Strategies for Reducing Blade Battery Production Waste

AUG 7, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Waste Reduction Background and Objectives

The blade battery, a revolutionary technology in the electric vehicle (EV) industry, has garnered significant attention due to its enhanced safety features and improved energy density. However, as with any manufacturing process, the production of blade batteries generates waste, which poses both environmental and economic challenges. This report aims to explore strategies for reducing blade battery production waste, focusing on the background and objectives of this critical issue.

The development of blade batteries represents a significant leap forward in EV battery technology. Introduced by BYD in 2020, these batteries are designed to be safer and more space-efficient than traditional lithium-ion batteries. The blade-like cells are arranged in a way that maximizes energy density while minimizing the risk of thermal runaway. As the demand for EVs continues to grow globally, the production of blade batteries is expected to increase substantially in the coming years.

However, the manufacturing process of blade batteries, like any industrial production, generates waste. This waste can take various forms, including rejected cells, electrolyte residues, metal scraps, and packaging materials. The environmental impact of this waste is a growing concern, particularly as the scale of production expands to meet rising demand. Moreover, the economic implications of waste generation are significant, as it represents a loss of valuable materials and resources.

The primary objective of waste reduction strategies in blade battery production is to minimize the environmental footprint of the manufacturing process while simultaneously improving economic efficiency. This dual goal aligns with broader sustainability initiatives in the automotive and energy storage sectors. By reducing waste, manufacturers can not only lower their environmental impact but also decrease production costs, potentially making EVs more affordable and accessible to a wider market.

Another crucial objective is to enhance resource efficiency. Many of the materials used in blade battery production, such as lithium, cobalt, and nickel, are finite resources with complex supply chains. Reducing waste in the production process can help conserve these valuable materials and reduce dependence on raw material extraction. This approach is particularly important given the growing concerns about the sustainability and ethical sourcing of battery materials.

Furthermore, waste reduction strategies aim to improve the overall quality and consistency of blade battery production. By identifying and addressing the root causes of waste generation, manufacturers can refine their processes, leading to higher yields and more reliable products. This improvement in quality control can have far-reaching effects on the performance and longevity of EVs, further enhancing their appeal to consumers.

In conclusion, the background and objectives of reducing blade battery production waste are multifaceted, encompassing environmental, economic, and quality considerations. As the EV market continues to expand, developing effective waste reduction strategies will be crucial for sustainable growth in the industry. The following sections of this report will delve deeper into specific approaches and technologies that can be employed to achieve these objectives.

The development of blade batteries represents a significant leap forward in EV battery technology. Introduced by BYD in 2020, these batteries are designed to be safer and more space-efficient than traditional lithium-ion batteries. The blade-like cells are arranged in a way that maximizes energy density while minimizing the risk of thermal runaway. As the demand for EVs continues to grow globally, the production of blade batteries is expected to increase substantially in the coming years.

However, the manufacturing process of blade batteries, like any industrial production, generates waste. This waste can take various forms, including rejected cells, electrolyte residues, metal scraps, and packaging materials. The environmental impact of this waste is a growing concern, particularly as the scale of production expands to meet rising demand. Moreover, the economic implications of waste generation are significant, as it represents a loss of valuable materials and resources.

The primary objective of waste reduction strategies in blade battery production is to minimize the environmental footprint of the manufacturing process while simultaneously improving economic efficiency. This dual goal aligns with broader sustainability initiatives in the automotive and energy storage sectors. By reducing waste, manufacturers can not only lower their environmental impact but also decrease production costs, potentially making EVs more affordable and accessible to a wider market.

Another crucial objective is to enhance resource efficiency. Many of the materials used in blade battery production, such as lithium, cobalt, and nickel, are finite resources with complex supply chains. Reducing waste in the production process can help conserve these valuable materials and reduce dependence on raw material extraction. This approach is particularly important given the growing concerns about the sustainability and ethical sourcing of battery materials.

Furthermore, waste reduction strategies aim to improve the overall quality and consistency of blade battery production. By identifying and addressing the root causes of waste generation, manufacturers can refine their processes, leading to higher yields and more reliable products. This improvement in quality control can have far-reaching effects on the performance and longevity of EVs, further enhancing their appeal to consumers.

