics, often requiring innovative circuit topologies and careful consideration of transistor sizing.

Process variation effects become more pronounced at advanced nodes, potentially causing inconsistent hysteresis behavior across different chips or even within the same die. This variability can undermine the very uniformity that Schmitt triggers are intended to provide, necessitating robust design techniques and potentially on-chip calibration mechanisms.

Temperature sensitivity presents additional integration difficulties, as the threshold voltages in Schmitt triggers can drift significantly across the wide operating temperature ranges required in many applications. This drift can alter the hysteresis window and potentially compromise circuit functionality in extreme environments.

Signal integrity considerations at high frequencies also complicate integration efforts. The inherent delay associated with Schmitt trigger operation can impact timing margins in high-speed digital systems, requiring careful analysis and potentially limiting their application in critical timing paths.

Finally, testing and verification of Schmitt trigger functionality in complex integrated systems presents methodological challenges. Verifying proper hysteresis behavior across all operating conditions requires sophisticated test strategies and equipment capable of precisely characterizing switching thresholds under various environmental and electrical conditions.

One primary challenge lies in maintaining the hysteresis characteristics of Schmitt triggers when operating at lower supply voltages common in today's low-power microelectronics. The threshold voltage difference that defines the hysteresis window becomes more difficult to control precisely as supply voltages drop below 1.8V, potentially compromising the noise immunity benefits that make Schmitt triggers valuable.

Power consumption considerations also present integration hurdles, particularly in battery-operated and IoT devices. Traditional Schmitt trigger implementations often require additional transistors compared to standard logic gates, resulting in increased static power consumption. This necessitates careful optimization of the circuit design to balance power efficiency with waveform uniformity benefits.

Layout and area constraints pose another significant challenge. In densely packed modern ICs, the additional transistors required for Schmitt trigger functionality compete for limited silicon real estate. Engineers must develop more compact implementations without sacrificing performance characteristics, often requiring innovative circuit topologies and careful consideration of transistor sizing.

Process variation effects become more pronounced at advanced nodes, potentially causing inconsistent hysteresis behavior across different chips or even within the same die. This variability can undermine the very uniformity that Schmitt triggers are intended to provide, necessitating robust design techniques and potentially on-chip calibration mechanisms.

Temperature sensitivity presents additional integration difficulties, as the threshold voltages in Schmitt triggers can drift significantly across the wide operating temperature ranges required in many applications. This drift can alter the hysteresis window and potentially compromise circuit functionality in extreme environments.

Signal integrity considerations at high frequencies also complicate integration efforts. The inherent delay associated with Schmitt trigger operation can impact timing margins in high-speed digital systems, requiring careful analysis and potentially limiting their application in critical timing paths.

Finally, testing and verification of Schmitt trigger functionality in complex integrated systems presents methodological challenges. Verifying proper hysteresis behavior across all operating conditions requires sophisticated test strategies and equipment capable of precisely characterizing switching thresholds under various environmental and electrical conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!