How Blade Battery Reduces Maintenance Costs in Electric Cars

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Blade Battery Evolution and Objectives

The evolution of blade batteries represents a significant leap forward in electric vehicle (EV) technology, addressing key challenges in battery performance, safety, and cost-effectiveness. Originating from the need to overcome limitations of traditional lithium-ion batteries, blade batteries have emerged as a promising solution to enhance energy density, reduce fire risks, and improve overall efficiency in EVs.

The development of blade batteries can be traced back to the early 2010s when researchers began exploring alternative battery designs to overcome the inherent limitations of conventional cylindrical and prismatic cells. The primary objective was to create a battery that could maximize space utilization within the vehicle while simultaneously improving energy density and thermal management.

As the technology progressed, manufacturers focused on refining the blade battery's unique structural design. This innovative approach involves arranging battery cells in a blade-like configuration, allowing for more efficient packaging and better heat dissipation. The result is a battery system that can achieve higher energy density within the same volume, translating to increased range for electric vehicles.

One of the key objectives driving blade battery development has been to enhance safety features. Traditional lithium-ion batteries are susceptible to thermal runaway, which can lead to fires or explosions. Blade batteries aim to mitigate this risk through improved structural integrity and advanced thermal management systems, significantly reducing the likelihood of catastrophic failures.

Another critical goal in the evolution of blade batteries has been to address the issue of battery degradation over time. By optimizing the cell arrangement and implementing advanced battery management systems, blade batteries aim to maintain their performance characteristics for longer periods, thereby reducing the need for frequent replacements or extensive maintenance.

The focus on reducing maintenance costs has been a driving force behind blade battery development. Engineers have worked to create a more robust and reliable battery system that requires less frequent servicing, potentially lowering the total cost of ownership for electric vehicle users. This objective aligns with the broader industry goal of making EVs more accessible and economically viable for a wider range of consumers.

As the technology continues to mature, researchers and manufacturers are setting ambitious targets for the next generation of blade batteries. These objectives include further improvements in energy density, faster charging capabilities, and even greater longevity. The ultimate aim is to develop a battery technology that not only reduces maintenance costs but also significantly enhances the overall performance and appeal of electric vehicles in the global automotive market.

The development of blade batteries can be traced back to the early 2010s when researchers began exploring alternative battery designs to overcome the inherent limitations of conventional cylindrical and prismatic cells. The primary objective was to create a battery that could maximize space utilization within the vehicle while simultaneously improving energy density and thermal management.

As the technology progressed, manufacturers focused on refining the blade battery's unique structural design. This innovative approach involves arranging battery cells in a blade-like configuration, allowing for more efficient packaging and better heat dissipation. The result is a battery system that can achieve higher energy density within the same volume, translating to increased range for electric vehicles.

One of the key objectives driving blade battery development has been to enhance safety features. Traditional lithium-ion batteries are susceptible to thermal runaway, which can lead to fires or explosions. Blade batteries aim to mitigate this risk through improved structural integrity and advanced thermal management systems, significantly reducing the likelihood of catastrophic failures.

Another critical goal in the evolution of blade batteries has been to address the issue of battery degradation over time. By optimizing the cell arrangement and implementing advanced battery management systems, blade batteries aim to maintain their performance characteristics for longer periods, thereby reducing the need for frequent replacements or extensive maintenance.

The focus on reducing maintenance costs has been a driving force behind blade battery development. Engineers have worked to create a more robust and reliable battery system that requires less frequent servicing, potentially lowering the total cost of ownership for electric vehicle users. This objective aligns with the broader industry goal of making EVs more accessible and economically viable for a wider range of consumers.

As the technology continues to mature, researchers and manufacturers are setting ambitious targets for the next generation of blade batteries. These objectives include further improvements in energy density, faster charging capabilities, and even greater longevity. The ultimate aim is to develop a battery technology that not only reduces maintenance costs but also significantly enhances the overall performance and appeal of electric vehicles in the global automotive market.

EV Market Demand for Low-Maintenance Batteries

The electric vehicle (EV) market has been experiencing a significant shift towards low-maintenance batteries, driven by consumer demand for more reliable and cost-effective transportation solutions. This trend is particularly evident in the growing interest in blade batteries, which offer reduced maintenance costs and improved longevity compared to traditional lithium-ion batteries.

