Application of AI in Blade Battery Performance Monitoring

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AI in Blade Battery: Background and Objectives

The application of Artificial Intelligence (AI) in blade battery performance monitoring represents a significant advancement in the field of energy storage technology. Blade batteries, a type of lithium iron phosphate (LFP) battery, have gained prominence due to their enhanced safety features and improved energy density. The integration of AI into this technology aims to optimize battery performance, extend lifespan, and enhance overall system reliability.

The evolution of battery technology has been driven by the increasing demand for sustainable energy solutions, particularly in electric vehicles and renewable energy storage systems. Blade batteries, introduced in recent years, have emerged as a promising solution to address safety concerns associated with traditional lithium-ion batteries. The incorporation of AI in monitoring these batteries marks a new frontier in battery management systems.

AI-powered monitoring systems for blade batteries leverage machine learning algorithms and advanced data analytics to provide real-time insights into battery health and performance. These systems can analyze vast amounts of data collected from various sensors, including voltage, current, temperature, and internal resistance measurements. By processing this data, AI can detect patterns and anomalies that may be indicative of potential issues or degradation in battery performance.

The primary objectives of implementing AI in blade battery performance monitoring are multifaceted. Firstly, it aims to enhance safety by identifying potential risks before they escalate into critical issues. This proactive approach can prevent thermal runaway events and other safety hazards associated with battery failures. Secondly, AI-driven monitoring seeks to optimize battery performance by adjusting charging and discharging parameters based on real-time data and historical trends.

Another key goal is to extend the lifespan of blade batteries through predictive maintenance. By analyzing performance data over time, AI algorithms can forecast when maintenance or replacement might be necessary, allowing for timely interventions that can significantly prolong battery life. This not only reduces operational costs but also contributes to sustainability efforts by minimizing waste.

Furthermore, the application of AI in blade battery monitoring aims to improve overall system efficiency. By providing accurate state-of-charge and state-of-health estimations, AI enables more precise energy management, which is crucial for applications in electric vehicles and grid-scale energy storage. This level of precision can lead to improved range predictions in electric vehicles and more effective load balancing in power grids.

As the technology continues to evolve, researchers and industry experts anticipate further advancements in AI capabilities for battery monitoring. Future developments may include more sophisticated predictive models, enhanced integration with other vehicle or grid systems, and the potential for self-learning algorithms that can adapt to changing battery conditions over time.

The evolution of battery technology has been driven by the increasing demand for sustainable energy solutions, particularly in electric vehicles and renewable energy storage systems. Blade batteries, introduced in recent years, have emerged as a promising solution to address safety concerns associated with traditional lithium-ion batteries. The incorporation of AI in monitoring these batteries marks a new frontier in battery management systems.

AI-powered monitoring systems for blade batteries leverage machine learning algorithms and advanced data analytics to provide real-time insights into battery health and performance. These systems can analyze vast amounts of data collected from various sensors, including voltage, current, temperature, and internal resistance measurements. By processing this data, AI can detect patterns and anomalies that may be indicative of potential issues or degradation in battery performance.

The primary objectives of implementing AI in blade battery performance monitoring are multifaceted. Firstly, it aims to enhance safety by identifying potential risks before they escalate into critical issues. This proactive approach can prevent thermal runaway events and other safety hazards associated with battery failures. Secondly, AI-driven monitoring seeks to optimize battery performance by adjusting charging and discharging parameters based on real-time data and historical trends.

Another key goal is to extend the lifespan of blade batteries through predictive maintenance. By analyzing performance data over time, AI algorithms can forecast when maintenance or replacement might be necessary, allowing for timely interventions that can significantly prolong battery life. This not only reduces operational costs but also contributes to sustainability efforts by minimizing waste.

Furthermore, the application of AI in blade battery monitoring aims to improve overall system efficiency. By providing accurate state-of-charge and state-of-health estimations, AI enables more precise energy management, which is crucial for applications in electric vehicles and grid-scale energy storage. This level of precision can lead to improved range predictions in electric vehicles and more effective load balancing in power grids.

