Sensor Technology Developments in Blade Battery System Monitoring

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Blade Battery Sensing Evolution and Objectives

Blade battery technology has emerged as a significant innovation in the field of electric vehicle (EV) energy storage systems. The evolution of sensing technologies for blade batteries has been driven by the need for enhanced safety, performance, and longevity of these advanced energy storage solutions. Initially, blade battery monitoring systems focused primarily on basic parameters such as voltage and temperature. However, as the technology matured, the objectives for sensing systems expanded to encompass a wider range of critical metrics.

The primary goal of blade battery sensing evolution has been to develop more sophisticated and accurate monitoring capabilities. This includes real-time tracking of individual cell performance, early detection of potential failure modes, and precise state-of-charge (SOC) and state-of-health (SOH) estimations. These advancements aim to improve overall battery management, extend battery life, and enhance safety measures.

One of the key objectives in blade battery sensing has been the integration of advanced sensor technologies. This includes the development of miniaturized sensors capable of being embedded within the battery structure without compromising its compact design. These sensors are designed to provide high-resolution data on various battery parameters, enabling more granular monitoring and control.

Another significant focus has been on the development of non-invasive sensing techniques. These methods aim to gather critical data without the need for physical contact with battery components, reducing the risk of sensor-induced failures and simplifying maintenance procedures. Technologies such as ultrasonic sensing and electromagnetic field analysis have shown promise in this area.

The evolution of blade battery sensing also encompasses the integration of artificial intelligence and machine learning algorithms. These advanced data processing techniques enable predictive maintenance, adaptive charging strategies, and more accurate forecasting of battery performance and lifespan. The objective is to create intelligent battery management systems that can optimize performance based on real-time data and historical trends.

Improving the reliability and durability of sensing systems in harsh operating conditions has been another crucial objective. This includes developing sensors that can withstand high temperatures, vibrations, and electromagnetic interference typically encountered in EV environments. The goal is to ensure consistent and accurate data collection throughout the battery's operational life.

As the automotive industry moves towards more sustainable and efficient energy solutions, the objectives for blade battery sensing continue to evolve. Current focus areas include developing sensors for next-generation solid-state batteries, enhancing thermal management through advanced temperature sensing, and improving the integration of battery data with vehicle control systems for optimized energy management.

The primary goal of blade battery sensing evolution has been to develop more sophisticated and accurate monitoring capabilities. This includes real-time tracking of individual cell performance, early detection of potential failure modes, and precise state-of-charge (SOC) and state-of-health (SOH) estimations. These advancements aim to improve overall battery management, extend battery life, and enhance safety measures.

One of the key objectives in blade battery sensing has been the integration of advanced sensor technologies. This includes the development of miniaturized sensors capable of being embedded within the battery structure without compromising its compact design. These sensors are designed to provide high-resolution data on various battery parameters, enabling more granular monitoring and control.

Another significant focus has been on the development of non-invasive sensing techniques. These methods aim to gather critical data without the need for physical contact with battery components, reducing the risk of sensor-induced failures and simplifying maintenance procedures. Technologies such as ultrasonic sensing and electromagnetic field analysis have shown promise in this area.

The evolution of blade battery sensing also encompasses the integration of artificial intelligence and machine learning algorithms. These advanced data processing techniques enable predictive maintenance, adaptive charging strategies, and more accurate forecasting of battery performance and lifespan. The objective is to create intelligent battery management systems that can optimize performance based on real-time data and historical trends.

Improving the reliability and durability of sensing systems in harsh operating conditions has been another crucial objective. This includes developing sensors that can withstand high temperatures, vibrations, and electromagnetic interference typically encountered in EV environments. The goal is to ensure consistent and accurate data collection throughout the battery's operational life.

As the automotive industry moves towards more sustainable and efficient energy solutions, the objectives for blade battery sensing continue to evolve. Current focus areas include developing sensors for next-generation solid-state batteries, enhancing thermal management through advanced temperature sensing, and improving the integration of battery data with vehicle control systems for optimized energy management.

Market Demand for Advanced Battery Monitoring

The market demand for advanced battery monitoring systems in blade batteries has been steadily increasing, driven by the rapid growth of electric vehicles (EVs) and renewable energy storage solutions. As blade batteries gain prominence due to their enhanced safety features and higher energy density, the need for sophisticated monitoring technologies has become paramount.