The demand for low-maintenance batteries in EVs stems from several factors. Firstly, consumers are increasingly aware of the total cost of ownership associated with electric vehicles. While the initial purchase price of EVs has been a barrier for some, the potential for lower maintenance costs over the vehicle's lifetime has become a compelling selling point. Blade batteries, with their enhanced durability and reduced degradation rates, address this concern directly by promising lower long-term maintenance expenses.

Furthermore, the EV market has seen a surge in demand for vehicles with longer range capabilities. This has put pressure on battery manufacturers to develop solutions that not only provide extended range but also maintain their performance over time. Blade batteries, with their improved energy density and slower capacity loss, align well with this market requirement, further driving their popularity among both manufacturers and consumers.

Another key factor contributing to the demand for low-maintenance batteries is the growing emphasis on sustainability in the automotive industry. Consumers are becoming more environmentally conscious and are seeking vehicles that not only produce zero emissions during operation but also have a reduced environmental impact throughout their lifecycle. Blade batteries, with their potential for longer lifespan and reduced need for replacement, cater to this eco-friendly sentiment.

The commercial sector, particularly fleet operators, has also shown significant interest in low-maintenance battery technologies. For businesses operating large fleets of electric vehicles, minimizing downtime and reducing maintenance costs are crucial for operational efficiency. The promise of blade batteries to deliver consistent performance with less frequent servicing aligns perfectly with these commercial needs, driving adoption in this segment of the market.

As charging infrastructure continues to expand and improve, there is an increasing expectation for batteries that can withstand frequent fast charging without significant degradation. Blade batteries have demonstrated superior performance in this aspect, further fueling market demand. This capability is particularly attractive for urban dwellers and long-distance travelers who rely on public charging networks.

The demand for low-maintenance batteries in EVs stems from several factors. Firstly, consumers are increasingly aware of the total cost of ownership associated with electric vehicles. While the initial purchase price of EVs has been a barrier for some, the potential for lower maintenance costs over the vehicle's lifetime has become a compelling selling point. Blade batteries, with their enhanced durability and reduced degradation rates, address this concern directly by promising lower long-term maintenance expenses.

Furthermore, the EV market has seen a surge in demand for vehicles with longer range capabilities. This has put pressure on battery manufacturers to develop solutions that not only provide extended range but also maintain their performance over time. Blade batteries, with their improved energy density and slower capacity loss, align well with this market requirement, further driving their popularity among both manufacturers and consumers.

Another key factor contributing to the demand for low-maintenance batteries is the growing emphasis on sustainability in the automotive industry. Consumers are becoming more environmentally conscious and are seeking vehicles that not only produce zero emissions during operation but also have a reduced environmental impact throughout their lifecycle. Blade batteries, with their potential for longer lifespan and reduced need for replacement, cater to this eco-friendly sentiment.

The commercial sector, particularly fleet operators, has also shown significant interest in low-maintenance battery technologies. For businesses operating large fleets of electric vehicles, minimizing downtime and reducing maintenance costs are crucial for operational efficiency. The promise of blade batteries to deliver consistent performance with less frequent servicing aligns perfectly with these commercial needs, driving adoption in this segment of the market.

As charging infrastructure continues to expand and improve, there is an increasing expectation for batteries that can withstand frequent fast charging without significant degradation. Blade batteries have demonstrated superior performance in this aspect, further fueling market demand. This capability is particularly attractive for urban dwellers and long-distance travelers who rely on public charging networks.

Blade Battery Technology: Current Status and Challenges

Blade battery technology has emerged as a significant innovation in the electric vehicle (EV) industry, offering potential solutions to several challenges faced by traditional lithium-ion batteries. Developed by BYD, a leading Chinese automaker and battery manufacturer, blade batteries represent a new approach to battery cell design and packaging.

The current status of blade battery technology is characterized by its unique structural design. Unlike conventional prismatic or cylindrical cells, blade batteries are long, thin cells that can be arranged in a pack more efficiently. This design allows for higher energy density and improved thermal management, addressing two critical issues in EV battery technology.

One of the primary challenges that blade batteries aim to overcome is the risk of thermal runaway, a major safety concern in lithium-ion batteries. The blade design, coupled with LFP (lithium iron phosphate) chemistry, significantly reduces this risk. Tests have shown that blade batteries can withstand extreme conditions without catching fire or exploding, a crucial advancement in EV safety.

