Heat Dispersion Techniques in Blade Battery Packs

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Management Evolution and Objectives

Battery thermal management has evolved significantly over the past decades, driven by the increasing demand for high-performance, safe, and long-lasting energy storage solutions. The evolution of thermal management techniques in blade battery packs reflects the industry's continuous efforts to address the challenges of heat generation and dissipation in compact, high-energy-density configurations.

In the early stages of battery development, thermal management was often an afterthought, with simple air cooling systems being the norm. As energy densities increased and the automotive industry began to adopt lithium-ion batteries, the need for more sophisticated thermal management became apparent. The transition from cylindrical and prismatic cells to blade-type cells introduced new challenges and opportunities in heat dispersion.

The primary objective of thermal management in blade battery packs is to maintain optimal operating temperatures across all cells, typically between 20°C and 40°C. This temperature range ensures maximum battery performance, longevity, and safety. Achieving this goal requires addressing several key challenges, including heat generation during charging and discharging, thermal runaway prevention, and the mitigation of temperature gradients within the pack.

Another critical objective is to minimize the overall weight and volume of the thermal management system while maximizing its efficiency. This is particularly important in electric vehicles, where every kilogram and liter of space impacts range and performance. The evolution of thermal management techniques has thus focused on developing more compact, lightweight solutions that can effectively manage heat in the densely packed blade battery configuration.

The industry has also set objectives to improve the uniformity of temperature distribution across the battery pack. Uneven temperature distribution can lead to differential aging of cells, reducing overall pack life and performance. Advanced thermal management techniques aim to create more homogeneous thermal environments, ensuring that all cells operate under similar conditions.

As environmental concerns grow, the sustainability of thermal management solutions has become an increasingly important objective. This includes developing systems that are not only effective but also energy-efficient, recyclable, and manufactured using environmentally friendly processes. The use of natural refrigerants and the integration of battery thermal management with vehicle climate control systems are examples of this trend.

Looking forward, the objectives of battery thermal management continue to evolve. There is a growing focus on predictive thermal management, leveraging artificial intelligence and real-time data to anticipate and preemptively address thermal issues. Additionally, as fast charging becomes more prevalent, thermal management systems must adapt to handle the increased heat generation associated with high-power charging events.

In the early stages of battery development, thermal management was often an afterthought, with simple air cooling systems being the norm. As energy densities increased and the automotive industry began to adopt lithium-ion batteries, the need for more sophisticated thermal management became apparent. The transition from cylindrical and prismatic cells to blade-type cells introduced new challenges and opportunities in heat dispersion.

The primary objective of thermal management in blade battery packs is to maintain optimal operating temperatures across all cells, typically between 20°C and 40°C. This temperature range ensures maximum battery performance, longevity, and safety. Achieving this goal requires addressing several key challenges, including heat generation during charging and discharging, thermal runaway prevention, and the mitigation of temperature gradients within the pack.

Another critical objective is to minimize the overall weight and volume of the thermal management system while maximizing its efficiency. This is particularly important in electric vehicles, where every kilogram and liter of space impacts range and performance. The evolution of thermal management techniques has thus focused on developing more compact, lightweight solutions that can effectively manage heat in the densely packed blade battery configuration.

The industry has also set objectives to improve the uniformity of temperature distribution across the battery pack. Uneven temperature distribution can lead to differential aging of cells, reducing overall pack life and performance. Advanced thermal management techniques aim to create more homogeneous thermal environments, ensuring that all cells operate under similar conditions.

As environmental concerns grow, the sustainability of thermal management solutions has become an increasingly important objective. This includes developing systems that are not only effective but also energy-efficient, recyclable, and manufactured using environmentally friendly processes. The use of natural refrigerants and the integration of battery thermal management with vehicle climate control systems are examples of this trend.

Looking forward, the objectives of battery thermal management continue to evolve. There is a growing focus on predictive thermal management, leveraging artificial intelligence and real-time data to anticipate and preemptively address thermal issues. Additionally, as fast charging becomes more prevalent, thermal management systems must adapt to handle the increased heat generation associated with high-power charging events.

Market Demand for Efficient EV Battery Cooling

The market demand for efficient electric vehicle (EV) battery cooling systems has been growing exponentially in recent years, driven by the rapid expansion of the global EV market. As EV adoption continues to accelerate, the need for advanced thermal management solutions, particularly for blade battery packs, has become increasingly critical.