The automotive sector, particularly the EV market, is a primary driver for this demand. With major automakers transitioning towards electrification, the safety and performance of battery systems have become critical factors. Advanced monitoring systems enable real-time tracking of battery health, temperature, and charge status, ensuring optimal performance and longevity of blade batteries in EVs.

In the renewable energy sector, large-scale energy storage systems utilizing blade batteries require robust monitoring solutions to maintain efficiency and prevent potential failures. The integration of smart grid technologies further amplifies the need for advanced battery monitoring, as it allows for better energy management and grid stability.

Consumer electronics manufacturers are also showing increased interest in blade battery technology, particularly for devices requiring high energy density and enhanced safety. This sector demands miniaturized yet highly effective monitoring systems to ensure device safety and optimize battery life.

The industrial sector, including manufacturing and logistics, is another significant market for advanced battery monitoring in blade battery systems. As industrial automation and electric material handling equipment become more prevalent, the demand for reliable and long-lasting battery solutions with sophisticated monitoring capabilities continues to grow.

Emerging markets in developing countries present substantial growth opportunities for blade battery monitoring systems. As these regions invest in electrification and renewable energy infrastructure, the demand for advanced battery technologies and associated monitoring systems is expected to surge.

The increasing focus on sustainability and environmental regulations is also driving market demand. Advanced monitoring systems contribute to more efficient battery usage, longer lifespans, and improved recycling processes, aligning with global sustainability goals.

Furthermore, the rise of the Internet of Things (IoT) and artificial intelligence (AI) is creating new opportunities for innovative battery monitoring solutions. These technologies enable predictive maintenance, remote diagnostics, and data-driven optimization of battery performance, adding value to blade battery systems across various applications.

The automotive sector, particularly the EV market, is a primary driver for this demand. With major automakers transitioning towards electrification, the safety and performance of battery systems have become critical factors. Advanced monitoring systems enable real-time tracking of battery health, temperature, and charge status, ensuring optimal performance and longevity of blade batteries in EVs.

In the renewable energy sector, large-scale energy storage systems utilizing blade batteries require robust monitoring solutions to maintain efficiency and prevent potential failures. The integration of smart grid technologies further amplifies the need for advanced battery monitoring, as it allows for better energy management and grid stability.

Consumer electronics manufacturers are also showing increased interest in blade battery technology, particularly for devices requiring high energy density and enhanced safety. This sector demands miniaturized yet highly effective monitoring systems to ensure device safety and optimize battery life.

The industrial sector, including manufacturing and logistics, is another significant market for advanced battery monitoring in blade battery systems. As industrial automation and electric material handling equipment become more prevalent, the demand for reliable and long-lasting battery solutions with sophisticated monitoring capabilities continues to grow.

Emerging markets in developing countries present substantial growth opportunities for blade battery monitoring systems. As these regions invest in electrification and renewable energy infrastructure, the demand for advanced battery technologies and associated monitoring systems is expected to surge.

The increasing focus on sustainability and environmental regulations is also driving market demand. Advanced monitoring systems contribute to more efficient battery usage, longer lifespans, and improved recycling processes, aligning with global sustainability goals.

Furthermore, the rise of the Internet of Things (IoT) and artificial intelligence (AI) is creating new opportunities for innovative battery monitoring solutions. These technologies enable predictive maintenance, remote diagnostics, and data-driven optimization of battery performance, adding value to blade battery systems across various applications.

Current Sensor Challenges in Blade Batteries

Blade batteries, a revolutionary technology in the electric vehicle (EV) industry, present unique challenges for sensor systems. The primary difficulty lies in accurately monitoring the internal state of these long, thin cells without compromising their structural integrity or performance. Traditional sensing methods often prove inadequate due to the blade battery's compact design and high energy density.

One of the most significant challenges is temperature monitoring. Blade batteries generate heat during charging and discharging cycles, and uneven temperature distribution can lead to reduced efficiency and potential safety hazards. Conventional temperature sensors struggle to provide precise readings across the entire length of the blade cell, leaving potential hotspots undetected.

Pressure sensing within blade batteries poses another substantial challenge. As these cells expand and contract during use, internal pressure changes can affect performance and longevity. However, integrating pressure sensors without disrupting the cell's structure or increasing its size remains a complex task for engineers.