As the technology continues to evolve, researchers and industry experts anticipate further advancements in AI capabilities for battery monitoring. Future developments may include more sophisticated predictive models, enhanced integration with other vehicle or grid systems, and the potential for self-learning algorithms that can adapt to changing battery conditions over time.

Market Analysis for AI-Enhanced Battery Monitoring

The market for AI-enhanced battery monitoring systems, particularly in the context of blade batteries, is experiencing significant growth and transformation. This surge is primarily driven by the increasing adoption of electric vehicles (EVs) and the growing demand for more efficient and reliable energy storage solutions. The global EV battery market, which forms a substantial part of this sector, is projected to reach $133.46 billion by 2027, with a compound annual growth rate (CAGR) of 18.0% from 2020 to 2027.

The application of AI in blade battery performance monitoring addresses several critical market needs. Firstly, it enhances the safety and reliability of battery systems, a paramount concern for EV manufacturers and consumers alike. AI algorithms can predict potential failures, detect anomalies, and optimize battery performance in real-time, significantly reducing the risk of thermal runaway and other safety hazards associated with lithium-ion batteries.

Secondly, AI-enhanced monitoring systems contribute to extending battery life and improving overall efficiency. By continuously analyzing battery health and performance data, these systems can optimize charging and discharging cycles, potentially increasing the lifespan of blade batteries by up to 20-30%. This longevity is a key selling point in the EV market, where battery life directly impacts vehicle range and long-term cost of ownership.

The market for these advanced monitoring systems is not limited to the automotive sector. There is growing demand in renewable energy storage, consumer electronics, and industrial applications. The global energy storage market, which heavily relies on advanced battery technologies, is expected to deploy 411 GWh of capacity by 2030, presenting a vast opportunity for AI-enhanced monitoring solutions.

Geographically, the market shows strong growth in regions with high EV adoption rates and supportive government policies. China, the world's largest EV market, is expected to lead in the adoption of AI-enhanced battery monitoring systems, followed by Europe and North America. The Asia-Pacific region as a whole is projected to witness the highest CAGR in the battery management system market, driven by the presence of major battery manufacturers and the rapid expansion of EV production.

Key market drivers include stringent safety regulations, increasing investments in R&D for battery technologies, and the push for sustainable transportation solutions. However, challenges such as high initial implementation costs and the need for standardization in AI algorithms across different battery types may impact market growth.

In conclusion, the market for AI-enhanced battery monitoring, particularly for blade batteries, shows robust growth potential. The technology's ability to address critical issues of safety, efficiency, and longevity positions it as a crucial component in the evolving landscape of energy storage and electric mobility.

The application of AI in blade battery performance monitoring addresses several critical market needs. Firstly, it enhances the safety and reliability of battery systems, a paramount concern for EV manufacturers and consumers alike. AI algorithms can predict potential failures, detect anomalies, and optimize battery performance in real-time, significantly reducing the risk of thermal runaway and other safety hazards associated with lithium-ion batteries.

Secondly, AI-enhanced monitoring systems contribute to extending battery life and improving overall efficiency. By continuously analyzing battery health and performance data, these systems can optimize charging and discharging cycles, potentially increasing the lifespan of blade batteries by up to 20-30%. This longevity is a key selling point in the EV market, where battery life directly impacts vehicle range and long-term cost of ownership.

The market for these advanced monitoring systems is not limited to the automotive sector. There is growing demand in renewable energy storage, consumer electronics, and industrial applications. The global energy storage market, which heavily relies on advanced battery technologies, is expected to deploy 411 GWh of capacity by 2030, presenting a vast opportunity for AI-enhanced monitoring solutions.

Geographically, the market shows strong growth in regions with high EV adoption rates and supportive government policies. China, the world's largest EV market, is expected to lead in the adoption of AI-enhanced battery monitoring systems, followed by Europe and North America. The Asia-Pacific region as a whole is projected to witness the highest CAGR in the battery management system market, driven by the presence of major battery manufacturers and the rapid expansion of EV production.

