Role of Nanomaterials in Blade Battery Performance Improvement

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanomaterials in Batteries: Background and Objectives

Nanomaterials have emerged as a revolutionary force in the field of battery technology, particularly in the development of blade batteries. These advanced energy storage devices have gained significant attention due to their potential to enhance safety, energy density, and overall performance. The evolution of nanomaterials in battery technology can be traced back to the early 2000s when researchers began exploring the unique properties of materials at the nanoscale.

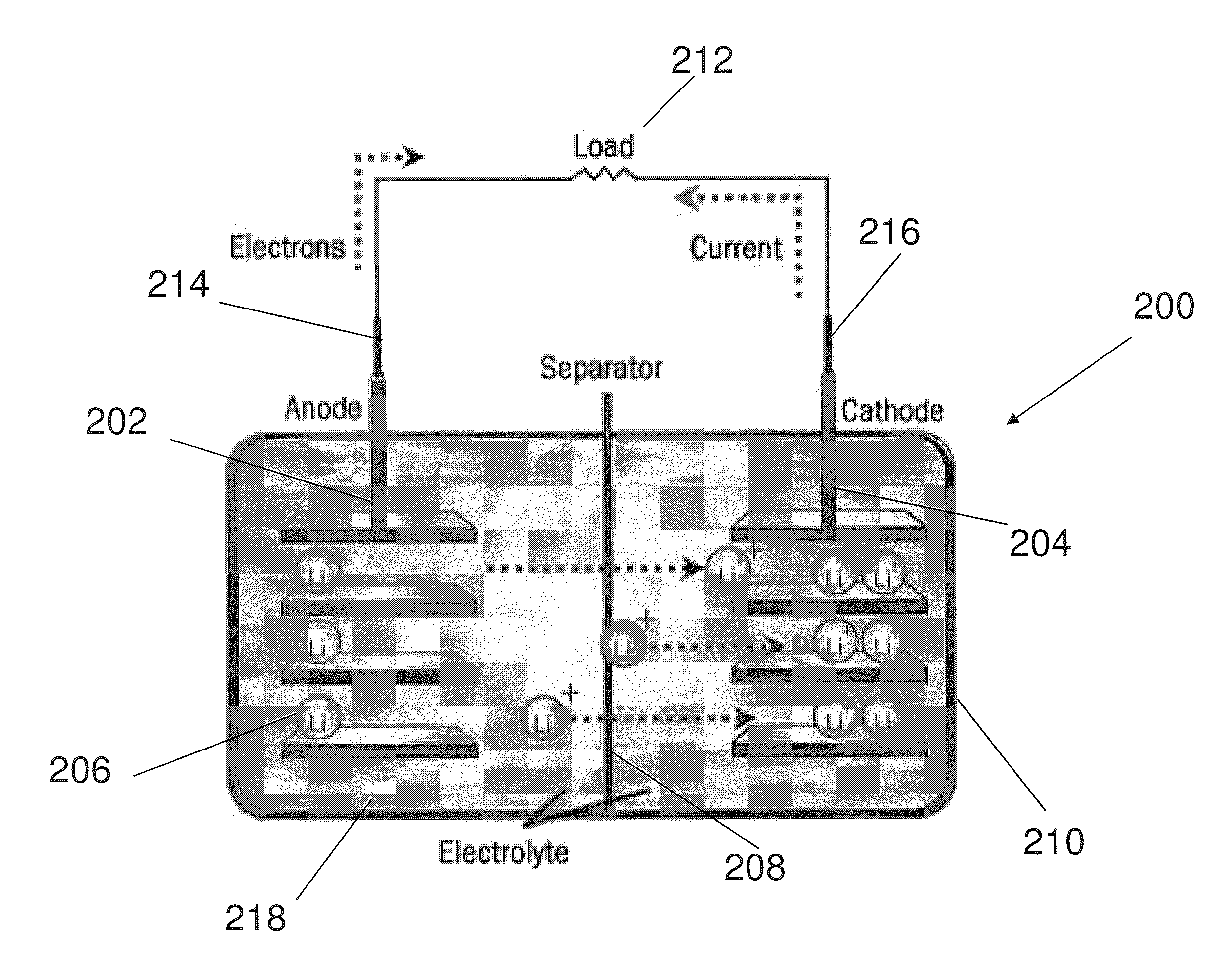

The primary objective of incorporating nanomaterials into blade batteries is to address the limitations of conventional lithium-ion batteries, such as limited energy density, slow charging rates, and safety concerns. By leveraging the exceptional properties of nanomaterials, including high surface area, improved electrical conductivity, and enhanced mechanical strength, researchers aim to develop next-generation batteries that can meet the growing demands of various applications, from electric vehicles to grid-scale energy storage.

