Innovations in Blade Battery Pack Design

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Evolution Goals

The evolution of blade battery pack design is driven by several key goals aimed at enhancing the overall performance, safety, and efficiency of electric vehicles. One primary objective is to increase energy density, allowing for greater range without significantly increasing the battery pack's weight or size. This goal is crucial for addressing range anxiety and improving the competitiveness of electric vehicles against traditional combustion engine counterparts.

Another critical aim is to enhance the safety features of blade battery packs. This includes improving thermal management systems to prevent overheating and potential fire hazards, as well as developing more robust structural designs to protect the battery cells in the event of a collision. The integration of advanced battery management systems (BMS) is also a key focus, enabling more precise monitoring and control of individual cells to optimize performance and longevity.

Reducing production costs is an essential goal in the evolution of blade battery pack design. This involves streamlining manufacturing processes, exploring new materials that offer better performance at lower costs, and designing for easier assembly and maintenance. The aim is to make electric vehicles more affordable and accessible to a broader market, accelerating the transition to sustainable transportation.

Improving charging speed is another significant objective in blade battery pack evolution. Researchers and engineers are working on developing battery chemistries and pack designs that can handle higher charging rates without compromising safety or long-term durability. This goal is crucial for enhancing the practicality of electric vehicles for long-distance travel and reducing charging times to levels comparable with refueling conventional vehicles.

Sustainability and environmental impact are also key considerations in the evolution of blade battery pack design. This includes developing more environmentally friendly production methods, improving the recyclability of battery components, and exploring the use of more abundant and less environmentally harmful materials. The aim is to reduce the overall carbon footprint of electric vehicle production and ensure a more sustainable lifecycle for battery packs.

Lastly, the evolution of blade battery pack design is focused on enhancing modularity and scalability. This goal aims to create flexible battery pack architectures that can be easily adapted to different vehicle models and sizes, reducing development costs and time-to-market for new electric vehicle designs. It also facilitates easier upgrades and replacements, potentially extending the usable life of electric vehicles and improving their long-term value proposition.

Another critical aim is to enhance the safety features of blade battery packs. This includes improving thermal management systems to prevent overheating and potential fire hazards, as well as developing more robust structural designs to protect the battery cells in the event of a collision. The integration of advanced battery management systems (BMS) is also a key focus, enabling more precise monitoring and control of individual cells to optimize performance and longevity.

Reducing production costs is an essential goal in the evolution of blade battery pack design. This involves streamlining manufacturing processes, exploring new materials that offer better performance at lower costs, and designing for easier assembly and maintenance. The aim is to make electric vehicles more affordable and accessible to a broader market, accelerating the transition to sustainable transportation.

Improving charging speed is another significant objective in blade battery pack evolution. Researchers and engineers are working on developing battery chemistries and pack designs that can handle higher charging rates without compromising safety or long-term durability. This goal is crucial for enhancing the practicality of electric vehicles for long-distance travel and reducing charging times to levels comparable with refueling conventional vehicles.

Sustainability and environmental impact are also key considerations in the evolution of blade battery pack design. This includes developing more environmentally friendly production methods, improving the recyclability of battery components, and exploring the use of more abundant and less environmentally harmful materials. The aim is to reduce the overall carbon footprint of electric vehicle production and ensure a more sustainable lifecycle for battery packs.

Lastly, the evolution of blade battery pack design is focused on enhancing modularity and scalability. This goal aims to create flexible battery pack architectures that can be easily adapted to different vehicle models and sizes, reducing development costs and time-to-market for new electric vehicle designs. It also facilitates easier upgrades and replacements, potentially extending the usable life of electric vehicles and improving their long-term value proposition.

Market Demand Analysis

The market demand for blade battery pack designs has been experiencing significant growth, driven by the rapid expansion of the electric vehicle (EV) industry. As governments worldwide implement stricter emissions regulations and consumers become more environmentally conscious, the demand for efficient and safe battery technologies has surged. Blade batteries, with their innovative design and improved safety features, have emerged as a promising solution to meet these market needs.

The global EV market has been expanding at an unprecedented rate, with annual sales projected to reach 26.8 million units by 2030. This growth is fueling the demand for advanced battery technologies, including blade batteries. The blade battery pack design offers several advantages that align with market requirements, such as improved energy density, enhanced safety, and more efficient space utilization within vehicles.