Voltage and current monitoring also present unique difficulties in blade battery systems. The high energy density and rapid charge/discharge rates require sensors capable of handling large power fluctuations while maintaining accuracy. Additionally, the compact nature of blade batteries limits the space available for sensor placement, necessitating innovative solutions for comprehensive monitoring.

State of charge (SOC) and state of health (SOH) estimation pose further challenges. These critical parameters require sophisticated algorithms and sensor fusion techniques to accurately assess the battery's condition. The unique characteristics of blade batteries, such as their elongated shape and cell chemistry, demand tailored approaches to SOC and SOH estimation that differ from those used in traditional lithium-ion batteries.

Electromagnetic interference (EMI) is another significant concern in blade battery sensor systems. The high current flows and compact design can generate electromagnetic fields that interfere with sensor readings, potentially leading to inaccurate data and compromised battery management.

Durability and longevity of sensors in the harsh environment of a blade battery system present ongoing challenges. Sensors must withstand extreme temperatures, vibrations, and chemical exposure while maintaining accuracy over the battery's entire lifespan, which can span several years in automotive applications.

Lastly, the integration of sensors into the blade battery manufacturing process poses significant challenges. Ensuring consistent sensor placement and calibration across mass-produced cells requires advanced manufacturing techniques and quality control measures. The need for non-invasive sensing methods that do not compromise the battery's structural integrity further complicates this process.

One of the most significant challenges is temperature monitoring. Blade batteries generate heat during charging and discharging cycles, and uneven temperature distribution can lead to reduced efficiency and potential safety hazards. Conventional temperature sensors struggle to provide precise readings across the entire length of the blade cell, leaving potential hotspots undetected.

Pressure sensing within blade batteries poses another substantial challenge. As these cells expand and contract during use, internal pressure changes can affect performance and longevity. However, integrating pressure sensors without disrupting the cell's structure or increasing its size remains a complex task for engineers.

Voltage and current monitoring also present unique difficulties in blade battery systems. The high energy density and rapid charge/discharge rates require sensors capable of handling large power fluctuations while maintaining accuracy. Additionally, the compact nature of blade batteries limits the space available for sensor placement, necessitating innovative solutions for comprehensive monitoring.

State of charge (SOC) and state of health (SOH) estimation pose further challenges. These critical parameters require sophisticated algorithms and sensor fusion techniques to accurately assess the battery's condition. The unique characteristics of blade batteries, such as their elongated shape and cell chemistry, demand tailored approaches to SOC and SOH estimation that differ from those used in traditional lithium-ion batteries.

Electromagnetic interference (EMI) is another significant concern in blade battery sensor systems. The high current flows and compact design can generate electromagnetic fields that interfere with sensor readings, potentially leading to inaccurate data and compromised battery management.

Durability and longevity of sensors in the harsh environment of a blade battery system present ongoing challenges. Sensors must withstand extreme temperatures, vibrations, and chemical exposure while maintaining accuracy over the battery's entire lifespan, which can span several years in automotive applications.

Lastly, the integration of sensors into the blade battery manufacturing process poses significant challenges. Ensuring consistent sensor placement and calibration across mass-produced cells requires advanced manufacturing techniques and quality control measures. The need for non-invasive sensing methods that do not compromise the battery's structural integrity further complicates this process.

Existing Blade Battery Monitoring Solutions

01 Battery cell voltage monitoring

Monitoring individual cell voltages in a blade battery system to detect anomalies, ensure balanced charging, and prevent overcharging or undercharging. This approach allows for early detection of potential issues and helps maintain optimal battery performance and longevity.- Battery Management System for Blade Batteries: A battery management system specifically designed for blade batteries, which monitors various parameters such as voltage, current, temperature, and state of charge. This system ensures optimal performance, safety, and longevity of blade battery packs used in electric vehicles and energy storage systems.

- Real-time Monitoring and Fault Detection: Advanced monitoring techniques for blade battery systems that provide real-time data on battery health and performance. These methods include early fault detection, predictive maintenance, and anomaly identification to prevent potential failures and optimize battery life.

- Thermal Management in Blade Battery Systems: Innovative thermal management solutions for blade batteries, including temperature monitoring, heat dissipation techniques, and cooling systems. These approaches help maintain optimal operating temperatures, prevent thermal runaway, and enhance overall battery efficiency and safety.