Key market drivers include stringent safety regulations, increasing investments in R&D for battery technologies, and the push for sustainable transportation solutions. However, challenges such as high initial implementation costs and the need for standardization in AI algorithms across different battery types may impact market growth.

In conclusion, the market for AI-enhanced battery monitoring, particularly for blade batteries, shows robust growth potential. The technology's ability to address critical issues of safety, efficiency, and longevity positions it as a crucial component in the evolving landscape of energy storage and electric mobility.

Current AI Applications in Battery Performance Monitoring

Artificial Intelligence (AI) has made significant strides in battery performance monitoring, particularly for blade batteries. Current applications leverage machine learning algorithms and advanced data analytics to enhance the efficiency, safety, and longevity of battery systems.

One prominent application is predictive maintenance, where AI models analyze real-time sensor data to forecast potential battery failures or performance degradation. These systems can detect subtle changes in voltage, current, and temperature patterns that may indicate impending issues, allowing for proactive maintenance and reducing downtime.

AI-driven Battery Management Systems (BMS) have also become increasingly sophisticated. These systems use neural networks to optimize charging and discharging cycles, adapting to various environmental conditions and usage patterns. By continuously learning from operational data, AI-enhanced BMS can extend battery life and improve overall energy efficiency.

Anomaly detection is another critical area where AI excels in blade battery monitoring. Machine learning algorithms can identify unusual behavior or deviations from expected performance metrics, flagging potential safety risks or quality issues in real-time. This capability is particularly valuable in large-scale battery installations, where manual monitoring would be impractical.

Computer vision techniques are being applied to battery manufacturing and quality control processes. AI-powered image recognition systems can detect microscopic defects or irregularities in blade battery components during production, ensuring higher quality standards and reducing the risk of faulty batteries reaching the market.

AI is also being utilized for performance optimization in blade battery systems. Reinforcement learning algorithms are employed to dynamically adjust battery parameters based on usage patterns, environmental factors, and grid conditions. This adaptive approach maximizes energy output while minimizing wear and tear on the battery cells.

In the realm of battery research and development, AI is accelerating the discovery of new materials and designs. Machine learning models can simulate and predict the performance of novel battery compositions, significantly reducing the time and cost associated with traditional experimental methods.

Lastly, AI-driven energy management systems are integrating blade batteries into smart grids more effectively. These systems use predictive algorithms to balance energy supply and demand, optimizing the use of battery storage in conjunction with renewable energy sources and conventional power generation.

One prominent application is predictive maintenance, where AI models analyze real-time sensor data to forecast potential battery failures or performance degradation. These systems can detect subtle changes in voltage, current, and temperature patterns that may indicate impending issues, allowing for proactive maintenance and reducing downtime.

AI-driven Battery Management Systems (BMS) have also become increasingly sophisticated. These systems use neural networks to optimize charging and discharging cycles, adapting to various environmental conditions and usage patterns. By continuously learning from operational data, AI-enhanced BMS can extend battery life and improve overall energy efficiency.

Anomaly detection is another critical area where AI excels in blade battery monitoring. Machine learning algorithms can identify unusual behavior or deviations from expected performance metrics, flagging potential safety risks or quality issues in real-time. This capability is particularly valuable in large-scale battery installations, where manual monitoring would be impractical.

Computer vision techniques are being applied to battery manufacturing and quality control processes. AI-powered image recognition systems can detect microscopic defects or irregularities in blade battery components during production, ensuring higher quality standards and reducing the risk of faulty batteries reaching the market.

AI is also being utilized for performance optimization in blade battery systems. Reinforcement learning algorithms are employed to dynamically adjust battery parameters based on usage patterns, environmental factors, and grid conditions. This adaptive approach maximizes energy output while minimizing wear and tear on the battery cells.

