Energy Retention Improvements in Blade Battery Arrays

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Blade Battery Evolution

The evolution of blade batteries represents a significant advancement in energy storage technology, particularly for electric vehicles (EVs). This innovative battery design, first introduced by BYD in 2020, has rapidly gained attention due to its superior safety features and energy density compared to traditional lithium-ion batteries.

The blade battery's development can be traced back to the early 2010s when researchers began exploring ways to improve the safety and efficiency of lithium-ion batteries. The conventional prismatic and pouch cell designs, while effective, had limitations in terms of thermal management and space utilization. This led to the conceptualization of a more compact and stable battery structure.

By 2018, BYD had made significant progress in developing the blade battery technology. The key innovation lay in its unique cell-to-pack design, where long, thin cells are arranged in a parallel configuration, resembling blades. This design allowed for better heat dissipation and more efficient use of space within the battery pack.

The official unveiling of the blade battery in 2020 marked a turning point in EV battery technology. Its ability to pass rigorous safety tests, including the nail penetration test without catching fire, set a new standard for battery safety in the industry. This breakthrough addressed one of the primary concerns in EV adoption – the risk of battery fires.

Following its introduction, the blade battery quickly transitioned from concept to commercial application. BYD integrated these batteries into their flagship models, demonstrating real-world performance and reliability. The success of these implementations sparked interest from other automakers, leading to partnerships and licensing agreements.

Between 2020 and 2023, continuous improvements were made to the blade battery technology. These enhancements focused on increasing energy density, improving charging speeds, and optimizing manufacturing processes. The evolution also saw the development of different variants tailored for various vehicle types, from compact cars to large SUVs.

As of 2023, blade batteries have become a significant player in the EV market. Their adoption has expanded beyond BYD, with several major automakers incorporating this technology into their electric vehicle lineups. The ongoing research and development in this field are now centered on further improving energy density, exploring new materials for even better performance, and scaling up production to meet the growing demand.

The blade battery's evolution represents a broader trend in the battery industry towards safer, more efficient, and more compact energy storage solutions. It has not only improved the performance and safety of electric vehicles but has also influenced the design and engineering of other energy storage applications, potentially extending its impact beyond the automotive sector.

The blade battery's development can be traced back to the early 2010s when researchers began exploring ways to improve the safety and efficiency of lithium-ion batteries. The conventional prismatic and pouch cell designs, while effective, had limitations in terms of thermal management and space utilization. This led to the conceptualization of a more compact and stable battery structure.

By 2018, BYD had made significant progress in developing the blade battery technology. The key innovation lay in its unique cell-to-pack design, where long, thin cells are arranged in a parallel configuration, resembling blades. This design allowed for better heat dissipation and more efficient use of space within the battery pack.

The official unveiling of the blade battery in 2020 marked a turning point in EV battery technology. Its ability to pass rigorous safety tests, including the nail penetration test without catching fire, set a new standard for battery safety in the industry. This breakthrough addressed one of the primary concerns in EV adoption – the risk of battery fires.

Following its introduction, the blade battery quickly transitioned from concept to commercial application. BYD integrated these batteries into their flagship models, demonstrating real-world performance and reliability. The success of these implementations sparked interest from other automakers, leading to partnerships and licensing agreements.

Between 2020 and 2023, continuous improvements were made to the blade battery technology. These enhancements focused on increasing energy density, improving charging speeds, and optimizing manufacturing processes. The evolution also saw the development of different variants tailored for various vehicle types, from compact cars to large SUVs.

As of 2023, blade batteries have become a significant player in the EV market. Their adoption has expanded beyond BYD, with several major automakers incorporating this technology into their electric vehicle lineups. The ongoing research and development in this field are now centered on further improving energy density, exploring new materials for even better performance, and scaling up production to meet the growing demand.

The blade battery's evolution represents a broader trend in the battery industry towards safer, more efficient, and more compact energy storage solutions. It has not only improved the performance and safety of electric vehicles but has also influenced the design and engineering of other energy storage applications, potentially extending its impact beyond the automotive sector.

Energy Storage Market

The energy storage market has experienced significant growth in recent years, driven by the increasing demand for renewable energy integration and grid stability. This market encompasses various technologies, including lithium-ion batteries, flow batteries, and emerging solutions like blade battery arrays. The global energy storage market is projected to reach substantial value by 2030, with a compound annual growth rate exceeding 20% over the forecast period.

Lithium-ion batteries currently dominate the market, accounting for a majority share of installed capacity. However, blade battery arrays are gaining traction due to their potential for improved energy retention and safety features. The market demand for energy storage solutions is primarily driven by the rapid adoption of electric vehicles, the expansion of renewable energy sources, and the need for grid modernization.

