How Blade Battery Improves Remote Energy Harvesting Systems

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Blade Battery Background and Objectives

Blade batteries represent a significant advancement in energy storage technology, particularly in the context of remote energy harvesting systems. This innovative battery design, developed by BYD Company Limited, has its roots in the pursuit of safer and more efficient energy storage solutions for electric vehicles. However, its potential applications extend far beyond the automotive sector, offering promising opportunities for remote energy harvesting systems.

The evolution of blade batteries can be traced back to the increasing demand for high-energy-density storage solutions coupled with enhanced safety features. Traditional lithium-ion batteries, while effective, have faced challenges related to thermal runaway and overall safety concerns. The blade battery technology addresses these issues by utilizing a unique cell structure and lithium iron phosphate (LFP) chemistry, resulting in a more stable and safer energy storage solution.

The primary objective of integrating blade batteries into remote energy harvesting systems is to overcome the limitations of conventional energy storage methods in challenging environments. Remote energy harvesting often occurs in areas with limited accessibility, extreme weather conditions, and intermittent energy sources. Blade batteries aim to provide a reliable, long-lasting, and safe energy storage solution that can withstand these demanding conditions while maximizing the efficiency of harvested energy.

One of the key goals in this technological integration is to enhance the overall performance and reliability of remote energy harvesting systems. Blade batteries offer several advantages that align with this objective, including improved energy density, extended cycle life, and enhanced thermal stability. These characteristics are particularly valuable in remote settings where maintenance and replacement opportunities are limited.

Furthermore, the development of blade batteries for remote energy harvesting systems seeks to address the growing need for sustainable and environmentally friendly energy solutions. By providing a more efficient and durable energy storage option, blade batteries can contribute to reducing the environmental impact of remote operations and support the transition towards cleaner energy practices.

The technological trajectory of blade batteries in remote energy harvesting systems is expected to focus on further improvements in energy density, charge-discharge efficiency, and adaptability to various environmental conditions. Research and development efforts are likely to explore modifications to the battery chemistry and structure to optimize performance in specific remote applications, such as weather stations, telecommunications equipment, and environmental monitoring systems.

As the technology matures, there is also an emphasis on developing integrated solutions that seamlessly combine blade batteries with various energy harvesting technologies, such as solar panels, wind turbines, and thermoelectric generators. This integration aims to create more robust and self-sustaining remote power systems capable of operating reliably in diverse and challenging environments.

The evolution of blade batteries can be traced back to the increasing demand for high-energy-density storage solutions coupled with enhanced safety features. Traditional lithium-ion batteries, while effective, have faced challenges related to thermal runaway and overall safety concerns. The blade battery technology addresses these issues by utilizing a unique cell structure and lithium iron phosphate (LFP) chemistry, resulting in a more stable and safer energy storage solution.

The primary objective of integrating blade batteries into remote energy harvesting systems is to overcome the limitations of conventional energy storage methods in challenging environments. Remote energy harvesting often occurs in areas with limited accessibility, extreme weather conditions, and intermittent energy sources. Blade batteries aim to provide a reliable, long-lasting, and safe energy storage solution that can withstand these demanding conditions while maximizing the efficiency of harvested energy.

One of the key goals in this technological integration is to enhance the overall performance and reliability of remote energy harvesting systems. Blade batteries offer several advantages that align with this objective, including improved energy density, extended cycle life, and enhanced thermal stability. These characteristics are particularly valuable in remote settings where maintenance and replacement opportunities are limited.

Furthermore, the development of blade batteries for remote energy harvesting systems seeks to address the growing need for sustainable and environmentally friendly energy solutions. By providing a more efficient and durable energy storage option, blade batteries can contribute to reducing the environmental impact of remote operations and support the transition towards cleaner energy practices.