- State of Charge and State of Health Estimation: Advanced algorithms and methods for accurately estimating the state of charge (SOC) and state of health (SOH) of blade batteries. These techniques improve battery performance prediction, optimize charging strategies, and extend battery lifespan.

- Wireless Monitoring and Data Communication: Implementation of wireless communication technologies for blade battery monitoring systems. These solutions enable remote monitoring, data collection, and analysis of battery performance, facilitating efficient management and maintenance of large-scale battery installations.

02 Temperature monitoring and management

Implementing temperature sensors and control systems to monitor and regulate the temperature of blade battery cells. This helps prevent overheating, ensures safe operation, and optimizes battery performance across various environmental conditions.Expand Specific Solutions03 State of charge (SOC) estimation

Utilizing advanced algorithms and sensors to accurately estimate the state of charge of blade batteries. This enables better energy management, improves range prediction in electric vehicles, and helps optimize charging and discharging cycles.Expand Specific Solutions04 Battery management system (BMS) integration

Developing comprehensive battery management systems that integrate various monitoring functions, including voltage, current, temperature, and state of health. These systems provide real-time data analysis, fault detection, and communication with other vehicle systems for optimal battery performance and safety.Expand Specific Solutions05 Wireless monitoring and diagnostics

Implementing wireless communication technologies for remote monitoring, diagnostics, and data collection from blade battery systems. This enables real-time performance tracking, predictive maintenance, and over-the-air updates to improve battery management and extend battery life.Expand Specific Solutions

Key Players in Battery Sensor Industry

The sensor technology developments in blade battery system monitoring are in a growth phase, with increasing market size driven by the expanding electric vehicle industry. The technology is maturing rapidly, with companies like LG Energy Solution, Robert Bosch, and Sensata Technologies leading innovation. Universities such as Tianjin University and Beijing Institute of Technology are contributing to research advancements. The competitive landscape is diverse, including established automotive suppliers, specialized battery technology firms, and emerging startups. As the technology evolves, we're seeing a focus on improving safety, efficiency, and longevity of blade battery systems through advanced sensing and monitoring solutions.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced sensor technologies for blade battery system monitoring. Their approach integrates multiple sensor types, including temperature, voltage, and current sensors, into a comprehensive Battery Management System (BMS). The company utilizes high-precision thin-film sensors embedded directly into the battery cells, allowing for real-time monitoring of individual cell performance[1]. Additionally, LG has implemented machine learning algorithms to analyze sensor data, enabling predictive maintenance and early fault detection[3]. Their system also incorporates wireless sensor networks for improved data transmission and reduced wiring complexity within the battery pack[5].

Strengths: High precision monitoring, predictive maintenance capabilities, and reduced system complexity. Weaknesses: Potentially higher initial costs and increased computational requirements for data processing.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive sensor technology suite for blade battery system monitoring. Their solution incorporates a network of smart sensors that measure various parameters such as temperature, voltage, and internal resistance. Bosch's system utilizes advanced signal processing techniques to filter out noise and improve measurement accuracy[2]. The company has also implemented a distributed sensor architecture, allowing for more localized data processing and reducing the load on the central BMS[4]. Furthermore, Bosch has integrated their sensors with cloud-based analytics platforms, enabling remote monitoring and advanced diagnostics capabilities[6].

Strengths: Robust and reliable sensor network, advanced signal processing, and cloud integration. Weaknesses: Potential cybersecurity concerns with cloud connectivity and higher system complexity.

Core Innovations in Battery Sensing

BATTERY MONITORING SYSTEM

PatentPendingBR102019022219A8

Innovation

- Comprehensive monitoring system that measures multiple battery parameters (voltage, temperature, solution level, and current) with high precision.

- Software-based problem detection for individual battery elements within a bank of batteries.

- Modular system design incorporating analysis, reporting, simulation, documentation handling, and training functionalities.

