Prospects of Blade Battery in Personal Mobility Devices

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Blade Battery Evolution and Objectives

Blade batteries, a revolutionary technology in the energy storage sector, have emerged as a promising solution for personal mobility devices. This innovative battery design, characterized by its long, thin cells arranged in a parallel configuration, has undergone significant evolution since its inception. The development of blade batteries can be traced back to the early 2010s when researchers began exploring ways to improve energy density and safety in lithium-ion batteries.

The primary objective of blade battery technology is to address the limitations of traditional lithium-ion batteries, particularly in terms of safety, energy density, and longevity. By adopting a unique cell structure, blade batteries aim to minimize the risk of thermal runaway and enhance overall performance. This aligns with the growing demand for safer and more efficient power sources in personal mobility devices, such as electric scooters, e-bikes, and hoverboards.

Throughout its evolution, blade battery technology has undergone several iterations, each focusing on refining the cell design, improving manufacturing processes, and optimizing the battery management system. Early prototypes demonstrated the potential for increased energy density and improved thermal management, but faced challenges in scalability and production costs.

Recent advancements in blade battery technology have led to significant improvements in energy density, with some designs achieving up to 30% higher capacity compared to conventional lithium-ion batteries of similar size. This breakthrough has caught the attention of personal mobility device manufacturers, who are constantly seeking ways to extend the range and reduce the weight of their products.

The evolution of blade batteries has also been driven by the need for enhanced safety features. By utilizing a more stable cathode material and implementing advanced cooling systems, blade batteries have shown remarkable resistance to thermal runaway, a critical factor in personal mobility applications where user safety is paramount.

Looking ahead, the objectives for blade battery technology in personal mobility devices are multifaceted. Researchers and manufacturers are focusing on further increasing energy density while maintaining the high safety standards that have become a hallmark of blade batteries. Additionally, efforts are being made to reduce production costs and improve manufacturing efficiency to make blade batteries more accessible for a wider range of personal mobility applications.

Another key objective is to enhance the longevity and cycle life of blade batteries, ensuring that they can withstand the frequent charging and discharging cycles typical in personal mobility devices. This involves ongoing research into advanced electrode materials and electrolyte formulations that can minimize capacity degradation over time.

As the personal mobility market continues to expand, the development of blade batteries is expected to accelerate, driven by the increasing demand for safer, more efficient, and longer-lasting power sources. The technology's potential to revolutionize the energy storage landscape in personal mobility devices positions it as a key area of focus for both established manufacturers and emerging startups in the coming years.

The primary objective of blade battery technology is to address the limitations of traditional lithium-ion batteries, particularly in terms of safety, energy density, and longevity. By adopting a unique cell structure, blade batteries aim to minimize the risk of thermal runaway and enhance overall performance. This aligns with the growing demand for safer and more efficient power sources in personal mobility devices, such as electric scooters, e-bikes, and hoverboards.

Throughout its evolution, blade battery technology has undergone several iterations, each focusing on refining the cell design, improving manufacturing processes, and optimizing the battery management system. Early prototypes demonstrated the potential for increased energy density and improved thermal management, but faced challenges in scalability and production costs.

Recent advancements in blade battery technology have led to significant improvements in energy density, with some designs achieving up to 30% higher capacity compared to conventional lithium-ion batteries of similar size. This breakthrough has caught the attention of personal mobility device manufacturers, who are constantly seeking ways to extend the range and reduce the weight of their products.

The evolution of blade batteries has also been driven by the need for enhanced safety features. By utilizing a more stable cathode material and implementing advanced cooling systems, blade batteries have shown remarkable resistance to thermal runaway, a critical factor in personal mobility applications where user safety is paramount.

Looking ahead, the objectives for blade battery technology in personal mobility devices are multifaceted. Researchers and manufacturers are focusing on further increasing energy density while maintaining the high safety standards that have become a hallmark of blade batteries. Additionally, efforts are being made to reduce production costs and improve manufacturing efficiency to make blade batteries more accessible for a wider range of personal mobility applications.