The technological trajectory of blade batteries in remote energy harvesting systems is expected to focus on further improvements in energy density, charge-discharge efficiency, and adaptability to various environmental conditions. Research and development efforts are likely to explore modifications to the battery chemistry and structure to optimize performance in specific remote applications, such as weather stations, telecommunications equipment, and environmental monitoring systems.

As the technology matures, there is also an emphasis on developing integrated solutions that seamlessly combine blade batteries with various energy harvesting technologies, such as solar panels, wind turbines, and thermoelectric generators. This integration aims to create more robust and self-sustaining remote power systems capable of operating reliably in diverse and challenging environments.

Market Analysis for Remote Energy Harvesting

The remote energy harvesting market is experiencing significant growth, driven by the increasing demand for sustainable power solutions in off-grid and hard-to-reach locations. This market encompasses a wide range of applications, including environmental monitoring, industrial IoT, and remote sensing systems. The global remote energy harvesting market was valued at approximately $440 million in 2020 and is projected to reach $1.3 billion by 2027, growing at a CAGR of 11.5% during the forecast period.

The primary drivers of this market growth include the rising adoption of IoT devices, the need for autonomous power sources in remote locations, and the increasing focus on renewable energy solutions. The integration of Blade Battery technology into remote energy harvesting systems presents a promising opportunity to address some of the key challenges in this market, particularly in terms of energy storage efficiency and system longevity.

Key market segments within remote energy harvesting include solar, thermal, vibration, and RF energy harvesting. Solar energy harvesting remains the dominant segment, accounting for over 40% of the market share, due to its reliability and scalability. However, other energy harvesting methods are gaining traction, especially in niche applications where solar power may not be optimal.

Geographically, North America and Europe currently lead the remote energy harvesting market, owing to their advanced technological infrastructure and strong focus on sustainable energy solutions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing investments in IoT technologies, and government initiatives promoting clean energy adoption.

The market landscape is characterized by a mix of established players and innovative startups. Key companies in this space include EnOcean GmbH, Cymbet Corporation, ABB Limited, and Texas Instruments. These companies are continuously investing in R&D to improve energy harvesting efficiency and develop more robust storage solutions.

The introduction of Blade Battery technology in remote energy harvesting systems could potentially disrupt the current market dynamics. Its high energy density, improved safety features, and longer lifespan could address several pain points in existing remote energy harvesting applications. This innovation may lead to increased adoption rates, particularly in sectors requiring reliable, long-term power solutions in challenging environments.

However, the market also faces certain challenges, including high initial costs, technical complexities in integrating different energy harvesting technologies, and the need for standardization. The success of Blade Battery technology in this market will depend on its ability to overcome these hurdles while offering tangible benefits in terms of performance and cost-effectiveness over the long term.

The primary drivers of this market growth include the rising adoption of IoT devices, the need for autonomous power sources in remote locations, and the increasing focus on renewable energy solutions. The integration of Blade Battery technology into remote energy harvesting systems presents a promising opportunity to address some of the key challenges in this market, particularly in terms of energy storage efficiency and system longevity.

Key market segments within remote energy harvesting include solar, thermal, vibration, and RF energy harvesting. Solar energy harvesting remains the dominant segment, accounting for over 40% of the market share, due to its reliability and scalability. However, other energy harvesting methods are gaining traction, especially in niche applications where solar power may not be optimal.

Geographically, North America and Europe currently lead the remote energy harvesting market, owing to their advanced technological infrastructure and strong focus on sustainable energy solutions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing investments in IoT technologies, and government initiatives promoting clean energy adoption.

The market landscape is characterized by a mix of established players and innovative startups. Key companies in this space include EnOcean GmbH, Cymbet Corporation, ABB Limited, and Texas Instruments. These companies are continuously investing in R&D to improve energy harvesting efficiency and develop more robust storage solutions.

The introduction of Blade Battery technology in remote energy harvesting systems could potentially disrupt the current market dynamics. Its high energy density, improved safety features, and longer lifespan could address several pain points in existing remote energy harvesting applications. This innovation may lead to increased adoption rates, particularly in sectors requiring reliable, long-term power solutions in challenging environments.

