Innovations in Blade Battery for Smart Grid Integration

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Blade Battery Evolution and Smart Grid Goals

The evolution of blade batteries represents a significant leap forward in energy storage technology, particularly in the context of smart grid integration. Originating from the need for safer and more efficient energy storage solutions, blade batteries have emerged as a promising alternative to traditional lithium-ion batteries. This technology, characterized by its unique structural design and enhanced safety features, has been steadily advancing over the past decade.

The primary goal of blade battery development in relation to smart grid integration is to create a more resilient, flexible, and efficient energy storage system. As smart grids become increasingly complex and decentralized, the demand for advanced energy storage solutions that can seamlessly integrate with these systems has grown exponentially. Blade batteries aim to meet this demand by offering improved energy density, faster charging capabilities, and enhanced safety features.

One of the key objectives in the evolution of blade batteries is to increase their energy density while maintaining or improving safety standards. This is crucial for smart grid applications, where space efficiency and reliability are paramount. Researchers and manufacturers are focusing on optimizing the battery's internal structure and materials to achieve higher energy storage capacity without compromising on safety or longevity.

Another important goal is to enhance the charging and discharging capabilities of blade batteries. In smart grid environments, the ability to rapidly respond to fluctuations in energy demand and supply is essential. Blade battery technology is being refined to support faster charging rates and more efficient energy transfer, enabling better grid stabilization and load balancing.

Durability and lifespan are also key considerations in the development of blade batteries for smart grid integration. The aim is to create batteries that can withstand numerous charge-discharge cycles while maintaining consistent performance over an extended period. This longevity is crucial for reducing maintenance costs and ensuring the reliability of smart grid infrastructure.

Furthermore, the integration of advanced monitoring and management systems into blade batteries is a critical goal. These systems aim to provide real-time data on battery health, performance, and energy flow, facilitating more efficient grid management and predictive maintenance. This level of intelligence is essential for optimizing the overall performance of smart grids and ensuring seamless integration of renewable energy sources.

As the technology continues to evolve, there is also a focus on improving the environmental sustainability of blade batteries. This includes developing more eco-friendly manufacturing processes, using recyclable materials, and designing batteries that are easier to disassemble and recycle at the end of their lifecycle. These efforts align with the broader goals of smart grids in promoting sustainable energy solutions.

The primary goal of blade battery development in relation to smart grid integration is to create a more resilient, flexible, and efficient energy storage system. As smart grids become increasingly complex and decentralized, the demand for advanced energy storage solutions that can seamlessly integrate with these systems has grown exponentially. Blade batteries aim to meet this demand by offering improved energy density, faster charging capabilities, and enhanced safety features.

One of the key objectives in the evolution of blade batteries is to increase their energy density while maintaining or improving safety standards. This is crucial for smart grid applications, where space efficiency and reliability are paramount. Researchers and manufacturers are focusing on optimizing the battery's internal structure and materials to achieve higher energy storage capacity without compromising on safety or longevity.

Another important goal is to enhance the charging and discharging capabilities of blade batteries. In smart grid environments, the ability to rapidly respond to fluctuations in energy demand and supply is essential. Blade battery technology is being refined to support faster charging rates and more efficient energy transfer, enabling better grid stabilization and load balancing.

Durability and lifespan are also key considerations in the development of blade batteries for smart grid integration. The aim is to create batteries that can withstand numerous charge-discharge cycles while maintaining consistent performance over an extended period. This longevity is crucial for reducing maintenance costs and ensuring the reliability of smart grid infrastructure.

Furthermore, the integration of advanced monitoring and management systems into blade batteries is a critical goal. These systems aim to provide real-time data on battery health, performance, and energy flow, facilitating more efficient grid management and predictive maintenance. This level of intelligence is essential for optimizing the overall performance of smart grids and ensuring seamless integration of renewable energy sources.