The primary driver of this demand is the automotive industry's push towards longer-range EVs with faster charging capabilities. Consumers are seeking vehicles that can travel further on a single charge and recharge quickly, necessitating more powerful and energy-dense battery packs. However, these high-performance batteries generate significant heat during operation and charging, which can negatively impact battery life, performance, and safety if not properly managed.

Blade battery packs, known for their high energy density and space efficiency, are particularly susceptible to thermal challenges due to their compact design. As a result, there is a strong market pull for innovative heat dispersion techniques specifically tailored to these battery configurations. Automotive manufacturers and battery suppliers are actively seeking solutions that can effectively maintain optimal operating temperatures while minimizing weight, space, and energy consumption.

The demand for efficient cooling systems extends beyond just performance and longevity concerns. Safety is a paramount consideration in EV design, and effective thermal management plays a crucial role in preventing thermal runaway events. This has led to increased investment in research and development of advanced cooling technologies, with a focus on solutions that can rapidly dissipate heat and maintain uniform temperature distribution across the battery pack.

Furthermore, the growing emphasis on sustainability in the automotive sector has created a demand for cooling systems that not only perform efficiently but also contribute to the overall energy efficiency of the vehicle. This has spurred interest in passive cooling techniques and smart thermal management systems that can adapt to varying operating conditions and minimize parasitic energy losses.

The market for EV battery cooling solutions is also being shaped by regulatory pressures. Governments worldwide are implementing stricter safety standards and performance requirements for EVs, many of which directly or indirectly relate to thermal management. This regulatory landscape is compelling manufacturers to prioritize the development and integration of advanced cooling technologies in their EV designs.

As the EV market continues to mature, the demand for efficient battery cooling systems is expected to intensify further. Industry analysts project substantial growth in this segment, with opportunities for both established players and innovative startups to capture market share through technological advancements in heat dispersion techniques for blade battery packs.

The primary driver of this demand is the automotive industry's push towards longer-range EVs with faster charging capabilities. Consumers are seeking vehicles that can travel further on a single charge and recharge quickly, necessitating more powerful and energy-dense battery packs. However, these high-performance batteries generate significant heat during operation and charging, which can negatively impact battery life, performance, and safety if not properly managed.

Blade battery packs, known for their high energy density and space efficiency, are particularly susceptible to thermal challenges due to their compact design. As a result, there is a strong market pull for innovative heat dispersion techniques specifically tailored to these battery configurations. Automotive manufacturers and battery suppliers are actively seeking solutions that can effectively maintain optimal operating temperatures while minimizing weight, space, and energy consumption.

The demand for efficient cooling systems extends beyond just performance and longevity concerns. Safety is a paramount consideration in EV design, and effective thermal management plays a crucial role in preventing thermal runaway events. This has led to increased investment in research and development of advanced cooling technologies, with a focus on solutions that can rapidly dissipate heat and maintain uniform temperature distribution across the battery pack.

Furthermore, the growing emphasis on sustainability in the automotive sector has created a demand for cooling systems that not only perform efficiently but also contribute to the overall energy efficiency of the vehicle. This has spurred interest in passive cooling techniques and smart thermal management systems that can adapt to varying operating conditions and minimize parasitic energy losses.

The market for EV battery cooling solutions is also being shaped by regulatory pressures. Governments worldwide are implementing stricter safety standards and performance requirements for EVs, many of which directly or indirectly relate to thermal management. This regulatory landscape is compelling manufacturers to prioritize the development and integration of advanced cooling technologies in their EV designs.

As the EV market continues to mature, the demand for efficient battery cooling systems is expected to intensify further. Industry analysts project substantial growth in this segment, with opportunities for both established players and innovative startups to capture market share through technological advancements in heat dispersion techniques for blade battery packs.

Current Challenges in Blade Battery Thermal Control

Blade batteries, while offering significant advantages in energy density and safety, face critical thermal management challenges. The primary issue stems from their unique structural design, which limits heat dissipation pathways. Unlike traditional battery packs with spaces between cells, blade batteries are tightly packed, reducing surface area for heat exchange. This compact arrangement exacerbates heat accumulation, particularly during rapid charging and discharging cycles.

One of the most pressing challenges is the uneven temperature distribution within the battery pack. The cells in the center tend to experience higher temperatures compared to those at the edges, leading to thermal gradients. These gradients not only affect the overall performance of the battery but also accelerate degradation of the hotter cells, potentially reducing the lifespan of the entire pack.

