Reliability Testing Frameworks for Blade Battery Adoption

AUG 7, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Blade Battery Testing Background and Objectives

The blade battery, a revolutionary lithium-ion battery technology developed by BYD, has garnered significant attention in the electric vehicle (EV) industry due to its enhanced safety features and improved energy density. As the automotive sector rapidly transitions towards electrification, ensuring the reliability and safety of battery systems has become paramount. This technological shift necessitates the development of comprehensive and robust testing frameworks specifically tailored for blade batteries.

The evolution of battery technology in the EV industry has been marked by continuous improvements in energy density, charging speeds, and safety features. The blade battery represents a significant leap forward in addressing some of the key challenges faced by traditional lithium-ion batteries, particularly in terms of thermal runaway risks and overall safety performance. As such, the primary objective of reliability testing frameworks for blade battery adoption is to rigorously evaluate and validate the safety, performance, and longevity of these innovative battery systems under various operating conditions and potential failure scenarios.

The development of these testing frameworks is driven by several key factors. Firstly, the unique structural design of blade batteries, which utilizes long, thin cells arranged in a parallel configuration, requires specialized testing methodologies that differ from those used for conventional battery pack designs. Secondly, the increasing demand for longer-range EVs and faster charging capabilities puts additional stress on battery systems, necessitating more comprehensive reliability assessments.

Furthermore, the global push for stricter safety regulations in the automotive industry, particularly concerning battery-powered vehicles, underscores the need for rigorous and standardized testing protocols. These frameworks must not only address the immediate safety concerns but also anticipate potential long-term issues that may arise from widespread adoption of blade battery technology.

The objectives of blade battery testing frameworks extend beyond mere compliance with existing standards. They aim to establish new benchmarks for battery safety and reliability in the EV industry. This includes developing accelerated aging tests to predict long-term performance, simulating extreme environmental conditions to assess thermal management capabilities, and conducting advanced crash simulations to evaluate structural integrity under impact.

Additionally, these testing frameworks seek to validate the claimed advantages of blade batteries, such as their resistance to thermal runaway and improved energy density, through empirical data and reproducible test results. This validation is crucial for building consumer confidence and accelerating the adoption of blade battery technology across various vehicle segments.

As the EV market continues to expand and evolve, the reliability testing frameworks for blade batteries must also adapt to address emerging challenges and technological advancements. This includes incorporating new testing methodologies for next-generation battery chemistries, evaluating the integration of blade batteries with advanced battery management systems, and assessing their compatibility with ultra-fast charging infrastructures.

The evolution of battery technology in the EV industry has been marked by continuous improvements in energy density, charging speeds, and safety features. The blade battery represents a significant leap forward in addressing some of the key challenges faced by traditional lithium-ion batteries, particularly in terms of thermal runaway risks and overall safety performance. As such, the primary objective of reliability testing frameworks for blade battery adoption is to rigorously evaluate and validate the safety, performance, and longevity of these innovative battery systems under various operating conditions and potential failure scenarios.

The development of these testing frameworks is driven by several key factors. Firstly, the unique structural design of blade batteries, which utilizes long, thin cells arranged in a parallel configuration, requires specialized testing methodologies that differ from those used for conventional battery pack designs. Secondly, the increasing demand for longer-range EVs and faster charging capabilities puts additional stress on battery systems, necessitating more comprehensive reliability assessments.

Furthermore, the global push for stricter safety regulations in the automotive industry, particularly concerning battery-powered vehicles, underscores the need for rigorous and standardized testing protocols. These frameworks must not only address the immediate safety concerns but also anticipate potential long-term issues that may arise from widespread adoption of blade battery technology.

The objectives of blade battery testing frameworks extend beyond mere compliance with existing standards. They aim to establish new benchmarks for battery safety and reliability in the EV industry. This includes developing accelerated aging tests to predict long-term performance, simulating extreme environmental conditions to assess thermal management capabilities, and conducting advanced crash simulations to evaluate structural integrity under impact.