In conclusion, the background and objectives of reducing blade battery production waste are multifaceted, encompassing environmental, economic, and quality considerations. As the EV market continues to expand, developing effective waste reduction strategies will be crucial for sustainable growth in the industry. The following sections of this report will delve deeper into specific approaches and technologies that can be employed to achieve these objectives.

Market Demand for Sustainable Battery Production

The market demand for sustainable battery production has been growing rapidly in recent years, driven by increasing environmental awareness and stringent regulations. As the electric vehicle (EV) market expands, there is a pressing need for more efficient and eco-friendly battery manufacturing processes. The blade battery, known for its high energy density and improved safety features, has gained significant attention in the EV industry.

Consumers are becoming more conscious of the environmental impact of their purchases, leading to a surge in demand for sustainably produced batteries. This shift in consumer behavior has prompted automotive manufacturers to prioritize partnerships with battery suppliers that can demonstrate environmentally responsible production methods. The reduction of production waste in blade battery manufacturing aligns perfectly with this market trend.

Government policies and regulations worldwide are also playing a crucial role in shaping the market demand for sustainable battery production. Many countries have implemented or are in the process of implementing stricter environmental standards for manufacturing processes, including those in the battery industry. These regulations often include targets for reducing waste, emissions, and resource consumption, creating a strong incentive for battery manufacturers to adopt more sustainable practices.

The financial sector has also recognized the importance of sustainable production methods. Investors are increasingly considering environmental, social, and governance (ESG) factors when making investment decisions. Companies that can demonstrate a commitment to reducing production waste and improving sustainability in their battery manufacturing processes are more likely to attract investment and secure favorable financing terms.

In the competitive landscape of battery production, sustainability has become a key differentiator. Battery manufacturers that can effectively reduce production waste not only lower their operational costs but also enhance their brand image and market position. This competitive advantage is particularly significant in the high-end EV market, where consumers are often willing to pay a premium for products with strong environmental credentials.

The demand for sustainable battery production extends beyond the automotive sector. As renewable energy systems become more prevalent, there is a growing need for large-scale energy storage solutions. The blade battery's potential applications in grid storage and other stationary energy storage systems further amplify the market demand for sustainable production methods in this technology.

As the global focus on circular economy principles intensifies, there is an increasing emphasis on the entire lifecycle of batteries, from production to recycling. Manufacturers that can demonstrate reduced waste in their production processes are better positioned to address concerns about the overall environmental impact of battery technologies. This holistic approach to sustainability is becoming increasingly important to both consumers and regulatory bodies, further driving the demand for waste reduction strategies in blade battery production.

Consumers are becoming more conscious of the environmental impact of their purchases, leading to a surge in demand for sustainably produced batteries. This shift in consumer behavior has prompted automotive manufacturers to prioritize partnerships with battery suppliers that can demonstrate environmentally responsible production methods. The reduction of production waste in blade battery manufacturing aligns perfectly with this market trend.

Government policies and regulations worldwide are also playing a crucial role in shaping the market demand for sustainable battery production. Many countries have implemented or are in the process of implementing stricter environmental standards for manufacturing processes, including those in the battery industry. These regulations often include targets for reducing waste, emissions, and resource consumption, creating a strong incentive for battery manufacturers to adopt more sustainable practices.

The financial sector has also recognized the importance of sustainable production methods. Investors are increasingly considering environmental, social, and governance (ESG) factors when making investment decisions. Companies that can demonstrate a commitment to reducing production waste and improving sustainability in their battery manufacturing processes are more likely to attract investment and secure favorable financing terms.

In the competitive landscape of battery production, sustainability has become a key differentiator. Battery manufacturers that can effectively reduce production waste not only lower their operational costs but also enhance their brand image and market position. This competitive advantage is particularly significant in the high-end EV market, where consumers are often willing to pay a premium for products with strong environmental credentials.

The demand for sustainable battery production extends beyond the automotive sector. As renewable energy systems become more prevalent, there is a growing need for large-scale energy storage solutions. The blade battery's potential applications in grid storage and other stationary energy storage systems further amplify the market demand for sustainable production methods in this technology.