Another key objective is to enhance the longevity and cycle life of blade batteries, ensuring that they can withstand the frequent charging and discharging cycles typical in personal mobility devices. This involves ongoing research into advanced electrode materials and electrolyte formulations that can minimize capacity degradation over time.

As the personal mobility market continues to expand, the development of blade batteries is expected to accelerate, driven by the increasing demand for safer, more efficient, and longer-lasting power sources. The technology's potential to revolutionize the energy storage landscape in personal mobility devices positions it as a key area of focus for both established manufacturers and emerging startups in the coming years.

Market Analysis for PMD Batteries

The personal mobility device (PMD) battery market is experiencing significant growth, driven by the increasing adoption of electric scooters, e-bikes, and other small electric vehicles. This market segment is characterized by a growing demand for lightweight, high-energy-density batteries that can provide extended range and quick charging capabilities.

The global PMD battery market size was valued at approximately $2.5 billion in 2020 and is projected to reach $7.3 billion by 2027, growing at a CAGR of 16.8% during the forecast period. This growth is primarily attributed to the rising urbanization, increasing environmental concerns, and the need for efficient last-mile transportation solutions.

Lithium-ion batteries currently dominate the PMD battery market, accounting for over 80% of the market share. These batteries offer high energy density, longer lifespan, and faster charging times compared to traditional lead-acid batteries. However, safety concerns related to thermal runaway and fire risks have led to increased interest in alternative battery technologies.

The blade battery, developed by BYD, presents a promising solution for the PMD battery market. This lithium iron phosphate (LFP) battery design offers enhanced safety features, improved energy density, and longer cycle life compared to traditional lithium-ion batteries. The blade battery's unique cell-to-pack design allows for better space utilization and thermal management, making it particularly suitable for compact PMDs.

Market analysis indicates that the blade battery technology could potentially capture a significant portion of the PMD battery market in the coming years. Its safety advantages and cost-effectiveness make it an attractive option for manufacturers looking to differentiate their products and address consumer concerns about battery safety.

Geographically, Asia-Pacific is expected to remain the largest market for PMD batteries, with China leading in both production and consumption. Europe and North America are also witnessing rapid growth in the PMD battery market, driven by supportive government policies promoting electric mobility and sustainable transportation solutions.

Key market players in the PMD battery segment include Panasonic, LG Chem, Samsung SDI, and BYD. These companies are investing heavily in research and development to improve battery performance, safety, and cost-effectiveness. The entry of automotive battery manufacturers into the PMD market is expected to intensify competition and drive innovation in the coming years.

Consumer preferences are shifting towards PMDs with longer range and faster charging capabilities. This trend is likely to benefit advanced battery technologies like the blade battery, which can offer improved performance metrics compared to conventional lithium-ion batteries. Additionally, the growing emphasis on sustainability and recyclability in battery production aligns well with the blade battery's environmentally friendly characteristics.

The global PMD battery market size was valued at approximately $2.5 billion in 2020 and is projected to reach $7.3 billion by 2027, growing at a CAGR of 16.8% during the forecast period. This growth is primarily attributed to the rising urbanization, increasing environmental concerns, and the need for efficient last-mile transportation solutions.

Lithium-ion batteries currently dominate the PMD battery market, accounting for over 80% of the market share. These batteries offer high energy density, longer lifespan, and faster charging times compared to traditional lead-acid batteries. However, safety concerns related to thermal runaway and fire risks have led to increased interest in alternative battery technologies.

The blade battery, developed by BYD, presents a promising solution for the PMD battery market. This lithium iron phosphate (LFP) battery design offers enhanced safety features, improved energy density, and longer cycle life compared to traditional lithium-ion batteries. The blade battery's unique cell-to-pack design allows for better space utilization and thermal management, making it particularly suitable for compact PMDs.

Market analysis indicates that the blade battery technology could potentially capture a significant portion of the PMD battery market in the coming years. Its safety advantages and cost-effectiveness make it an attractive option for manufacturers looking to differentiate their products and address consumer concerns about battery safety.