Additionally, these testing frameworks seek to validate the claimed advantages of blade batteries, such as their resistance to thermal runaway and improved energy density, through empirical data and reproducible test results. This validation is crucial for building consumer confidence and accelerating the adoption of blade battery technology across various vehicle segments.

As the EV market continues to expand and evolve, the reliability testing frameworks for blade batteries must also adapt to address emerging challenges and technological advancements. This includes incorporating new testing methodologies for next-generation battery chemistries, evaluating the integration of blade batteries with advanced battery management systems, and assessing their compatibility with ultra-fast charging infrastructures.

Market Demand Analysis for Blade Batteries

The market demand for blade batteries has been experiencing significant growth, driven by the rapid expansion of the electric vehicle (EV) industry and the increasing focus on energy storage solutions. Blade batteries, known for their enhanced safety features and higher energy density compared to traditional lithium-ion batteries, have garnered substantial interest from automotive manufacturers and energy storage system developers.

In the automotive sector, the shift towards electrification has created a surge in demand for high-performance, safe, and cost-effective battery solutions. Blade batteries, with their improved thermal stability and reduced risk of thermal runaway, address critical safety concerns that have plagued the EV industry. This has led to increased adoption by major automakers, particularly in China where blade battery technology was first introduced.

The energy storage market also presents a substantial opportunity for blade batteries. As renewable energy sources become more prevalent, the need for efficient and reliable energy storage systems has grown exponentially. Blade batteries' compact design and high energy density make them well-suited for both residential and commercial energy storage applications, contributing to their rising demand in this sector.

Market analysis indicates that the global demand for blade batteries is expected to grow at a compound annual growth rate (CAGR) significantly higher than that of traditional lithium-ion batteries over the next five years. This growth is primarily attributed to the technology's advantages in safety, energy density, and cost-effectiveness.

However, the market demand for blade batteries is not without challenges. The technology is relatively new, and concerns about long-term reliability and performance under various conditions persist. This is where the importance of robust reliability testing frameworks comes into play. Potential customers, especially in the automotive industry, require comprehensive data on the long-term performance and safety of blade batteries before committing to large-scale adoption.

The demand for reliable testing frameworks is therefore closely tied to the market demand for blade batteries themselves. As more manufacturers consider incorporating blade batteries into their products, the need for standardized, rigorous testing protocols becomes increasingly critical. This demand extends beyond just the batteries themselves to include testing of battery management systems, thermal management solutions, and overall integration with various applications.

Furthermore, regulatory bodies and industry standards organizations are closely watching the development and adoption of blade batteries. As the technology gains traction, there is a growing need for established testing frameworks that can be used to certify blade batteries for different applications and markets. This regulatory aspect further drives the demand for comprehensive reliability testing solutions.

In the automotive sector, the shift towards electrification has created a surge in demand for high-performance, safe, and cost-effective battery solutions. Blade batteries, with their improved thermal stability and reduced risk of thermal runaway, address critical safety concerns that have plagued the EV industry. This has led to increased adoption by major automakers, particularly in China where blade battery technology was first introduced.

The energy storage market also presents a substantial opportunity for blade batteries. As renewable energy sources become more prevalent, the need for efficient and reliable energy storage systems has grown exponentially. Blade batteries' compact design and high energy density make them well-suited for both residential and commercial energy storage applications, contributing to their rising demand in this sector.

Market analysis indicates that the global demand for blade batteries is expected to grow at a compound annual growth rate (CAGR) significantly higher than that of traditional lithium-ion batteries over the next five years. This growth is primarily attributed to the technology's advantages in safety, energy density, and cost-effectiveness.

However, the market demand for blade batteries is not without challenges. The technology is relatively new, and concerns about long-term reliability and performance under various conditions persist. This is where the importance of robust reliability testing frameworks comes into play. Potential customers, especially in the automotive industry, require comprehensive data on the long-term performance and safety of blade batteries before committing to large-scale adoption.