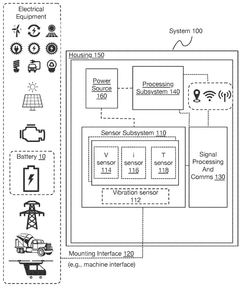

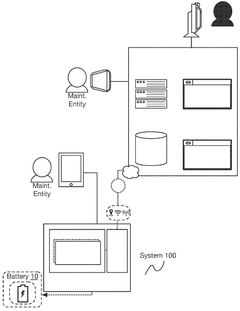

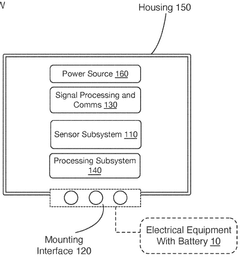

Systems and methods for monitoring and managing battery systems

PatentWO2025034431A2

Innovation

- The development of a system and method for monitoring battery systems that utilizes a sensor subsystem, signal conditioning and communications subsystem, and processing subsystem to detect and analyze signals indicative of battery health and performance, allowing for improved detection and prediction of faults without the need for extensive data management or equipment-specific designs.

Safety Standards for Battery Monitoring

Safety standards for battery monitoring in blade battery systems have become increasingly crucial as the technology continues to advance. These standards are designed to ensure the safe operation, reliable performance, and longevity of battery systems, particularly in high-stakes applications such as electric vehicles and renewable energy storage.

The primary focus of safety standards in this domain is on the accurate and real-time monitoring of key battery parameters. These include voltage, current, temperature, and state of charge (SOC) for individual cells and the overall battery pack. Advanced sensor technologies play a pivotal role in achieving this level of monitoring precision.

One of the key aspects of safety standards is the requirement for redundancy in sensor systems. This approach ensures that if one sensor fails, others can continue to provide critical data, maintaining the overall safety of the battery system. Redundancy is particularly important for temperature sensors, as overheating is a significant risk factor in battery failures.

Another crucial element of safety standards is the integration of intelligent battery management systems (BMS). These systems utilize data from multiple sensors to make real-time decisions about battery operation, including adjusting charging rates, balancing cell voltages, and initiating safety protocols when abnormal conditions are detected.

Standards also emphasize the importance of sensor calibration and regular maintenance. This ensures that the monitoring system remains accurate over time, as sensor drift or degradation could lead to false readings and potentially dangerous situations.

Furthermore, safety standards mandate the implementation of fail-safe mechanisms. These are designed to automatically shut down the battery system or isolate problematic cells in the event of critical sensor readings or system malfunctions. This rapid response capability is essential for preventing thermal runaway and other catastrophic failure modes.

Electromagnetic compatibility (EMC) is another critical aspect covered by safety standards. As blade batteries often operate in environments with high electromagnetic interference, sensors and monitoring systems must be shielded and tested to ensure they function reliably under these conditions.

Lastly, data security and integrity are increasingly important components of safety standards for battery monitoring. With the rise of connected and smart battery systems, standards now include requirements for secure data transmission, storage, and protection against cyber threats that could potentially compromise the battery monitoring system.

The primary focus of safety standards in this domain is on the accurate and real-time monitoring of key battery parameters. These include voltage, current, temperature, and state of charge (SOC) for individual cells and the overall battery pack. Advanced sensor technologies play a pivotal role in achieving this level of monitoring precision.

One of the key aspects of safety standards is the requirement for redundancy in sensor systems. This approach ensures that if one sensor fails, others can continue to provide critical data, maintaining the overall safety of the battery system. Redundancy is particularly important for temperature sensors, as overheating is a significant risk factor in battery failures.

Another crucial element of safety standards is the integration of intelligent battery management systems (BMS). These systems utilize data from multiple sensors to make real-time decisions about battery operation, including adjusting charging rates, balancing cell voltages, and initiating safety protocols when abnormal conditions are detected.

Standards also emphasize the importance of sensor calibration and regular maintenance. This ensures that the monitoring system remains accurate over time, as sensor drift or degradation could lead to false readings and potentially dangerous situations.

Furthermore, safety standards mandate the implementation of fail-safe mechanisms. These are designed to automatically shut down the battery system or isolate problematic cells in the event of critical sensor readings or system malfunctions. This rapid response capability is essential for preventing thermal runaway and other catastrophic failure modes.

Electromagnetic compatibility (EMC) is another critical aspect covered by safety standards. As blade batteries often operate in environments with high electromagnetic interference, sensors and monitoring systems must be shielded and tested to ensure they function reliably under these conditions.