Geographically, Asia-Pacific is expected to remain the largest market for PMD batteries, with China leading in both production and consumption. Europe and North America are also witnessing rapid growth in the PMD battery market, driven by supportive government policies promoting electric mobility and sustainable transportation solutions.

Key market players in the PMD battery segment include Panasonic, LG Chem, Samsung SDI, and BYD. These companies are investing heavily in research and development to improve battery performance, safety, and cost-effectiveness. The entry of automotive battery manufacturers into the PMD market is expected to intensify competition and drive innovation in the coming years.

Consumer preferences are shifting towards PMDs with longer range and faster charging capabilities. This trend is likely to benefit advanced battery technologies like the blade battery, which can offer improved performance metrics compared to conventional lithium-ion batteries. Additionally, the growing emphasis on sustainability and recyclability in battery production aligns well with the blade battery's environmentally friendly characteristics.

Current Challenges in PMD Battery Technology

Personal Mobility Devices (PMDs) have gained significant popularity in recent years, offering convenient and eco-friendly transportation options for short-distance travel. However, the battery technology powering these devices faces several challenges that hinder their widespread adoption and optimal performance.

One of the primary challenges in PMD battery technology is energy density. Current lithium-ion batteries used in most PMDs struggle to provide sufficient range for extended use without frequent recharging. This limitation restricts the practical utility of PMDs, especially for users who require longer travel distances or multiple trips throughout the day.

Safety concerns pose another significant challenge for PMD batteries. Incidents of battery fires and explosions, although rare, have raised public awareness and regulatory scrutiny. The compact design of PMDs often necessitates tightly packed battery cells, increasing the risk of thermal runaway and potential safety hazards. Addressing these safety issues is crucial for building consumer trust and ensuring widespread adoption of PMDs.

Charging speed and infrastructure present additional hurdles. Many PMD users face inconvenience due to long charging times, which can range from several hours to overnight. The lack of standardized charging infrastructure and limited availability of charging stations in public spaces further exacerbate this issue, potentially deterring potential users from embracing PMDs as a reliable mode of transportation.

Durability and lifespan of PMD batteries also remain areas of concern. The frequent charging cycles and exposure to various environmental conditions can lead to accelerated battery degradation. This not only affects the device's performance over time but also raises questions about the long-term cost-effectiveness and environmental impact of PMDs.

Weight and size constraints pose unique challenges for PMD battery design. The need for compact and lightweight devices often conflicts with the desire for higher capacity batteries. Striking the right balance between battery capacity and overall device portability is a constant struggle for manufacturers.

Environmental considerations add another layer of complexity to PMD battery technology. The production and disposal of lithium-ion batteries raise concerns about resource depletion and environmental pollution. Developing more sustainable battery technologies and implementing effective recycling processes are crucial for the long-term viability of PMDs as an eco-friendly transportation solution.

Lastly, cost remains a significant barrier to widespread PMD adoption. High-quality batteries with advanced features often contribute substantially to the overall price of PMDs, making them less accessible to a broader consumer base. Reducing battery costs while maintaining performance and safety standards is a key challenge for the industry.

One of the primary challenges in PMD battery technology is energy density. Current lithium-ion batteries used in most PMDs struggle to provide sufficient range for extended use without frequent recharging. This limitation restricts the practical utility of PMDs, especially for users who require longer travel distances or multiple trips throughout the day.

Safety concerns pose another significant challenge for PMD batteries. Incidents of battery fires and explosions, although rare, have raised public awareness and regulatory scrutiny. The compact design of PMDs often necessitates tightly packed battery cells, increasing the risk of thermal runaway and potential safety hazards. Addressing these safety issues is crucial for building consumer trust and ensuring widespread adoption of PMDs.

Charging speed and infrastructure present additional hurdles. Many PMD users face inconvenience due to long charging times, which can range from several hours to overnight. The lack of standardized charging infrastructure and limited availability of charging stations in public spaces further exacerbate this issue, potentially deterring potential users from embracing PMDs as a reliable mode of transportation.