As the technology continues to evolve, there is also a focus on improving the environmental sustainability of blade batteries. This includes developing more eco-friendly manufacturing processes, using recyclable materials, and designing batteries that are easier to disassemble and recycle at the end of their lifecycle. These efforts align with the broader goals of smart grids in promoting sustainable energy solutions.

Smart Grid Market Demand Analysis

The smart grid market is experiencing significant growth driven by the increasing demand for efficient and reliable energy distribution systems. As the global energy landscape shifts towards renewable sources and decentralized generation, the need for advanced grid management solutions has become paramount. The integration of blade batteries into smart grid systems represents a crucial innovation in this evolving market.

Market analysis indicates that the smart grid sector is projected to expand rapidly in the coming years, with a particular focus on energy storage solutions. The blade battery technology, known for its enhanced safety features and high energy density, is well-positioned to address the growing demand for reliable and efficient energy storage within smart grid infrastructures.

One of the primary drivers for smart grid adoption is the push for greater grid resilience and flexibility. As extreme weather events become more frequent and severe, utilities and grid operators are seeking robust solutions to maintain power supply stability. Blade batteries, with their improved thermal management and reduced risk of thermal runaway, offer a compelling solution for grid-scale energy storage, potentially reducing downtime and improving overall grid reliability.

The integration of renewable energy sources into existing power grids presents another significant market opportunity for blade battery technology. As solar and wind power generation continues to increase, the need for advanced energy storage systems to manage intermittency and load balancing becomes critical. Blade batteries, with their high cycle life and fast charging capabilities, are well-suited to support the integration of these variable renewable energy sources into smart grid systems.

Furthermore, the growing trend towards electric vehicle (EV) adoption is creating new challenges and opportunities for smart grid development. The potential for vehicle-to-grid (V2G) technology, where EVs can serve as distributed energy resources, aligns well with the capabilities of blade batteries. Their high energy density and improved safety features make them an attractive option for both EV manufacturers and grid operators looking to leverage V2G technology.

The market demand for smart grid solutions is also being driven by regulatory initiatives and government incentives aimed at modernizing energy infrastructure and reducing carbon emissions. Many countries have set ambitious targets for renewable energy integration and grid modernization, creating a favorable environment for innovative technologies like blade batteries.

In conclusion, the market demand for smart grid solutions incorporating advanced energy storage technologies such as blade batteries is robust and growing. The combination of increasing renewable energy integration, the need for grid resilience, and the electrification of transportation is creating a fertile ground for innovations in this space. As the technology continues to mature and demonstrate its value in real-world applications, it is likely to play an increasingly important role in shaping the future of smart grid infrastructure.

Market analysis indicates that the smart grid sector is projected to expand rapidly in the coming years, with a particular focus on energy storage solutions. The blade battery technology, known for its enhanced safety features and high energy density, is well-positioned to address the growing demand for reliable and efficient energy storage within smart grid infrastructures.

One of the primary drivers for smart grid adoption is the push for greater grid resilience and flexibility. As extreme weather events become more frequent and severe, utilities and grid operators are seeking robust solutions to maintain power supply stability. Blade batteries, with their improved thermal management and reduced risk of thermal runaway, offer a compelling solution for grid-scale energy storage, potentially reducing downtime and improving overall grid reliability.

The integration of renewable energy sources into existing power grids presents another significant market opportunity for blade battery technology. As solar and wind power generation continues to increase, the need for advanced energy storage systems to manage intermittency and load balancing becomes critical. Blade batteries, with their high cycle life and fast charging capabilities, are well-suited to support the integration of these variable renewable energy sources into smart grid systems.

Furthermore, the growing trend towards electric vehicle (EV) adoption is creating new challenges and opportunities for smart grid development. The potential for vehicle-to-grid (V2G) technology, where EVs can serve as distributed energy resources, aligns well with the capabilities of blade batteries. Their high energy density and improved safety features make them an attractive option for both EV manufacturers and grid operators looking to leverage V2G technology.