As the global focus on circular economy principles intensifies, there is an increasing emphasis on the entire lifecycle of batteries, from production to recycling. Manufacturers that can demonstrate reduced waste in their production processes are better positioned to address concerns about the overall environmental impact of battery technologies. This holistic approach to sustainability is becoming increasingly important to both consumers and regulatory bodies, further driving the demand for waste reduction strategies in blade battery production.

Current Challenges in Blade Battery Manufacturing

Blade battery production faces several significant challenges that impact efficiency, quality, and waste reduction efforts. One of the primary issues is the complexity of the manufacturing process, which involves multiple stages and precise control requirements. The intricate nature of blade battery assembly makes it susceptible to errors and inconsistencies, leading to increased waste and reduced yield rates.

Material handling and alignment present another major challenge. The thin, flexible nature of the battery components makes them difficult to manipulate and position accurately during assembly. Misalignment or damage during handling can result in defective units that must be discarded, contributing to production waste.

Quality control and consistency are ongoing concerns in blade battery manufacturing. Ensuring uniform electrode coating, electrolyte distribution, and sealing across large production volumes is challenging. Variations in these parameters can lead to performance inconsistencies and increased rejection rates, further exacerbating waste issues.

The high-precision requirements of blade battery production also pose challenges in terms of equipment calibration and maintenance. Even minor deviations in machine settings or wear and tear can result in out-of-specification products, necessitating frequent adjustments and potentially increasing downtime and waste.

Energy management during the production process is another critical challenge. The energy-intensive nature of certain manufacturing steps, such as electrode drying and cell formation, can lead to inefficiencies and increased costs if not optimized. Balancing energy consumption with production speed and quality is a delicate task that directly impacts waste generation and overall efficiency.

Raw material variability and supply chain management also contribute to manufacturing challenges. Inconsistencies in incoming materials can lead to quality issues downstream, while supply chain disruptions can result in production delays and potential waste of time-sensitive components.

Lastly, the rapid pace of technological advancement in battery design presents an ongoing challenge for manufacturers. Adapting production lines to accommodate new materials, designs, or processes while maintaining efficiency and minimizing waste requires continuous innovation and investment in flexible manufacturing systems.

Addressing these challenges is crucial for reducing blade battery production waste and improving overall manufacturing efficiency. Strategies for overcoming these obstacles will likely involve a combination of advanced process control, automation, improved material handling techniques, and innovative quality assurance methods.

Material handling and alignment present another major challenge. The thin, flexible nature of the battery components makes them difficult to manipulate and position accurately during assembly. Misalignment or damage during handling can result in defective units that must be discarded, contributing to production waste.

Quality control and consistency are ongoing concerns in blade battery manufacturing. Ensuring uniform electrode coating, electrolyte distribution, and sealing across large production volumes is challenging. Variations in these parameters can lead to performance inconsistencies and increased rejection rates, further exacerbating waste issues.

The high-precision requirements of blade battery production also pose challenges in terms of equipment calibration and maintenance. Even minor deviations in machine settings or wear and tear can result in out-of-specification products, necessitating frequent adjustments and potentially increasing downtime and waste.

Energy management during the production process is another critical challenge. The energy-intensive nature of certain manufacturing steps, such as electrode drying and cell formation, can lead to inefficiencies and increased costs if not optimized. Balancing energy consumption with production speed and quality is a delicate task that directly impacts waste generation and overall efficiency.

Raw material variability and supply chain management also contribute to manufacturing challenges. Inconsistencies in incoming materials can lead to quality issues downstream, while supply chain disruptions can result in production delays and potential waste of time-sensitive components.

Lastly, the rapid pace of technological advancement in battery design presents an ongoing challenge for manufacturers. Adapting production lines to accommodate new materials, designs, or processes while maintaining efficiency and minimizing waste requires continuous innovation and investment in flexible manufacturing systems.

Addressing these challenges is crucial for reducing blade battery production waste and improving overall manufacturing efficiency. Strategies for overcoming these obstacles will likely involve a combination of advanced process control, automation, improved material handling techniques, and innovative quality assurance methods.