Durability and lifespan of PMD batteries also remain areas of concern. The frequent charging cycles and exposure to various environmental conditions can lead to accelerated battery degradation. This not only affects the device's performance over time but also raises questions about the long-term cost-effectiveness and environmental impact of PMDs.

Weight and size constraints pose unique challenges for PMD battery design. The need for compact and lightweight devices often conflicts with the desire for higher capacity batteries. Striking the right balance between battery capacity and overall device portability is a constant struggle for manufacturers.

Environmental considerations add another layer of complexity to PMD battery technology. The production and disposal of lithium-ion batteries raise concerns about resource depletion and environmental pollution. Developing more sustainable battery technologies and implementing effective recycling processes are crucial for the long-term viability of PMDs as an eco-friendly transportation solution.

Lastly, cost remains a significant barrier to widespread PMD adoption. High-quality batteries with advanced features often contribute substantially to the overall price of PMDs, making them less accessible to a broader consumer base. Reducing battery costs while maintaining performance and safety standards is a key challenge for the industry.

Existing Blade Battery Solutions for PMDs

01 Blade battery structure and design

Blade batteries feature a unique structural design that optimizes space utilization and energy density. This design typically involves a flat, elongated shape that allows for efficient stacking and integration into electric vehicle battery packs. The blade-like structure contributes to improved thermal management and overall battery performance.- Blade battery structure and design: Blade batteries feature a unique structural design that optimizes space utilization and energy density. The thin, elongated shape allows for efficient packaging in electric vehicles, improving overall battery performance and range. This design also enhances heat dissipation and structural integrity, contributing to improved safety and longevity of the battery pack.

- Safety features of blade batteries: Blade batteries incorporate advanced safety features to prevent thermal runaway and enhance overall battery safety. These may include improved thermal management systems, robust cell separators, and innovative electrode designs. The safety enhancements aim to reduce the risk of fire or explosion, making blade batteries a safer option for electric vehicles.

- Manufacturing processes for blade batteries: The production of blade batteries involves specialized manufacturing techniques to achieve the desired thin profile and high energy density. This may include advanced electrode coating methods, precise cell assembly processes, and innovative packaging techniques. The manufacturing processes are designed to ensure consistent quality and performance of the blade batteries.

- Integration of blade batteries in electric vehicles: Blade batteries are designed for seamless integration into electric vehicle platforms. Their unique form factor allows for flexible placement within the vehicle chassis, potentially improving weight distribution and vehicle dynamics. The integration process may involve specialized mounting systems and cooling solutions to optimize performance and safety.

- Performance characteristics of blade batteries: Blade batteries offer several performance advantages, including high energy density, fast charging capabilities, and long cycle life. These characteristics contribute to extended driving range, reduced charging times, and improved overall efficiency of electric vehicles. The performance of blade batteries is continually being enhanced through ongoing research and development efforts.

02 Safety features of blade batteries

Blade batteries incorporate advanced safety features to prevent thermal runaway and enhance overall battery safety. These may include improved insulation materials, innovative cooling systems, and structural reinforcements. The design aims to minimize the risk of fire or explosion, even under extreme conditions.Expand Specific Solutions03 Manufacturing processes for blade batteries

The production of blade batteries involves specialized manufacturing techniques to ensure precision and quality. This may include advanced assembly methods, automated production lines, and stringent quality control measures. The manufacturing process focuses on maintaining consistent performance and reliability across all produced units.Expand Specific Solutions04 Integration of blade batteries in electric vehicles

Blade batteries are designed for optimal integration into electric vehicle platforms. Their unique form factor allows for efficient packaging within the vehicle chassis, potentially increasing the overall battery capacity without compromising vehicle design. This integration may involve specialized mounting systems and electrical connections.Expand Specific Solutions05 Performance characteristics of blade batteries

Blade batteries offer several performance advantages, including high energy density, improved charging speeds, and enhanced cycle life. These batteries may utilize advanced cathode and anode materials to achieve superior energy storage capabilities. The design also aims to maintain consistent performance across a wide range of operating temperatures and conditions.Expand Specific Solutions