One of the key drivers of market demand for blade batteries is their superior safety performance. Traditional lithium-ion batteries have faced concerns regarding thermal runaway and potential fire hazards. Blade batteries, with their unique structural design and use of lithium iron phosphate (LiFePO4) chemistry, significantly reduce these risks. This enhanced safety profile is particularly attractive to automakers and consumers alike, as it addresses one of the primary concerns in EV adoption.

The automotive industry's shift towards longer-range EVs has also contributed to the increasing demand for blade battery packs. These batteries offer higher energy density compared to conventional designs, allowing for greater driving range without significantly increasing the battery pack's size or weight. This characteristic is crucial for automakers striving to develop EVs that can compete with traditional internal combustion engine vehicles in terms of range and performance.

Furthermore, the blade battery pack design's space efficiency is highly valued in the market. As automakers seek to optimize vehicle designs and maximize interior space, the compact nature of blade batteries allows for more flexible integration into vehicle architectures. This advantage is particularly relevant for smaller EVs and urban mobility solutions, where space constraints are more pronounced.

The market demand for blade batteries extends beyond personal vehicles. The commercial EV sector, including electric buses and trucks, is also showing interest in this technology due to its potential for longer operational ranges and improved safety. Additionally, the energy storage system (ESS) market is exploring the application of blade battery technology for grid-scale storage solutions, further expanding the potential market reach.

As the EV market continues to mature, there is an increasing emphasis on sustainable and environmentally friendly battery technologies. Blade batteries, with their improved lifecycle and potential for easier recycling, align well with these market trends. This aspect is becoming increasingly important as consumers and regulators focus on the entire lifecycle impact of EVs, from production to end-of-life management.

The global EV market has been expanding at an unprecedented rate, with annual sales projected to reach 26.8 million units by 2030. This growth is fueling the demand for advanced battery technologies, including blade batteries. The blade battery pack design offers several advantages that align with market requirements, such as improved energy density, enhanced safety, and more efficient space utilization within vehicles.

One of the key drivers of market demand for blade batteries is their superior safety performance. Traditional lithium-ion batteries have faced concerns regarding thermal runaway and potential fire hazards. Blade batteries, with their unique structural design and use of lithium iron phosphate (LiFePO4) chemistry, significantly reduce these risks. This enhanced safety profile is particularly attractive to automakers and consumers alike, as it addresses one of the primary concerns in EV adoption.

The automotive industry's shift towards longer-range EVs has also contributed to the increasing demand for blade battery packs. These batteries offer higher energy density compared to conventional designs, allowing for greater driving range without significantly increasing the battery pack's size or weight. This characteristic is crucial for automakers striving to develop EVs that can compete with traditional internal combustion engine vehicles in terms of range and performance.

Furthermore, the blade battery pack design's space efficiency is highly valued in the market. As automakers seek to optimize vehicle designs and maximize interior space, the compact nature of blade batteries allows for more flexible integration into vehicle architectures. This advantage is particularly relevant for smaller EVs and urban mobility solutions, where space constraints are more pronounced.

The market demand for blade batteries extends beyond personal vehicles. The commercial EV sector, including electric buses and trucks, is also showing interest in this technology due to its potential for longer operational ranges and improved safety. Additionally, the energy storage system (ESS) market is exploring the application of blade battery technology for grid-scale storage solutions, further expanding the potential market reach.

As the EV market continues to mature, there is an increasing emphasis on sustainable and environmentally friendly battery technologies. Blade batteries, with their improved lifecycle and potential for easier recycling, align well with these market trends. This aspect is becoming increasingly important as consumers and regulators focus on the entire lifecycle impact of EVs, from production to end-of-life management.

Blade Battery Challenges

Blade batteries, while offering significant advantages in energy density and safety, face several challenges that need to be addressed for widespread adoption and optimal performance. One of the primary challenges is thermal management. The compact design of blade batteries can lead to heat accumulation, potentially affecting battery life and performance. Efficient cooling systems and thermal dissipation strategies are crucial to maintain optimal operating temperatures and prevent thermal runaway.

Another significant challenge lies in the manufacturing process. The unique shape and structure of blade batteries require specialized production techniques and equipment. Ensuring consistent quality and high production yields while scaling up manufacturing remains a complex task. This challenge is further compounded by the need for precision in cell alignment and connection within the battery pack.

Mechanical stress is also a concern for blade batteries. The long, thin form factor makes them potentially more susceptible to bending or warping under certain conditions. This could lead to internal short circuits or compromised structural integrity. Developing robust casing designs and internal support structures is essential to mitigate these risks and ensure long-term reliability.