The market demand for smart grid solutions is also being driven by regulatory initiatives and government incentives aimed at modernizing energy infrastructure and reducing carbon emissions. Many countries have set ambitious targets for renewable energy integration and grid modernization, creating a favorable environment for innovative technologies like blade batteries.

In conclusion, the market demand for smart grid solutions incorporating advanced energy storage technologies such as blade batteries is robust and growing. The combination of increasing renewable energy integration, the need for grid resilience, and the electrification of transportation is creating a fertile ground for innovations in this space. As the technology continues to mature and demonstrate its value in real-world applications, it is likely to play an increasingly important role in shaping the future of smart grid infrastructure.

Blade Battery Technology Challenges

The integration of Blade Battery technology into smart grid systems presents several significant challenges that need to be addressed for successful implementation. One of the primary obstacles is the optimization of battery management systems (BMS) to handle the unique characteristics of Blade Batteries. These batteries require sophisticated control algorithms to manage their charge and discharge cycles effectively, ensuring optimal performance and longevity within the smart grid environment.

Another critical challenge lies in the thermal management of Blade Batteries when integrated into large-scale energy storage systems. The compact design of these batteries, while advantageous for energy density, can lead to heat accumulation issues. Developing efficient cooling systems that can maintain optimal operating temperatures across diverse environmental conditions is crucial for ensuring the reliability and safety of smart grid installations.

Scalability presents a further hurdle in the widespread adoption of Blade Batteries for smart grid applications. As energy demands fluctuate, the ability to seamlessly integrate additional battery capacity or replace aging units becomes essential. This requires the development of modular designs and standardized interfaces that allow for easy expansion and maintenance of energy storage systems without disrupting grid operations.

The long-term cycling stability of Blade Batteries in smart grid scenarios is another area of concern. While these batteries show promising performance in laboratory settings, their behavior under real-world conditions, including frequent charge-discharge cycles and varying load profiles, needs further investigation. Ensuring consistent performance over extended periods is crucial for the economic viability of smart grid projects.

Data management and communication protocols pose additional challenges. Smart grids require real-time monitoring and control of energy storage systems. Developing robust, secure, and interoperable communication systems that can handle the vast amount of data generated by Blade Battery installations is essential for effective grid management and optimization.

Safety considerations remain paramount, particularly given the high energy density of Blade Batteries. Implementing fail-safe mechanisms, advanced fire suppression systems, and rigorous safety protocols is critical to mitigate risks associated with large-scale battery deployments in urban and industrial settings.

Lastly, the environmental impact and end-of-life management of Blade Batteries present ongoing challenges. Developing efficient recycling processes and establishing a circular economy for battery materials are essential for ensuring the long-term sustainability of this technology in smart grid applications.

Another critical challenge lies in the thermal management of Blade Batteries when integrated into large-scale energy storage systems. The compact design of these batteries, while advantageous for energy density, can lead to heat accumulation issues. Developing efficient cooling systems that can maintain optimal operating temperatures across diverse environmental conditions is crucial for ensuring the reliability and safety of smart grid installations.

Scalability presents a further hurdle in the widespread adoption of Blade Batteries for smart grid applications. As energy demands fluctuate, the ability to seamlessly integrate additional battery capacity or replace aging units becomes essential. This requires the development of modular designs and standardized interfaces that allow for easy expansion and maintenance of energy storage systems without disrupting grid operations.

The long-term cycling stability of Blade Batteries in smart grid scenarios is another area of concern. While these batteries show promising performance in laboratory settings, their behavior under real-world conditions, including frequent charge-discharge cycles and varying load profiles, needs further investigation. Ensuring consistent performance over extended periods is crucial for the economic viability of smart grid projects.

Data management and communication protocols pose additional challenges. Smart grids require real-time monitoring and control of energy storage systems. Developing robust, secure, and interoperable communication systems that can handle the vast amount of data generated by Blade Battery installations is essential for effective grid management and optimization.