Key Players in Blade Battery Industry

The Blade Battery technology in personal mobility devices is in an early growth stage, with increasing market potential as the demand for efficient and safe energy storage solutions rises. The market size is expanding rapidly, driven by the growing adoption of electric vehicles and portable electronics. Technologically, the Blade Battery is advancing, with major players like Contemporary Amperex Technology Co., Ltd. (CATL) and LG Energy Solution Ltd. leading innovation. Companies such as Honda Motor Co., Ltd. and Hyundai Motor Co., Ltd. are exploring integration into their product lines, while emerging players like EVE Energy Co., Ltd. are also contributing to the competitive landscape. The technology's maturity is progressing, with ongoing research and development efforts focused on improving energy density, safety, and cost-effectiveness.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a revolutionary Blade Battery specifically designed for personal mobility devices. This lithium iron phosphate (LFP) battery utilizes a unique cell-to-pack (CTP) technology, eliminating the need for module assembly[1]. The Blade Battery's ultra-thin cells are arranged in a blade-like structure, significantly increasing energy density and space utilization. For personal mobility devices, CATL has optimized the battery to deliver high energy density (up to 200Wh/kg), fast charging capabilities (80% in 15 minutes), and enhanced safety features, including improved thermal management and nail penetration resistance[2]. The company has also integrated smart battery management systems (BMS) to optimize performance and extend battery life in various mobility applications[3].

Strengths: High energy density, fast charging, improved safety, and space efficiency. Weaknesses: Higher initial cost compared to traditional batteries, potential supply chain constraints due to high demand.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced lithium-ion battery technologies tailored for personal mobility devices. Their solution incorporates high-nickel cathodes (NCM 811) to achieve energy densities exceeding 250 Wh/kg[4]. For personal mobility applications, LG has focused on creating compact, lightweight battery packs with enhanced durability and cycle life. Their batteries feature advanced thermal management systems, utilizing phase-change materials to maintain optimal operating temperatures[5]. LG has also implemented silicon-based anodes to increase energy capacity and reduce charging times. The company's smart BMS incorporates AI algorithms to predict battery health and optimize charging patterns, extending the overall lifespan of the battery in mobility devices[6].

Strengths: High energy density, advanced thermal management, and smart BMS for optimized performance. Weaknesses: Potential safety concerns with high-nickel cathodes, higher production costs.

Core Innovations in Blade Battery Technology

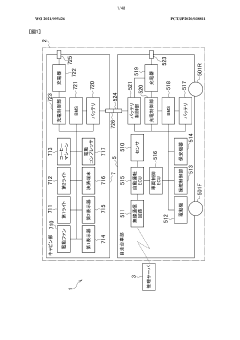

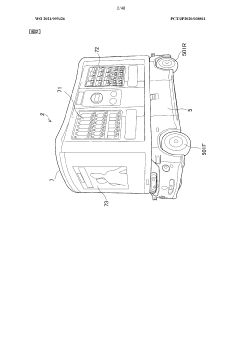

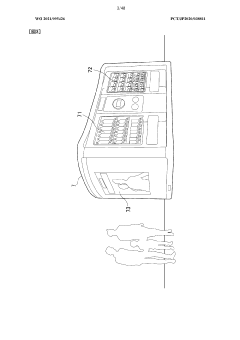

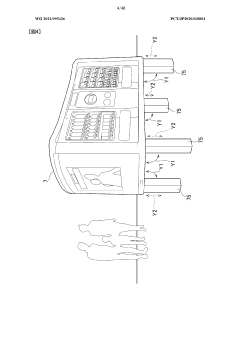

Moving body

PatentWO2021095426A1

Innovation

- A mobile object configuration with a first body equipped with wheels and a detachable second body, each containing secondary batteries, allowing for flexible power management and charging strategies to extend travel distance and optimize charging timing.

Battery module

PatentPendingKR1020240082991A

Innovation

- A battery module design incorporating a frame, bus bar frame assembly, and barriers made of refractory sheets and pads, with specific slot and hole configurations to stabilize and seal the barriers, preventing heat and gas propagation.