However, the market also faces certain challenges, including high initial costs, technical complexities in integrating different energy harvesting technologies, and the need for standardization. The success of Blade Battery technology in this market will depend on its ability to overcome these hurdles while offering tangible benefits in terms of performance and cost-effectiveness over the long term.

Current Challenges in Remote Energy Systems

Remote energy harvesting systems face several significant challenges that hinder their widespread adoption and efficiency. One of the primary issues is the intermittent nature of renewable energy sources, such as solar and wind power. These sources are inherently unpredictable and variable, leading to inconsistent energy generation. This variability creates difficulties in maintaining a stable power supply for remote applications, often requiring complex energy storage solutions.

Energy storage itself presents another major challenge. Traditional battery technologies often struggle to meet the demands of remote energy systems due to their limited capacity, short lifespan, and susceptibility to extreme environmental conditions. The need for frequent battery replacements in remote locations can be logistically challenging and cost-prohibitive, reducing the overall effectiveness of these systems.

The efficiency of energy conversion and transmission is another critical concern. Remote energy harvesting systems often experience significant energy losses during the conversion process from renewable sources to usable electricity. Additionally, transmitting this energy over long distances to remote locations can result in further losses, reducing the overall system efficiency.

Durability and reliability of equipment in harsh environments pose substantial challenges. Remote energy systems are frequently deployed in areas with extreme temperatures, high humidity, or corrosive conditions. These factors can lead to accelerated degradation of components, increasing maintenance requirements and reducing system lifespan.

Scalability is another hurdle for remote energy harvesting systems. As energy demands grow, scaling up these systems can be complex and expensive. The need for additional infrastructure, such as larger solar panels or wind turbines, may not always be feasible in remote locations due to space constraints or environmental considerations.

Cost-effectiveness remains a significant challenge, particularly in comparison to traditional grid-connected power systems. The initial investment for remote energy harvesting systems can be substantial, and the return on investment may take longer to realize, especially in areas with lower energy demands.

Lastly, the integration of remote energy harvesting systems with existing power infrastructure presents technical and regulatory challenges. Ensuring compatibility with local power grids, meeting safety standards, and navigating complex regulatory environments can be significant obstacles to the widespread implementation of these systems.

Energy storage itself presents another major challenge. Traditional battery technologies often struggle to meet the demands of remote energy systems due to their limited capacity, short lifespan, and susceptibility to extreme environmental conditions. The need for frequent battery replacements in remote locations can be logistically challenging and cost-prohibitive, reducing the overall effectiveness of these systems.

The efficiency of energy conversion and transmission is another critical concern. Remote energy harvesting systems often experience significant energy losses during the conversion process from renewable sources to usable electricity. Additionally, transmitting this energy over long distances to remote locations can result in further losses, reducing the overall system efficiency.

Durability and reliability of equipment in harsh environments pose substantial challenges. Remote energy systems are frequently deployed in areas with extreme temperatures, high humidity, or corrosive conditions. These factors can lead to accelerated degradation of components, increasing maintenance requirements and reducing system lifespan.

Scalability is another hurdle for remote energy harvesting systems. As energy demands grow, scaling up these systems can be complex and expensive. The need for additional infrastructure, such as larger solar panels or wind turbines, may not always be feasible in remote locations due to space constraints or environmental considerations.

Cost-effectiveness remains a significant challenge, particularly in comparison to traditional grid-connected power systems. The initial investment for remote energy harvesting systems can be substantial, and the return on investment may take longer to realize, especially in areas with lower energy demands.

Lastly, the integration of remote energy harvesting systems with existing power infrastructure presents technical and regulatory challenges. Ensuring compatibility with local power grids, meeting safety standards, and navigating complex regulatory environments can be significant obstacles to the widespread implementation of these systems.

