Blade Battery Temperature Regulation for Optimal Operation

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Management Background and Objectives

Battery thermal management has become a critical aspect of electric vehicle (EV) technology, particularly for blade batteries, which are known for their high energy density and compact design. The evolution of battery technology has led to increased energy storage capacity and faster charging capabilities, but it has also introduced new challenges in managing heat generation and dissipation. The primary objective of this research is to explore and develop advanced temperature regulation techniques for blade batteries to ensure optimal operation, enhance performance, and extend battery life.

The historical development of battery thermal management systems has seen a shift from simple air cooling to more sophisticated liquid cooling and phase change material (PCM) solutions. As blade batteries have gained prominence in the EV industry, the need for tailored thermal management strategies has become increasingly apparent. These batteries, with their unique form factor and high energy density, require precise temperature control to maintain efficiency and prevent thermal runaway incidents.

Current market trends indicate a growing demand for EVs with longer range and faster charging times, putting additional pressure on battery thermal management systems. The blade battery's potential to meet these demands has sparked intense interest in optimizing its thermal performance. This research aims to address the specific thermal challenges posed by blade batteries, including heat distribution across the battery pack, thermal gradients within individual cells, and the impact of rapid charging on temperature profiles.

The technological landscape of battery thermal management is rapidly evolving, with innovations in materials science, heat transfer mechanisms, and control algorithms. This research will explore cutting-edge approaches such as advanced cooling fluids, smart thermal materials, and predictive thermal management systems. By leveraging these technologies, we aim to develop a comprehensive solution that can maintain blade batteries within their optimal temperature range under various operating conditions and environmental factors.

Furthermore, this research will consider the broader implications of improved thermal management on EV performance, safety, and sustainability. Efficient temperature regulation can lead to increased battery longevity, reduced charging times, and enhanced overall vehicle efficiency. These improvements align with global efforts to accelerate the adoption of electric mobility and reduce carbon emissions in the transportation sector.

By focusing on blade battery temperature regulation, this research seeks to contribute to the advancement of EV technology and address key challenges in the industry. The outcomes of this study will not only benefit blade battery manufacturers but also have far-reaching implications for the entire EV ecosystem, potentially influencing future battery designs and thermal management strategies across various battery types and applications.

The historical development of battery thermal management systems has seen a shift from simple air cooling to more sophisticated liquid cooling and phase change material (PCM) solutions. As blade batteries have gained prominence in the EV industry, the need for tailored thermal management strategies has become increasingly apparent. These batteries, with their unique form factor and high energy density, require precise temperature control to maintain efficiency and prevent thermal runaway incidents.

Current market trends indicate a growing demand for EVs with longer range and faster charging times, putting additional pressure on battery thermal management systems. The blade battery's potential to meet these demands has sparked intense interest in optimizing its thermal performance. This research aims to address the specific thermal challenges posed by blade batteries, including heat distribution across the battery pack, thermal gradients within individual cells, and the impact of rapid charging on temperature profiles.

The technological landscape of battery thermal management is rapidly evolving, with innovations in materials science, heat transfer mechanisms, and control algorithms. This research will explore cutting-edge approaches such as advanced cooling fluids, smart thermal materials, and predictive thermal management systems. By leveraging these technologies, we aim to develop a comprehensive solution that can maintain blade batteries within their optimal temperature range under various operating conditions and environmental factors.

Furthermore, this research will consider the broader implications of improved thermal management on EV performance, safety, and sustainability. Efficient temperature regulation can lead to increased battery longevity, reduced charging times, and enhanced overall vehicle efficiency. These improvements align with global efforts to accelerate the adoption of electric mobility and reduce carbon emissions in the transportation sector.

By focusing on blade battery temperature regulation, this research seeks to contribute to the advancement of EV technology and address key challenges in the industry. The outcomes of this study will not only benefit blade battery manufacturers but also have far-reaching implications for the entire EV ecosystem, potentially influencing future battery designs and thermal management strategies across various battery types and applications.

Market Demand for Advanced EV Battery Systems

The market demand for advanced electric vehicle (EV) battery systems has been experiencing significant growth in recent years, driven by the global shift towards sustainable transportation and the increasing adoption of electric vehicles. As governments worldwide implement stricter emissions regulations and offer incentives for EV adoption, automakers are intensifying their focus on developing more efficient and high-performance battery technologies.