Another significant hurdle is the limited cooling options available for blade batteries. Traditional air cooling systems struggle to effectively penetrate the dense pack structure, while liquid cooling systems face design constraints due to the tight integration of cells. This limitation in cooling efficiency becomes particularly problematic during fast charging scenarios or in high-performance applications where heat generation is intensified.

The thermal runaway risk, although reduced in blade batteries compared to some other designs, still poses a challenge. The compact nature of the pack means that if thermal runaway occurs in one cell, it can quickly spread to adjacent cells. Developing effective heat barriers and isolation techniques within the tight confines of a blade battery pack remains a significant engineering challenge.

Moreover, the thermal control systems must be designed to operate effectively across a wide range of environmental conditions. Extreme temperatures, both hot and cold, can significantly impact battery performance and safety. Designing a thermal management system that can maintain optimal operating temperatures in diverse climates, from arctic cold to desert heat, adds another layer of complexity to the challenge.

Balancing thermal management with weight and space constraints is another critical issue. Effective cooling systems often add bulk and weight to the battery pack, which can negate some of the energy density advantages of blade batteries. Engineers must find innovative ways to integrate thermal management solutions without significantly increasing the overall size and weight of the battery system.

One of the most pressing challenges is the uneven temperature distribution within the battery pack. The cells in the center tend to experience higher temperatures compared to those at the edges, leading to thermal gradients. These gradients not only affect the overall performance of the battery but also accelerate degradation of the hotter cells, potentially reducing the lifespan of the entire pack.

Another significant hurdle is the limited cooling options available for blade batteries. Traditional air cooling systems struggle to effectively penetrate the dense pack structure, while liquid cooling systems face design constraints due to the tight integration of cells. This limitation in cooling efficiency becomes particularly problematic during fast charging scenarios or in high-performance applications where heat generation is intensified.

The thermal runaway risk, although reduced in blade batteries compared to some other designs, still poses a challenge. The compact nature of the pack means that if thermal runaway occurs in one cell, it can quickly spread to adjacent cells. Developing effective heat barriers and isolation techniques within the tight confines of a blade battery pack remains a significant engineering challenge.

Moreover, the thermal control systems must be designed to operate effectively across a wide range of environmental conditions. Extreme temperatures, both hot and cold, can significantly impact battery performance and safety. Designing a thermal management system that can maintain optimal operating temperatures in diverse climates, from arctic cold to desert heat, adds another layer of complexity to the challenge.

Balancing thermal management with weight and space constraints is another critical issue. Effective cooling systems often add bulk and weight to the battery pack, which can negate some of the energy density advantages of blade batteries. Engineers must find innovative ways to integrate thermal management solutions without significantly increasing the overall size and weight of the battery system.

Existing Heat Dispersion Methods for Blade Batteries

01 Heat dissipation structures for blade battery packs

Blade battery packs incorporate specialized heat dissipation structures to manage thermal issues. These may include heat sinks, cooling fins, or thermal interface materials strategically placed within the battery pack to efficiently transfer and disperse heat generated during operation. Such structures help maintain optimal operating temperatures and extend battery life.- Heat dissipation structures for blade battery packs: Blade battery packs incorporate specialized heat dissipation structures to manage thermal issues. These may include heat sinks, cooling fins, or thermal interface materials strategically placed within the battery pack to efficiently transfer and disperse heat generated during operation.

- Liquid cooling systems for blade batteries: Advanced liquid cooling systems are implemented in blade battery packs to enhance heat dispersion. These systems circulate coolant through channels or plates within the battery pack, effectively removing heat from the cells and maintaining optimal operating temperatures.

- Thermal management using phase change materials: Phase change materials (PCMs) are incorporated into blade battery packs to absorb and release thermal energy during temperature fluctuations. This passive cooling method helps maintain consistent temperatures and prevents overheating in high-power applications.

- Smart thermal management systems: Intelligent thermal management systems are integrated into blade battery packs, utilizing sensors and control algorithms to monitor and regulate temperature. These systems can adjust cooling mechanisms in real-time, optimizing heat dispersion based on operating conditions and battery load.