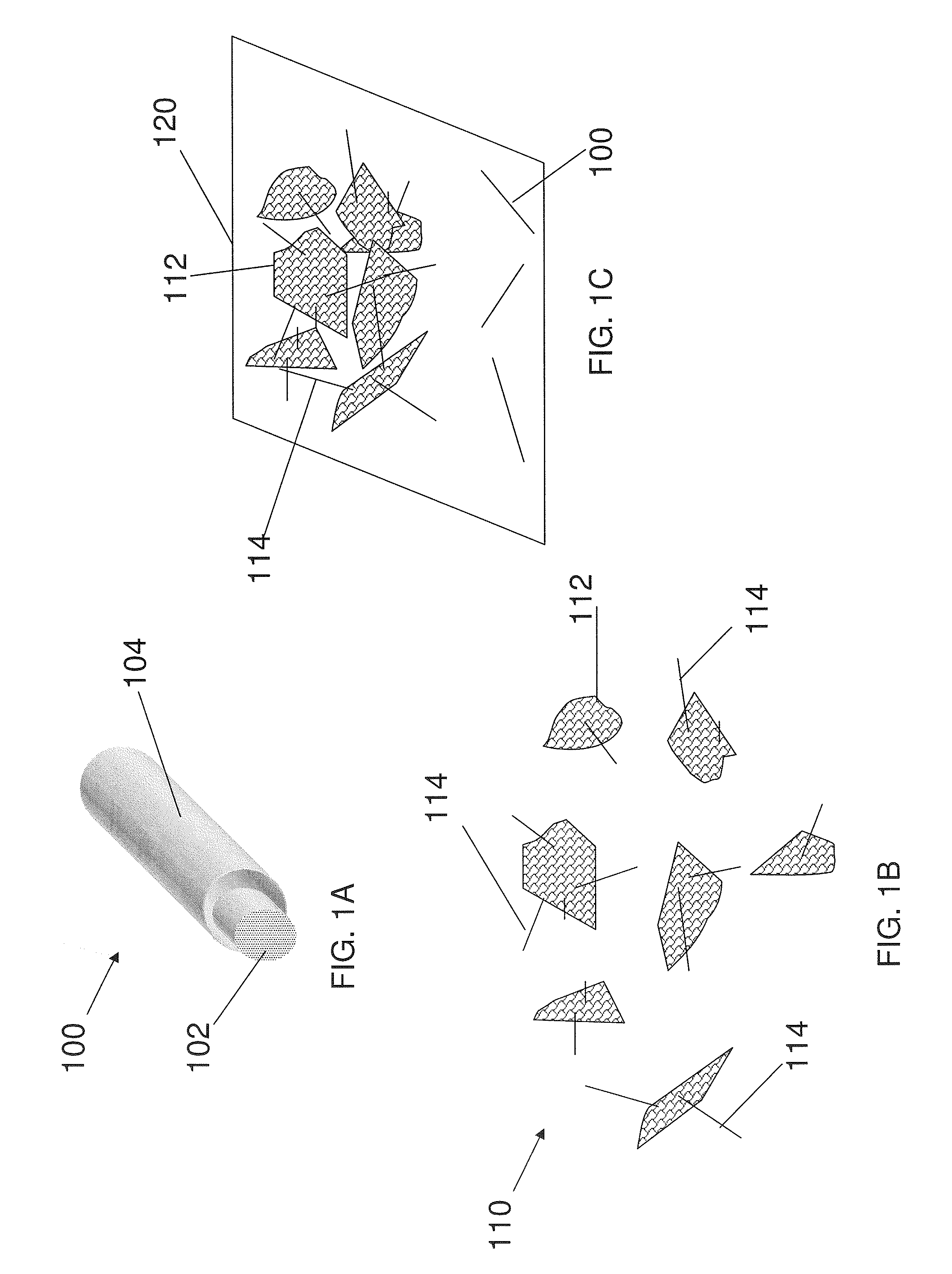

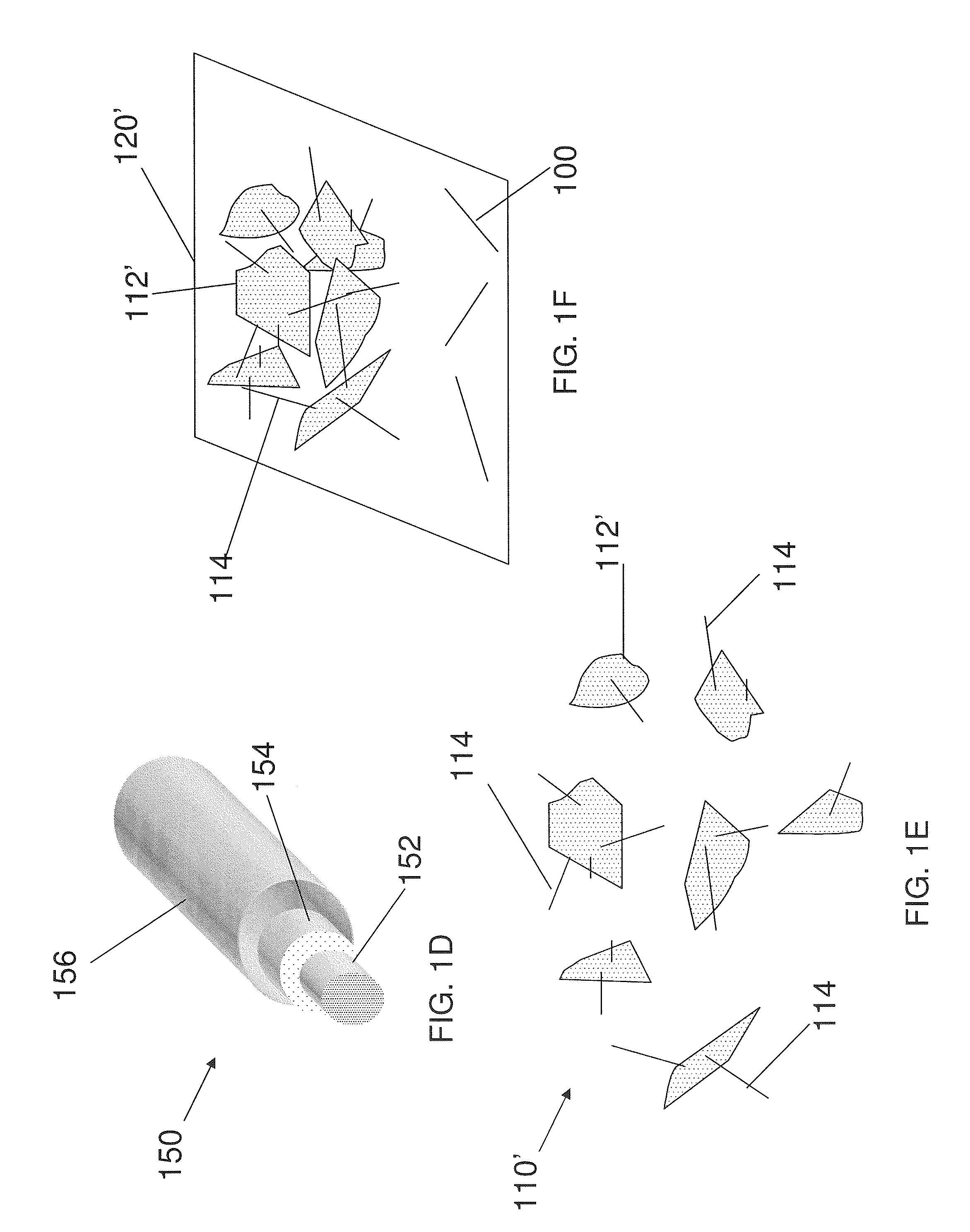

One of the key trends in this field is the development of nanostructured electrode materials. These materials, such as nanoparticles, nanowires, and nanotubes, offer increased surface area for electrochemical reactions, leading to improved energy storage capacity and faster charge/discharge rates. Additionally, nanomaterials can enhance the structural stability of electrodes, mitigating issues like volume expansion during cycling and prolonging battery life.

Another significant trend is the exploration of novel nanomaterial compositions and hybrid structures. Researchers are investigating a wide range of materials, including carbon-based nanomaterials, metal oxides, and composite structures, to optimize the electrochemical properties of blade batteries. These efforts are driven by the need to balance multiple performance parameters, such as energy density, power density, cycle life, and safety.

The integration of nanomaterials in blade batteries also aims to address safety concerns, which are paramount in battery technology. Nanomaterials can contribute to the development of more stable electrolytes, improved separators, and enhanced thermal management systems, reducing the risk of thermal runaway and improving overall battery safety.

As the field progresses, researchers are focusing on scalable and cost-effective production methods for nanomaterials, as well as their integration into existing battery manufacturing processes. This is crucial for the widespread adoption of nanomaterial-enhanced blade batteries in commercial applications. The ultimate goal is to create batteries that not only outperform current technologies but also meet the stringent requirements of safety, reliability, and cost-effectiveness demanded by various industries.