The blade battery, a novel lithium iron phosphate (LFP) battery design, has emerged as a promising solution to address key challenges in the EV battery market. Its unique structure and composition offer advantages in terms of safety, energy density, and cost-effectiveness, making it particularly attractive for mass-market electric vehicles. The demand for blade batteries is expected to rise substantially as automakers seek to improve the range, safety, and affordability of their electric vehicle offerings.

One of the critical aspects of advanced EV battery systems is thermal management, which directly impacts battery performance, longevity, and safety. Efficient temperature regulation is essential for maintaining optimal operating conditions and maximizing the battery's potential. As such, there is a growing market demand for innovative temperature regulation solutions specifically tailored for blade batteries.

The automotive industry is increasingly recognizing the importance of advanced thermal management systems in EV batteries. Major automakers and battery manufacturers are investing heavily in research and development to enhance temperature regulation technologies. This trend is driven by the need to address consumer concerns regarding battery life, charging times, and overall vehicle performance in various climate conditions.

Furthermore, the market demand for advanced EV battery systems extends beyond personal vehicles. Commercial fleets, public transportation, and emerging electric aviation sectors are also seeking improved battery technologies with superior thermal management capabilities. This diversification of applications is expanding the potential market for blade batteries and associated temperature regulation solutions.

As the EV market continues to mature, consumers are becoming more discerning about battery performance and safety features. This heightened awareness is creating a competitive landscape where advanced temperature regulation technologies can serve as a key differentiator for EV manufacturers. Consequently, there is a growing demand for sophisticated battery management systems that can effectively monitor and control temperature across a wide range of operating conditions.

In conclusion, the market demand for advanced EV battery systems, particularly those incorporating innovative temperature regulation solutions for blade batteries, is poised for substantial growth. This demand is driven by the automotive industry's push for improved performance, safety, and cost-effectiveness in electric vehicles, as well as the expanding applications of EV technology across various sectors.

The blade battery, a novel lithium iron phosphate (LFP) battery design, has emerged as a promising solution to address key challenges in the EV battery market. Its unique structure and composition offer advantages in terms of safety, energy density, and cost-effectiveness, making it particularly attractive for mass-market electric vehicles. The demand for blade batteries is expected to rise substantially as automakers seek to improve the range, safety, and affordability of their electric vehicle offerings.

One of the critical aspects of advanced EV battery systems is thermal management, which directly impacts battery performance, longevity, and safety. Efficient temperature regulation is essential for maintaining optimal operating conditions and maximizing the battery's potential. As such, there is a growing market demand for innovative temperature regulation solutions specifically tailored for blade batteries.

The automotive industry is increasingly recognizing the importance of advanced thermal management systems in EV batteries. Major automakers and battery manufacturers are investing heavily in research and development to enhance temperature regulation technologies. This trend is driven by the need to address consumer concerns regarding battery life, charging times, and overall vehicle performance in various climate conditions.

Furthermore, the market demand for advanced EV battery systems extends beyond personal vehicles. Commercial fleets, public transportation, and emerging electric aviation sectors are also seeking improved battery technologies with superior thermal management capabilities. This diversification of applications is expanding the potential market for blade batteries and associated temperature regulation solutions.

As the EV market continues to mature, consumers are becoming more discerning about battery performance and safety features. This heightened awareness is creating a competitive landscape where advanced temperature regulation technologies can serve as a key differentiator for EV manufacturers. Consequently, there is a growing demand for sophisticated battery management systems that can effectively monitor and control temperature across a wide range of operating conditions.

In conclusion, the market demand for advanced EV battery systems, particularly those incorporating innovative temperature regulation solutions for blade batteries, is poised for substantial growth. This demand is driven by the automotive industry's push for improved performance, safety, and cost-effectiveness in electric vehicles, as well as the expanding applications of EV technology across various sectors.

Current Challenges in Blade Battery Temperature Control

Blade batteries, a revolutionary technology in the electric vehicle (EV) industry, face significant challenges in temperature control, which is crucial for their optimal operation and longevity. One of the primary issues is the uneven heat distribution within the battery pack. Due to the unique structure of blade batteries, heat tends to concentrate in certain areas, leading to thermal hotspots that can potentially degrade battery performance and lifespan.

Another major challenge is the limited space for thermal management systems. The compact design of blade batteries, while beneficial for energy density, restricts the implementation of traditional cooling methods. This constraint necessitates innovative approaches to temperature regulation that can effectively operate within the confined spaces of modern EV designs.

The dynamic nature of EV operation poses additional difficulties for temperature control. Rapid charging and discharging cycles, coupled with varying environmental conditions, create fluctuating thermal loads that are challenging to manage consistently. This variability requires adaptive thermal management systems capable of responding quickly to changing conditions while maintaining optimal battery temperature.