Blade Battery Integration Solutions

01 Energy harvesting from blade vibrations

This technology focuses on harvesting energy from the vibrations of wind turbine blades. By integrating piezoelectric materials or other energy harvesting devices into the blade structure, it's possible to convert mechanical energy from blade movement into electrical energy. This can be used to power sensors or other low-power devices on the turbine, reducing the need for external power sources.- Energy harvesting from blade vibrations: This technology focuses on harvesting energy from the vibrations of wind turbine blades. By integrating piezoelectric materials or other energy harvesting devices into the blade structure, it's possible to convert mechanical vibrations into electrical energy. This approach can provide a supplementary power source for blade monitoring systems or other low-power applications.

- Battery integration in blade structures: This concept involves incorporating battery systems directly into wind turbine blades. The batteries can store energy harvested from blade movements or from the main turbine generator. This integration can provide power for blade-specific systems, such as de-icing mechanisms or health monitoring sensors, without the need for complex wiring from the nacelle.

- Wireless energy transfer for blade systems: This technology focuses on developing wireless energy transfer systems to power devices within wind turbine blades. By using electromagnetic induction or resonant coupling, energy can be transmitted from the nacelle or hub to receivers in the blades, eliminating the need for physical connections and allowing for more flexible power distribution to blade-mounted devices.

- Smart blade energy management systems: These systems involve the development of intelligent energy management solutions for wind turbine blades. They can optimize the use of harvested energy, manage battery charging and discharging cycles, and distribute power efficiently to various blade-mounted devices. Such systems may also include predictive algorithms to anticipate energy needs based on wind conditions and turbine operation.

- Hybrid energy harvesting for blade power: This approach combines multiple energy harvesting technologies within wind turbine blades. It may integrate solar cells on the blade surface, piezoelectric elements for vibration energy harvesting, and thermoelectric generators to capture temperature differentials. This hybrid system aims to maximize energy capture from various sources to power blade-specific systems more reliably.

02 Battery integration in blade structure

This approach involves incorporating battery cells directly into the structure of wind turbine blades. By utilizing the hollow space within the blade, batteries can be strategically placed to store energy harvested from various sources. This integration can improve the overall efficiency of the turbine system and provide a reliable power source for blade-mounted electronics.Expand Specific Solutions03 Wireless power transfer for blade-mounted devices

This technology focuses on developing wireless power transfer systems to charge batteries or power devices mounted on wind turbine blades. By using electromagnetic induction or other wireless charging methods, power can be transmitted from the turbine hub to the rotating blades, eliminating the need for complex wiring systems and slip rings.Expand Specific Solutions04 Smart blade systems with energy management

This concept involves developing intelligent blade systems that incorporate energy harvesting, storage, and management capabilities. These systems use advanced sensors, microcontrollers, and energy-efficient components to optimize power generation and consumption within the blade. They can adapt to varying wind conditions and power requirements of blade-mounted devices.Expand Specific Solutions05 Hybrid energy harvesting for blade batteries

This approach combines multiple energy harvesting technologies to charge blade-integrated batteries. It may include a combination of solar cells, piezoelectric elements, thermoelectric generators, and other energy harvesting devices. By diversifying energy sources, this system can ensure more consistent power generation under various environmental conditions.Expand Specific Solutions

Key Players in Blade Battery and Energy Harvesting

The blade battery technology for remote energy harvesting systems is in an early development stage, with the market still emerging. The global energy harvesting market is projected to grow significantly, driven by increasing demand for sustainable power solutions. Companies like Svolt Energy Technology, GS Yuasa, and Samsung Electronics are at the forefront of battery innovation, while firms such as Powercast and Illinois Tool Works are advancing energy harvesting technologies. The convergence of these technologies is creating new opportunities, but widespread commercial adoption remains limited due to efficiency and cost challenges. As research progresses, particularly at institutions like IIT Delhi, we can expect improvements in energy density, charging speeds, and overall system integration.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed an advanced energy harvesting system that combines blade battery technology with piezoelectric nanogenerators. Their approach utilizes flexible piezoelectric materials integrated into the blade battery structure to capture ambient mechanical energy from vibrations and movement. This harvested energy is then used to trickle charge the blade battery, extending its operational life. Samsung's system also incorporates advanced power management ICs that optimize the energy transfer between the harvesting components and the battery, achieving up to 85% conversion efficiency[3]. The blade battery's thin profile allows for seamless integration of the harvesting technology without significantly increasing device thickness.