The integration of blade batteries into existing vehicle designs presents another hurdle. While their shape allows for more efficient space utilization, it also requires rethinking traditional battery pack layouts and vehicle architectures. This may necessitate significant changes in vehicle design and manufacturing processes, which can be costly and time-consuming for automakers.

Safety considerations remain paramount in battery technology, and blade batteries are no exception. While they have demonstrated improved safety in puncture tests, ongoing research is needed to ensure their safety under various real-world conditions, including extreme temperatures, high-impact collisions, and long-term use.

The battery management system (BMS) for blade batteries also poses unique challenges. The elongated shape of the cells requires a more sophisticated BMS to monitor and balance the cells effectively. Ensuring uniform charging and discharging across the length of each blade cell is critical for optimal performance and longevity.

Lastly, the recyclability and end-of-life management of blade batteries present environmental and economic challenges. Developing efficient recycling processes for these batteries, considering their unique structure and materials, is crucial for sustainable adoption and minimizing environmental impact.

Another significant challenge lies in the manufacturing process. The unique shape and structure of blade batteries require specialized production techniques and equipment. Ensuring consistent quality and high production yields while scaling up manufacturing remains a complex task. This challenge is further compounded by the need for precision in cell alignment and connection within the battery pack.

Mechanical stress is also a concern for blade batteries. The long, thin form factor makes them potentially more susceptible to bending or warping under certain conditions. This could lead to internal short circuits or compromised structural integrity. Developing robust casing designs and internal support structures is essential to mitigate these risks and ensure long-term reliability.

The integration of blade batteries into existing vehicle designs presents another hurdle. While their shape allows for more efficient space utilization, it also requires rethinking traditional battery pack layouts and vehicle architectures. This may necessitate significant changes in vehicle design and manufacturing processes, which can be costly and time-consuming for automakers.

Safety considerations remain paramount in battery technology, and blade batteries are no exception. While they have demonstrated improved safety in puncture tests, ongoing research is needed to ensure their safety under various real-world conditions, including extreme temperatures, high-impact collisions, and long-term use.

The battery management system (BMS) for blade batteries also poses unique challenges. The elongated shape of the cells requires a more sophisticated BMS to monitor and balance the cells effectively. Ensuring uniform charging and discharging across the length of each blade cell is critical for optimal performance and longevity.

Lastly, the recyclability and end-of-life management of blade batteries present environmental and economic challenges. Developing efficient recycling processes for these batteries, considering their unique structure and materials, is crucial for sustainable adoption and minimizing environmental impact.

Current Blade Designs

01 Battery pack structure and assembly

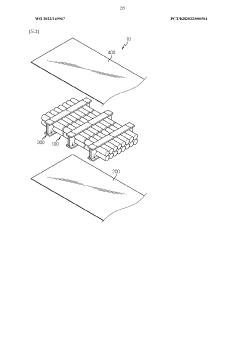

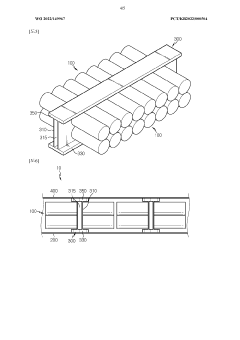

Blade battery pack designs focus on optimizing the structure and assembly of battery cells. This includes innovative arrangements of cells, integration of cooling systems, and efficient packaging to maximize energy density while maintaining safety. The design often incorporates features for easy maintenance and replacement of individual cells or modules.- Battery pack structure and assembly: Blade battery pack designs focus on optimizing the structure and assembly of battery cells. This includes innovative arrangements of cells, improved interconnections, and efficient packaging to maximize energy density and structural integrity. The design aims to enhance overall performance, safety, and thermal management of the battery pack.

- Thermal management systems: Effective thermal management is crucial in blade battery pack design. This involves incorporating cooling systems, heat dissipation mechanisms, and temperature control strategies to maintain optimal operating conditions. Advanced thermal management helps prevent overheating, extends battery life, and enhances overall safety and performance.

- Battery management and control systems: Sophisticated battery management systems (BMS) are integrated into blade battery pack designs. These systems monitor and control various parameters such as voltage, current, and temperature of individual cells and the entire pack. Advanced BMS implementations optimize charging, discharging, and overall battery performance while ensuring safety and longevity.