Another challenge addressed by blade batteries is the need for increased energy density. By optimizing the cell arrangement within the battery pack, blade batteries can achieve higher volumetric energy density compared to traditional designs. This translates to longer driving ranges or smaller battery packs for the same range, both of which are highly desirable in EV development.

Durability and longevity are also key focus areas for blade battery technology. The current status shows promising results in cycle life and capacity retention, potentially leading to reduced maintenance costs and longer vehicle lifespans. However, further long-term data is needed to fully validate these claims in real-world conditions.

Manufacturing scalability presents both an opportunity and a challenge for blade battery technology. While the design lends itself to efficient production processes, scaling up to meet growing EV demand requires significant investment in new manufacturing facilities and equipment.

Cost-effectiveness remains a critical challenge. Although blade batteries promise reduced costs through improved energy density and potentially lower material costs, the initial investment in new production lines is substantial. Achieving cost parity or advantage over traditional lithium-ion batteries is crucial for widespread adoption.

Lastly, the integration of blade batteries into existing EV designs poses engineering challenges. The unique form factor of blade cells requires rethinking battery pack design and vehicle architecture. This may necessitate significant changes in EV manufacturing processes and supply chains.

The current status of blade battery technology is characterized by its unique structural design. Unlike conventional prismatic or cylindrical cells, blade batteries are long, thin cells that can be arranged in a pack more efficiently. This design allows for higher energy density and improved thermal management, addressing two critical issues in EV battery technology.

One of the primary challenges that blade batteries aim to overcome is the risk of thermal runaway, a major safety concern in lithium-ion batteries. The blade design, coupled with LFP (lithium iron phosphate) chemistry, significantly reduces this risk. Tests have shown that blade batteries can withstand extreme conditions without catching fire or exploding, a crucial advancement in EV safety.

Another challenge addressed by blade batteries is the need for increased energy density. By optimizing the cell arrangement within the battery pack, blade batteries can achieve higher volumetric energy density compared to traditional designs. This translates to longer driving ranges or smaller battery packs for the same range, both of which are highly desirable in EV development.

Durability and longevity are also key focus areas for blade battery technology. The current status shows promising results in cycle life and capacity retention, potentially leading to reduced maintenance costs and longer vehicle lifespans. However, further long-term data is needed to fully validate these claims in real-world conditions.

Manufacturing scalability presents both an opportunity and a challenge for blade battery technology. While the design lends itself to efficient production processes, scaling up to meet growing EV demand requires significant investment in new manufacturing facilities and equipment.

Cost-effectiveness remains a critical challenge. Although blade batteries promise reduced costs through improved energy density and potentially lower material costs, the initial investment in new production lines is substantial. Achieving cost parity or advantage over traditional lithium-ion batteries is crucial for widespread adoption.

Lastly, the integration of blade batteries into existing EV designs poses engineering challenges. The unique form factor of blade cells requires rethinking battery pack design and vehicle architecture. This may necessitate significant changes in EV manufacturing processes and supply chains.

Blade Battery Design and Cost-Reduction Mechanisms

01 Battery management systems for cost-effective maintenance

Advanced battery management systems are implemented to monitor and optimize blade battery performance, reducing maintenance costs. These systems can predict potential issues, schedule preventive maintenance, and extend battery life through intelligent charging and discharging strategies.- Battery management systems for cost-effective maintenance: Advanced battery management systems are implemented to monitor and optimize the performance of blade batteries, reducing maintenance costs. These systems can predict potential issues, schedule preventive maintenance, and extend battery life through intelligent charging and discharging strategies.

- Automated diagnostic and maintenance procedures: Automated diagnostic tools and maintenance procedures are developed to streamline the maintenance process for blade batteries. These technologies can quickly identify issues, suggest repairs, and even perform some maintenance tasks autonomously, reducing labor costs and downtime.

- Modular design for easy replacement and repair: Blade batteries are designed with a modular approach, allowing for easy replacement of individual components or cells. This reduces the overall maintenance costs by enabling targeted repairs and upgrades without replacing the entire battery pack.

- Remote monitoring and predictive maintenance: Remote monitoring systems are implemented to track battery performance and health in real-time. This enables predictive maintenance strategies, allowing for timely interventions and reducing the need for costly emergency repairs or replacements.