The demand for reliable testing frameworks is therefore closely tied to the market demand for blade batteries themselves. As more manufacturers consider incorporating blade batteries into their products, the need for standardized, rigorous testing protocols becomes increasingly critical. This demand extends beyond just the batteries themselves to include testing of battery management systems, thermal management solutions, and overall integration with various applications.

Furthermore, regulatory bodies and industry standards organizations are closely watching the development and adoption of blade batteries. As the technology gains traction, there is a growing need for established testing frameworks that can be used to certify blade batteries for different applications and markets. This regulatory aspect further drives the demand for comprehensive reliability testing solutions.

Current Challenges in Blade Battery Reliability Testing

The reliability testing of blade batteries presents several significant challenges that need to be addressed for successful adoption in various applications. One of the primary concerns is the lack of standardized testing protocols specifically designed for blade batteries. Unlike traditional lithium-ion batteries, blade batteries have a unique form factor and internal structure, which requires tailored testing methodologies to accurately assess their performance and safety characteristics.

Another challenge lies in the long-term durability assessment of blade batteries. Given their relatively recent introduction to the market, there is limited data available on their long-term performance and degradation patterns. This makes it difficult to predict their lifespan and reliability over extended periods, especially in demanding applications such as electric vehicles or grid energy storage systems.

The thermal management of blade batteries during testing poses another significant challenge. Due to their compact design and high energy density, blade batteries can generate substantial heat during operation. Developing effective cooling strategies and accurately simulating real-world thermal conditions during reliability testing is crucial to ensure the validity of test results and prevent thermal runaway incidents.

Furthermore, the mechanical stress testing of blade batteries presents unique challenges. The elongated shape of these batteries makes them susceptible to different types of mechanical stresses compared to conventional battery designs. Developing appropriate vibration, shock, and bending tests that accurately reflect the conditions blade batteries may encounter in various applications is essential for comprehensive reliability assessment.

The integration of blade batteries into larger battery packs and systems also introduces complexities in reliability testing. Evaluating the performance and safety of individual blade cells in isolation may not fully capture the behavior of the entire battery system. Developing testing frameworks that can assess the interactions between multiple blade cells and their management systems is crucial for ensuring overall system reliability.

Additionally, the accelerated aging and life cycle testing of blade batteries present challenges in terms of time and resource management. Developing methods to accurately simulate years of usage within a reasonable testing timeframe, while maintaining the validity of results, is a significant hurdle in reliability assessment.

Lastly, the environmental impact of blade battery testing must be considered. Developing eco-friendly testing procedures that minimize waste and energy consumption, while still providing comprehensive reliability data, is an ongoing challenge in the field. Balancing the need for thorough testing with sustainability concerns requires innovative approaches and technologies in reliability testing frameworks for blade battery adoption.

Another challenge lies in the long-term durability assessment of blade batteries. Given their relatively recent introduction to the market, there is limited data available on their long-term performance and degradation patterns. This makes it difficult to predict their lifespan and reliability over extended periods, especially in demanding applications such as electric vehicles or grid energy storage systems.

The thermal management of blade batteries during testing poses another significant challenge. Due to their compact design and high energy density, blade batteries can generate substantial heat during operation. Developing effective cooling strategies and accurately simulating real-world thermal conditions during reliability testing is crucial to ensure the validity of test results and prevent thermal runaway incidents.

Furthermore, the mechanical stress testing of blade batteries presents unique challenges. The elongated shape of these batteries makes them susceptible to different types of mechanical stresses compared to conventional battery designs. Developing appropriate vibration, shock, and bending tests that accurately reflect the conditions blade batteries may encounter in various applications is essential for comprehensive reliability assessment.

The integration of blade batteries into larger battery packs and systems also introduces complexities in reliability testing. Evaluating the performance and safety of individual blade cells in isolation may not fully capture the behavior of the entire battery system. Developing testing frameworks that can assess the interactions between multiple blade cells and their management systems is crucial for ensuring overall system reliability.