Furthermore, the high energy density of blade batteries intensifies the risk of thermal runaway. While blade batteries are inherently safer than some other lithium-ion battery designs, the potential for cascading thermal events still exists, making precise temperature control critical for safety assurance.

The integration of blade batteries with vehicle systems presents another layer of complexity. Balancing the thermal needs of the battery with those of other vehicle components, such as the powertrain and cabin climate control, requires sophisticated thermal management strategies that optimize overall vehicle efficiency.

Cost considerations also play a significant role in the challenges faced by blade battery temperature control. Implementing advanced thermal management systems can substantially increase the overall cost of the battery pack and vehicle. Striking a balance between effective temperature regulation and economic viability is a persistent challenge for manufacturers.

Lastly, the regulatory landscape surrounding EV battery safety and performance sets stringent requirements for temperature control. Meeting these standards while pushing the boundaries of battery technology demands continuous innovation in thermal management techniques and materials.

Addressing these challenges requires a multifaceted approach, combining advancements in materials science, thermal engineering, and control systems. The development of novel cooling technologies, smart thermal management algorithms, and improved battery designs are all critical areas of focus in overcoming the current limitations in blade battery temperature control.

Another major challenge is the limited space for thermal management systems. The compact design of blade batteries, while beneficial for energy density, restricts the implementation of traditional cooling methods. This constraint necessitates innovative approaches to temperature regulation that can effectively operate within the confined spaces of modern EV designs.

The dynamic nature of EV operation poses additional difficulties for temperature control. Rapid charging and discharging cycles, coupled with varying environmental conditions, create fluctuating thermal loads that are challenging to manage consistently. This variability requires adaptive thermal management systems capable of responding quickly to changing conditions while maintaining optimal battery temperature.

Furthermore, the high energy density of blade batteries intensifies the risk of thermal runaway. While blade batteries are inherently safer than some other lithium-ion battery designs, the potential for cascading thermal events still exists, making precise temperature control critical for safety assurance.

The integration of blade batteries with vehicle systems presents another layer of complexity. Balancing the thermal needs of the battery with those of other vehicle components, such as the powertrain and cabin climate control, requires sophisticated thermal management strategies that optimize overall vehicle efficiency.

Cost considerations also play a significant role in the challenges faced by blade battery temperature control. Implementing advanced thermal management systems can substantially increase the overall cost of the battery pack and vehicle. Striking a balance between effective temperature regulation and economic viability is a persistent challenge for manufacturers.

Lastly, the regulatory landscape surrounding EV battery safety and performance sets stringent requirements for temperature control. Meeting these standards while pushing the boundaries of battery technology demands continuous innovation in thermal management techniques and materials.

Addressing these challenges requires a multifaceted approach, combining advancements in materials science, thermal engineering, and control systems. The development of novel cooling technologies, smart thermal management algorithms, and improved battery designs are all critical areas of focus in overcoming the current limitations in blade battery temperature control.

Existing Blade Battery Cooling Solutions

01 Temperature monitoring and control systems for blade batteries

Advanced temperature monitoring and control systems are implemented in blade batteries to maintain optimal operating conditions. These systems utilize sensors and control algorithms to regulate battery temperature, prevent overheating, and ensure safe operation across various environmental conditions.- Temperature monitoring and control systems for blade batteries: Advanced temperature monitoring and control systems are implemented in blade batteries to maintain optimal operating conditions. These systems utilize sensors to continuously measure battery temperature and adjust cooling mechanisms accordingly, ensuring safety and efficiency.

- Thermal management solutions for blade batteries: Various thermal management solutions are employed to regulate blade battery temperature. These may include liquid cooling systems, heat dissipation structures, and thermal interface materials to efficiently transfer heat away from the battery cells, preventing overheating and maintaining performance.

- Battery management systems for temperature regulation: Sophisticated battery management systems are developed to monitor and regulate blade battery temperature. These systems incorporate algorithms to predict temperature changes, adjust charging and discharging rates, and activate cooling mechanisms to prevent thermal runaway and extend battery life.

- Temperature-resistant materials and designs for blade batteries: Innovative materials and structural designs are utilized to enhance the temperature resistance of blade batteries. This includes the use of high-temperature resistant separators, thermally stable electrolytes, and optimized cell arrangements to improve heat dissipation and overall thermal performance.