Safety considerations remain paramount, particularly given the high energy density of Blade Batteries. Implementing fail-safe mechanisms, advanced fire suppression systems, and rigorous safety protocols is critical to mitigate risks associated with large-scale battery deployments in urban and industrial settings.

Lastly, the environmental impact and end-of-life management of Blade Batteries present ongoing challenges. Developing efficient recycling processes and establishing a circular economy for battery materials are essential for ensuring the long-term sustainability of this technology in smart grid applications.

Current Blade Battery Integration Solutions

01 Battery structure and design

Blade batteries feature a unique structural design that optimizes space utilization and energy density. The design typically involves thin, elongated cells arranged in a parallel configuration, resembling blades. This structure allows for improved thermal management and enhanced safety features compared to traditional battery designs.- Blade battery structure and design: Blade batteries feature a unique structural design that optimizes space utilization and energy density. The thin, elongated shape allows for efficient packaging in electric vehicles, improving overall battery performance and range. This design also enhances heat dissipation and structural integrity, contributing to improved safety and longevity of the battery pack.

- Safety features of blade batteries: Blade batteries incorporate advanced safety features to prevent thermal runaway and enhance overall battery safety. These may include improved thermal management systems, robust cell separators, and innovative electrode designs. The safety enhancements aim to reduce the risk of fire or explosion, making blade batteries a safer option for electric vehicles.

- Manufacturing processes for blade batteries: The production of blade batteries involves specialized manufacturing techniques to ensure high quality and consistency. This may include advanced electrode coating methods, precise cell assembly processes, and stringent quality control measures. The manufacturing processes are designed to optimize the performance and reliability of blade batteries while maintaining cost-effectiveness.

- Integration of blade batteries in electric vehicles: Blade batteries are designed for seamless integration into electric vehicle platforms. Their unique form factor allows for flexible placement within the vehicle chassis, potentially improving weight distribution and vehicle dynamics. The integration process may involve specialized mounting systems and cooling solutions to maximize the benefits of the blade battery design.

- Performance characteristics of blade batteries: Blade batteries offer several performance advantages, including high energy density, fast charging capabilities, and long cycle life. These batteries may exhibit improved power output and better low-temperature performance compared to traditional lithium-ion batteries. The unique design of blade batteries contributes to their overall efficiency and reliability in electric vehicle applications.

02 Safety mechanisms

Blade batteries incorporate advanced safety mechanisms to prevent thermal runaway and other potential hazards. These may include improved insulation materials, pressure relief systems, and innovative cell separation techniques. The design aims to enhance overall battery safety and reliability in various applications.Expand Specific Solutions03 Manufacturing and assembly processes

The production of blade batteries involves specialized manufacturing and assembly processes. These may include precision cutting techniques for electrode materials, advanced stacking methods for cell components, and automated assembly lines designed specifically for blade battery production. The processes aim to ensure consistent quality and high production efficiency.Expand Specific Solutions04 Integration with electric vehicles

Blade batteries are particularly well-suited for integration into electric vehicle designs. Their compact form factor allows for efficient packaging within vehicle chassis, potentially increasing range and performance. Specialized mounting systems and cooling solutions may be employed to optimize the battery's performance in automotive applications.Expand Specific Solutions05 Battery management and monitoring systems

Advanced battery management systems (BMS) are crucial for optimizing the performance and longevity of blade batteries. These systems may include sophisticated monitoring of individual cell voltages, temperatures, and state of charge. Additionally, they may incorporate predictive algorithms for battery health assessment and adaptive charging strategies.Expand Specific Solutions

Key Players in Blade Battery and Smart Grid

The blade battery technology for smart grid integration is in an early growth stage, with increasing market potential as smart grids expand globally. The market size is projected to grow significantly, driven by the rising demand for efficient energy storage solutions. Technologically, blade batteries are advancing rapidly, with companies like BYD Co., Ltd. and Svolt Energy Technology Co., Ltd. leading innovation. These firms, along with others like LG Energy Solution Ltd. and Johnson Controls, Inc., are investing heavily in R&D to improve energy density, charging speed, and grid integration capabilities. The competitive landscape is intensifying as both established players and startups vie for market share in this promising sector.