- Cost-effective recycling and end-of-life management: Efficient recycling processes and end-of-life management strategies are developed to reduce the overall lifecycle costs of blade batteries. These approaches focus on recovering valuable materials and minimizing environmental impact, potentially offsetting some maintenance and replacement costs.

02 Automated maintenance and inspection processes

Automated systems and robotic technologies are utilized for blade battery maintenance and inspection, reducing labor costs and improving efficiency. These systems can perform routine checks, identify potential issues, and even carry out minor repairs without human intervention.Expand Specific Solutions03 Predictive maintenance using AI and machine learning

Artificial intelligence and machine learning algorithms are employed to analyze battery performance data and predict maintenance needs. This proactive approach helps prevent unexpected failures, optimize maintenance schedules, and reduce overall maintenance costs.Expand Specific Solutions04 Cost-effective recycling and refurbishment processes

Innovative recycling and refurbishment techniques are developed to extend the lifespan of blade batteries and reduce replacement costs. These processes involve recovering and reusing valuable materials, as well as restoring partially degraded batteries to optimal performance levels.Expand Specific Solutions05 Remote monitoring and diagnostics for blade batteries

Remote monitoring systems are implemented to continuously track blade battery performance and health. These systems enable real-time diagnostics, early detection of issues, and remote troubleshooting, reducing the need for on-site inspections and minimizing maintenance costs.Expand Specific Solutions

Major Players in Blade Battery Development

The blade battery technology in electric cars is currently in a growth phase, with increasing market adoption and technological advancements. The market size for this technology is expanding rapidly, driven by the growing demand for electric vehicles and the need for more efficient, safer battery solutions. The technology's maturity is progressing, with key players like Contemporary Amperex Technology Co., Ltd. (CATL) and LG Energy Solution Ltd. leading the way in research and development. Other major automotive manufacturers such as AUDI AG, Mercedes-Benz Group AG, and BMW are also investing in blade battery technology, indicating its potential for widespread implementation. As the technology continues to evolve, it is expected to significantly reduce maintenance costs in electric cars, further accelerating its adoption in the automotive industry.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL's Blade Battery technology significantly reduces maintenance costs in electric cars through its innovative design and superior performance. The Blade Battery utilizes LFP (Lithium Iron Phosphate) chemistry, which offers enhanced safety and longevity compared to traditional lithium-ion batteries[1]. The unique cell-to-pack design eliminates the need for module housings, resulting in higher energy density and simplified maintenance procedures[2]. CATL claims that the Blade Battery can achieve over 1 million kilometers of use without significant degradation, potentially lasting the entire lifetime of the vehicle[3]. This extended lifespan dramatically reduces the need for battery replacements, a major component of EV maintenance costs.

Strengths: Exceptional safety, long lifespan, and high energy density. Weaknesses: Higher initial cost compared to some traditional battery technologies, and potential limitations in extreme fast charging capabilities.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution's approach to reducing maintenance costs in electric cars focuses on their advanced lithium-ion battery technology. Their batteries utilize a proprietary cathode material composition that enhances cycle life and thermal stability[4]. LG's battery management system (BMS) incorporates predictive maintenance algorithms, which can detect potential issues before they become critical, reducing unexpected downtime and repair costs[5]. The company has also developed a modular battery pack design that allows for easier replacement of individual modules rather than the entire pack, potentially lowering long-term maintenance expenses[6]. LG Energy Solution's batteries are designed to maintain over 80% of their original capacity after 1000 charge cycles, contributing to extended vehicle range and reduced frequency of battery-related maintenance[7].

Strengths: Advanced BMS with predictive maintenance, modular design for easier repairs, and good cycle life. Weaknesses: Potentially higher production costs due to advanced materials, and ongoing research to further improve energy density.

Key Innovations in Blade Battery Technology

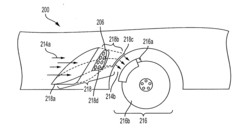

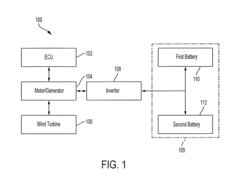

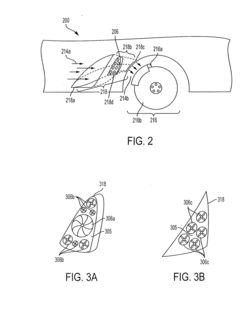

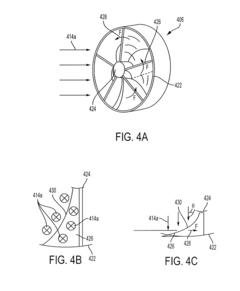

Wind turbine systems and air channels in vehicles for enhancing energy generation, cooling, and aerodynamics

PatentActiveUS20170082092A1

Innovation

- The integration of a wind turbine system within air channels of vehicles, which includes an air duct with wind turbines positioned at strategic locations to increase airflow velocity and redirect airflow for enhanced cooling and energy generation, utilizing a generator to convert kinetic energy into electrical energy stored in a battery, and an electronic control unit to optimize energy production and cooling.