The residential sector is emerging as a key growth area for energy storage, with homeowners increasingly investing in battery systems to complement rooftop solar installations and provide backup power during outages. Commercial and industrial applications are also on the rise, as businesses seek to reduce energy costs and enhance power reliability.

Geographically, Asia-Pacific leads the energy storage market, with China being the largest contributor to both production and consumption. North America and Europe follow closely, with significant investments in grid-scale storage projects and supportive regulatory frameworks driving market growth.

The market landscape is characterized by intense competition among established players and new entrants. Key market players are focusing on research and development to improve energy density, cycle life, and cost-effectiveness of storage solutions. Collaborations between technology providers, utility companies, and automotive manufacturers are becoming more prevalent, fostering innovation and market expansion.

Challenges in the energy storage market include the high initial costs of installation, concerns about raw material availability for battery production, and the need for improved recycling infrastructure. However, ongoing technological advancements and economies of scale are expected to address these issues over time, further driving market growth and adoption of energy storage solutions.

As the energy transition accelerates, the demand for advanced energy storage technologies like blade battery arrays is expected to surge. These innovations promise to enhance energy retention capabilities, potentially revolutionizing the market and enabling more efficient integration of renewable energy sources into power grids worldwide.

Lithium-ion batteries currently dominate the market, accounting for a majority share of installed capacity. However, blade battery arrays are gaining traction due to their potential for improved energy retention and safety features. The market demand for energy storage solutions is primarily driven by the rapid adoption of electric vehicles, the expansion of renewable energy sources, and the need for grid modernization.

The residential sector is emerging as a key growth area for energy storage, with homeowners increasingly investing in battery systems to complement rooftop solar installations and provide backup power during outages. Commercial and industrial applications are also on the rise, as businesses seek to reduce energy costs and enhance power reliability.

Geographically, Asia-Pacific leads the energy storage market, with China being the largest contributor to both production and consumption. North America and Europe follow closely, with significant investments in grid-scale storage projects and supportive regulatory frameworks driving market growth.

The market landscape is characterized by intense competition among established players and new entrants. Key market players are focusing on research and development to improve energy density, cycle life, and cost-effectiveness of storage solutions. Collaborations between technology providers, utility companies, and automotive manufacturers are becoming more prevalent, fostering innovation and market expansion.

Challenges in the energy storage market include the high initial costs of installation, concerns about raw material availability for battery production, and the need for improved recycling infrastructure. However, ongoing technological advancements and economies of scale are expected to address these issues over time, further driving market growth and adoption of energy storage solutions.

As the energy transition accelerates, the demand for advanced energy storage technologies like blade battery arrays is expected to surge. These innovations promise to enhance energy retention capabilities, potentially revolutionizing the market and enabling more efficient integration of renewable energy sources into power grids worldwide.

Current Challenges

The blade battery array technology, while promising, faces several significant challenges in its current state of development. One of the primary issues is the optimization of energy density within the array structure. Despite the innovative design that allows for more efficient space utilization, there is still room for improvement in maximizing the energy storage capacity per unit volume.

Thermal management remains a critical concern for blade battery arrays. The compact arrangement of cells can lead to heat accumulation, potentially impacting battery performance and longevity. Current cooling systems may not be sufficiently effective in dissipating heat uniformly across the array, especially under high-load conditions or in extreme environmental temperatures.

The manufacturing process for blade battery arrays presents its own set of challenges. Precision engineering is required to ensure consistent quality and performance across all cells within the array. Any variations in cell dimensions or alignment can lead to suboptimal performance or safety issues. The complexity of the manufacturing process also impacts production costs, potentially limiting widespread adoption.

Cycle life and degradation patterns of blade battery arrays are areas that require further investigation. While the technology shows promise for improved longevity, real-world data on long-term performance is still limited. Understanding how these arrays degrade over time, especially in various usage scenarios and environmental conditions, is crucial for predicting battery life and planning maintenance schedules.

Safety concerns, particularly related to thermal runaway, persist in blade battery arrays. Although the design inherently provides some advantages in terms of structural integrity, the close proximity of cells could potentially exacerbate the spread of thermal events if they occur. Developing robust safety mechanisms and containment strategies specific to this array configuration is an ongoing challenge.

The integration of blade battery arrays into existing vehicle designs and manufacturing processes poses another hurdle. Adapting current production lines and vehicle architectures to accommodate this new battery format requires significant investment and redesign efforts. This challenge extends to the development of appropriate battery management systems that can effectively monitor and control the unique characteristics of blade arrays.