- Structural design for improved heat dissipation: The physical design and arrangement of cells within blade battery packs are optimized for enhanced heat dispersion. This includes strategic cell spacing, the use of thermally conductive materials, and the integration of air channels or vents to facilitate natural convection cooling.

02 Liquid cooling systems for blade batteries

Advanced liquid cooling systems are employed in blade battery packs to enhance heat dispersion. These systems circulate coolant through channels or plates integrated into the battery structure, effectively absorbing and removing heat. This approach allows for more uniform temperature control across the battery pack, improving overall performance and longevity.Expand Specific Solutions03 Thermal management using phase change materials

Phase change materials (PCMs) are incorporated into blade battery packs to absorb excess heat during operation. These materials change state at specific temperatures, storing or releasing latent heat to regulate battery temperature. This passive cooling method helps maintain consistent temperatures and reduces the load on active cooling systems.Expand Specific Solutions04 Smart thermal management systems

Intelligent thermal management systems are integrated into blade battery packs to optimize heat dispersion. These systems use sensors and control algorithms to monitor temperature variations and adjust cooling mechanisms accordingly. By dynamically managing heat distribution, these smart systems enhance battery efficiency and prevent localized hot spots.Expand Specific Solutions05 Structural design for improved heat dissipation

The physical design of blade battery packs is optimized for enhanced heat dispersion. This includes the arrangement of cells, the use of thermally conductive materials, and the incorporation of air channels or gaps to facilitate natural convection. Such design considerations help to distribute heat more evenly and improve overall thermal management efficiency.Expand Specific Solutions

Key Players in EV Battery Thermal Solutions

The heat dispersion techniques in blade battery packs market is in a growth phase, driven by increasing demand for electric vehicles and energy storage solutions. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing quickly, with major players like BYD, LG Energy Solution, and Panasonic leading innovation. These companies are investing heavily in R&D to improve heat management, enhance battery performance, and increase safety. Emerging players such as Svolt Energy and SK On are also making strides, introducing new technologies and competing for market share. The competition is fierce, with companies racing to develop more efficient and cost-effective solutions for heat dispersion in blade battery packs.

BYD Co., Ltd.

Technical Solution: BYD's Blade Battery utilizes a novel heat dispersion technique that integrates thermal management directly into the battery structure. The long, thin cells are arranged in a parallel configuration, creating channels for coolant flow between them. This design maximizes the surface area for heat exchange, allowing for more efficient cooling. BYD employs a liquid cooling system that circulates through these channels, maintaining optimal temperature across the entire battery pack. The company claims this approach can reduce battery pack temperature by up to 30% compared to conventional designs[1]. Additionally, the Blade Battery's structural integrity contributes to heat dissipation by allowing for better thermal conductivity throughout the pack[2].

Strengths: Efficient cooling, improved safety, and higher energy density. Weaknesses: Potentially higher manufacturing complexity and cost compared to traditional battery designs.

Panasonic Holdings Corp.

Technical Solution: Panasonic has developed advanced heat dispersion techniques for their battery packs, focusing on both active and passive cooling strategies. Their approach includes the use of phase change materials (PCMs) integrated into the battery structure to absorb excess heat during high-load operations[3]. This is complemented by a sophisticated liquid cooling system that utilizes a proprietary coolant formulation for enhanced heat transfer. Panasonic's design also incorporates heat-spreading materials between cells to distribute thermal energy more evenly. The company has reported that this combined approach can maintain battery temperature within a 5°C range even under extreme operating conditions[4].

Strengths: Effective temperature control, improved battery longevity, and versatility for various applications. Weaknesses: Increased complexity in battery pack design and potential for higher costs due to specialized materials.

Innovative Cooling Techniques for Blade Battery Packs

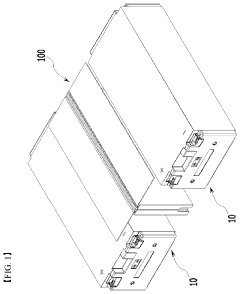

Heat Dissipating Device for a Battery Pack, and a Battery Pack Using the Same

PatentActiveUS20080292949A1

Innovation

- A heat dissipating device comprising a heat pipe and heat collecting plates with holes, where the heat pipe connects the plates to efficiently transmit and dissipate heat generated by the cells, utilizing high conductivity materials and designs like U-shaped heat pipes to enhance heat transfer.