Existing Waste Reduction Techniques in Battery Production

01 Waste management systems for blade battery production

Specialized waste management systems are designed for blade battery production facilities. These systems focus on efficient collection, sorting, and processing of various waste materials generated during manufacturing. They often include automated sorting mechanisms, waste reduction techniques, and environmentally friendly disposal methods to minimize the environmental impact of battery production.- Waste management in blade battery production: Efficient waste management systems are implemented in blade battery production to minimize environmental impact. These systems include recycling processes for materials like electrolytes and electrode scraps, as well as treatment methods for hazardous waste. Advanced filtration and separation techniques are used to recover valuable materials and reduce the volume of waste sent to landfills.

- Recycling of battery components: Innovative recycling methods are developed to recover and reuse various components of blade batteries. These techniques focus on extracting valuable metals, such as lithium, cobalt, and nickel, from spent batteries and production waste. The recycled materials can be reintegrated into the battery production process, reducing raw material costs and environmental impact.

- Waste reduction in manufacturing processes: Advanced manufacturing techniques are employed to minimize waste generation during blade battery production. These include precision cutting methods, optimized electrode coating processes, and improved quality control measures. By reducing material waste and improving production efficiency, manufacturers can significantly decrease the overall waste output.

- Treatment of hazardous waste: Specialized treatment processes are developed for handling hazardous waste generated during blade battery production. These include neutralization of acidic or alkaline waste, detoxification of heavy metals, and safe disposal of organic solvents. Advanced containment and treatment facilities ensure that hazardous materials are properly managed to prevent environmental contamination.

- Energy recovery from waste materials: Innovative technologies are implemented to recover energy from waste materials generated during blade battery production. These include thermal treatment processes that convert organic waste into usable energy, as well as methods for capturing and utilizing heat generated during various production stages. Energy recovery helps to offset the overall environmental impact of battery manufacturing.

02 Recycling and recovery of battery materials

Advanced recycling processes are developed to recover valuable materials from blade battery production waste. These methods typically involve chemical or mechanical separation techniques to extract metals, electrolytes, and other reusable components. The recovered materials can be reintegrated into the battery production cycle, reducing raw material costs and environmental impact.Expand Specific Solutions03 Waste reduction techniques in battery manufacturing

Innovative manufacturing processes are implemented to minimize waste generation in blade battery production. These techniques may include precision cutting methods, optimized material usage, and improved quality control measures. By reducing waste at the source, manufacturers can significantly decrease the overall environmental footprint of battery production.Expand Specific Solutions04 Treatment of hazardous waste from battery production

Specialized treatment processes are developed for handling hazardous waste generated during blade battery production. These may include neutralization of acidic or alkaline substances, detoxification of heavy metals, and safe disposal of volatile organic compounds. The goal is to render hazardous waste inert or less harmful before final disposal, ensuring compliance with environmental regulations.Expand Specific Solutions05 Energy recovery from battery production waste

Systems are designed to recover energy from waste materials generated in blade battery production. These may include thermal treatment processes that convert organic waste into usable heat or electricity, or biogas generation from biodegradable waste components. Energy recovery helps offset the power consumption of the manufacturing process, improving overall energy efficiency.Expand Specific Solutions

Key Players in Blade Battery Industry

The market for blade battery production waste reduction strategies is in a growth phase, driven by increasing demand for electric vehicles and sustainable energy storage solutions. The market size is expanding rapidly, with major players like Contemporary Amperex Technology Co., Ltd. (CATL), LG Energy Solution, and Samsung SDI investing heavily in research and development. Technologically, the field is advancing quickly, with companies like Panasonic and SK On developing innovative processes to minimize waste and improve efficiency. However, the technology is not yet fully mature, as evidenced by ongoing research efforts from institutions like the University of California and emerging startups entering the space. The competitive landscape is characterized by a mix of established battery manufacturers and specialized recycling firms, indicating a growing focus on circular economy principles in the industry.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a comprehensive strategy for reducing blade battery production waste. Their approach includes advanced manufacturing techniques, such as precision cutting and automated assembly, which minimize material waste during production[1]. They have also implemented a closed-loop recycling system, where production scrap and end-of-life batteries are collected and processed to recover valuable materials[2]. CATL's blade battery design itself contributes to waste reduction by using a simplified structure that requires fewer components and generates less waste during assembly[3]. Additionally, they have invested in AI-powered quality control systems that detect defects early in the production process, reducing the number of rejected batteries and associated waste[4].