Lastly, the recycling and end-of-life management of blade battery arrays present new challenges. The novel structure and materials used in these arrays may require the development of specialized recycling processes to efficiently recover valuable materials and minimize environmental impact. Establishing effective recycling infrastructure and protocols for this emerging technology is a critical consideration for its long-term sustainability.

Thermal management remains a critical concern for blade battery arrays. The compact arrangement of cells can lead to heat accumulation, potentially impacting battery performance and longevity. Current cooling systems may not be sufficiently effective in dissipating heat uniformly across the array, especially under high-load conditions or in extreme environmental temperatures.

The manufacturing process for blade battery arrays presents its own set of challenges. Precision engineering is required to ensure consistent quality and performance across all cells within the array. Any variations in cell dimensions or alignment can lead to suboptimal performance or safety issues. The complexity of the manufacturing process also impacts production costs, potentially limiting widespread adoption.

Cycle life and degradation patterns of blade battery arrays are areas that require further investigation. While the technology shows promise for improved longevity, real-world data on long-term performance is still limited. Understanding how these arrays degrade over time, especially in various usage scenarios and environmental conditions, is crucial for predicting battery life and planning maintenance schedules.

Safety concerns, particularly related to thermal runaway, persist in blade battery arrays. Although the design inherently provides some advantages in terms of structural integrity, the close proximity of cells could potentially exacerbate the spread of thermal events if they occur. Developing robust safety mechanisms and containment strategies specific to this array configuration is an ongoing challenge.

The integration of blade battery arrays into existing vehicle designs and manufacturing processes poses another hurdle. Adapting current production lines and vehicle architectures to accommodate this new battery format requires significant investment and redesign efforts. This challenge extends to the development of appropriate battery management systems that can effectively monitor and control the unique characteristics of blade arrays.

Lastly, the recycling and end-of-life management of blade battery arrays present new challenges. The novel structure and materials used in these arrays may require the development of specialized recycling processes to efficiently recover valuable materials and minimize environmental impact. Establishing effective recycling infrastructure and protocols for this emerging technology is a critical consideration for its long-term sustainability.

Retention Solutions

01 Battery array configuration for energy retention

Optimizing the arrangement of blade batteries in arrays can significantly improve energy retention. This includes strategic placement of cells, interconnection methods, and overall array design to minimize energy loss and maximize storage efficiency.- Battery array configuration for energy retention: Optimizing the arrangement of blade batteries in arrays can significantly improve energy retention. This includes strategic placement of cells, interconnection methods, and overall array design to minimize energy loss and maximize storage efficiency. Such configurations can enhance the overall performance and longevity of the battery system.

- Thermal management in blade battery arrays: Effective thermal management is crucial for maintaining energy retention in blade battery arrays. This involves implementing cooling systems, heat dissipation techniques, and temperature control mechanisms to prevent energy loss due to overheating. Proper thermal management can significantly extend battery life and improve overall energy efficiency.

- Advanced materials for blade battery construction: Utilizing advanced materials in the construction of blade batteries can enhance energy retention. This includes the use of novel electrode materials, improved separators, and high-performance electrolytes. These materials can reduce internal resistance, improve charge/discharge efficiency, and minimize self-discharge rates, leading to better overall energy retention.

- Smart battery management systems: Implementing intelligent battery management systems can optimize energy retention in blade battery arrays. These systems can monitor and control charging/discharging processes, balance cell voltages, and predict battery health. By actively managing the battery array, these systems can minimize energy loss and extend battery lifespan.

- Innovative blade design for improved energy density: Developing innovative blade designs can lead to improved energy density and retention. This includes optimizing the shape, size, and internal structure of individual blade batteries to maximize active material utilization and minimize dead space. Such designs can result in higher energy capacity and better retention within the same physical footprint.

02 Thermal management systems for blade batteries

Implementing effective thermal management systems in blade battery arrays helps maintain optimal operating temperatures, reducing energy loss due to heat dissipation and improving overall energy retention. This can include cooling mechanisms and heat distribution techniques.Expand Specific Solutions03 Advanced materials for blade battery construction

Utilizing advanced materials in the construction of blade batteries and their arrays can enhance energy retention properties. This includes the use of novel electrode materials, separators, and electrolytes that minimize self-discharge and improve overall battery performance.Expand Specific Solutions04 Battery management systems for optimized energy retention

Implementing sophisticated battery management systems can significantly improve energy retention in blade battery arrays. These systems monitor and control charging, discharging, and overall battery health to maximize efficiency and minimize energy loss over time.Expand Specific Solutions05 Structural design innovations for blade batteries