Environmental Impact of Blade Batteries

The environmental impact of Blade Batteries in electric cars is a crucial aspect to consider when evaluating their overall sustainability. These innovative batteries, developed by BYD, offer several environmental advantages over traditional lithium-ion batteries used in electric vehicles.

One of the primary environmental benefits of Blade Batteries is their improved energy density. This higher energy density allows for longer driving ranges with smaller battery packs, reducing the overall weight of electric vehicles. As a result, less energy is required to propel the vehicle, leading to increased efficiency and reduced energy consumption throughout the vehicle's lifecycle.

The manufacturing process of Blade Batteries also contributes to their positive environmental impact. BYD has implemented advanced production techniques that minimize waste and energy consumption during battery production. This approach not only reduces the carbon footprint associated with battery manufacturing but also helps conserve valuable resources.

Blade Batteries are designed with a focus on longevity and durability, which has significant environmental implications. Their extended lifespan means fewer batteries need to be produced and replaced over time, reducing the overall demand for raw materials and energy required for battery production. This longevity also translates to less electronic waste generated from discarded batteries.

Furthermore, the Blade Battery's unique design enhances its safety profile, reducing the risk of thermal runaway and fire incidents. This improved safety not only protects users but also minimizes the potential for environmental damage caused by battery-related accidents or improper disposal.

The recyclability of Blade Batteries is another crucial factor in their environmental impact. BYD has developed advanced recycling processes specifically tailored for these batteries, allowing for more efficient recovery of valuable materials. This closed-loop approach helps reduce the need for new raw material extraction and minimizes the environmental impact associated with battery disposal.

In terms of emissions, electric vehicles equipped with Blade Batteries contribute to reduced air pollution and greenhouse gas emissions compared to internal combustion engine vehicles. The batteries' efficiency and longevity further enhance this benefit by maximizing the environmental advantages of electric mobility over an extended period.

However, it is important to note that the full environmental impact of Blade Batteries also depends on the source of electricity used for charging. To maximize their positive environmental effect, it is crucial to pair these batteries with renewable energy sources for charging, further reducing the overall carbon footprint of electric vehicles.

One of the primary environmental benefits of Blade Batteries is their improved energy density. This higher energy density allows for longer driving ranges with smaller battery packs, reducing the overall weight of electric vehicles. As a result, less energy is required to propel the vehicle, leading to increased efficiency and reduced energy consumption throughout the vehicle's lifecycle.

The manufacturing process of Blade Batteries also contributes to their positive environmental impact. BYD has implemented advanced production techniques that minimize waste and energy consumption during battery production. This approach not only reduces the carbon footprint associated with battery manufacturing but also helps conserve valuable resources.

Blade Batteries are designed with a focus on longevity and durability, which has significant environmental implications. Their extended lifespan means fewer batteries need to be produced and replaced over time, reducing the overall demand for raw materials and energy required for battery production. This longevity also translates to less electronic waste generated from discarded batteries.

Furthermore, the Blade Battery's unique design enhances its safety profile, reducing the risk of thermal runaway and fire incidents. This improved safety not only protects users but also minimizes the potential for environmental damage caused by battery-related accidents or improper disposal.

The recyclability of Blade Batteries is another crucial factor in their environmental impact. BYD has developed advanced recycling processes specifically tailored for these batteries, allowing for more efficient recovery of valuable materials. This closed-loop approach helps reduce the need for new raw material extraction and minimizes the environmental impact associated with battery disposal.

In terms of emissions, electric vehicles equipped with Blade Batteries contribute to reduced air pollution and greenhouse gas emissions compared to internal combustion engine vehicles. The batteries' efficiency and longevity further enhance this benefit by maximizing the environmental advantages of electric mobility over an extended period.