Additionally, the accelerated aging and life cycle testing of blade batteries present challenges in terms of time and resource management. Developing methods to accurately simulate years of usage within a reasonable testing timeframe, while maintaining the validity of results, is a significant hurdle in reliability assessment.

Lastly, the environmental impact of blade battery testing must be considered. Developing eco-friendly testing procedures that minimize waste and energy consumption, while still providing comprehensive reliability data, is an ongoing challenge in the field. Balancing the need for thorough testing with sustainability concerns requires innovative approaches and technologies in reliability testing frameworks for blade battery adoption.

Existing Reliability Testing Frameworks for Blade Batteries

01 Battery structure and design improvements

Blade batteries incorporate structural enhancements to improve reliability. These include optimized cell arrangements, reinforced casings, and innovative cooling systems. Such design improvements help to enhance the battery's overall performance, safety, and longevity under various operating conditions.- Battery structure and design improvements: Blade batteries incorporate structural enhancements to improve reliability. These include optimized cell arrangement, reinforced casing, and improved thermal management systems. Such design improvements help prevent internal short circuits, enhance mechanical strength, and ensure stable performance under various conditions.

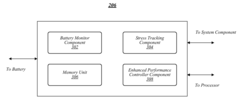

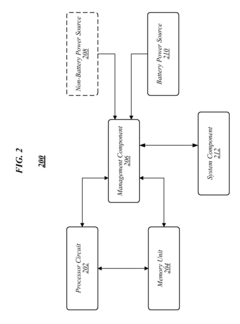

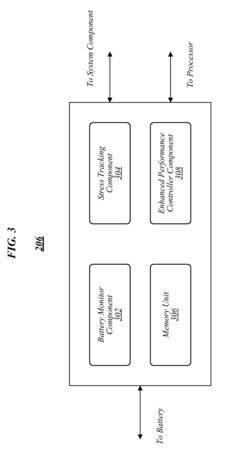

- Advanced battery management systems: Implementing sophisticated battery management systems (BMS) is crucial for blade battery reliability. These systems monitor and control various parameters such as temperature, voltage, and current. They also incorporate algorithms for state-of-charge estimation and fault detection, enhancing overall battery safety and longevity.

- Innovative electrode materials and compositions: Developing and utilizing advanced electrode materials and compositions contribute to improved blade battery reliability. This includes the use of high-performance cathode and anode materials, as well as optimized electrolyte formulations. These innovations enhance energy density, cycling stability, and overall battery performance.

- Enhanced safety features and mechanisms: Incorporating advanced safety features is essential for blade battery reliability. This includes the implementation of protective circuits, pressure relief mechanisms, and thermal runaway prevention systems. These safety enhancements help mitigate risks associated with overcharging, overheating, and other potential failure modes.

- Quality control and testing procedures: Implementing rigorous quality control measures and comprehensive testing procedures is crucial for ensuring blade battery reliability. This includes conducting extensive cycle life tests, abuse tests, and environmental stress tests. Advanced diagnostic tools and techniques are employed to identify potential defects and validate battery performance under various conditions.

02 Advanced battery management systems

Implementing sophisticated battery management systems (BMS) is crucial for blade battery reliability. These systems monitor and control various parameters such as temperature, voltage, and current. They also incorporate predictive algorithms to optimize battery performance and prevent potential failures, thereby enhancing overall reliability.Expand Specific Solutions03 Thermal management solutions

Effective thermal management is essential for maintaining blade battery reliability. This includes advanced cooling techniques, heat dissipation methods, and temperature control mechanisms. Proper thermal management prevents overheating, extends battery life, and ensures consistent performance across various environmental conditions.Expand Specific Solutions04 Material innovations for enhanced durability