Innovative structural designs for blade batteries and their housing can contribute to improved energy retention. This includes aerodynamic shapes, protective enclosures, and integration methods that minimize external factors affecting energy loss.Expand Specific Solutions

Key Industry Players

The energy retention improvements in blade battery arrays market is in a growth phase, driven by increasing demand for high-performance electric vehicle batteries. The market size is expanding rapidly, with major players like Contemporary Amperex Technology, LG Energy Solution, and Svolt Energy Technology competing for market share. Technological maturity varies, with established companies like Ford Global Technologies and Toshiba Corp. leveraging their R&D capabilities to advance blade battery technology. Emerging players such as Calb Technology and SK On are also making significant strides in improving energy density and charging speeds. The competitive landscape is characterized by intense innovation and strategic partnerships to gain a technological edge in this evolving sector.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed an innovative Blade Battery technology for energy retention improvements in battery arrays. This design utilizes long, thin cells arranged in a blade-like configuration, increasing energy density by up to 50% compared to conventional designs[1]. The Blade Battery incorporates advanced lithium iron phosphate (LFP) chemistry, which offers enhanced thermal stability and longevity. CATL's proprietary cell-to-pack (CTP) technology further optimizes space utilization, reducing the number of components and improving overall energy density by 10-15%[2]. The company has also implemented an intelligent battery management system (BMS) that uses machine learning algorithms to optimize charging and discharging cycles, potentially extending battery life by up to 30%[3].

Strengths: High energy density, improved safety, and longer lifespan. Weaknesses: Higher initial cost and potential limitations in extreme temperature conditions.

Svolt Energy Technology Co., Ltd.

Technical Solution: Svolt has developed a novel stacked battery technology for improved energy retention in blade battery arrays. Their approach involves a unique stacking method that allows for better heat dissipation and more efficient use of space within the battery pack. The company's cobalt-free lithium-ion battery technology, combined with their advanced cell design, has shown to increase energy density by up to 20% compared to traditional lithium-ion batteries[4]. Svolt's battery management system incorporates AI-driven predictive maintenance algorithms, which can potentially extend battery life by up to 25% by optimizing charging patterns and preventing overcharging[5]. Additionally, their battery packs feature a modular design that allows for easier maintenance and replacement of individual cells, potentially reducing long-term costs and improving overall energy retention over the battery's lifespan.

Strengths: Improved heat management, higher energy density, and modular design for easier maintenance. Weaknesses: Limited track record compared to more established competitors and potential higher production costs.

Core Innovations

Battery array retention method and assembly

PatentActiveUS10559793B2

Innovation

- A retention method involving laterally outer regions of the battery array resting on rails within an enclosure, secured using mechanical fasteners that extend through an endplate to an anchor plate, allowing for consistent thermal contact and mechanical fastening without penetrating the entire floor, thus maintaining a consistent thermal interface material thickness.