- Safety mechanisms for temperature-related issues in blade batteries: Various safety mechanisms are incorporated into blade batteries to address temperature-related issues. These may include thermal fuses, pressure relief valves, and intelligent disconnection systems that activate in response to abnormal temperature increases, ensuring the safety of the battery and the device it powers.

02 Thermal management solutions for blade batteries

Innovative thermal management solutions are developed for blade batteries, including cooling systems, heat dissipation mechanisms, and thermal insulation techniques. These solutions aim to improve battery performance, extend lifespan, and enhance safety by efficiently managing heat generation and distribution within the battery pack.Expand Specific Solutions03 Temperature-based battery management systems

Sophisticated battery management systems are designed to monitor and regulate blade battery temperature. These systems incorporate temperature sensors, control units, and algorithms to optimize charging and discharging processes, adjust power output, and implement protective measures based on temperature data.Expand Specific Solutions04 Temperature-resistant materials and designs for blade batteries

Advanced materials and structural designs are employed to enhance the temperature resistance of blade batteries. These innovations include heat-resistant electrode materials, thermally stable separators, and optimized cell configurations to improve overall battery performance and safety under various temperature conditions.Expand Specific Solutions05 Temperature-based safety mechanisms for blade batteries

Safety mechanisms are integrated into blade batteries to prevent temperature-related incidents. These include thermal fuses, temperature-activated shut-off switches, and intelligent temperature monitoring systems that can initiate protective measures or disconnect the battery when critical temperature thresholds are reached.Expand Specific Solutions

Key Players in EV Battery Thermal Management

The research on blade battery temperature regulation for optimal operation is currently in a growth phase, with increasing market size and technological advancements. The global electric vehicle battery market, which includes blade batteries, is projected to expand significantly in the coming years. Companies like Contemporary Amperex Technology (CATL), LG Energy Solution, and Samsung SDI are leading players in this field, with substantial investments in R&D and production capacity. The technology is maturing rapidly, with improvements in thermal management systems, battery chemistry, and manufacturing processes. However, there is still room for innovation in areas such as advanced cooling techniques, smart temperature control algorithms, and integration with vehicle systems for optimal performance and safety.

Robert Bosch GmbH

Technical Solution: Bosch has developed a holistic approach to blade battery temperature regulation, leveraging its expertise in automotive systems integration. Their solution combines hardware and software innovations to optimize battery performance and longevity. The hardware component includes a modular cooling system that can be tailored to different vehicle platforms, utilizing a combination of liquid cooling and thermoelectric elements for precise temperature control. Bosch's proprietary coolant formulation offers improved thermal conductivity and reduced pumping energy requirements. On the software side, Bosch has implemented an AI-driven thermal management algorithm that learns from vehicle usage patterns and environmental data to predict and preemptively adjust cooling needs. This predictive approach can reduce overall energy consumption for thermal management by up to 15%[13]. Additionally, Bosch's system integrates with the vehicle's HVAC system to utilize waste heat for cabin warming in cold conditions, improving overall energy efficiency[14][15].

Strengths: Highly adaptable system, AI-driven optimization, and integration with vehicle systems for improved efficiency. Weaknesses: Potential for increased system complexity and reliance on advanced software that may require frequent updates.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL's blade battery technology incorporates an advanced thermal management system for optimal temperature regulation. The system utilizes a liquid cooling solution that circulates through channels integrated within the battery pack. This design allows for efficient heat dissipation and maintains a uniform temperature distribution across the cells. CATL has implemented a smart thermal control algorithm that adjusts cooling intensity based on real-time temperature data and operational conditions. The company claims that this system can maintain the battery temperature within an optimal range of 20-35°C, even under high-load scenarios[1][3]. Additionally, CATL has developed a novel phase-change material (PCM) that absorbs excess heat during rapid charging or discharging, further enhancing temperature stability[5].

Strengths: Efficient heat dissipation, uniform temperature distribution, and adaptive thermal management. Weaknesses: Potential complexity in manufacturing and higher initial costs compared to traditional battery designs.