BYD Co., Ltd.

Technical Solution: BYD's Blade Battery is a revolutionary innovation for smart grid integration. This lithium iron phosphate (LFP) battery utilizes a unique cell-to-pack design, eliminating the need for module housing[1]. The blade-shaped cells are arranged in arrays and inserted into a battery pack, significantly improving space utilization and energy density. For smart grid applications, BYD has developed advanced battery management systems (BMS) that enable real-time monitoring and control of each cell[2]. This allows for more efficient power distribution and grid stabilization. The Blade Battery also incorporates Vehicle-to-Grid (V2G) technology, enabling electric vehicles to act as mobile energy storage units, feeding power back to the grid during peak demand periods[3]. BYD has also implemented predictive maintenance algorithms that use AI to optimize battery performance and longevity in grid-connected systems[4].

Strengths: High energy density, improved safety, long cycle life, and advanced grid integration capabilities. Weaknesses: Higher initial cost compared to traditional batteries, and potential scalability challenges for widespread grid adoption.

Johnson Controls, Inc.

Technical Solution: Johnson Controls has developed innovative battery solutions for smart grid integration, leveraging their expertise in both building technologies and energy storage. Their focus has been on advanced lead-acid and lithium-ion battery systems optimized for grid-scale applications. Johnson Controls' batteries utilize a proprietary electrolyte formulation that enhances cycle life and performance in grid storage scenarios[1]. For smart grid integration, they have implemented an intelligent power management system that optimizes battery performance based on real-time grid demand and renewable energy generation[2]. Their batteries incorporate advanced thermal management techniques, including liquid cooling systems, to maintain optimal operating temperatures in large-scale grid storage installations[3]. Johnson Controls has also developed a modular, scalable battery architecture that allows for easy expansion and integration with existing grid infrastructure[4]. Additionally, they have implemented predictive maintenance algorithms and remote monitoring capabilities to enhance the reliability and efficiency of grid-connected battery systems[5].

Strengths: Extensive experience in energy storage, advanced power management systems, and scalable solutions for grid applications. Weaknesses: Potential limitations in energy density for lead-acid technologies, and competition from newer, more specialized battery manufacturers in the smart grid sector.

Core Innovations in Blade Battery Technology

Smart battery

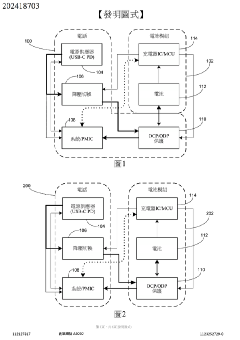

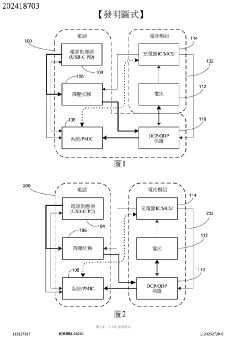

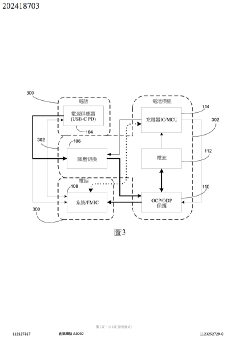

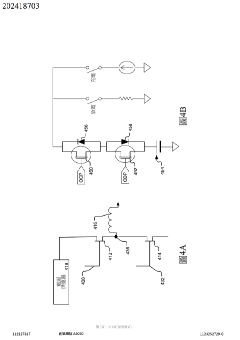

PatentActiveTW202418703A

Innovation

- Incorporation of integrated intelligence (processing capability and/or memory) within the battery to facilitate sophisticated charging techniques.

- Positioning of functional units of the charging circuit between the mobile device and the battery unit.

- Adaptability to new battery arrangements, allowing for battery technology upgrades in mobile devices.