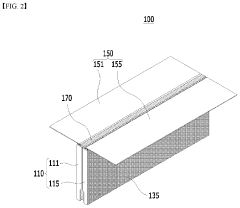

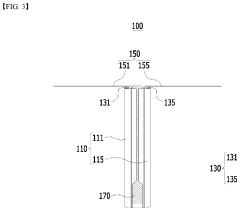

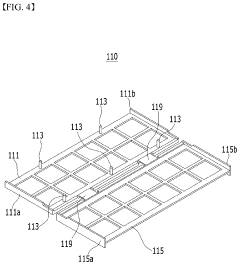

Heat dissipation member and battery pack including the same

PatentPendingUS20230369672A1

Innovation

- A heat dissipation member comprising a frame with connected first and second frames, heat insulating and dispersion members, and a central insulating member, designed to prevent heat transfer between adjacent battery modules by using bent surfaces and protrusions for efficient heat dispersion.

Safety Standards for EV Battery Thermal Systems

Safety standards for EV battery thermal systems are crucial for ensuring the safe operation and performance of electric vehicles. These standards encompass a wide range of requirements and guidelines aimed at mitigating thermal risks associated with battery packs, particularly in blade battery configurations.

One of the primary focuses of these safety standards is the establishment of temperature limits for battery cells and packs. These limits are typically set to prevent thermal runaway, a potentially catastrophic event where excessive heat generation leads to a chain reaction of cell failures. The standards often specify maximum operating temperatures, as well as temperature gradients across the battery pack, to ensure uniform heat distribution and prevent localized hot spots.

Thermal management system requirements are another key aspect of these safety standards. They outline the necessary cooling and heating capabilities to maintain optimal battery temperature under various operating conditions. This includes specifications for coolant flow rates, heat exchanger efficiencies, and thermal insulation properties. The standards may also address the integration of active and passive cooling methods, such as liquid cooling systems or phase change materials.

Safety standards also emphasize the importance of robust thermal monitoring and control systems. These systems must be capable of accurately measuring temperatures across the battery pack and responding quickly to any thermal anomalies. The standards often specify the required number and placement of temperature sensors, as well as the frequency of temperature data sampling and reporting.

Fail-safe mechanisms and emergency thermal management protocols are integral components of these safety standards. They outline procedures for safely shutting down the battery system in the event of a thermal incident, as well as requirements for thermal isolation and containment to prevent the spread of heat or fire to other vehicle components.

Testing and certification procedures form a significant part of the safety standards. These include thermal abuse tests, such as nail penetration or overcharging, to evaluate the battery's response to extreme thermal conditions. The standards also define thermal cycling tests to assess the long-term durability and performance of the battery pack under repeated temperature fluctuations.

Environmental considerations are increasingly being incorporated into these safety standards. This includes requirements for thermal performance across a wide range of ambient temperatures, from extreme cold to hot climates. The standards may also address thermal management during charging, particularly fast charging scenarios where heat generation can be significant.

Lastly, these safety standards often include guidelines for thermal design validation and quality control processes. This ensures that manufacturers consistently produce battery packs that meet the required thermal safety specifications throughout the production lifecycle.

One of the primary focuses of these safety standards is the establishment of temperature limits for battery cells and packs. These limits are typically set to prevent thermal runaway, a potentially catastrophic event where excessive heat generation leads to a chain reaction of cell failures. The standards often specify maximum operating temperatures, as well as temperature gradients across the battery pack, to ensure uniform heat distribution and prevent localized hot spots.

Thermal management system requirements are another key aspect of these safety standards. They outline the necessary cooling and heating capabilities to maintain optimal battery temperature under various operating conditions. This includes specifications for coolant flow rates, heat exchanger efficiencies, and thermal insulation properties. The standards may also address the integration of active and passive cooling methods, such as liquid cooling systems or phase change materials.

Safety standards also emphasize the importance of robust thermal monitoring and control systems. These systems must be capable of accurately measuring temperatures across the battery pack and responding quickly to any thermal anomalies. The standards often specify the required number and placement of temperature sensors, as well as the frequency of temperature data sampling and reporting.

Fail-safe mechanisms and emergency thermal management protocols are integral components of these safety standards. They outline procedures for safely shutting down the battery system in the event of a thermal incident, as well as requirements for thermal isolation and containment to prevent the spread of heat or fire to other vehicle components.