In the realm of battery research and development, AI is accelerating the discovery of new materials and designs. Machine learning models can simulate and predict the performance of novel battery compositions, significantly reducing the time and cost associated with traditional experimental methods.

Lastly, AI-driven energy management systems are integrating blade batteries into smart grids more effectively. These systems use predictive algorithms to balance energy supply and demand, optimizing the use of battery storage in conjunction with renewable energy sources and conventional power generation.

Existing AI Solutions for Blade Battery Monitoring

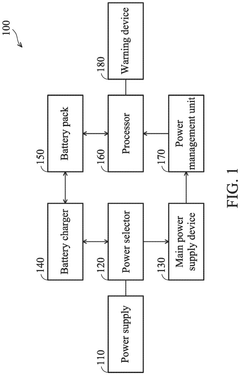

01 Battery Management System for Blade Batteries

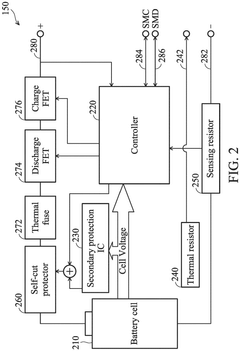

Advanced battery management systems are crucial for optimizing blade battery performance. These systems monitor and control various parameters such as temperature, voltage, and current to ensure efficient operation and longevity of the battery. They also implement safety features and balancing algorithms to maintain optimal performance across all cells in the battery pack.- Battery Management System for Blade Batteries: Advanced battery management systems are crucial for optimizing blade battery performance. These systems monitor and control various parameters such as temperature, voltage, and current to ensure efficient operation and longevity of the battery. They also implement safety features to prevent overcharging, over-discharging, and thermal runaway.

- Thermal Management in Blade Batteries: Effective thermal management is essential for maintaining optimal blade battery performance. This includes innovative cooling systems, heat dissipation techniques, and temperature control mechanisms. Proper thermal management helps prevent capacity loss, extends battery life, and ensures consistent performance across various operating conditions.

- Blade Battery Cell Design and Configuration: The design and configuration of blade battery cells significantly impact overall performance. This includes optimizing cell geometry, electrode materials, and electrolyte composition. Advanced cell designs focus on improving energy density, power output, and structural integrity while minimizing internal resistance and maximizing cycle life.

- Safety Features in Blade Batteries: Incorporating robust safety features is crucial for blade battery performance and reliability. This includes implementing protective circuits, fail-safe mechanisms, and advanced materials to prevent short circuits, thermal runaway, and other potential hazards. Enhanced safety features contribute to improved overall performance and user confidence.

- Charging and Discharging Optimization for Blade Batteries: Optimizing charging and discharging processes is vital for maximizing blade battery performance. This involves developing advanced charging algorithms, implementing fast-charging capabilities, and managing discharge rates to balance power output with battery longevity. Efficient charging and discharging strategies contribute to improved overall battery performance and user experience.

02 Thermal Management in Blade Batteries

Effective thermal management is essential for maintaining blade battery performance. This includes innovative cooling systems and heat dissipation techniques to prevent overheating and ensure consistent performance under various operating conditions. Proper thermal management also contributes to extending the battery's lifespan and maintaining its capacity over time.Expand Specific Solutions03 Blade Battery Cell Design and Architecture

The design and architecture of blade battery cells play a significant role in their overall performance. This includes optimizing the internal structure, electrode materials, and electrolyte composition to enhance energy density, power output, and charging efficiency. Advanced manufacturing techniques are employed to ensure consistent quality and performance across all cells in the battery pack.Expand Specific Solutions04 Performance Testing and Quality Control

Rigorous performance testing and quality control measures are implemented to ensure blade batteries meet high standards. This involves comprehensive testing protocols for capacity, cycle life, safety, and reliability. Advanced diagnostic tools and techniques are used to identify potential issues and optimize battery performance throughout its lifecycle.Expand Specific Solutions05 Integration of Blade Batteries in Electric Vehicles