The primary objective of incorporating nanomaterials into blade batteries is to address the limitations of conventional lithium-ion batteries, such as limited energy density, slow charging rates, and safety concerns. By leveraging the exceptional properties of nanomaterials, including high surface area, improved electrical conductivity, and enhanced mechanical strength, researchers aim to develop next-generation batteries that can meet the growing demands of various applications, from electric vehicles to grid-scale energy storage.

One of the key trends in this field is the development of nanostructured electrode materials. These materials, such as nanoparticles, nanowires, and nanotubes, offer increased surface area for electrochemical reactions, leading to improved energy storage capacity and faster charge/discharge rates. Additionally, nanomaterials can enhance the structural stability of electrodes, mitigating issues like volume expansion during cycling and prolonging battery life.

Another significant trend is the exploration of novel nanomaterial compositions and hybrid structures. Researchers are investigating a wide range of materials, including carbon-based nanomaterials, metal oxides, and composite structures, to optimize the electrochemical properties of blade batteries. These efforts are driven by the need to balance multiple performance parameters, such as energy density, power density, cycle life, and safety.

The integration of nanomaterials in blade batteries also aims to address safety concerns, which are paramount in battery technology. Nanomaterials can contribute to the development of more stable electrolytes, improved separators, and enhanced thermal management systems, reducing the risk of thermal runaway and improving overall battery safety.

As the field progresses, researchers are focusing on scalable and cost-effective production methods for nanomaterials, as well as their integration into existing battery manufacturing processes. This is crucial for the widespread adoption of nanomaterial-enhanced blade batteries in commercial applications. The ultimate goal is to create batteries that not only outperform current technologies but also meet the stringent requirements of safety, reliability, and cost-effectiveness demanded by various industries.

Market Analysis for Advanced Battery Technologies

The advanced battery technology market is experiencing rapid growth, driven by increasing demand for electric vehicles, renewable energy storage, and portable electronics. The global market for advanced batteries is projected to reach $110 billion by 2025, with a compound annual growth rate of 12.3% from 2020 to 2025. This growth is primarily fueled by the automotive sector, which is expected to account for over 60% of the market share by 2025.

Lithium-ion batteries currently dominate the advanced battery market, with a market share of approximately 70%. However, emerging technologies such as solid-state batteries, lithium-sulfur batteries, and sodium-ion batteries are gaining traction due to their potential for higher energy density, improved safety, and lower costs. The blade battery, a type of lithium iron phosphate (LiFePO4) battery, has recently gained attention for its enhanced safety features and cost-effectiveness.

The role of nanomaterials in improving battery performance is becoming increasingly significant. Nanomaterials can enhance various aspects of battery performance, including energy density, power density, cycle life, and charging speed. For instance, nanostructured electrode materials can provide larger surface areas for electrochemical reactions, leading to improved energy and power densities. Carbon nanotubes and graphene are being explored as conductive additives to enhance electrode conductivity and stability.

In the context of blade batteries, nanomaterials are being investigated for their potential to further improve performance and safety. Nanostructured LiFePO4 cathodes can enhance the battery's rate capability and energy density. Additionally, nano-coatings on electrode surfaces can improve the stability of the electrode-electrolyte interface, leading to better cycle life and safety characteristics.

The market for nanomaterials in advanced batteries is expected to grow significantly, with a projected market value of $3.5 billion by 2025. This growth is driven by the increasing adoption of nanomaterials in various battery components, including electrodes, electrolytes, and separators. Major battery manufacturers and automotive companies are investing heavily in nanomaterial research and development to gain a competitive edge in the market.

However, challenges remain in the widespread adoption of nanomaterials in battery technologies. These include the high cost of nanomaterial production, scalability issues, and potential environmental and health concerns. Overcoming these challenges will be crucial for the successful integration of nanomaterials in advanced battery technologies, including blade batteries.

Lithium-ion batteries currently dominate the advanced battery market, with a market share of approximately 70%. However, emerging technologies such as solid-state batteries, lithium-sulfur batteries, and sodium-ion batteries are gaining traction due to their potential for higher energy density, improved safety, and lower costs. The blade battery, a type of lithium iron phosphate (LiFePO4) battery, has recently gained attention for its enhanced safety features and cost-effectiveness.

The role of nanomaterials in improving battery performance is becoming increasingly significant. Nanomaterials can enhance various aspects of battery performance, including energy density, power density, cycle life, and charging speed. For instance, nanostructured electrode materials can provide larger surface areas for electrochemical reactions, leading to improved energy and power densities. Carbon nanotubes and graphene are being explored as conductive additives to enhance electrode conductivity and stability.