Lastly, data security and integrity are increasingly important components of safety standards for battery monitoring. With the rise of connected and smart battery systems, standards now include requirements for secure data transmission, storage, and protection against cyber threats that could potentially compromise the battery monitoring system.

Environmental Impact of Sensor Materials

The environmental impact of sensor materials used in blade battery system monitoring is a critical consideration in the development and deployment of these technologies. As sensor technologies advance, the materials used in their production and operation can have significant implications for sustainability and ecological balance.

Sensor materials commonly used in blade battery systems include various metals, semiconductors, and composite materials. These often incorporate rare earth elements, precious metals, and other specialized compounds. The extraction and processing of these materials can lead to substantial environmental consequences, including habitat disruption, water pollution, and greenhouse gas emissions.

Mining operations for rare earth elements, which are crucial components in many advanced sensors, often involve extensive land use and can result in soil erosion and contamination of local water sources. The refining processes for these materials typically require significant energy inputs and may produce toxic byproducts, further contributing to environmental degradation.

The manufacturing of sensors also raises environmental concerns. The production of semiconductor-based sensors, for instance, involves energy-intensive processes and the use of potentially hazardous chemicals. Clean room environments, essential for sensor fabrication, demand substantial energy for maintaining controlled conditions, contributing to the overall carbon footprint of sensor production.

Disposal and end-of-life management of sensors present additional environmental challenges. Many sensor components contain materials that are difficult to recycle or dispose of safely. Improper disposal can lead to the leaching of harmful substances into soil and groundwater, posing risks to ecosystems and human health.

However, advancements in sensor technology are also driving improvements in environmental performance. Researchers are developing more eco-friendly sensor materials, such as biodegradable sensors and those made from renewable resources. These innovations aim to reduce the environmental impact throughout the sensor lifecycle, from production to disposal.

Moreover, the application of advanced sensors in blade battery systems can contribute to environmental benefits by improving the efficiency and lifespan of batteries. More accurate monitoring can lead to optimized battery performance, reduced waste, and enhanced energy storage capabilities, potentially offsetting some of the environmental costs associated with sensor production.

As the demand for blade battery systems and their associated sensors grows, it becomes increasingly important to consider the full environmental lifecycle of these technologies. This includes not only the immediate impacts of production and use but also long-term effects on resource depletion and ecosystem health. Balancing technological advancement with environmental stewardship remains a key challenge in the ongoing development of sensor technologies for blade battery systems.

Sensor materials commonly used in blade battery systems include various metals, semiconductors, and composite materials. These often incorporate rare earth elements, precious metals, and other specialized compounds. The extraction and processing of these materials can lead to substantial environmental consequences, including habitat disruption, water pollution, and greenhouse gas emissions.

Mining operations for rare earth elements, which are crucial components in many advanced sensors, often involve extensive land use and can result in soil erosion and contamination of local water sources. The refining processes for these materials typically require significant energy inputs and may produce toxic byproducts, further contributing to environmental degradation.

The manufacturing of sensors also raises environmental concerns. The production of semiconductor-based sensors, for instance, involves energy-intensive processes and the use of potentially hazardous chemicals. Clean room environments, essential for sensor fabrication, demand substantial energy for maintaining controlled conditions, contributing to the overall carbon footprint of sensor production.

Disposal and end-of-life management of sensors present additional environmental challenges. Many sensor components contain materials that are difficult to recycle or dispose of safely. Improper disposal can lead to the leaching of harmful substances into soil and groundwater, posing risks to ecosystems and human health.

However, advancements in sensor technology are also driving improvements in environmental performance. Researchers are developing more eco-friendly sensor materials, such as biodegradable sensors and those made from renewable resources. These innovations aim to reduce the environmental impact throughout the sensor lifecycle, from production to disposal.

Moreover, the application of advanced sensors in blade battery systems can contribute to environmental benefits by improving the efficiency and lifespan of batteries. More accurate monitoring can lead to optimized battery performance, reduced waste, and enhanced energy storage capabilities, potentially offsetting some of the environmental costs associated with sensor production.

As the demand for blade battery systems and their associated sensors grows, it becomes increasingly important to consider the full environmental lifecycle of these technologies. This includes not only the immediate impacts of production and use but also long-term effects on resource depletion and ecosystem health. Balancing technological advancement with environmental stewardship remains a key challenge in the ongoing development of sensor technologies for blade battery systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!