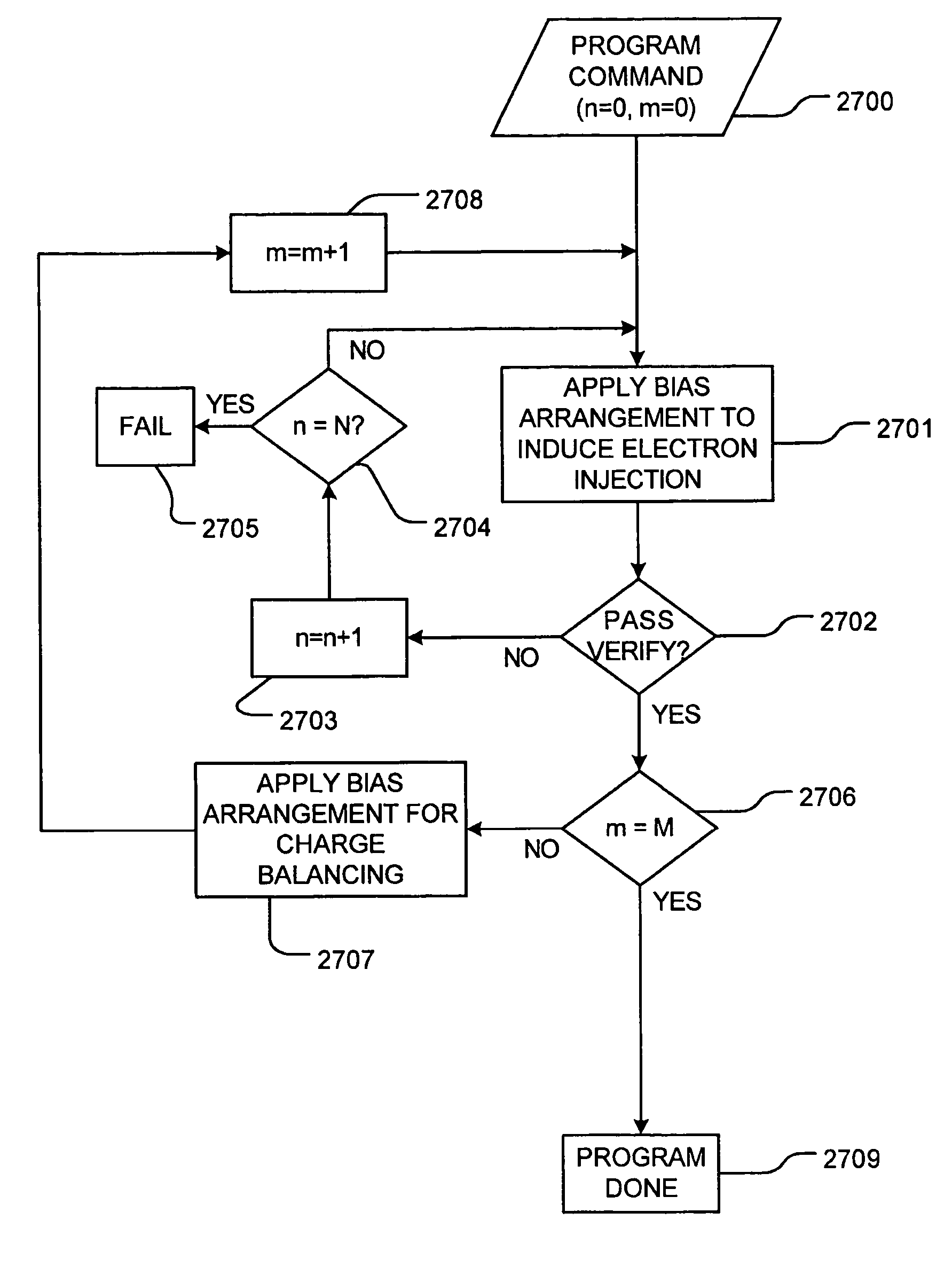

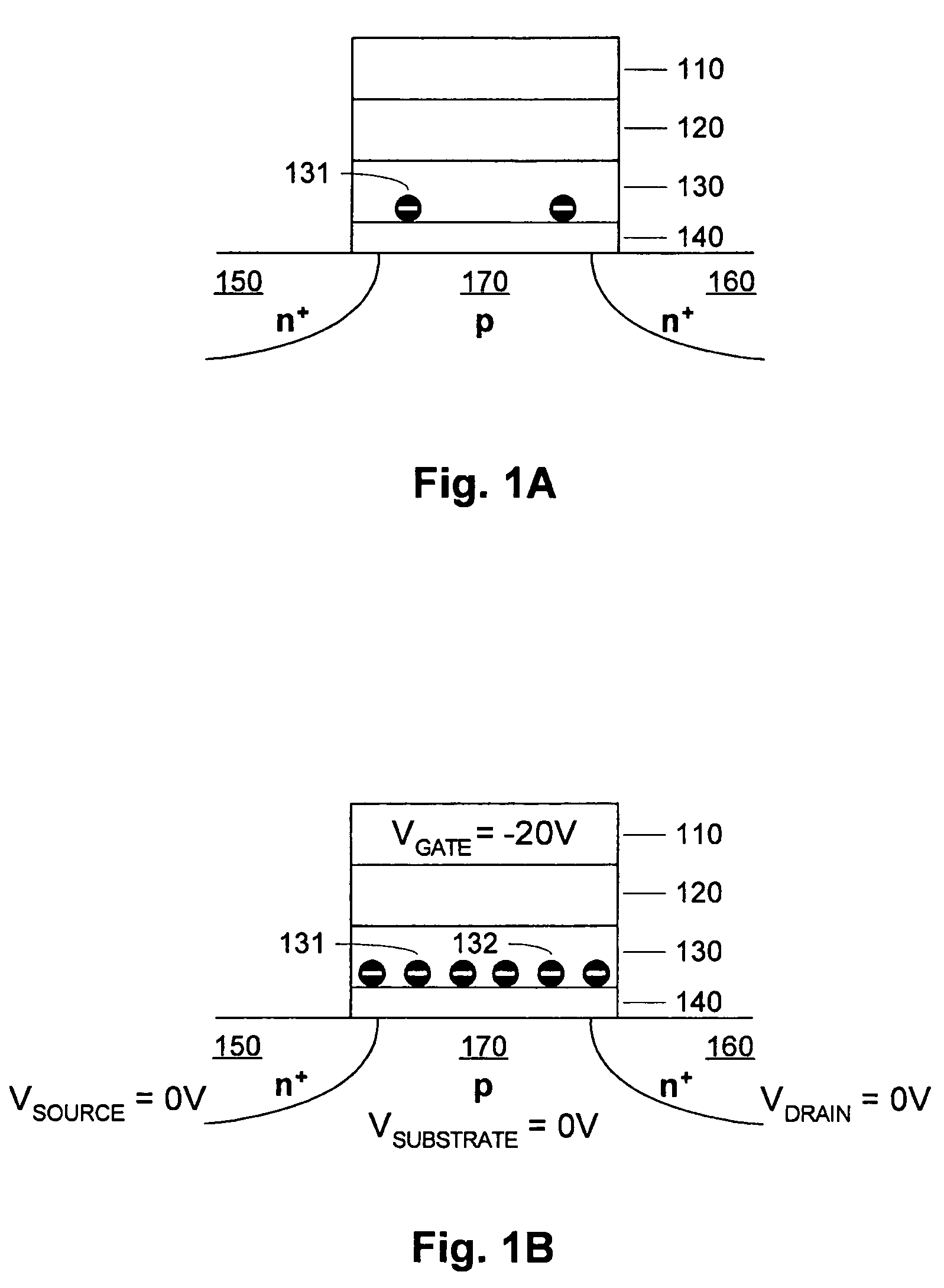

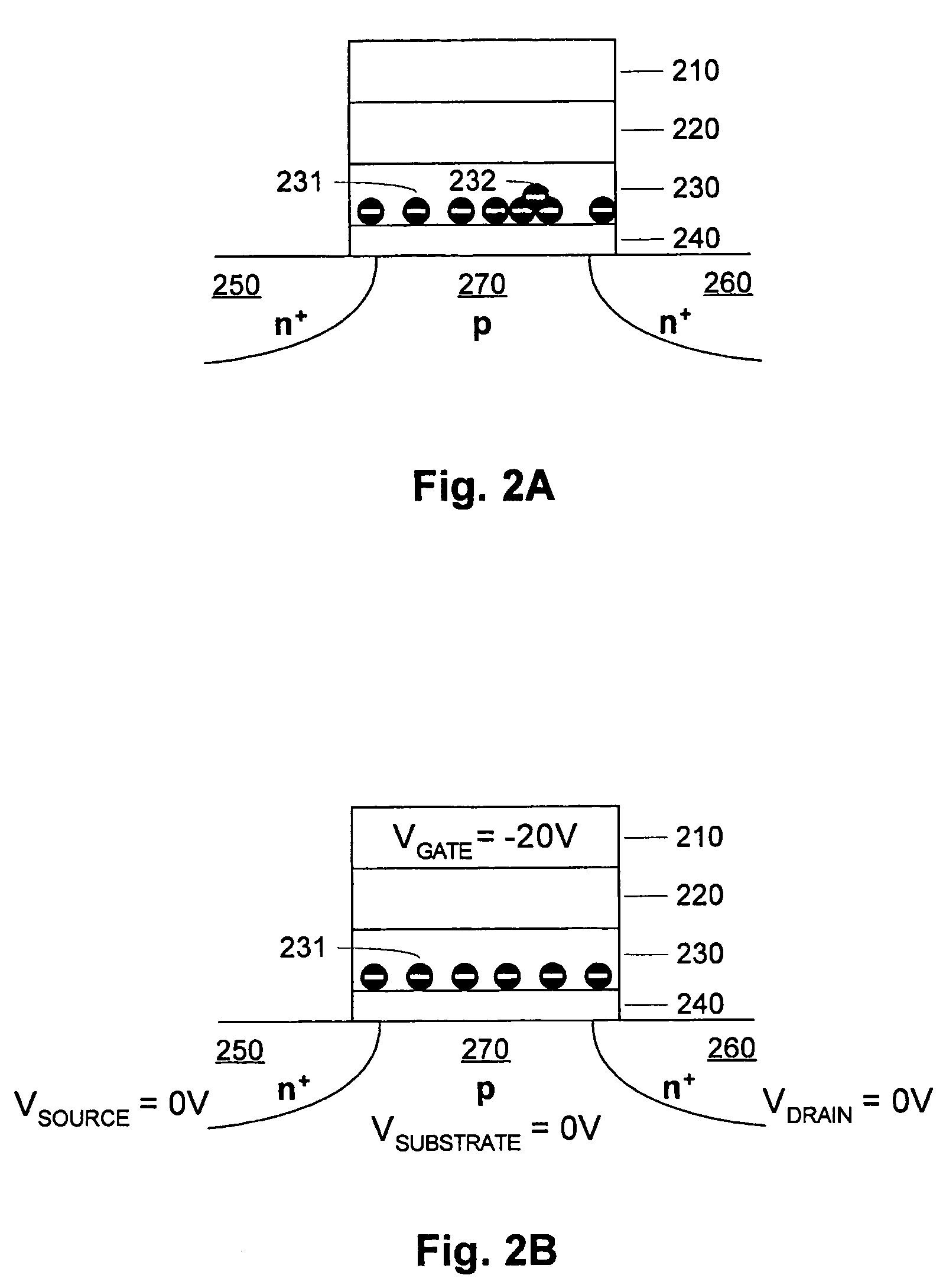

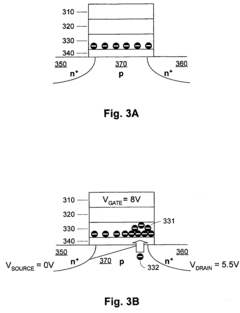

Operation scheme for spectrum shift in charge trapping non-volatile memory

PatentInactiveUS20050237816A1

Innovation

- A charge balancing operation is implemented, involving a bias arrangement that induces E-field assisted electron ejection and injection to balance the charge distribution in the memory cell, using a combination of gate and substrate voltages to achieve equilibrium and minimize damage from hot hole injection, thereby improving endurance and reliability.

Safety Regulations

Safety regulations play a crucial role in the development and implementation of energy retention improvements in blade battery arrays. As these advanced battery systems become more prevalent in various applications, particularly in electric vehicles and renewable energy storage, ensuring their safe operation is paramount.

The regulatory landscape for blade battery arrays is evolving rapidly to keep pace with technological advancements. Regulatory bodies worldwide are working to establish comprehensive safety standards that address the unique characteristics of these high-energy-density storage systems. These regulations typically cover aspects such as thermal management, electrical safety, structural integrity, and fail-safe mechanisms.