However, it is important to note that the full environmental impact of Blade Batteries also depends on the source of electricity used for charging. To maximize their positive environmental effect, it is crucial to pair these batteries with renewable energy sources for charging, further reducing the overall carbon footprint of electric vehicles.

Blade Battery Integration in EV Ecosystems

The integration of Blade Battery technology into electric vehicle (EV) ecosystems represents a significant advancement in battery management and overall EV performance. This innovative battery design, characterized by its long, thin cells arranged in a blade-like configuration, offers numerous advantages that extend beyond mere energy storage.

Blade Batteries seamlessly integrate into existing EV architectures, allowing for more efficient use of space within the vehicle. This integration enables manufacturers to increase battery capacity without significantly altering the vehicle's design or compromising interior space. The compact nature of Blade Batteries also contributes to improved weight distribution, enhancing the vehicle's handling and stability.

From a thermal management perspective, Blade Batteries exhibit superior heat dissipation properties. The increased surface area of the blade-like cells facilitates more effective cooling, reducing the risk of thermal runaway and enhancing overall battery safety. This improved thermal management translates to longer battery life and more consistent performance across various operating conditions.

The integration of Blade Batteries also impacts the EV's charging infrastructure. These batteries are designed to support high-speed charging without compromising safety or longevity. This compatibility with fast-charging systems aligns well with the growing demand for rapid charging solutions in the EV ecosystem, potentially reducing charging times and improving the overall user experience.

Furthermore, the Blade Battery design allows for more flexible battery pack configurations. Manufacturers can tailor the battery layout to specific vehicle models, optimizing space utilization and energy density. This flexibility extends to the potential for modular battery systems, where individual blade units could be replaced or upgraded as needed, enhancing the vehicle's long-term serviceability and potentially reducing lifecycle costs.

The integration of Blade Batteries also has implications for the broader EV ecosystem, including manufacturing processes and supply chains. The simplified structure of these batteries may lead to more streamlined production methods, potentially reducing manufacturing costs and environmental impact. Additionally, the materials used in Blade Batteries, typically lithium iron phosphate (LFP), are generally more abundant and less prone to supply chain disruptions compared to some other battery chemistries.

In conclusion, the integration of Blade Batteries into EV ecosystems represents a holistic approach to improving electric vehicle performance, safety, and sustainability. By addressing key challenges in battery design and management, this technology has the potential to accelerate the adoption of EVs and contribute to the ongoing evolution of sustainable transportation solutions.

Blade Batteries seamlessly integrate into existing EV architectures, allowing for more efficient use of space within the vehicle. This integration enables manufacturers to increase battery capacity without significantly altering the vehicle's design or compromising interior space. The compact nature of Blade Batteries also contributes to improved weight distribution, enhancing the vehicle's handling and stability.

From a thermal management perspective, Blade Batteries exhibit superior heat dissipation properties. The increased surface area of the blade-like cells facilitates more effective cooling, reducing the risk of thermal runaway and enhancing overall battery safety. This improved thermal management translates to longer battery life and more consistent performance across various operating conditions.

The integration of Blade Batteries also impacts the EV's charging infrastructure. These batteries are designed to support high-speed charging without compromising safety or longevity. This compatibility with fast-charging systems aligns well with the growing demand for rapid charging solutions in the EV ecosystem, potentially reducing charging times and improving the overall user experience.

Furthermore, the Blade Battery design allows for more flexible battery pack configurations. Manufacturers can tailor the battery layout to specific vehicle models, optimizing space utilization and energy density. This flexibility extends to the potential for modular battery systems, where individual blade units could be replaced or upgraded as needed, enhancing the vehicle's long-term serviceability and potentially reducing lifecycle costs.

The integration of Blade Batteries also has implications for the broader EV ecosystem, including manufacturing processes and supply chains. The simplified structure of these batteries may lead to more streamlined production methods, potentially reducing manufacturing costs and environmental impact. Additionally, the materials used in Blade Batteries, typically lithium iron phosphate (LFP), are generally more abundant and less prone to supply chain disruptions compared to some other battery chemistries.

In conclusion, the integration of Blade Batteries into EV ecosystems represents a holistic approach to improving electric vehicle performance, safety, and sustainability. By addressing key challenges in battery design and management, this technology has the potential to accelerate the adoption of EVs and contribute to the ongoing evolution of sustainable transportation solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!