Strengths: Integrated recycling system, advanced manufacturing techniques, and AI-powered quality control. Weaknesses: High initial investment costs for implementing waste reduction technologies and potential challenges in scaling up recycling operations for increasing production volumes.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has implemented a multi-faceted approach to reduce blade battery production waste. They have developed a proprietary "smart factory" system that utilizes big data and AI to optimize production processes and minimize material waste[1]. Their strategy includes the use of laser cutting technology for precise electrode manufacturing, which significantly reduces scrap rates[2]. LG has also invested in advanced recycling technologies, including a hydrometallurgical process that can recover up to 95% of key materials from battery waste[3]. Furthermore, they have implemented a modular battery design that allows for easier disassembly and recycling at the end of the battery's life, indirectly reducing overall waste in the battery lifecycle[4].

Strengths: High-tech manufacturing processes, advanced recycling capabilities, and modular design approach. Weaknesses: Dependence on complex technologies may lead to higher production costs and potential disruptions if systems fail.

Innovative Approaches to Minimize Battery Material Waste

Blade and production methods

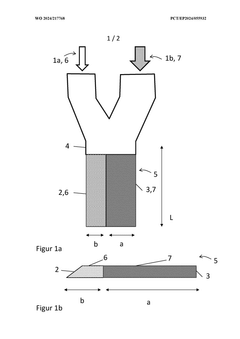

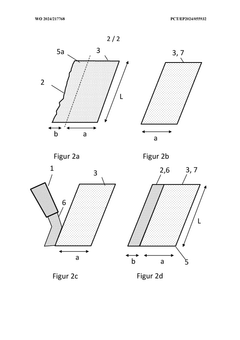

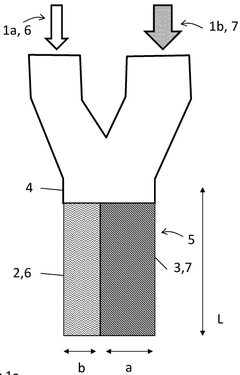

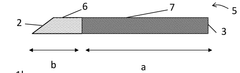

PatentWO2024217768A1

Innovation

- A blade composed of two polymer components, where a high-quality first component is used for the wear side and a lower-quality second component for the holder side, with the latter potentially being regranulated or recycled material, allowing for a high proportion of reused material and reducing waste through coextrusion or reprocessing of old blades.

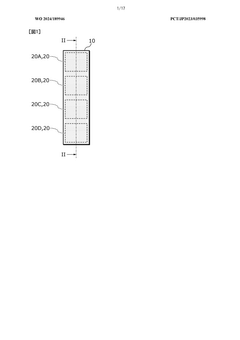

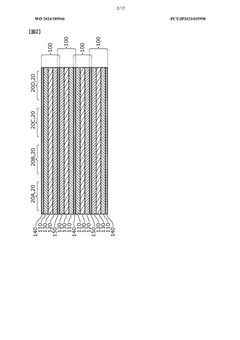

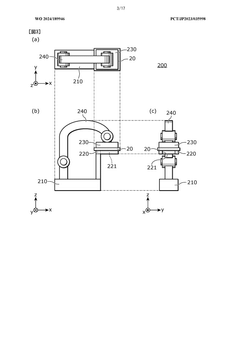

Battery manufacturing method and battery manufacturing system

PatentWO2024189946A1

Innovation

- A battery manufacturing method and system that involves fixing power generation elements in a flat plate, cutting them individually, and using holding units with adjustable positional relationships to maintain optimal positions for subsequent processing steps, including polishing and coating, to enhance productivity and reduce the risk of damage.

Environmental Regulations Impact on Battery Production

Environmental regulations play a crucial role in shaping the landscape of battery production, particularly in the context of reducing blade battery production waste. These regulations are designed to mitigate the environmental impact of manufacturing processes and promote sustainable practices within the industry.