- Safety features and protection mechanisms: Blade battery pack designs incorporate various safety features and protection mechanisms. These include overcharge protection, short-circuit prevention, and fail-safe systems to mitigate risks associated with battery operation. Advanced materials and structural designs are employed to enhance the overall safety and reliability of the battery pack.

- Integration and compatibility with electric vehicles: Blade battery pack designs focus on seamless integration with electric vehicle systems. This includes optimizing the pack's form factor, weight distribution, and electrical interfaces to enhance overall vehicle performance. Considerations for easy installation, maintenance, and potential future upgrades are also incorporated into the design process.

02 Thermal management systems

Effective thermal management is crucial in blade battery pack design. This involves the integration of cooling channels, heat dissipation materials, and temperature monitoring systems. Advanced designs may incorporate phase change materials or liquid cooling systems to maintain optimal operating temperatures and prevent thermal runaway.Expand Specific Solutions03 Battery management and control systems

Sophisticated battery management systems (BMS) are essential for blade battery packs. These systems monitor cell voltages, temperatures, and state of charge, ensuring optimal performance and longevity. Advanced BMS designs may incorporate artificial intelligence for predictive maintenance and adaptive charging strategies.Expand Specific Solutions04 Safety features and protection mechanisms

Safety is paramount in blade battery pack design. This includes the integration of overcharge protection, short circuit prevention, and thermal runaway mitigation systems. Advanced designs may incorporate fire-resistant materials, pressure relief mechanisms, and isolation systems to contain potential failures.Expand Specific Solutions05 Integration with vehicle systems

Blade battery pack designs often focus on seamless integration with vehicle systems. This includes optimizing the pack's shape and size for specific vehicle platforms, designing efficient power distribution systems, and developing interfaces for fast charging and vehicle-to-grid technologies.Expand Specific Solutions

Key Industry Players

The blade battery pack design innovation landscape is characterized by intense competition among established players and emerging entrants in a rapidly evolving market. The industry is in a growth phase, driven by increasing demand for electric vehicles and energy storage solutions. Market size is expanding significantly, with projections indicating substantial growth in the coming years. Technologically, the field is advancing quickly, with companies like LG Energy Solution, Samsung SDI, and SVOLT Energy Technology leading in research and development. These firms, along with others such as Sony Group and Panasonic, are investing heavily in improving battery performance, safety, and efficiency. The competitive landscape is further intensified by automotive manufacturers like Honda and Bosch, who are also developing proprietary battery technologies to secure their supply chains and maintain a competitive edge in the electric vehicle market.

Svolt Energy Technology Co., Ltd.

Technical Solution: Svolt has made significant advancements in blade battery pack design with their "Dragon Armor" technology. This innovative approach uses long, thin cells arranged in a stacked configuration, maximizing energy density and structural strength. Svolt's blade batteries incorporate a proprietary separator technology that enhances safety by preventing internal short circuits[11]. The company has also developed a unique cooling system integrated into the battery structure, ensuring optimal temperature control. Svolt's blade battery packs feature advanced battery management systems that use machine learning algorithms to optimize charging strategies and extend battery life[12].

Strengths: High energy density, enhanced safety features, and advanced thermal management. Weaknesses: Potential challenges in scaling up production and adapting to different vehicle designs.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has innovated in blade battery pack design with their "S-Blade" technology. This design utilizes ultra-thin prismatic cells arranged in a blade-like configuration, maximizing energy density and structural integrity. Samsung's approach includes a novel cathode material composition that enhances energy capacity and reduces the risk of thermal runaway[7]. The S-Blade packs feature a modular design that allows for easy scalability and customization for different vehicle models. Samsung SDI has also implemented advanced battery monitoring systems that use real-time data analytics to optimize charging and discharging processes, extending battery life[8].

Strengths: High energy density, modular design for scalability, and advanced monitoring systems. Weaknesses: Potential higher production costs and complexity in manufacturing processes.

Core Blade Innovations

Battery pack

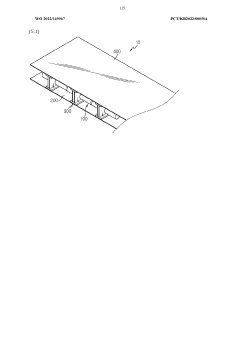

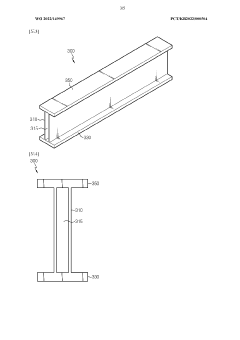

PatentPendingUS20250192298A1

Innovation

- The battery pack design includes a housing with a cooling plate and a center plate, featuring first and second battery cell assemblies with cross-beams of different shapes, and a reinforcing part coupled to the center beam, which enhances mechanical strength and energy density.