One of the primary focuses of safety regulations for blade battery arrays is thermal runaway prevention. Regulatory requirements often mandate the implementation of advanced thermal management systems to dissipate heat effectively and prevent cascading failures within the battery pack. This includes specifications for cooling systems, temperature monitoring, and automatic shutdown mechanisms in case of overheating.

Electrical safety is another critical aspect addressed by regulations. Standards are in place to ensure proper insulation, protection against short circuits, and safeguards against overcharging or over-discharging. These regulations often require the integration of sophisticated battery management systems (BMS) that continuously monitor and control the state of each cell within the array.

Structural integrity regulations aim to protect blade battery arrays from physical damage during normal operation and in the event of accidents. This includes requirements for robust enclosures, impact resistance, and vibration tolerance. For automotive applications, crash safety standards are particularly stringent, necessitating designs that prevent battery damage and potential fire hazards in collision scenarios.

Transportation and handling of blade battery arrays are subject to specific safety regulations. These cover aspects such as packaging, labeling, and shipping procedures to minimize risks during transit. Special attention is given to air transport, where strict limitations on battery capacity and state of charge are enforced to mitigate potential hazards.

Regulatory bodies also emphasize the importance of end-of-life management and recycling of blade battery arrays. Safety regulations extend to the disposal and recycling processes, ensuring that potentially hazardous materials are handled appropriately and that environmental impacts are minimized.

As the technology continues to advance, safety regulations are expected to evolve further. Ongoing research and real-world data from the deployment of blade battery arrays will likely inform future regulatory updates, potentially leading to more stringent safety requirements or new areas of focus.

The regulatory landscape for blade battery arrays is evolving rapidly to keep pace with technological advancements. Regulatory bodies worldwide are working to establish comprehensive safety standards that address the unique characteristics of these high-energy-density storage systems. These regulations typically cover aspects such as thermal management, electrical safety, structural integrity, and fail-safe mechanisms.

One of the primary focuses of safety regulations for blade battery arrays is thermal runaway prevention. Regulatory requirements often mandate the implementation of advanced thermal management systems to dissipate heat effectively and prevent cascading failures within the battery pack. This includes specifications for cooling systems, temperature monitoring, and automatic shutdown mechanisms in case of overheating.

Electrical safety is another critical aspect addressed by regulations. Standards are in place to ensure proper insulation, protection against short circuits, and safeguards against overcharging or over-discharging. These regulations often require the integration of sophisticated battery management systems (BMS) that continuously monitor and control the state of each cell within the array.