Safety Regulations for PMD Batteries

The safety regulations for Personal Mobility Device (PMD) batteries, including blade batteries, are becoming increasingly stringent as these devices gain popularity in urban transportation. Regulatory bodies worldwide are focusing on ensuring the safety of users and the general public, given the potential risks associated with battery malfunctions.

In many jurisdictions, PMD batteries must comply with international safety standards such as IEC 62133 or UL 2271. These standards cover various aspects of battery safety, including electrical, mechanical, and environmental considerations. Manufacturers are required to conduct rigorous testing to demonstrate compliance with these standards before their products can be approved for use in PMDs.

One of the key safety requirements for PMD batteries is the implementation of a Battery Management System (BMS). The BMS monitors and controls critical parameters such as voltage, current, and temperature to prevent overcharging, over-discharging, and thermal runaway. For blade batteries in PMDs, the BMS must be specifically designed to account for the unique characteristics of this battery type, including its high energy density and thin form factor.

Fire safety is a paramount concern in PMD battery regulations. Many jurisdictions now mandate that PMD batteries undergo fire resistance testing and incorporate fire-retardant materials in their construction. Some regions have also introduced requirements for thermal runaway protection, which aims to prevent the propagation of thermal events from one cell to another within the battery pack.

Regulations are also addressing the issue of battery disposal and recycling. As the number of PMDs increases, there is growing concern about the environmental impact of discarded batteries. Many countries now require manufacturers to implement take-back programs or participate in battery recycling schemes to ensure proper disposal of end-of-life batteries.

Transportation of PMD batteries is another area of regulatory focus. Given the potential fire risks, many airlines and shipping companies have imposed restrictions on the transportation of lithium-ion batteries, including those used in PMDs. Manufacturers and users must adhere to specific packaging and labeling requirements when transporting these batteries.

As blade battery technology continues to evolve, regulators are closely monitoring its performance and safety characteristics. Some jurisdictions are considering specific regulations for blade batteries in PMDs, taking into account their unique properties such as improved thermal stability and reduced risk of internal short circuits. These regulations may include additional testing requirements or specific design criteria to ensure the safe integration of blade batteries into PMDs.

In many jurisdictions, PMD batteries must comply with international safety standards such as IEC 62133 or UL 2271. These standards cover various aspects of battery safety, including electrical, mechanical, and environmental considerations. Manufacturers are required to conduct rigorous testing to demonstrate compliance with these standards before their products can be approved for use in PMDs.

One of the key safety requirements for PMD batteries is the implementation of a Battery Management System (BMS). The BMS monitors and controls critical parameters such as voltage, current, and temperature to prevent overcharging, over-discharging, and thermal runaway. For blade batteries in PMDs, the BMS must be specifically designed to account for the unique characteristics of this battery type, including its high energy density and thin form factor.

Fire safety is a paramount concern in PMD battery regulations. Many jurisdictions now mandate that PMD batteries undergo fire resistance testing and incorporate fire-retardant materials in their construction. Some regions have also introduced requirements for thermal runaway protection, which aims to prevent the propagation of thermal events from one cell to another within the battery pack.

Regulations are also addressing the issue of battery disposal and recycling. As the number of PMDs increases, there is growing concern about the environmental impact of discarded batteries. Many countries now require manufacturers to implement take-back programs or participate in battery recycling schemes to ensure proper disposal of end-of-life batteries.

Transportation of PMD batteries is another area of regulatory focus. Given the potential fire risks, many airlines and shipping companies have imposed restrictions on the transportation of lithium-ion batteries, including those used in PMDs. Manufacturers and users must adhere to specific packaging and labeling requirements when transporting these batteries.

As blade battery technology continues to evolve, regulators are closely monitoring its performance and safety characteristics. Some jurisdictions are considering specific regulations for blade batteries in PMDs, taking into account their unique properties such as improved thermal stability and reduced risk of internal short circuits. These regulations may include additional testing requirements or specific design criteria to ensure the safe integration of blade batteries into PMDs.