Regulatory Framework for Grid-Connected Batteries

The regulatory framework for grid-connected batteries plays a crucial role in the integration of Blade Batteries into smart grid systems. As these innovative energy storage solutions become more prevalent, governments and regulatory bodies are developing comprehensive guidelines to ensure their safe and efficient operation within the existing power infrastructure.

At the federal level, the Federal Energy Regulatory Commission (FERC) has issued several orders to facilitate the integration of energy storage resources into wholesale electricity markets. Order No. 841, in particular, requires grid operators to establish market rules that recognize the unique characteristics of energy storage resources, including Blade Batteries. This order aims to remove barriers to participation and create a level playing field for energy storage technologies.

State-level regulations also significantly impact the deployment of grid-connected batteries. Many states have implemented energy storage targets and incentive programs to encourage the adoption of advanced battery technologies. For instance, California's Assembly Bill 2514 mandates that utilities procure specific amounts of energy storage capacity, driving innovation and investment in technologies like Blade Batteries.

Interconnection standards are another critical aspect of the regulatory framework. IEEE 1547, the standard for interconnecting distributed energy resources with electric power systems, has been updated to address the unique characteristics of energy storage systems. This standard provides guidelines for the safe and reliable integration of Blade Batteries and other storage technologies into the grid.

Safety regulations are paramount in the deployment of grid-connected batteries. The National Fire Protection Association (NFPA) has developed standards specifically for the installation of stationary energy storage systems, addressing fire protection and safety concerns associated with large-scale battery installations.

Environmental regulations also play a role in shaping the deployment of Blade Batteries. The Environmental Protection Agency (EPA) has established guidelines for the proper disposal and recycling of lithium-ion batteries, which may apply to Blade Batteries at the end of their lifecycle.

As the technology evolves, regulatory frameworks are expected to adapt to address new challenges and opportunities presented by Blade Batteries and other advanced energy storage solutions. Ongoing collaboration between industry stakeholders, policymakers, and regulatory bodies will be essential to create a supportive environment for the widespread adoption of these innovative technologies in smart grid applications.

At the federal level, the Federal Energy Regulatory Commission (FERC) has issued several orders to facilitate the integration of energy storage resources into wholesale electricity markets. Order No. 841, in particular, requires grid operators to establish market rules that recognize the unique characteristics of energy storage resources, including Blade Batteries. This order aims to remove barriers to participation and create a level playing field for energy storage technologies.

State-level regulations also significantly impact the deployment of grid-connected batteries. Many states have implemented energy storage targets and incentive programs to encourage the adoption of advanced battery technologies. For instance, California's Assembly Bill 2514 mandates that utilities procure specific amounts of energy storage capacity, driving innovation and investment in technologies like Blade Batteries.

Interconnection standards are another critical aspect of the regulatory framework. IEEE 1547, the standard for interconnecting distributed energy resources with electric power systems, has been updated to address the unique characteristics of energy storage systems. This standard provides guidelines for the safe and reliable integration of Blade Batteries and other storage technologies into the grid.

Safety regulations are paramount in the deployment of grid-connected batteries. The National Fire Protection Association (NFPA) has developed standards specifically for the installation of stationary energy storage systems, addressing fire protection and safety concerns associated with large-scale battery installations.

Environmental regulations also play a role in shaping the deployment of Blade Batteries. The Environmental Protection Agency (EPA) has established guidelines for the proper disposal and recycling of lithium-ion batteries, which may apply to Blade Batteries at the end of their lifecycle.

As the technology evolves, regulatory frameworks are expected to adapt to address new challenges and opportunities presented by Blade Batteries and other advanced energy storage solutions. Ongoing collaboration between industry stakeholders, policymakers, and regulatory bodies will be essential to create a supportive environment for the widespread adoption of these innovative technologies in smart grid applications.

Environmental Impact of Blade Batteries

The environmental impact of blade batteries in smart grid integration is a crucial consideration as these innovative energy storage solutions become more prevalent. Blade batteries, known for their high energy density and improved safety features, offer significant advantages in terms of efficiency and reliability. However, their environmental footprint throughout their lifecycle must be carefully assessed.