One of the primary areas of focus for environmental regulations is the management of hazardous materials used in battery production. Many countries have implemented strict guidelines for the handling, storage, and disposal of chemicals and materials that pose potential risks to the environment. These regulations often require manufacturers to implement robust waste management systems, including proper segregation, treatment, and disposal of hazardous waste.

Additionally, regulations often mandate the implementation of pollution control measures to minimize air and water emissions from battery production facilities. This may include the installation of advanced filtration systems, scrubbers, and other technologies to capture and treat pollutants before they are released into the environment. Compliance with these regulations often necessitates significant investments in infrastructure and equipment upgrades.

Energy efficiency is another key aspect addressed by environmental regulations. Many jurisdictions have established energy consumption standards for manufacturing processes, encouraging companies to adopt more efficient technologies and practices. This not only reduces the environmental footprint of battery production but also helps to lower operational costs in the long run.

The concept of extended producer responsibility (EPR) has gained traction in recent years, with regulations requiring battery manufacturers to take responsibility for the entire lifecycle of their products. This includes the collection, recycling, and proper disposal of batteries at the end of their useful life. Such regulations aim to promote a circular economy approach and reduce the overall environmental impact of battery production and consumption.

Water usage and conservation are also subject to regulatory scrutiny in many regions. Manufacturers may be required to implement water recycling systems, reduce overall water consumption, and ensure proper treatment of wastewater before discharge. These measures are particularly important in areas facing water scarcity or where water resources are under stress.

As the demand for batteries continues to grow, particularly in the electric vehicle sector, regulatory bodies are increasingly focusing on the sustainability of raw material sourcing. This includes requirements for responsible mining practices, traceability of materials, and the use of recycled content in battery production. Such regulations aim to address concerns about the environmental and social impacts of resource extraction.

The impact of these environmental regulations on battery production strategies is significant. Manufacturers must continuously adapt their processes and technologies to meet evolving regulatory requirements while striving to maintain competitiveness in the market. This often drives innovation in production techniques, materials science, and waste reduction strategies, ultimately contributing to the development of more sustainable and environmentally friendly battery technologies.

One of the primary areas of focus for environmental regulations is the management of hazardous materials used in battery production. Many countries have implemented strict guidelines for the handling, storage, and disposal of chemicals and materials that pose potential risks to the environment. These regulations often require manufacturers to implement robust waste management systems, including proper segregation, treatment, and disposal of hazardous waste.

Additionally, regulations often mandate the implementation of pollution control measures to minimize air and water emissions from battery production facilities. This may include the installation of advanced filtration systems, scrubbers, and other technologies to capture and treat pollutants before they are released into the environment. Compliance with these regulations often necessitates significant investments in infrastructure and equipment upgrades.

Energy efficiency is another key aspect addressed by environmental regulations. Many jurisdictions have established energy consumption standards for manufacturing processes, encouraging companies to adopt more efficient technologies and practices. This not only reduces the environmental footprint of battery production but also helps to lower operational costs in the long run.

The concept of extended producer responsibility (EPR) has gained traction in recent years, with regulations requiring battery manufacturers to take responsibility for the entire lifecycle of their products. This includes the collection, recycling, and proper disposal of batteries at the end of their useful life. Such regulations aim to promote a circular economy approach and reduce the overall environmental impact of battery production and consumption.

Water usage and conservation are also subject to regulatory scrutiny in many regions. Manufacturers may be required to implement water recycling systems, reduce overall water consumption, and ensure proper treatment of wastewater before discharge. These measures are particularly important in areas facing water scarcity or where water resources are under stress.

As the demand for batteries continues to grow, particularly in the electric vehicle sector, regulatory bodies are increasingly focusing on the sustainability of raw material sourcing. This includes requirements for responsible mining practices, traceability of materials, and the use of recycled content in battery production. Such regulations aim to address concerns about the environmental and social impacts of resource extraction.

The impact of these environmental regulations on battery production strategies is significant. Manufacturers must continuously adapt their processes and technologies to meet evolving regulatory requirements while striving to maintain competitiveness in the market. This often drives innovation in production techniques, materials science, and waste reduction strategies, ultimately contributing to the development of more sustainable and environmentally friendly battery technologies.