Environmental Impact of Blade Batteries

The environmental impact of blade batteries in personal mobility devices is a crucial consideration as these innovative power sources gain traction in the market. Blade batteries, developed by BYD, offer several environmental advantages over traditional lithium-ion batteries. Their unique design allows for higher energy density and improved safety, which translates to reduced material usage and potentially lower environmental impact during production.

One of the primary environmental benefits of blade batteries is their increased energy density. This characteristic enables personal mobility devices to achieve longer ranges with smaller battery packs, reducing the overall material requirements for manufacturing. As a result, fewer raw materials need to be extracted and processed, leading to a decrease in the environmental footprint associated with battery production.

The improved safety features of blade batteries also contribute to their environmental friendliness. These batteries are less prone to thermal runaway and have a lower risk of fire or explosion compared to conventional lithium-ion batteries. This enhanced safety profile reduces the likelihood of environmental contamination due to battery-related accidents or improper disposal.

Furthermore, blade batteries have demonstrated superior longevity and cycle life compared to traditional lithium-ion batteries. This extended lifespan means that personal mobility devices equipped with blade batteries may require less frequent battery replacements, potentially reducing electronic waste and the need for battery recycling over time.

The manufacturing process of blade batteries also presents opportunities for environmental improvements. The simplified structure of these batteries may lead to more efficient production methods, potentially reducing energy consumption and waste generation during manufacturing. Additionally, the materials used in blade batteries, such as lithium iron phosphate (LFP), are generally considered more environmentally friendly and have a lower carbon footprint compared to some other battery chemistries.

However, it is important to note that the full environmental impact of blade batteries in personal mobility devices is still being studied. As with any emerging technology, long-term effects and potential unforeseen consequences need to be carefully monitored and assessed. Factors such as the sourcing of raw materials, energy consumption during production, and end-of-life recycling processes all play crucial roles in determining the overall environmental sustainability of blade batteries.

As the adoption of blade batteries in personal mobility devices increases, it will be essential to develop and implement robust recycling and disposal systems specifically tailored to this technology. Proper end-of-life management will be critical in maximizing the environmental benefits of blade batteries and minimizing their potential negative impacts on ecosystems and human health.

One of the primary environmental benefits of blade batteries is their increased energy density. This characteristic enables personal mobility devices to achieve longer ranges with smaller battery packs, reducing the overall material requirements for manufacturing. As a result, fewer raw materials need to be extracted and processed, leading to a decrease in the environmental footprint associated with battery production.

The improved safety features of blade batteries also contribute to their environmental friendliness. These batteries are less prone to thermal runaway and have a lower risk of fire or explosion compared to conventional lithium-ion batteries. This enhanced safety profile reduces the likelihood of environmental contamination due to battery-related accidents or improper disposal.

Furthermore, blade batteries have demonstrated superior longevity and cycle life compared to traditional lithium-ion batteries. This extended lifespan means that personal mobility devices equipped with blade batteries may require less frequent battery replacements, potentially reducing electronic waste and the need for battery recycling over time.

The manufacturing process of blade batteries also presents opportunities for environmental improvements. The simplified structure of these batteries may lead to more efficient production methods, potentially reducing energy consumption and waste generation during manufacturing. Additionally, the materials used in blade batteries, such as lithium iron phosphate (LFP), are generally considered more environmentally friendly and have a lower carbon footprint compared to some other battery chemistries.

However, it is important to note that the full environmental impact of blade batteries in personal mobility devices is still being studied. As with any emerging technology, long-term effects and potential unforeseen consequences need to be carefully monitored and assessed. Factors such as the sourcing of raw materials, energy consumption during production, and end-of-life recycling processes all play crucial roles in determining the overall environmental sustainability of blade batteries.

As the adoption of blade batteries in personal mobility devices increases, it will be essential to develop and implement robust recycling and disposal systems specifically tailored to this technology. Proper end-of-life management will be critical in maximizing the environmental benefits of blade batteries and minimizing their potential negative impacts on ecosystems and human health.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!