The production of blade batteries involves the extraction and processing of raw materials, including lithium, iron, and phosphate. While these materials are generally more abundant and less environmentally harmful than those used in traditional lithium-ion batteries, their mining and refinement still have ecological implications. Efforts are being made to develop more sustainable sourcing practices and to increase the use of recycled materials in battery production.

During their operational life, blade batteries contribute to reducing greenhouse gas emissions by enabling greater integration of renewable energy sources into smart grids. They help balance supply and demand, storing excess energy during peak production periods and releasing it when needed. This capability significantly enhances the efficiency of renewable energy systems and reduces reliance on fossil fuel-based power generation.

The long lifespan of blade batteries, typically exceeding that of conventional lithium-ion batteries, is another environmental advantage. This durability means fewer replacements are needed over time, reducing the overall resource consumption and waste generation associated with battery production and disposal. Additionally, the improved safety features of blade batteries, such as enhanced thermal stability, reduce the risk of fires and other hazardous incidents that could have negative environmental consequences.

End-of-life management is a critical aspect of blade battery environmental impact. As these batteries reach the end of their useful life in grid applications, proper recycling and disposal processes are essential. The battery industry is developing advanced recycling technologies to recover valuable materials from spent blade batteries, minimizing waste and reducing the need for virgin raw materials in new battery production.

The integration of blade batteries into smart grids also has indirect environmental benefits. By improving grid stability and efficiency, these batteries enable greater adoption of electric vehicles and distributed energy resources. This shift away from fossil fuel-dependent transportation and centralized power generation contributes to overall reductions in carbon emissions and air pollution.

However, challenges remain in fully optimizing the environmental performance of blade batteries. Ongoing research focuses on further improving energy density, reducing the use of critical materials, and enhancing recycling processes. As the technology matures and production scales up, it is expected that the environmental footprint of blade batteries will continue to decrease, solidifying their role as a key component in sustainable energy systems.

The production of blade batteries involves the extraction and processing of raw materials, including lithium, iron, and phosphate. While these materials are generally more abundant and less environmentally harmful than those used in traditional lithium-ion batteries, their mining and refinement still have ecological implications. Efforts are being made to develop more sustainable sourcing practices and to increase the use of recycled materials in battery production.

During their operational life, blade batteries contribute to reducing greenhouse gas emissions by enabling greater integration of renewable energy sources into smart grids. They help balance supply and demand, storing excess energy during peak production periods and releasing it when needed. This capability significantly enhances the efficiency of renewable energy systems and reduces reliance on fossil fuel-based power generation.

The long lifespan of blade batteries, typically exceeding that of conventional lithium-ion batteries, is another environmental advantage. This durability means fewer replacements are needed over time, reducing the overall resource consumption and waste generation associated with battery production and disposal. Additionally, the improved safety features of blade batteries, such as enhanced thermal stability, reduce the risk of fires and other hazardous incidents that could have negative environmental consequences.

End-of-life management is a critical aspect of blade battery environmental impact. As these batteries reach the end of their useful life in grid applications, proper recycling and disposal processes are essential. The battery industry is developing advanced recycling technologies to recover valuable materials from spent blade batteries, minimizing waste and reducing the need for virgin raw materials in new battery production.

The integration of blade batteries into smart grids also has indirect environmental benefits. By improving grid stability and efficiency, these batteries enable greater adoption of electric vehicles and distributed energy resources. This shift away from fossil fuel-dependent transportation and centralized power generation contributes to overall reductions in carbon emissions and air pollution.

However, challenges remain in fully optimizing the environmental performance of blade batteries. Ongoing research focuses on further improving energy density, reducing the use of critical materials, and enhancing recycling processes. As the technology matures and production scales up, it is expected that the environmental footprint of blade batteries will continue to decrease, solidifying their role as a key component in sustainable energy systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!