Utilizing advanced materials in blade battery construction significantly improves reliability. This includes the use of high-performance electrode materials, improved separators, and durable electrolytes. These material innovations contribute to increased energy density, improved cycle life, and enhanced overall battery durability.Expand Specific Solutions05 Safety features and fail-safe mechanisms

Incorporating robust safety features and fail-safe mechanisms is crucial for blade battery reliability. This includes implementing short-circuit prevention systems, overcharge protection, and pressure relief mechanisms. These safety measures help prevent catastrophic failures and ensure the battery's reliability under various operating conditions.Expand Specific Solutions

Key Players in Blade Battery and Testing Equipment

The reliability testing frameworks for blade battery adoption are in a nascent stage of development, reflecting the emerging nature of this technology. The market for blade batteries is expanding rapidly, driven by the growing electric vehicle sector, with a projected market size reaching billions of dollars by 2025. However, the technology's maturity varies among key players. Companies like CATL, LG Energy Solution, and SK On are at the forefront, having made significant advancements in blade battery technology and reliability testing. Other major automotive manufacturers such as Volkswagen, Toyota, and Hyundai are also investing heavily in this area, indicating a competitive and dynamic landscape. The involvement of diverse players, from established automakers to specialized battery manufacturers, suggests a complex ecosystem developing around blade battery technology and its associated testing frameworks.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has implemented a robust reliability testing framework for their blade battery systems. The company utilizes a combination of physical and virtual testing methods, including accelerated life testing, environmental stress screening, and finite element analysis[1]. Their framework incorporates machine learning algorithms to predict battery degradation patterns and identify potential failure modes[2]. LG Energy Solution also conducts extensive thermal management tests, simulating extreme temperature conditions to ensure battery stability and performance[3]. The company's testing protocol includes cyclic testing to evaluate long-term performance and safety under various charge-discharge scenarios[4].

Strengths: Advanced predictive modeling, comprehensive thermal management testing, and long-term performance evaluation. Weaknesses: Potential for gaps in real-world performance prediction, high resource requirements for extensive testing.

Ningde Amperex Technology Ltd.

Technical Solution: Ningde Amperex Technology (ATL) has developed a sophisticated reliability testing framework for blade batteries. Their approach includes multi-stage verification processes, combining laboratory tests with real-world simulations[1]. ATL utilizes advanced electrochemical impedance spectroscopy (EIS) techniques to assess battery health and predict potential failures[2]. The company's framework also incorporates accelerated aging tests under various environmental conditions to evaluate long-term reliability[3]. ATL has implemented a data-driven approach, using big data analytics to identify patterns in battery performance and refine their testing methodologies[4].

Strengths: Advanced electrochemical analysis techniques, comprehensive environmental testing, and data-driven optimization. Weaknesses: Potential for overlooking rare failure modes, high costs associated with extensive testing infrastructure.

Core Innovations in Battery Testing Technologies

Battery reliability odometer

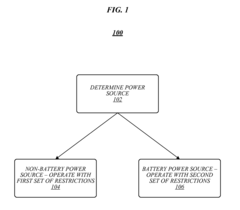

PatentActiveUS20170092996A1

Innovation

- A system that monitors battery stress history and compares it to a degradation baseline to determine a stress surplus or deficit, allowing for regulated operation of high power performance modes, enabling longer and more frequent use of turbo boosting while maintaining long-term battery reliability.

Device for testing operational reliability of composite blade subjected to impact, vibration, and high-temperature excitation

PatentWO2021031223A1

Innovation

- An experimental device including a power supply module, a measurement module, an adjustable-angle impact module, a clamping module, a thermal environment module, a projectile recovery module, a basic excitation module and a platform module is designed, which can simulate compounding under high temperature and vibration conditions. For the impact excitation of material blades, multi-degree-of-freedom experimental simulations are realized through components such as light gas cannons, infrared sights, hydraulic cylinders, servo motors, hot boxes and basic excitation modules.