Battery pack and vehicle comprising same

PatentWO2022149967A1

Innovation

- A battery pack design featuring a base plate and a cross beam unit with a coolant flow path, where battery cells are directly attached to beam members, eliminating the need for a traditional cell frame structure, enhancing rigidity and energy density while simplifying assembly and reducing costs.

Safety Regulations

Safety regulations play a crucial role in the development and implementation of blade battery pack designs. As the automotive industry shifts towards electric vehicles, ensuring the safety of battery systems becomes paramount. Regulatory bodies worldwide have established stringent standards to address potential risks associated with battery packs, particularly focusing on thermal runaway, electrical safety, and crash protection.

The United Nations Economic Commission for Europe (UNECE) has developed the R100 regulation, which sets comprehensive safety requirements for electric vehicle battery systems. This regulation covers various aspects, including vibration resistance, thermal shock, and fire protection. Manufacturers must demonstrate compliance with these standards through rigorous testing procedures before their battery packs can be approved for use in vehicles.

In the United States, the National Highway Traffic Safety Administration (NHTSA) has implemented Federal Motor Vehicle Safety Standard (FMVSS) No. 305, which specifically addresses electric vehicle safety. This standard outlines requirements for electrical isolation, battery retention, and electrolyte spillage prevention during and after crash events. Additionally, the Society of Automotive Engineers (SAE) has developed standards such as J2464 and J2929, which provide guidelines for electric and hybrid vehicle battery safety.

The European Union has also established regulations through the European New Car Assessment Programme (Euro NCAP), which includes specific protocols for testing the safety of electric vehicles and their battery systems. These tests evaluate the vehicle's ability to protect occupants and prevent battery-related hazards in various crash scenarios.

China, a significant player in the electric vehicle market, has implemented GB/T 31485-2015, a national standard for lithium-ion traction battery packs and systems used in electric vehicles. This standard covers safety requirements, test methods, and inspection rules for battery packs, ensuring they meet the necessary safety criteria for use in vehicles.

As blade battery technology advances, regulatory bodies are continually updating their standards to address new safety concerns. For instance, recent updates have focused on mitigating the risks associated with thermal propagation, where a single cell failure can lead to a cascading effect throughout the battery pack. Manufacturers are now required to implement design features that prevent or slow down thermal propagation, such as improved cell-to-cell insulation and advanced thermal management systems.

The evolving nature of safety regulations presents both challenges and opportunities for blade battery pack designers. While compliance with these standards can be complex and resource-intensive, it also drives innovation in battery design and manufacturing processes. Companies that can effectively navigate these regulatory requirements while pushing the boundaries of battery technology are likely to gain a competitive edge in the rapidly growing electric vehicle market.

The United Nations Economic Commission for Europe (UNECE) has developed the R100 regulation, which sets comprehensive safety requirements for electric vehicle battery systems. This regulation covers various aspects, including vibration resistance, thermal shock, and fire protection. Manufacturers must demonstrate compliance with these standards through rigorous testing procedures before their battery packs can be approved for use in vehicles.

In the United States, the National Highway Traffic Safety Administration (NHTSA) has implemented Federal Motor Vehicle Safety Standard (FMVSS) No. 305, which specifically addresses electric vehicle safety. This standard outlines requirements for electrical isolation, battery retention, and electrolyte spillage prevention during and after crash events. Additionally, the Society of Automotive Engineers (SAE) has developed standards such as J2464 and J2929, which provide guidelines for electric and hybrid vehicle battery safety.

The European Union has also established regulations through the European New Car Assessment Programme (Euro NCAP), which includes specific protocols for testing the safety of electric vehicles and their battery systems. These tests evaluate the vehicle's ability to protect occupants and prevent battery-related hazards in various crash scenarios.

China, a significant player in the electric vehicle market, has implemented GB/T 31485-2015, a national standard for lithium-ion traction battery packs and systems used in electric vehicles. This standard covers safety requirements, test methods, and inspection rules for battery packs, ensuring they meet the necessary safety criteria for use in vehicles.