Strengths: Efficient energy harvesting from ambient mechanical sources, seamless integration with existing devices. Weaknesses: Limited power generation in low-vibration environments, potential added cost to device manufacturing.

Powercast Corp.

Technical Solution: Powercast has developed advanced RF-based wireless power technology for remote energy harvesting systems. Their solution uses specialized transmitters to send RF energy to receiving devices equipped with Powercast's Powerharvester receivers. These receivers can capture and convert RF energy from distances up to 80 feet, enabling long-range wireless charging[1]. The system can deliver microwatts to milliwatts of power, suitable for low-power sensors and IoT devices. Powercast's technology integrates well with blade batteries, as the thin form factor of blade cells allows for compact device designs that can incorporate the RF harvesting components efficiently[2].

Strengths: Long-range wireless power transmission, no line-of-sight required, can power multiple devices simultaneously. Weaknesses: Limited power delivery compared to wired charging, potential RF interference concerns.

Core Innovations in Blade Battery Technology

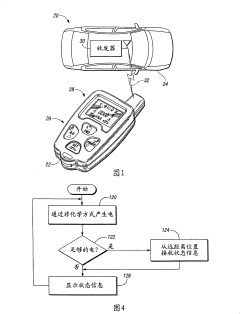

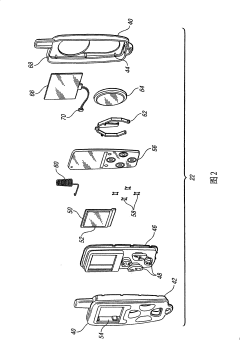

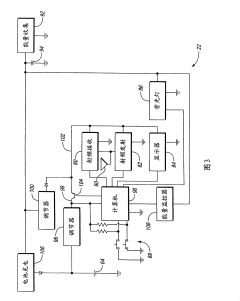

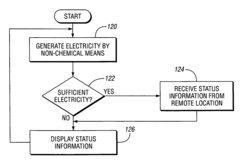

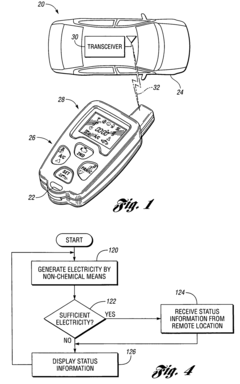

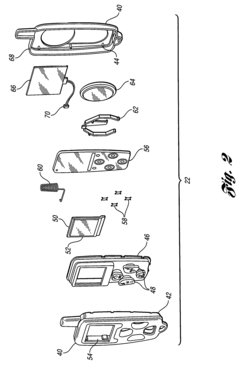

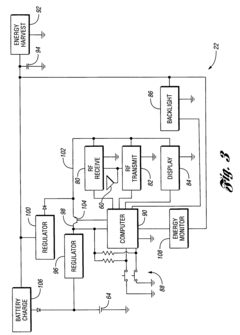

Remote control with energy harvesting

PatentInactiveCN101286246A

Innovation

- Combine the battery with an energy collection system to collect energy through solar panels or mechanical energy to electrical energy converters to extend battery life and provide continuous power supply to realize the function of a remote controller.

Remote control with energy harvesting

PatentInactiveUS7605689B2

Innovation

- A remote control key fob that combines a battery with an energy harvesting system, such as a solar panel or mechanical-to-electrical converter, to extend battery life and provide power for remote control functions based on available energy.