Safety Standards and Regulations for Blade Batteries

Safety standards and regulations play a crucial role in ensuring the safe adoption and implementation of blade batteries in various applications. These standards are designed to address the unique characteristics and potential risks associated with blade batteries, which differ from traditional lithium-ion battery designs.

One of the primary safety standards for blade batteries is the UN38.3 certification, which is mandatory for the transportation of lithium batteries. This standard includes a series of tests to evaluate the safety of batteries under various conditions, such as altitude simulation, thermal cycling, vibration, shock, and external short circuit. Blade batteries must pass these tests to be approved for transportation and commercial use.

In addition to UN38.3, the IEC 62133 standard is widely recognized for safety requirements for portable sealed secondary cells and batteries. This standard covers aspects such as abnormal operation, mechanical tests, and design evaluation. For blade batteries, specific attention is given to their unique structural characteristics and potential failure modes.

The automotive industry has its own set of standards for battery safety, particularly relevant for electric vehicles. The ISO 6469 series of standards addresses the safety specifications for electrically propelled road vehicles, including battery system safety. These standards cover aspects such as electrical safety, protection against failures, and post-crash safety requirements.

Regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP) have also developed specific guidelines for electric vehicle battery safety. These guidelines often include crash test protocols and performance criteria tailored to address the unique risks associated with high-voltage battery systems.

For consumer electronics applications, standards such as UL 1642 for lithium batteries and IEC 62133-2 for safety requirements for portable sealed secondary lithium cells and batteries are applicable. These standards cover aspects like electrical, mechanical, and environmental safety tests specific to lithium-based batteries.

As blade battery technology continues to evolve, safety standards and regulations are expected to adapt accordingly. Regulatory bodies and industry stakeholders are actively collaborating to develop new standards and update existing ones to address emerging safety concerns and technological advancements in blade battery design and manufacturing.

Compliance with these safety standards and regulations is not only a legal requirement but also a crucial factor in building consumer trust and ensuring the widespread adoption of blade battery technology across various industries.

One of the primary safety standards for blade batteries is the UN38.3 certification, which is mandatory for the transportation of lithium batteries. This standard includes a series of tests to evaluate the safety of batteries under various conditions, such as altitude simulation, thermal cycling, vibration, shock, and external short circuit. Blade batteries must pass these tests to be approved for transportation and commercial use.

In addition to UN38.3, the IEC 62133 standard is widely recognized for safety requirements for portable sealed secondary cells and batteries. This standard covers aspects such as abnormal operation, mechanical tests, and design evaluation. For blade batteries, specific attention is given to their unique structural characteristics and potential failure modes.

The automotive industry has its own set of standards for battery safety, particularly relevant for electric vehicles. The ISO 6469 series of standards addresses the safety specifications for electrically propelled road vehicles, including battery system safety. These standards cover aspects such as electrical safety, protection against failures, and post-crash safety requirements.

Regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP) have also developed specific guidelines for electric vehicle battery safety. These guidelines often include crash test protocols and performance criteria tailored to address the unique risks associated with high-voltage battery systems.

For consumer electronics applications, standards such as UL 1642 for lithium batteries and IEC 62133-2 for safety requirements for portable sealed secondary lithium cells and batteries are applicable. These standards cover aspects like electrical, mechanical, and environmental safety tests specific to lithium-based batteries.

As blade battery technology continues to evolve, safety standards and regulations are expected to adapt accordingly. Regulatory bodies and industry stakeholders are actively collaborating to develop new standards and update existing ones to address emerging safety concerns and technological advancements in blade battery design and manufacturing.

Compliance with these safety standards and regulations is not only a legal requirement but also a crucial factor in building consumer trust and ensuring the widespread adoption of blade battery technology across various industries.

Environmental Impact of Blade Battery Testing Processes

The environmental impact of blade battery testing processes is a critical consideration in the development and adoption of this emerging technology. As reliability testing frameworks for blade batteries evolve, it is essential to assess and mitigate potential environmental consequences associated with these procedures.