As blade battery technology advances, regulatory bodies are continually updating their standards to address new safety concerns. For instance, recent updates have focused on mitigating the risks associated with thermal propagation, where a single cell failure can lead to a cascading effect throughout the battery pack. Manufacturers are now required to implement design features that prevent or slow down thermal propagation, such as improved cell-to-cell insulation and advanced thermal management systems.

The evolving nature of safety regulations presents both challenges and opportunities for blade battery pack designers. While compliance with these standards can be complex and resource-intensive, it also drives innovation in battery design and manufacturing processes. Companies that can effectively navigate these regulatory requirements while pushing the boundaries of battery technology are likely to gain a competitive edge in the rapidly growing electric vehicle market.

Environmental Impact

The environmental impact of blade battery pack design innovations is a critical consideration in the development and adoption of this technology. Blade batteries, with their unique structural design, offer several environmental advantages over traditional battery pack configurations.

One of the primary environmental benefits of blade battery packs is their improved energy density. This increased efficiency allows for more compact and lightweight battery systems, reducing the overall material requirements for electric vehicles. As a result, fewer raw materials are needed in the manufacturing process, leading to a decrease in resource extraction and associated environmental impacts.

The streamlined design of blade battery packs also contributes to enhanced thermal management capabilities. This improved heat dissipation reduces the need for complex cooling systems, which often rely on environmentally harmful refrigerants. By minimizing the use of these substances, blade battery technology helps mitigate potential environmental risks associated with refrigerant leakage and disposal.

Furthermore, the structural integrity of blade batteries contributes to increased safety and longevity. This enhanced durability translates to a longer lifespan for battery packs, reducing the frequency of replacements and, consequently, the environmental burden of battery disposal. The improved safety features also minimize the risk of thermal runaway events, which can lead to fires and the release of toxic substances into the environment.

The manufacturing process for blade batteries also presents opportunities for environmental improvements. The simplified design allows for more efficient production lines, potentially reducing energy consumption and waste generation during manufacturing. Additionally, the compact nature of blade battery packs facilitates easier recycling and material recovery at the end of their life cycle.

In terms of vehicle performance, the reduced weight and improved energy efficiency of blade battery packs contribute to increased driving range and reduced energy consumption. This efficiency gain indirectly benefits the environment by lowering the overall energy demand for electric vehicle operation, potentially reducing the carbon footprint associated with electricity generation.

However, it is important to note that the environmental impact of blade battery technology extends beyond its operational phase. The sourcing of raw materials, particularly rare earth elements used in battery production, remains a significant environmental concern. Innovations in blade battery design must also address sustainable sourcing practices and the development of alternative materials to mitigate these upstream environmental impacts.

One of the primary environmental benefits of blade battery packs is their improved energy density. This increased efficiency allows for more compact and lightweight battery systems, reducing the overall material requirements for electric vehicles. As a result, fewer raw materials are needed in the manufacturing process, leading to a decrease in resource extraction and associated environmental impacts.

The streamlined design of blade battery packs also contributes to enhanced thermal management capabilities. This improved heat dissipation reduces the need for complex cooling systems, which often rely on environmentally harmful refrigerants. By minimizing the use of these substances, blade battery technology helps mitigate potential environmental risks associated with refrigerant leakage and disposal.

Furthermore, the structural integrity of blade batteries contributes to increased safety and longevity. This enhanced durability translates to a longer lifespan for battery packs, reducing the frequency of replacements and, consequently, the environmental burden of battery disposal. The improved safety features also minimize the risk of thermal runaway events, which can lead to fires and the release of toxic substances into the environment.

The manufacturing process for blade batteries also presents opportunities for environmental improvements. The simplified design allows for more efficient production lines, potentially reducing energy consumption and waste generation during manufacturing. Additionally, the compact nature of blade battery packs facilitates easier recycling and material recovery at the end of their life cycle.

In terms of vehicle performance, the reduced weight and improved energy efficiency of blade battery packs contribute to increased driving range and reduced energy consumption. This efficiency gain indirectly benefits the environment by lowering the overall energy demand for electric vehicle operation, potentially reducing the carbon footprint associated with electricity generation.

However, it is important to note that the environmental impact of blade battery technology extends beyond its operational phase. The sourcing of raw materials, particularly rare earth elements used in battery production, remains a significant environmental concern. Innovations in blade battery design must also address sustainable sourcing practices and the development of alternative materials to mitigate these upstream environmental impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!