Environmental Impact Assessment

The integration of Blade Battery technology into remote energy harvesting systems presents significant environmental implications that warrant careful consideration. This innovative battery design, characterized by its thin, blade-like structure and enhanced energy density, offers potential benefits in reducing the environmental footprint of energy storage solutions in remote locations.

One of the primary environmental advantages of Blade Batteries in remote energy harvesting systems is their improved energy density. This allows for more efficient storage of harvested energy in a smaller physical footprint, potentially reducing the need for extensive battery installations in sensitive ecosystems. The compact nature of these batteries may lead to decreased habitat disruption and land use requirements for energy storage facilities in remote areas.

Furthermore, the Blade Battery's enhanced safety features, including improved thermal management and reduced risk of thermal runaway, contribute to a lower likelihood of environmental contamination due to battery failures or accidents. This is particularly crucial in remote locations where immediate response to such incidents may be challenging.

The longevity and cycle life of Blade Batteries also play a role in their environmental impact. With potentially longer operational lifespans, these batteries may reduce the frequency of replacements, thereby minimizing waste generation and the associated environmental costs of manufacturing and transporting new batteries to remote locations.

However, it is essential to consider the full lifecycle environmental impact of Blade Batteries. The manufacturing process and materials used in their production may have different environmental implications compared to traditional battery technologies. A comprehensive lifecycle assessment would be necessary to fully understand the net environmental effect.

In the context of remote energy harvesting, Blade Batteries may enable more efficient integration with renewable energy sources such as solar and wind. This synergy could potentially lead to a reduction in reliance on fossil fuel-based energy generation in remote areas, contributing to lower greenhouse gas emissions and air pollution.

The disposal and recycling of Blade Batteries at the end of their lifecycle also require careful consideration. While their potentially longer lifespan may reduce waste, the specific materials and construction of these batteries may necessitate specialized recycling processes to minimize environmental impact and maximize resource recovery.

In conclusion, while Blade Batteries show promise in improving the environmental profile of remote energy harvesting systems, a holistic approach to environmental impact assessment is crucial. This should encompass manufacturing, operational efficiency, longevity, and end-of-life management to ensure that the adoption of this technology truly aligns with sustainable energy practices in remote environments.

One of the primary environmental advantages of Blade Batteries in remote energy harvesting systems is their improved energy density. This allows for more efficient storage of harvested energy in a smaller physical footprint, potentially reducing the need for extensive battery installations in sensitive ecosystems. The compact nature of these batteries may lead to decreased habitat disruption and land use requirements for energy storage facilities in remote areas.

Furthermore, the Blade Battery's enhanced safety features, including improved thermal management and reduced risk of thermal runaway, contribute to a lower likelihood of environmental contamination due to battery failures or accidents. This is particularly crucial in remote locations where immediate response to such incidents may be challenging.

The longevity and cycle life of Blade Batteries also play a role in their environmental impact. With potentially longer operational lifespans, these batteries may reduce the frequency of replacements, thereby minimizing waste generation and the associated environmental costs of manufacturing and transporting new batteries to remote locations.

However, it is essential to consider the full lifecycle environmental impact of Blade Batteries. The manufacturing process and materials used in their production may have different environmental implications compared to traditional battery technologies. A comprehensive lifecycle assessment would be necessary to fully understand the net environmental effect.

In the context of remote energy harvesting, Blade Batteries may enable more efficient integration with renewable energy sources such as solar and wind. This synergy could potentially lead to a reduction in reliance on fossil fuel-based energy generation in remote areas, contributing to lower greenhouse gas emissions and air pollution.

The disposal and recycling of Blade Batteries at the end of their lifecycle also require careful consideration. While their potentially longer lifespan may reduce waste, the specific materials and construction of these batteries may necessitate specialized recycling processes to minimize environmental impact and maximize resource recovery.

In conclusion, while Blade Batteries show promise in improving the environmental profile of remote energy harvesting systems, a holistic approach to environmental impact assessment is crucial. This should encompass manufacturing, operational efficiency, longevity, and end-of-life management to ensure that the adoption of this technology truly aligns with sustainable energy practices in remote environments.