Innovative Thermal Regulation Techniques for Blade Batteries

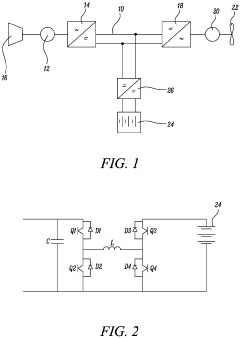

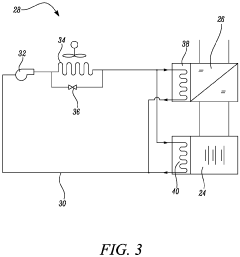

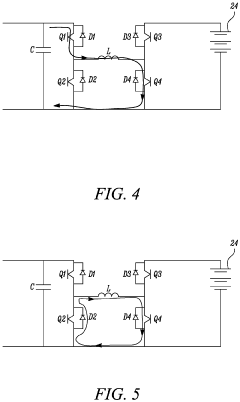

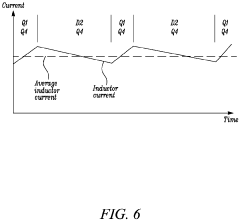

Electrical power supply system

PatentActiveEP3819978A1

Innovation

- An electrical power supply system utilizing a DC/DC converter with an inductor and switches that switches between ramping-up and freewheeling configurations to generate heat, which is transferred to the battery module through a heat transfer means, maintaining the battery temperature without resistive heating pads or additional charge-discharge cycles.

Environmental Impact of Battery Thermal Management

The environmental impact of battery thermal management systems (BTMS) in blade batteries is a critical consideration in the pursuit of sustainable energy storage solutions. These systems play a crucial role in maintaining optimal operating temperatures for batteries, which directly affects their performance, longevity, and safety. However, the implementation of BTMS also carries potential environmental consequences that must be carefully evaluated.

One of the primary environmental concerns associated with BTMS is energy consumption. Active cooling systems, such as liquid cooling or forced air circulation, require additional power to operate, which can increase the overall energy demand of the battery system. This increased energy consumption may lead to higher greenhouse gas emissions if the power source is not renewable. Passive cooling methods, while generally more energy-efficient, may not always provide sufficient temperature regulation for high-performance blade batteries.

The choice of materials used in BTMS also has environmental implications. Some cooling fluids and heat transfer materials may contain harmful chemicals or have a high global warming potential. The production and disposal of these materials can contribute to pollution and resource depletion. Additionally, the manufacturing processes for BTMS components, such as heat exchangers and cooling plates, may involve energy-intensive operations and the use of rare or non-renewable resources.

Waste generation is another environmental aspect to consider. As BTMS components wear out or become obsolete, they contribute to electronic waste streams. The complexity of these systems often makes recycling challenging, potentially leading to increased landfill usage. Furthermore, the disposal of cooling fluids and other consumables used in BTMS maintenance can pose environmental risks if not handled properly.

On the positive side, effective thermal management can significantly extend battery life, reducing the frequency of battery replacements and the associated environmental impact of battery production and disposal. By optimizing battery performance and efficiency, BTMS can also indirectly reduce the overall energy consumption of electric vehicles and stationary energy storage systems, potentially offsetting some of its direct environmental costs.

The development of more environmentally friendly BTMS technologies is an active area of research. Innovations in phase change materials, thermoelectric cooling, and advanced passive cooling designs show promise in reducing the environmental footprint of thermal management systems. Additionally, the integration of BTMS with renewable energy sources for powering active cooling components could further mitigate environmental concerns.

In conclusion, while BTMS is essential for the optimal operation of blade batteries, its environmental impact must be carefully managed. Balancing the benefits of improved battery performance against the potential environmental costs requires ongoing research and innovation in sustainable thermal management solutions.

One of the primary environmental concerns associated with BTMS is energy consumption. Active cooling systems, such as liquid cooling or forced air circulation, require additional power to operate, which can increase the overall energy demand of the battery system. This increased energy consumption may lead to higher greenhouse gas emissions if the power source is not renewable. Passive cooling methods, while generally more energy-efficient, may not always provide sufficient temperature regulation for high-performance blade batteries.

The choice of materials used in BTMS also has environmental implications. Some cooling fluids and heat transfer materials may contain harmful chemicals or have a high global warming potential. The production and disposal of these materials can contribute to pollution and resource depletion. Additionally, the manufacturing processes for BTMS components, such as heat exchangers and cooling plates, may involve energy-intensive operations and the use of rare or non-renewable resources.

Waste generation is another environmental aspect to consider. As BTMS components wear out or become obsolete, they contribute to electronic waste streams. The complexity of these systems often makes recycling challenging, potentially leading to increased landfill usage. Furthermore, the disposal of cooling fluids and other consumables used in BTMS maintenance can pose environmental risks if not handled properly.

On the positive side, effective thermal management can significantly extend battery life, reducing the frequency of battery replacements and the associated environmental impact of battery production and disposal. By optimizing battery performance and efficiency, BTMS can also indirectly reduce the overall energy consumption of electric vehicles and stationary energy storage systems, potentially offsetting some of its direct environmental costs.