Testing and certification procedures form a significant part of the safety standards. These include thermal abuse tests, such as nail penetration or overcharging, to evaluate the battery's response to extreme thermal conditions. The standards also define thermal cycling tests to assess the long-term durability and performance of the battery pack under repeated temperature fluctuations.

Environmental considerations are increasingly being incorporated into these safety standards. This includes requirements for thermal performance across a wide range of ambient temperatures, from extreme cold to hot climates. The standards may also address thermal management during charging, particularly fast charging scenarios where heat generation can be significant.

Lastly, these safety standards often include guidelines for thermal design validation and quality control processes. This ensures that manufacturers consistently produce battery packs that meet the required thermal safety specifications throughout the production lifecycle.

Environmental Impact of Battery Cooling Technologies

The environmental impact of battery cooling technologies in blade battery packs is a critical consideration as the automotive industry shifts towards electrification. Traditional cooling methods often rely on liquid coolants, which can pose significant environmental risks if not properly managed throughout the battery's lifecycle.

Liquid cooling systems typically use a mixture of water and glycol, which can be harmful to ecosystems if leaked. The production and disposal of these coolants contribute to carbon emissions and potential soil and water contamination. Moreover, the energy required to circulate liquid coolants adds to the overall environmental footprint of the vehicle.

Air cooling systems, while generally more environmentally friendly in terms of materials used, may require more energy to operate effectively, especially in extreme temperature conditions. This increased energy consumption can indirectly lead to higher greenhouse gas emissions if the electricity source is not renewable.

Phase change materials (PCMs) offer a promising alternative with potentially lower environmental impact. PCMs can absorb and release thermal energy without the need for continuous pumping or forced air circulation. However, the long-term environmental effects of PCM production and disposal are still being studied.

The manufacturing process of cooling systems also contributes to their environmental impact. The production of heat sinks, cooling plates, and thermal interface materials involves resource extraction and energy-intensive manufacturing processes. Efforts to use recycled materials and improve manufacturing efficiency can help mitigate these impacts.

End-of-life considerations are crucial for assessing the overall environmental impact of battery cooling technologies. The recyclability of cooling system components varies, with some materials being more easily recoverable than others. Designing cooling systems with recyclability in mind can significantly reduce their long-term environmental footprint.

Innovations in passive cooling techniques, such as the use of advanced thermal management materials and optimized battery pack designs, show promise in reducing the reliance on active cooling systems. These approaches could lead to simplified, more environmentally friendly cooling solutions with lower material and energy requirements.

As the industry progresses, there is a growing focus on developing cooling technologies that not only enhance battery performance and safety but also minimize environmental impact throughout the entire lifecycle of the battery pack. This holistic approach is essential for creating truly sustainable electric vehicle solutions.

Liquid cooling systems typically use a mixture of water and glycol, which can be harmful to ecosystems if leaked. The production and disposal of these coolants contribute to carbon emissions and potential soil and water contamination. Moreover, the energy required to circulate liquid coolants adds to the overall environmental footprint of the vehicle.

Air cooling systems, while generally more environmentally friendly in terms of materials used, may require more energy to operate effectively, especially in extreme temperature conditions. This increased energy consumption can indirectly lead to higher greenhouse gas emissions if the electricity source is not renewable.

Phase change materials (PCMs) offer a promising alternative with potentially lower environmental impact. PCMs can absorb and release thermal energy without the need for continuous pumping or forced air circulation. However, the long-term environmental effects of PCM production and disposal are still being studied.

The manufacturing process of cooling systems also contributes to their environmental impact. The production of heat sinks, cooling plates, and thermal interface materials involves resource extraction and energy-intensive manufacturing processes. Efforts to use recycled materials and improve manufacturing efficiency can help mitigate these impacts.

End-of-life considerations are crucial for assessing the overall environmental impact of battery cooling technologies. The recyclability of cooling system components varies, with some materials being more easily recoverable than others. Designing cooling systems with recyclability in mind can significantly reduce their long-term environmental footprint.

Innovations in passive cooling techniques, such as the use of advanced thermal management materials and optimized battery pack designs, show promise in reducing the reliance on active cooling systems. These approaches could lead to simplified, more environmentally friendly cooling solutions with lower material and energy requirements.

As the industry progresses, there is a growing focus on developing cooling technologies that not only enhance battery performance and safety but also minimize environmental impact throughout the entire lifecycle of the battery pack. This holistic approach is essential for creating truly sustainable electric vehicle solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!