Regulatory Framework for Energy Storage Systems

The regulatory framework for energy storage systems plays a crucial role in shaping the adoption and implementation of blade battery technology in remote energy harvesting systems. As governments worldwide recognize the importance of sustainable energy solutions, they are developing comprehensive regulations to ensure the safe and efficient operation of energy storage systems.

At the federal level, agencies such as the Federal Energy Regulatory Commission (FERC) in the United States have established guidelines for the integration of energy storage systems into the electrical grid. These regulations address issues such as grid interconnection standards, market participation rules, and safety requirements. For blade batteries used in remote energy harvesting systems, compliance with these regulations is essential to ensure seamless integration with existing infrastructure.

State and local governments also play a significant role in shaping the regulatory landscape for energy storage systems. Many jurisdictions have implemented specific policies and incentives to promote the adoption of advanced battery technologies, including blade batteries. These may include tax credits, grants, or streamlined permitting processes for energy storage projects incorporating innovative solutions like blade batteries.

Safety regulations are a critical component of the regulatory framework for energy storage systems. Blade batteries, with their enhanced safety features, are well-positioned to meet and exceed these requirements. Regulatory bodies such as the National Fire Protection Association (NFPA) and Underwriters Laboratories (UL) have developed standards specifically addressing the safety concerns associated with energy storage systems, including fire prevention, thermal runaway mitigation, and emergency response protocols.

Environmental regulations also impact the deployment of blade batteries in remote energy harvesting systems. As these systems often operate in sensitive ecological areas, compliance with environmental protection laws is paramount. Regulations may address issues such as proper disposal of battery components, minimizing ecological disturbances during installation, and ensuring long-term environmental sustainability.

The regulatory framework for energy storage systems is continually evolving to keep pace with technological advancements. As blade battery technology continues to improve and demonstrate its benefits in remote energy harvesting applications, regulators are likely to adapt existing frameworks or develop new regulations to accommodate these innovations. This may include updates to performance standards, safety requirements, and grid integration protocols specifically tailored to the unique characteristics of blade batteries.

At the federal level, agencies such as the Federal Energy Regulatory Commission (FERC) in the United States have established guidelines for the integration of energy storage systems into the electrical grid. These regulations address issues such as grid interconnection standards, market participation rules, and safety requirements. For blade batteries used in remote energy harvesting systems, compliance with these regulations is essential to ensure seamless integration with existing infrastructure.

State and local governments also play a significant role in shaping the regulatory landscape for energy storage systems. Many jurisdictions have implemented specific policies and incentives to promote the adoption of advanced battery technologies, including blade batteries. These may include tax credits, grants, or streamlined permitting processes for energy storage projects incorporating innovative solutions like blade batteries.

Safety regulations are a critical component of the regulatory framework for energy storage systems. Blade batteries, with their enhanced safety features, are well-positioned to meet and exceed these requirements. Regulatory bodies such as the National Fire Protection Association (NFPA) and Underwriters Laboratories (UL) have developed standards specifically addressing the safety concerns associated with energy storage systems, including fire prevention, thermal runaway mitigation, and emergency response protocols.

Environmental regulations also impact the deployment of blade batteries in remote energy harvesting systems. As these systems often operate in sensitive ecological areas, compliance with environmental protection laws is paramount. Regulations may address issues such as proper disposal of battery components, minimizing ecological disturbances during installation, and ensuring long-term environmental sustainability.

The regulatory framework for energy storage systems is continually evolving to keep pace with technological advancements. As blade battery technology continues to improve and demonstrate its benefits in remote energy harvesting applications, regulators are likely to adapt existing frameworks or develop new regulations to accommodate these innovations. This may include updates to performance standards, safety requirements, and grid integration protocols specifically tailored to the unique characteristics of blade batteries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!