Blade battery testing typically involves extensive cycling, thermal management, and safety evaluations. These processes can consume significant amounts of energy, potentially contributing to increased carbon emissions if not managed sustainably. To address this concern, many testing facilities are implementing renewable energy sources, such as solar panels or wind turbines, to power their operations. This shift towards clean energy not only reduces the carbon footprint of testing processes but also aligns with the overall goal of promoting sustainable energy storage solutions.

Water usage is another environmental factor to consider in blade battery testing. Thermal management systems and cooling mechanisms often require substantial water resources. To minimize water consumption, advanced cooling technologies and closed-loop systems are being developed and implemented. These innovations help conserve water and reduce the overall environmental impact of testing procedures.

The disposal of materials used in blade battery testing also presents environmental challenges. Test samples, electrolytes, and other components may contain hazardous substances that require proper handling and disposal. To address this issue, testing facilities are implementing comprehensive waste management protocols, including recycling programs for recoverable materials and safe disposal methods for hazardous waste. Additionally, researchers are exploring the use of more environmentally friendly materials in battery construction, which could reduce the environmental impact of both testing and production processes.

Noise pollution is another environmental concern associated with blade battery testing, particularly during safety and abuse tests. To mitigate this issue, testing facilities are investing in sound-proofing technologies and conducting high-noise tests in isolated areas. This approach helps minimize disturbances to surrounding ecosystems and communities.

As the demand for blade batteries grows, the scale of testing operations is likely to increase. This expansion could potentially lead to land use changes and habitat disruption if not carefully managed. To address this concern, testing facilities are exploring ways to optimize their spatial footprint, such as vertical integration of testing equipment and the use of modular, adaptable testing environments.

In conclusion, while blade battery testing processes present several environmental challenges, the industry is actively working to address these issues through innovative solutions and sustainable practices. By continuously improving testing methodologies and adopting environmentally friendly technologies, the blade battery sector can minimize its ecological impact while advancing the development of reliable, high-performance energy storage solutions.

Blade battery testing typically involves extensive cycling, thermal management, and safety evaluations. These processes can consume significant amounts of energy, potentially contributing to increased carbon emissions if not managed sustainably. To address this concern, many testing facilities are implementing renewable energy sources, such as solar panels or wind turbines, to power their operations. This shift towards clean energy not only reduces the carbon footprint of testing processes but also aligns with the overall goal of promoting sustainable energy storage solutions.

Water usage is another environmental factor to consider in blade battery testing. Thermal management systems and cooling mechanisms often require substantial water resources. To minimize water consumption, advanced cooling technologies and closed-loop systems are being developed and implemented. These innovations help conserve water and reduce the overall environmental impact of testing procedures.

The disposal of materials used in blade battery testing also presents environmental challenges. Test samples, electrolytes, and other components may contain hazardous substances that require proper handling and disposal. To address this issue, testing facilities are implementing comprehensive waste management protocols, including recycling programs for recoverable materials and safe disposal methods for hazardous waste. Additionally, researchers are exploring the use of more environmentally friendly materials in battery construction, which could reduce the environmental impact of both testing and production processes.

Noise pollution is another environmental concern associated with blade battery testing, particularly during safety and abuse tests. To mitigate this issue, testing facilities are investing in sound-proofing technologies and conducting high-noise tests in isolated areas. This approach helps minimize disturbances to surrounding ecosystems and communities.

As the demand for blade batteries grows, the scale of testing operations is likely to increase. This expansion could potentially lead to land use changes and habitat disruption if not carefully managed. To address this concern, testing facilities are exploring ways to optimize their spatial footprint, such as vertical integration of testing equipment and the use of modular, adaptable testing environments.

In conclusion, while blade battery testing processes present several environmental challenges, the industry is actively working to address these issues through innovative solutions and sustainable practices. By continuously improving testing methodologies and adopting environmentally friendly technologies, the blade battery sector can minimize its ecological impact while advancing the development of reliable, high-performance energy storage solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!