In the context of blade batteries, nanomaterials are being investigated for their potential to further improve performance and safety. Nanostructured LiFePO4 cathodes can enhance the battery's rate capability and energy density. Additionally, nano-coatings on electrode surfaces can improve the stability of the electrode-electrolyte interface, leading to better cycle life and safety characteristics.

The market for nanomaterials in advanced batteries is expected to grow significantly, with a projected market value of $3.5 billion by 2025. This growth is driven by the increasing adoption of nanomaterials in various battery components, including electrodes, electrolytes, and separators. Major battery manufacturers and automotive companies are investing heavily in nanomaterial research and development to gain a competitive edge in the market.

However, challenges remain in the widespread adoption of nanomaterials in battery technologies. These include the high cost of nanomaterial production, scalability issues, and potential environmental and health concerns. Overcoming these challenges will be crucial for the successful integration of nanomaterials in advanced battery technologies, including blade batteries.

Current Challenges in Blade Battery Technology

Blade batteries, a revolutionary technology in the field of electric vehicle (EV) energy storage, face several significant challenges that hinder their widespread adoption and performance optimization. One of the primary issues is the thermal management of these batteries. Due to their unique structure and high energy density, blade batteries are prone to heat accumulation, which can lead to reduced efficiency and potential safety risks.

Another critical challenge lies in the electrode materials used in blade batteries. While current materials offer improved energy density compared to traditional lithium-ion batteries, there is still a need for further enhancement to meet the increasing demands of long-range EVs. The development of advanced electrode materials that can provide higher capacity and faster charging capabilities remains a key focus area for researchers and manufacturers.

The manufacturing process of blade batteries also presents significant hurdles. The precision required in assembling these thin, elongated cells is considerably higher than that of conventional battery production. Ensuring consistent quality and performance across large-scale production runs is a complex task that requires advanced manufacturing techniques and stringent quality control measures.

Cycle life and degradation are additional concerns for blade battery technology. As with all lithium-ion batteries, blade batteries experience capacity fade over time and with repeated charge-discharge cycles. Improving the longevity of these batteries without compromising their energy density or safety features is a critical challenge that needs to be addressed.

Safety remains a paramount concern in battery technology, and blade batteries are no exception. While they have demonstrated improved safety characteristics compared to some other lithium-ion battery designs, particularly in puncture tests, there is still room for enhancement in overall safety performance, especially under extreme conditions or in the event of manufacturing defects.

The integration of blade batteries into existing EV designs also poses challenges. Their unique form factor, while beneficial for space utilization, requires redesigning of battery packs and cooling systems. This adaptation process can be complex and costly for automobile manufacturers, potentially slowing down the adoption of this technology.

Lastly, the cost of production for blade batteries remains higher than that of traditional lithium-ion batteries. Achieving cost parity or reduction while maintaining superior performance is crucial for the widespread adoption of this technology in the competitive EV market.

Another critical challenge lies in the electrode materials used in blade batteries. While current materials offer improved energy density compared to traditional lithium-ion batteries, there is still a need for further enhancement to meet the increasing demands of long-range EVs. The development of advanced electrode materials that can provide higher capacity and faster charging capabilities remains a key focus area for researchers and manufacturers.

The manufacturing process of blade batteries also presents significant hurdles. The precision required in assembling these thin, elongated cells is considerably higher than that of conventional battery production. Ensuring consistent quality and performance across large-scale production runs is a complex task that requires advanced manufacturing techniques and stringent quality control measures.

Cycle life and degradation are additional concerns for blade battery technology. As with all lithium-ion batteries, blade batteries experience capacity fade over time and with repeated charge-discharge cycles. Improving the longevity of these batteries without compromising their energy density or safety features is a critical challenge that needs to be addressed.

Safety remains a paramount concern in battery technology, and blade batteries are no exception. While they have demonstrated improved safety characteristics compared to some other lithium-ion battery designs, particularly in puncture tests, there is still room for enhancement in overall safety performance, especially under extreme conditions or in the event of manufacturing defects.

The integration of blade batteries into existing EV designs also poses challenges. Their unique form factor, while beneficial for space utilization, requires redesigning of battery packs and cooling systems. This adaptation process can be complex and costly for automobile manufacturers, potentially slowing down the adoption of this technology.

Lastly, the cost of production for blade batteries remains higher than that of traditional lithium-ion batteries. Achieving cost parity or reduction while maintaining superior performance is crucial for the widespread adoption of this technology in the competitive EV market.