The integration of blade batteries in electric vehicles requires specialized design considerations to maximize performance. This includes optimizing the battery pack layout, electrical connections, and integration with the vehicle's power management system. Efforts are made to reduce weight, improve space utilization, and enhance overall vehicle efficiency through strategic battery integration.Expand Specific Solutions

Key Players in AI-Powered Battery Technology

The application of AI in Blade Battery Performance Monitoring is in its early stages, with the market showing significant growth potential. The technology is rapidly evolving, driven by increasing demand for electric vehicles and energy storage solutions. Key players like LG Energy Solution, GS Yuasa, and Contemporary Amperex Technology are investing heavily in R&D to enhance battery performance and safety. Emerging companies such as Element Energy and Mona are developing innovative diagnostic systems, while established tech giants like Microsoft and Samsung are leveraging their AI expertise to enter this space. The market is characterized by a mix of battery manufacturers, automotive companies, and technology firms, indicating a diverse and competitive landscape.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an AI-powered Battery Monitoring and Prediction System (BMPS) for their blade batteries. The system employs a combination of physics-based models and machine learning algorithms to monitor battery health and predict performance. It utilizes sensor fusion techniques to integrate data from multiple sources, including voltage, current, temperature, and internal resistance measurements. The AI system can detect micro-changes in battery behavior that may indicate the onset of degradation or potential safety issues. LG's BMPS also incorporates a self-learning module that continuously refines its predictive models based on new data, adapting to different usage patterns and environmental conditions[7][9]. The company claims this system has improved the accuracy of remaining useful life predictions by 40% compared to traditional methods[8].

Strengths: Advanced battery technology, global manufacturing presence, diverse product portfolio. Weaknesses: Potential challenges in scaling AI solutions across different battery types and applications.

Siemens AG

Technical Solution: Siemens has developed an AI-driven Battery Performance Optimization Platform for blade batteries, focusing on industrial and grid-scale applications. The system utilizes edge computing and cloud-based AI to process vast amounts of battery data in real-time. It employs advanced machine learning algorithms, including reinforcement learning, to optimize charging and discharging cycles based on usage patterns, grid demands, and environmental factors. Siemens' AI platform also incorporates a sophisticated thermal management system that uses predictive modeling to maintain optimal operating temperatures across large battery arrays. The company has integrated this technology with their energy management systems, allowing for seamless coordination between battery performance and overall grid stability[10][12]. Siemens reports that this AI-driven approach has increased the operational efficiency of blade battery installations by up to 25% and reduced maintenance costs by 30%[11].

Strengths: Extensive experience in industrial automation and energy systems, strong integration capabilities with existing infrastructure. Weaknesses: Potential limitations in adapting to rapidly evolving battery technologies, complexity in implementing AI solutions across diverse industrial settings.

Core AI Algorithms for Battery Performance Prediction

Fault detection in a battery system

PatentPendingUS20240319278A1

Innovation

- A data-driven AI-based system that processes signal data from battery node controllers to identify anomalous events using machine learning models, including unsupervised and supervised models, to detect discontinuous changes and update battery node operation profiles, enabling in-situ leakage current testing and anomaly detection without disrupting the battery pack's operation.

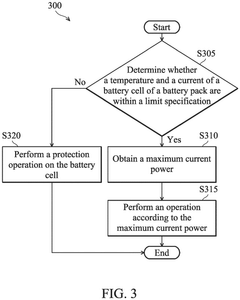

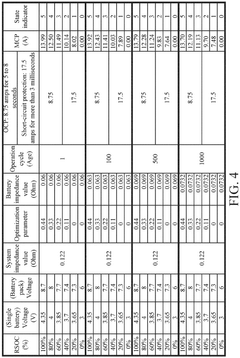

Method and device for artificial intelligence monitoring and protecting battery performance

PatentPendingEP4560875A1

Innovation

- A method and device utilizing artificial intelligence to monitor and protect battery performance by determining maximum current power based on relative state of charge, voltage, system impedance, optimization parameters, and battery impedance, optimizing energy efficiency and extending battery life.