The development of more environmentally friendly BTMS technologies is an active area of research. Innovations in phase change materials, thermoelectric cooling, and advanced passive cooling designs show promise in reducing the environmental footprint of thermal management systems. Additionally, the integration of BTMS with renewable energy sources for powering active cooling components could further mitigate environmental concerns.

In conclusion, while BTMS is essential for the optimal operation of blade batteries, its environmental impact must be carefully managed. Balancing the benefits of improved battery performance against the potential environmental costs requires ongoing research and innovation in sustainable thermal management solutions.

Safety Standards for EV Battery Systems

Safety standards for electric vehicle (EV) battery systems are crucial for ensuring the safe operation and widespread adoption of electric vehicles. These standards encompass a wide range of requirements, including thermal management, electrical safety, mechanical integrity, and fire protection. For blade batteries, which are a relatively new technology in the EV industry, temperature regulation is particularly important for optimal performance and safety.

The International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) have developed comprehensive standards for EV battery systems. These include IEC 62660 for performance and abuse testing of lithium-ion batteries, and SAE J2929 for electric and hybrid vehicle propulsion battery system safety standards. These standards outline specific temperature ranges for safe operation, typically between -30°C and 55°C for most lithium-ion batteries.

Thermal runaway prevention is a key focus of safety standards for EV batteries. This phenomenon can occur when a battery cell overheats, potentially leading to a chain reaction of heat generation and cell failure. Standards require manufacturers to implement robust thermal management systems that can effectively dissipate heat and maintain uniform temperature distribution across the battery pack.

For blade batteries, which are known for their high energy density and compact design, temperature regulation presents unique challenges. Safety standards mandate the use of advanced cooling systems, such as liquid cooling or phase-change materials, to ensure that the battery operates within safe temperature limits even under high-load conditions or in extreme environmental temperatures.

Battery management systems (BMS) play a critical role in meeting safety standards. These systems must continuously monitor cell temperatures, voltage, and current, and be capable of rapidly shutting down the battery in case of detected anomalies. Standards require BMS to have redundant safety features and fail-safe mechanisms to prevent thermal runaway and other safety hazards.

Mechanical integrity standards for EV batteries, including blade batteries, focus on protecting the cells from external impacts and vibrations. This includes requirements for robust enclosures, impact-resistant designs, and vibration isolation systems. These standards aim to prevent physical damage to the battery cells that could lead to short circuits or thermal events.

Fire safety is another crucial aspect of EV battery standards. Regulations mandate the use of fire-resistant materials in battery construction and the implementation of effective fire suppression systems. For blade batteries, which have a unique form factor, specific fire safety protocols may need to be developed to address their particular characteristics.

The International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) have developed comprehensive standards for EV battery systems. These include IEC 62660 for performance and abuse testing of lithium-ion batteries, and SAE J2929 for electric and hybrid vehicle propulsion battery system safety standards. These standards outline specific temperature ranges for safe operation, typically between -30°C and 55°C for most lithium-ion batteries.

Thermal runaway prevention is a key focus of safety standards for EV batteries. This phenomenon can occur when a battery cell overheats, potentially leading to a chain reaction of heat generation and cell failure. Standards require manufacturers to implement robust thermal management systems that can effectively dissipate heat and maintain uniform temperature distribution across the battery pack.

For blade batteries, which are known for their high energy density and compact design, temperature regulation presents unique challenges. Safety standards mandate the use of advanced cooling systems, such as liquid cooling or phase-change materials, to ensure that the battery operates within safe temperature limits even under high-load conditions or in extreme environmental temperatures.

Battery management systems (BMS) play a critical role in meeting safety standards. These systems must continuously monitor cell temperatures, voltage, and current, and be capable of rapidly shutting down the battery in case of detected anomalies. Standards require BMS to have redundant safety features and fail-safe mechanisms to prevent thermal runaway and other safety hazards.

Mechanical integrity standards for EV batteries, including blade batteries, focus on protecting the cells from external impacts and vibrations. This includes requirements for robust enclosures, impact-resistant designs, and vibration isolation systems. These standards aim to prevent physical damage to the battery cells that could lead to short circuits or thermal events.

Fire safety is another crucial aspect of EV battery standards. Regulations mandate the use of fire-resistant materials in battery construction and the implementation of effective fire suppression systems. For blade batteries, which have a unique form factor, specific fire safety protocols may need to be developed to address their particular characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!