Existing Nanomaterial Solutions for Blade Batteries

01 Battery Management System for Blade Batteries

Advanced battery management systems are crucial for optimizing blade battery performance. These systems monitor and control various parameters such as temperature, voltage, and current to ensure efficient operation and longevity of the battery. They also implement safety features and balancing algorithms to maintain optimal performance across all cells in the battery pack.- Battery Management System for Blade Batteries: Advanced battery management systems are crucial for optimizing blade battery performance. These systems monitor and control various parameters such as temperature, voltage, and current to ensure efficient operation and longevity of the battery. They also implement safety features and balancing algorithms to maintain optimal performance across all cells in the battery pack.

- Thermal Management in Blade Batteries: Effective thermal management is essential for maintaining blade battery performance. This includes innovative cooling systems and heat dissipation methods to prevent overheating and ensure consistent performance under various operating conditions. Proper thermal management contributes to increased battery life and improved safety.

- Cell Design and Configuration for Enhanced Performance: The design and configuration of individual cells within blade batteries significantly impact overall performance. This includes optimizing cell chemistry, electrode materials, and internal structure to improve energy density, power output, and cycle life. Advanced manufacturing techniques are employed to ensure consistency and quality in cell production.

- Safety Features in Blade Batteries: Incorporating robust safety features is crucial for blade battery performance and reliability. This includes advanced protection mechanisms against overcharging, over-discharging, short circuits, and thermal runaway. Safety innovations focus on cell-level and pack-level protection to ensure overall system integrity and user safety.

- Performance Monitoring and Diagnostics: Sophisticated monitoring and diagnostic systems are implemented to assess and maintain blade battery performance over time. These systems use advanced sensors and algorithms to detect performance degradation, predict potential issues, and provide real-time data for maintenance and optimization. This proactive approach helps in maintaining high performance and extending battery life.

02 Thermal Management in Blade Batteries

Effective thermal management is essential for maintaining blade battery performance. This includes innovative cooling systems and heat dissipation methods to prevent overheating and ensure consistent performance under various operating conditions. Proper thermal management contributes to increased battery life and improved safety.Expand Specific Solutions03 Blade Battery Cell Design and Architecture

The design and architecture of blade battery cells play a significant role in their overall performance. This includes optimizing the internal structure, electrode materials, and electrolyte composition to enhance energy density, power output, and cycle life. Innovative cell designs also focus on improving safety features and reducing internal resistance.Expand Specific Solutions04 Performance Testing and Evaluation Methods

Developing comprehensive testing and evaluation methods is crucial for assessing blade battery performance. This includes standardized procedures for measuring capacity, power output, cycle life, and safety parameters. Advanced diagnostic tools and algorithms are used to predict battery health and performance over time, enabling proactive maintenance and optimization.Expand Specific Solutions05 Integration of Blade Batteries in Electric Vehicles

Optimizing the integration of blade batteries in electric vehicles is key to maximizing their performance. This involves designing efficient power distribution systems, implementing regenerative braking technologies, and developing smart charging strategies. The integration also considers the structural aspects of the battery pack to enhance vehicle dynamics and safety.Expand Specific Solutions

Key Players in Nanomaterial-Enhanced Batteries

The nanomaterials market for blade battery performance improvement is in a growth phase, with increasing demand driven by the automotive industry's shift towards electric vehicles. The market size is expanding rapidly, expected to reach several billion dollars by 2025. Technologically, the field is advancing quickly but still evolving, with varying levels of maturity across different nanomaterial applications. Key players like Toyota, CATL, and Samsung SDI are investing heavily in R&D, while emerging companies such as EVOQ Nano and OneD Material are introducing innovative solutions. Universities like Shandong University and Tsinghua University are also contributing significantly to technological advancements in this area.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL's blade battery technology incorporates nanomaterials to enhance performance and safety. The company utilizes nano-scale lithium iron phosphate (LFP) cathode materials, which improve energy density and thermal stability[1]. The nano-LFP particles are engineered to have a specific crystal structure and size distribution, optimizing lithium-ion diffusion and electron transfer[2]. CATL also employs nano-coatings on electrode surfaces to enhance the electrode-electrolyte interface, reducing side reactions and improving cycling stability[3]. Additionally, they integrate nano-structured conductive additives into the electrode to enhance overall conductivity and rate capability[4].

Strengths: Enhanced safety, improved energy density, and longer cycle life. Weaknesses: Higher production costs and potential scalability challenges for nano-material synthesis.

OneD Material, Inc.

Technical Solution: OneD Material focuses on silicon nanowire technology for advanced battery anodes, which can be applied to blade battery configurations. Their SiNANOde® technology involves growing silicon nanowires directly on graphite particles, creating a hybrid anode material with significantly higher capacity than traditional graphite anodes[17]. The nanowire structure allows for better accommodation of silicon's volume expansion during cycling, improving the anode's stability and longevity[18]. OneD Material's process also includes a proprietary surface modification of the silicon nanowires, which enhances the solid-electrolyte interphase (SEI) formation and stability[19]. This technology can potentially increase the energy density of blade batteries while maintaining good cycle life and fast charging capabilities[20].