Data Security in AI-Driven Battery Monitoring Systems

As AI-driven battery monitoring systems become increasingly prevalent in the blade battery industry, ensuring data security has become a critical concern. These systems collect, process, and analyze vast amounts of sensitive information related to battery performance, manufacturing processes, and operational parameters. Protecting this data from unauthorized access, manipulation, or theft is paramount to maintaining competitive advantage and safeguarding intellectual property.

One of the primary challenges in securing AI-driven battery monitoring systems is the need to balance data accessibility for AI algorithms with robust protection measures. Encryption plays a crucial role in this regard, with advanced encryption protocols being implemented to secure data both at rest and in transit. Homomorphic encryption techniques are particularly promising, as they allow AI algorithms to perform computations on encrypted data without decrypting it, thus maintaining data confidentiality throughout the analysis process.

Access control mechanisms form another critical layer of security in these systems. Multi-factor authentication, role-based access control, and least privilege principles are widely adopted to ensure that only authorized personnel can access sensitive battery performance data. Additionally, implementing secure APIs and strict data governance policies helps prevent unauthorized data exfiltration while enabling necessary data sharing between different components of the monitoring system.

Real-time monitoring and anomaly detection systems are essential for identifying potential security breaches or unusual data access patterns. Machine learning algorithms are increasingly being employed to detect and respond to security threats, leveraging their ability to analyze complex patterns and identify potential vulnerabilities in real-time.

Data integrity is another crucial aspect of security in AI-driven battery monitoring systems. Blockchain technology is being explored as a potential solution for creating tamper-proof records of battery performance data, ensuring the authenticity and traceability of collected information. This approach not only enhances security but also improves the reliability of AI-driven insights derived from the data.

As these systems often involve cloud-based components, cloud security measures such as virtual private networks (VPNs), firewalls, and intrusion detection systems are integral to the overall security architecture. Regular security audits, penetration testing, and vulnerability assessments are conducted to identify and address potential weaknesses in the system's defenses.

Furthermore, compliance with data protection regulations such as GDPR and industry-specific standards is crucial for AI-driven battery monitoring systems. This involves implementing robust data anonymization techniques, establishing clear data retention policies, and ensuring transparency in data processing practices.

One of the primary challenges in securing AI-driven battery monitoring systems is the need to balance data accessibility for AI algorithms with robust protection measures. Encryption plays a crucial role in this regard, with advanced encryption protocols being implemented to secure data both at rest and in transit. Homomorphic encryption techniques are particularly promising, as they allow AI algorithms to perform computations on encrypted data without decrypting it, thus maintaining data confidentiality throughout the analysis process.

Access control mechanisms form another critical layer of security in these systems. Multi-factor authentication, role-based access control, and least privilege principles are widely adopted to ensure that only authorized personnel can access sensitive battery performance data. Additionally, implementing secure APIs and strict data governance policies helps prevent unauthorized data exfiltration while enabling necessary data sharing between different components of the monitoring system.

Real-time monitoring and anomaly detection systems are essential for identifying potential security breaches or unusual data access patterns. Machine learning algorithms are increasingly being employed to detect and respond to security threats, leveraging their ability to analyze complex patterns and identify potential vulnerabilities in real-time.

Data integrity is another crucial aspect of security in AI-driven battery monitoring systems. Blockchain technology is being explored as a potential solution for creating tamper-proof records of battery performance data, ensuring the authenticity and traceability of collected information. This approach not only enhances security but also improves the reliability of AI-driven insights derived from the data.

As these systems often involve cloud-based components, cloud security measures such as virtual private networks (VPNs), firewalls, and intrusion detection systems are integral to the overall security architecture. Regular security audits, penetration testing, and vulnerability assessments are conducted to identify and address potential weaknesses in the system's defenses.