Economic Analysis of Waste Reduction Strategies

The economic analysis of waste reduction strategies for blade battery production is crucial for optimizing manufacturing processes and enhancing overall efficiency. This analysis encompasses various aspects, including cost-benefit assessments, return on investment calculations, and long-term financial implications of implementing waste reduction measures.

One of the primary considerations in this analysis is the initial investment required for implementing waste reduction strategies. This may involve upgrading equipment, redesigning production lines, or introducing new technologies. While these upfront costs can be substantial, they need to be weighed against the potential long-term savings and benefits.

The cost savings from waste reduction can be significant and multifaceted. Direct material savings are often the most apparent benefit, as reducing waste means more efficient use of raw materials. This not only decreases material costs but also reduces expenses related to waste disposal and management. Additionally, improved production efficiency can lead to lower energy consumption and reduced labor costs associated with handling and processing waste.

Another economic factor to consider is the potential increase in production yield. By minimizing waste, manufacturers can produce more batteries from the same amount of raw materials, effectively increasing output without proportionally increasing input costs. This improved yield can have a substantial impact on overall profitability and competitiveness in the market.

The analysis should also take into account the potential for creating new revenue streams from waste materials. Some waste reduction strategies may involve recycling or repurposing materials that would otherwise be discarded. These recycled materials could be sold or used in other production processes, turning a cost center into a potential profit generator.

Environmental regulations and compliance costs are increasingly important factors in the economic analysis. As regulations become more stringent, the cost of non-compliance or inefficient waste management can be substantial. Implementing effective waste reduction strategies can help companies avoid fines, penalties, and other regulatory-related expenses.

The time frame for realizing returns on waste reduction investments is another critical aspect of the economic analysis. Some strategies may offer quick paybacks, while others might require a longer-term perspective to see significant economic benefits. This time-to-value consideration is essential for prioritizing different waste reduction initiatives and aligning them with the company's financial goals and constraints.

Lastly, the analysis should consider the broader market implications of waste reduction efforts. Companies that demonstrate strong environmental stewardship and efficient resource use may gain a competitive advantage in the market. This can lead to increased customer preference, potential price premiums, and improved brand value, all of which have tangible economic benefits that should be factored into the overall analysis.

One of the primary considerations in this analysis is the initial investment required for implementing waste reduction strategies. This may involve upgrading equipment, redesigning production lines, or introducing new technologies. While these upfront costs can be substantial, they need to be weighed against the potential long-term savings and benefits.

The cost savings from waste reduction can be significant and multifaceted. Direct material savings are often the most apparent benefit, as reducing waste means more efficient use of raw materials. This not only decreases material costs but also reduces expenses related to waste disposal and management. Additionally, improved production efficiency can lead to lower energy consumption and reduced labor costs associated with handling and processing waste.

Another economic factor to consider is the potential increase in production yield. By minimizing waste, manufacturers can produce more batteries from the same amount of raw materials, effectively increasing output without proportionally increasing input costs. This improved yield can have a substantial impact on overall profitability and competitiveness in the market.

The analysis should also take into account the potential for creating new revenue streams from waste materials. Some waste reduction strategies may involve recycling or repurposing materials that would otherwise be discarded. These recycled materials could be sold or used in other production processes, turning a cost center into a potential profit generator.

Environmental regulations and compliance costs are increasingly important factors in the economic analysis. As regulations become more stringent, the cost of non-compliance or inefficient waste management can be substantial. Implementing effective waste reduction strategies can help companies avoid fines, penalties, and other regulatory-related expenses.

The time frame for realizing returns on waste reduction investments is another critical aspect of the economic analysis. Some strategies may offer quick paybacks, while others might require a longer-term perspective to see significant economic benefits. This time-to-value consideration is essential for prioritizing different waste reduction initiatives and aligning them with the company's financial goals and constraints.

Lastly, the analysis should consider the broader market implications of waste reduction efforts. Companies that demonstrate strong environmental stewardship and efficient resource use may gain a competitive advantage in the market. This can lead to increased customer preference, potential price premiums, and improved brand value, all of which have tangible economic benefits that should be factored into the overall analysis.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!