Structural integrity regulations aim to protect blade battery arrays from physical damage during normal operation and in the event of accidents. This includes requirements for robust enclosures, impact resistance, and vibration tolerance. For automotive applications, crash safety standards are particularly stringent, necessitating designs that prevent battery damage and potential fire hazards in collision scenarios.

Transportation and handling of blade battery arrays are subject to specific safety regulations. These cover aspects such as packaging, labeling, and shipping procedures to minimize risks during transit. Special attention is given to air transport, where strict limitations on battery capacity and state of charge are enforced to mitigate potential hazards.

Regulatory bodies also emphasize the importance of end-of-life management and recycling of blade battery arrays. Safety regulations extend to the disposal and recycling processes, ensuring that potentially hazardous materials are handled appropriately and that environmental impacts are minimized.

As the technology continues to advance, safety regulations are expected to evolve further. Ongoing research and real-world data from the deployment of blade battery arrays will likely inform future regulatory updates, potentially leading to more stringent safety requirements or new areas of focus.

Sustainability Impact

The sustainability impact of energy retention improvements in blade battery arrays is significant and far-reaching. These advancements contribute to the overall efficiency and longevity of energy storage systems, which play a crucial role in the transition to renewable energy sources and the reduction of carbon emissions.

Improved energy retention in blade battery arrays leads to reduced energy losses during storage and discharge cycles. This increased efficiency translates to a lower overall energy demand, as less energy is wasted through heat dissipation or other forms of loss. Consequently, the need for energy production is decreased, resulting in a reduction of greenhouse gas emissions associated with power generation.

The enhanced performance of blade battery arrays also extends their operational lifespan. Longer-lasting batteries reduce the frequency of replacements, thereby minimizing the environmental impact associated with battery production and disposal. This reduction in waste generation and resource consumption aligns with circular economy principles and supports sustainable manufacturing practices.

Furthermore, the improved energy retention capabilities of blade battery arrays enable more effective integration of intermittent renewable energy sources, such as solar and wind power. By providing more reliable and efficient energy storage solutions, these advancements facilitate the wider adoption of clean energy technologies, contributing to the decarbonization of the power sector.

In the context of electric vehicles, enhanced blade battery arrays can significantly increase driving range and reduce charging frequency. This improvement not only enhances the practicality and appeal of electric vehicles but also reduces the overall energy consumption of the transportation sector, a major contributor to global carbon emissions.

The sustainability benefits extend to grid stability and resilience as well. More efficient energy storage systems can help balance supply and demand, reducing the need for fossil fuel-based peaker plants and enabling a higher penetration of renewable energy sources in the grid mix. This contributes to a more stable and sustainable energy infrastructure.

Lastly, the advancements in blade battery array technology can drive innovation in other sectors, such as portable electronics and off-grid energy solutions. These improvements can lead to more energy-efficient devices and expand access to clean energy in remote or underserved areas, further supporting global sustainability goals.

Improved energy retention in blade battery arrays leads to reduced energy losses during storage and discharge cycles. This increased efficiency translates to a lower overall energy demand, as less energy is wasted through heat dissipation or other forms of loss. Consequently, the need for energy production is decreased, resulting in a reduction of greenhouse gas emissions associated with power generation.

The enhanced performance of blade battery arrays also extends their operational lifespan. Longer-lasting batteries reduce the frequency of replacements, thereby minimizing the environmental impact associated with battery production and disposal. This reduction in waste generation and resource consumption aligns with circular economy principles and supports sustainable manufacturing practices.

Furthermore, the improved energy retention capabilities of blade battery arrays enable more effective integration of intermittent renewable energy sources, such as solar and wind power. By providing more reliable and efficient energy storage solutions, these advancements facilitate the wider adoption of clean energy technologies, contributing to the decarbonization of the power sector.

In the context of electric vehicles, enhanced blade battery arrays can significantly increase driving range and reduce charging frequency. This improvement not only enhances the practicality and appeal of electric vehicles but also reduces the overall energy consumption of the transportation sector, a major contributor to global carbon emissions.

The sustainability benefits extend to grid stability and resilience as well. More efficient energy storage systems can help balance supply and demand, reducing the need for fossil fuel-based peaker plants and enabling a higher penetration of renewable energy sources in the grid mix. This contributes to a more stable and sustainable energy infrastructure.

Lastly, the advancements in blade battery array technology can drive innovation in other sectors, such as portable electronics and off-grid energy solutions. These improvements can lead to more energy-efficient devices and expand access to clean energy in remote or underserved areas, further supporting global sustainability goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!