Furthermore, compliance with data protection regulations such as GDPR and industry-specific standards is crucial for AI-driven battery monitoring systems. This involves implementing robust data anonymization techniques, establishing clear data retention policies, and ensuring transparency in data processing practices.

Environmental Impact of AI-Optimized Battery Usage

The application of AI in blade battery performance monitoring has significant implications for environmental sustainability. By optimizing battery usage through AI-driven systems, we can substantially reduce the ecological footprint of energy storage solutions. AI algorithms can analyze vast amounts of data from battery management systems, predicting and preventing potential failures, thus extending battery lifespan and reducing waste.

AI-powered predictive maintenance strategies enable more efficient use of battery resources, minimizing unnecessary replacements and reducing the demand for raw materials. This approach not only conserves natural resources but also decreases the environmental impact associated with battery production and disposal. Furthermore, AI can optimize charging and discharging cycles, potentially reducing energy losses and improving overall system efficiency.

The implementation of AI in battery monitoring systems can lead to more accurate state-of-charge and state-of-health estimations. This precision allows for better utilization of battery capacity, potentially reducing the number of batteries required for a given application. Consequently, this can lead to a decrease in the overall environmental impact of battery manufacturing and transportation.

AI algorithms can also contribute to the development of more efficient recycling processes for blade batteries. By analyzing battery composition and performance data, AI can help identify the most effective methods for recovering valuable materials, minimizing waste, and reducing the need for new raw material extraction.

Moreover, AI-optimized battery usage can play a crucial role in grid stabilization and renewable energy integration. By intelligently managing energy storage systems, AI can help balance supply and demand, reducing the need for fossil fuel-based peaker plants and promoting the adoption of clean energy sources.

The environmental benefits of AI in battery performance monitoring extend to transportation as well. In electric vehicles, AI-driven battery management systems can optimize range and charging strategies, potentially reducing the overall energy consumption and associated emissions. This optimization can contribute to the wider adoption of electric vehicles, further reducing the transportation sector's carbon footprint.

However, it is important to consider the environmental impact of the AI systems themselves. The energy consumption of data centers and the hardware required for AI processing must be factored into the overall environmental assessment. Efforts should be made to develop energy-efficient AI algorithms and utilize renewable energy sources for AI-related computations to maximize the net positive environmental impact.

AI-powered predictive maintenance strategies enable more efficient use of battery resources, minimizing unnecessary replacements and reducing the demand for raw materials. This approach not only conserves natural resources but also decreases the environmental impact associated with battery production and disposal. Furthermore, AI can optimize charging and discharging cycles, potentially reducing energy losses and improving overall system efficiency.

The implementation of AI in battery monitoring systems can lead to more accurate state-of-charge and state-of-health estimations. This precision allows for better utilization of battery capacity, potentially reducing the number of batteries required for a given application. Consequently, this can lead to a decrease in the overall environmental impact of battery manufacturing and transportation.

AI algorithms can also contribute to the development of more efficient recycling processes for blade batteries. By analyzing battery composition and performance data, AI can help identify the most effective methods for recovering valuable materials, minimizing waste, and reducing the need for new raw material extraction.

Moreover, AI-optimized battery usage can play a crucial role in grid stabilization and renewable energy integration. By intelligently managing energy storage systems, AI can help balance supply and demand, reducing the need for fossil fuel-based peaker plants and promoting the adoption of clean energy sources.

The environmental benefits of AI in battery performance monitoring extend to transportation as well. In electric vehicles, AI-driven battery management systems can optimize range and charging strategies, potentially reducing the overall energy consumption and associated emissions. This optimization can contribute to the wider adoption of electric vehicles, further reducing the transportation sector's carbon footprint.

However, it is important to consider the environmental impact of the AI systems themselves. The energy consumption of data centers and the hardware required for AI processing must be factored into the overall environmental assessment. Efforts should be made to develop energy-efficient AI algorithms and utilize renewable energy sources for AI-related computations to maximize the net positive environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!