Strengths: Significantly increased energy density, improved cycling stability, and potential for fast charging. Weaknesses: Possible higher production costs and challenges in scaling up silicon nanowire production.

Innovative Nanomaterial Applications in Batteries

Nanostructured Materials for Battery Applications

PatentActiveUS20100297502A1

Innovation

- The use of carbon-comprising, Si-based nanostructures, such as Si-based nanowires with a core-shell structure, are integrated into battery slurries and electrodes, providing improved thermal stability and storage capacity by accommodating volume changes and enhancing conductivity.

Nanostructured materials for battery applications

PatentActiveEP2433475A1

Innovation

- The use of carbon-comprising, Si-based nanostructures, including Si-based nanowires with a core-shell structure, are added to battery slurries, providing enhanced conductivity and stability by incorporating a conductive polymer and embedding them in a carbon-based substrate or scaffold, which helps absorb volume changes during cycles.

Environmental Impact of Nanomaterial Use in Batteries

The use of nanomaterials in blade batteries has raised concerns about their potential environmental impact. As these advanced energy storage technologies become more prevalent, it is crucial to assess the ecological implications of incorporating nanomaterials throughout the battery lifecycle.

During the production phase, the synthesis of nanomaterials often requires energy-intensive processes and the use of potentially hazardous chemicals. This can lead to increased carbon emissions and the generation of toxic byproducts. However, advancements in green synthesis methods are gradually mitigating these issues, with some nanomaterial production techniques now utilizing more environmentally friendly precursors and lower energy requirements.

The integration of nanomaterials into blade batteries can have both positive and negative environmental effects. On the positive side, nanomaterials can enhance battery performance, leading to longer lifespans and reduced waste generation. Improved energy density and faster charging capabilities may also contribute to the wider adoption of electric vehicles, potentially reducing overall carbon emissions from transportation.

Conversely, the release of nanomaterials into the environment during battery use or disposal poses potential risks. Nanoparticles may enter ecosystems through water runoff or air dispersion, with uncertain long-term consequences for flora and fauna. Studies have shown that some nanomaterials can accumulate in organisms and potentially disrupt food chains, highlighting the need for careful monitoring and containment strategies.

End-of-life management of blade batteries containing nanomaterials presents unique challenges. Traditional recycling methods may not be suitable for efficiently recovering nanoscale components, potentially leading to the loss of valuable materials and increased environmental burden. However, innovative recycling technologies specifically designed for nanomaterial-enhanced batteries are emerging, promising improved resource recovery and reduced environmental impact.

The potential for nanomaterials to leach from improperly disposed batteries is a significant concern. To address this, researchers are developing encapsulation techniques and more stable nanomaterial formulations to minimize environmental release. Additionally, regulatory frameworks are evolving to encompass the specific risks associated with nanomaterials in battery applications, aiming to ensure responsible production, use, and disposal practices.

As the blade battery industry continues to grow, life cycle assessments (LCAs) are becoming increasingly important in evaluating the overall environmental impact of nanomaterial use. These comprehensive analyses consider factors such as resource depletion, energy consumption, and potential toxicity across all stages of battery production and use. LCAs help identify areas for improvement and guide the development of more sustainable nanomaterial-based battery technologies.

During the production phase, the synthesis of nanomaterials often requires energy-intensive processes and the use of potentially hazardous chemicals. This can lead to increased carbon emissions and the generation of toxic byproducts. However, advancements in green synthesis methods are gradually mitigating these issues, with some nanomaterial production techniques now utilizing more environmentally friendly precursors and lower energy requirements.

The integration of nanomaterials into blade batteries can have both positive and negative environmental effects. On the positive side, nanomaterials can enhance battery performance, leading to longer lifespans and reduced waste generation. Improved energy density and faster charging capabilities may also contribute to the wider adoption of electric vehicles, potentially reducing overall carbon emissions from transportation.

Conversely, the release of nanomaterials into the environment during battery use or disposal poses potential risks. Nanoparticles may enter ecosystems through water runoff or air dispersion, with uncertain long-term consequences for flora and fauna. Studies have shown that some nanomaterials can accumulate in organisms and potentially disrupt food chains, highlighting the need for careful monitoring and containment strategies.

End-of-life management of blade batteries containing nanomaterials presents unique challenges. Traditional recycling methods may not be suitable for efficiently recovering nanoscale components, potentially leading to the loss of valuable materials and increased environmental burden. However, innovative recycling technologies specifically designed for nanomaterial-enhanced batteries are emerging, promising improved resource recovery and reduced environmental impact.

The potential for nanomaterials to leach from improperly disposed batteries is a significant concern. To address this, researchers are developing encapsulation techniques and more stable nanomaterial formulations to minimize environmental release. Additionally, regulatory frameworks are evolving to encompass the specific risks associated with nanomaterials in battery applications, aiming to ensure responsible production, use, and disposal practices.

As the blade battery industry continues to grow, life cycle assessments (LCAs) are becoming increasingly important in evaluating the overall environmental impact of nanomaterial use. These comprehensive analyses consider factors such as resource depletion, energy consumption, and potential toxicity across all stages of battery production and use. LCAs help identify areas for improvement and guide the development of more sustainable nanomaterial-based battery technologies.

Safety Considerations for Nanomaterial-Enhanced Batteries

The integration of nanomaterials in blade batteries brings significant performance improvements but also introduces new safety considerations that must be carefully addressed. One primary concern is the potential release of nanoparticles during battery operation or in the event of a malfunction. These particles, due to their small size, can easily become airborne and may pose inhalation risks to workers or end-users if proper containment measures are not implemented.

The reactivity of nanomaterials is another critical safety aspect. Some nanomaterials used in battery enhancement, such as metal oxides or carbon nanotubes, may exhibit increased chemical reactivity compared to their bulk counterparts. This heightened reactivity could lead to unexpected chemical reactions within the battery, potentially causing thermal runaway or other safety incidents if not properly managed.

Electrical conductivity alterations due to nanomaterial incorporation must also be considered. While improved conductivity is often a desired outcome, it may also increase the risk of short circuits if not carefully controlled. This necessitates thorough testing and optimization of the battery's internal structure to ensure safe operation under various conditions.

The long-term stability of nanomaterials within the battery environment is another crucial safety factor. Over time, nanomaterials may degrade or change their properties, potentially affecting the battery's performance and safety profile. Accelerated aging tests and long-term stability studies are essential to predict and mitigate any potential risks associated with nanomaterial degradation.

Environmental and disposal considerations are also paramount. The unique properties of nanomaterials may present challenges in traditional battery recycling processes. There is a need to develop specialized recycling methods that can safely handle and recover nanomaterials without releasing them into the environment.

Standardization and regulatory compliance pose additional challenges. As the use of nanomaterials in batteries is relatively new, existing safety standards and regulations may not fully address the unique risks associated with these materials. Industry collaboration and engagement with regulatory bodies are crucial to establish comprehensive safety guidelines and testing protocols specific to nanomaterial-enhanced batteries.

Lastly, the potential for unexpected interactions between nanomaterials and other battery components must be thoroughly investigated. These interactions could lead to unforeseen chemical or physical changes within the battery, potentially compromising its safety and performance. Extensive compatibility testing and long-term stability studies are necessary to ensure the safe integration of nanomaterials in blade battery systems.

The reactivity of nanomaterials is another critical safety aspect. Some nanomaterials used in battery enhancement, such as metal oxides or carbon nanotubes, may exhibit increased chemical reactivity compared to their bulk counterparts. This heightened reactivity could lead to unexpected chemical reactions within the battery, potentially causing thermal runaway or other safety incidents if not properly managed.

Electrical conductivity alterations due to nanomaterial incorporation must also be considered. While improved conductivity is often a desired outcome, it may also increase the risk of short circuits if not carefully controlled. This necessitates thorough testing and optimization of the battery's internal structure to ensure safe operation under various conditions.

The long-term stability of nanomaterials within the battery environment is another crucial safety factor. Over time, nanomaterials may degrade or change their properties, potentially affecting the battery's performance and safety profile. Accelerated aging tests and long-term stability studies are essential to predict and mitigate any potential risks associated with nanomaterial degradation.

Environmental and disposal considerations are also paramount. The unique properties of nanomaterials may present challenges in traditional battery recycling processes. There is a need to develop specialized recycling methods that can safely handle and recover nanomaterials without releasing them into the environment.

Standardization and regulatory compliance pose additional challenges. As the use of nanomaterials in batteries is relatively new, existing safety standards and regulations may not fully address the unique risks associated with these materials. Industry collaboration and engagement with regulatory bodies are crucial to establish comprehensive safety guidelines and testing protocols specific to nanomaterial-enhanced batteries.

Lastly, the potential for unexpected interactions between nanomaterials and other battery components must be thoroughly investigated. These interactions could lead to unforeseen chemical or physical changes within the battery, potentially compromising its safety and performance. Extensive compatibility testing and long-term stability studies are necessary to ensure the safe integration of nanomaterials in blade battery systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!