How Blade Battery Affects Long-Distance Travel in EVs

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Blade Battery Evolution and Objectives

The evolution of blade batteries represents a significant milestone in the development of electric vehicle (EV) technology, particularly in addressing the challenges of long-distance travel. Originating from the need to enhance energy density and safety in EV batteries, blade batteries have emerged as a promising solution to extend driving range and improve overall performance.

The primary objective of blade battery technology is to optimize the utilization of space within the battery pack, thereby increasing energy density without compromising safety. This is achieved through a unique structural design that allows for more efficient packaging of battery cells. By adopting a long, thin form factor, blade batteries can be arranged more compactly, resulting in higher energy capacity within the same volume compared to traditional lithium-ion batteries.

Another key goal of blade battery development is to enhance the safety profile of EV batteries. The design inherently reduces the risk of thermal runaway, a critical safety concern in electric vehicles. This improved safety feature is particularly crucial for long-distance travel, where battery stress and heat generation are more pronounced.

The evolution of blade batteries also aims to address the issue of range anxiety, a significant barrier to EV adoption for long-distance travel. By increasing energy density and efficiency, blade batteries can potentially extend the driving range of electric vehicles, making them more viable for extended journeys without frequent charging stops.

Furthermore, the technology seeks to improve charging speeds, another critical factor for long-distance EV travel. The structural design of blade batteries allows for more efficient heat dissipation during charging, potentially enabling faster charging rates without compromising battery longevity or safety.

As the technology progresses, researchers and manufacturers are focusing on further enhancing the performance characteristics of blade batteries. This includes efforts to increase energy density even further, improve cycle life, and reduce production costs. These advancements are crucial for making electric vehicles more competitive with traditional internal combustion engine vehicles, especially for long-distance travel scenarios.

The ongoing development of blade batteries also aligns with broader industry trends towards sustainable transportation. By enabling longer-range electric vehicles, this technology contributes to reducing reliance on fossil fuels and lowering carbon emissions in the transportation sector. This environmental aspect is an important objective in the evolution of blade battery technology, supporting global efforts to combat climate change.

The primary objective of blade battery technology is to optimize the utilization of space within the battery pack, thereby increasing energy density without compromising safety. This is achieved through a unique structural design that allows for more efficient packaging of battery cells. By adopting a long, thin form factor, blade batteries can be arranged more compactly, resulting in higher energy capacity within the same volume compared to traditional lithium-ion batteries.

Another key goal of blade battery development is to enhance the safety profile of EV batteries. The design inherently reduces the risk of thermal runaway, a critical safety concern in electric vehicles. This improved safety feature is particularly crucial for long-distance travel, where battery stress and heat generation are more pronounced.

The evolution of blade batteries also aims to address the issue of range anxiety, a significant barrier to EV adoption for long-distance travel. By increasing energy density and efficiency, blade batteries can potentially extend the driving range of electric vehicles, making them more viable for extended journeys without frequent charging stops.

Furthermore, the technology seeks to improve charging speeds, another critical factor for long-distance EV travel. The structural design of blade batteries allows for more efficient heat dissipation during charging, potentially enabling faster charging rates without compromising battery longevity or safety.

As the technology progresses, researchers and manufacturers are focusing on further enhancing the performance characteristics of blade batteries. This includes efforts to increase energy density even further, improve cycle life, and reduce production costs. These advancements are crucial for making electric vehicles more competitive with traditional internal combustion engine vehicles, especially for long-distance travel scenarios.

The ongoing development of blade batteries also aligns with broader industry trends towards sustainable transportation. By enabling longer-range electric vehicles, this technology contributes to reducing reliance on fossil fuels and lowering carbon emissions in the transportation sector. This environmental aspect is an important objective in the evolution of blade battery technology, supporting global efforts to combat climate change.

EV Long-Distance Travel Market Analysis

The electric vehicle (EV) long-distance travel market has been experiencing significant growth and transformation in recent years. This shift is driven by increasing consumer demand for sustainable transportation options and advancements in battery technology, particularly the introduction of blade batteries. The market for long-distance EV travel is closely tied to the overall growth of the electric vehicle industry, which has seen a compound annual growth rate (CAGR) of over 20% in the past five years.

Consumer preferences are evolving, with a growing number of EV owners expressing interest in using their vehicles for long-distance travel. This trend is supported by improvements in charging infrastructure and battery range, addressing the primary concerns of range anxiety and charging time. The blade battery technology has played a crucial role in this market development, offering enhanced energy density and faster charging capabilities.

The long-distance EV travel market is segmented by vehicle type, including sedans, SUVs, and light commercial vehicles. Among these, SUVs have shown the highest growth rate due to their popularity and suitability for long trips. Geographically, North America and Europe lead the market, with China rapidly catching up due to government incentives and infrastructure investments.

Key market drivers include government regulations promoting electric vehicle adoption, increasing environmental awareness among consumers, and technological advancements in battery and charging systems. The blade battery technology has particularly impacted the market by addressing concerns related to battery safety, longevity, and performance during extended trips.

Market challenges persist, including the need for further expansion of charging networks, especially in rural and remote areas. Additionally, the higher upfront costs of EVs compared to traditional vehicles remain a barrier for some consumers, although this gap is narrowing with economies of scale and technological improvements.

The competitive landscape of the EV long-distance travel market is dynamic, with traditional automakers and new entrants vying for market share. Companies that have successfully integrated blade battery technology into their vehicles have gained a competitive edge, offering improved range and charging speeds to consumers.

Looking ahead, the market is expected to continue its robust growth trajectory. Factors such as ongoing improvements in battery technology, expansion of fast-charging networks, and increasing consumer acceptance of EVs for long-distance travel will drive this growth. The blade battery technology is poised to play a pivotal role in shaping the future of this market, potentially revolutionizing the way consumers perceive and use electric vehicles for extended journeys.

Consumer preferences are evolving, with a growing number of EV owners expressing interest in using their vehicles for long-distance travel. This trend is supported by improvements in charging infrastructure and battery range, addressing the primary concerns of range anxiety and charging time. The blade battery technology has played a crucial role in this market development, offering enhanced energy density and faster charging capabilities.

The long-distance EV travel market is segmented by vehicle type, including sedans, SUVs, and light commercial vehicles. Among these, SUVs have shown the highest growth rate due to their popularity and suitability for long trips. Geographically, North America and Europe lead the market, with China rapidly catching up due to government incentives and infrastructure investments.

Key market drivers include government regulations promoting electric vehicle adoption, increasing environmental awareness among consumers, and technological advancements in battery and charging systems. The blade battery technology has particularly impacted the market by addressing concerns related to battery safety, longevity, and performance during extended trips.

Market challenges persist, including the need for further expansion of charging networks, especially in rural and remote areas. Additionally, the higher upfront costs of EVs compared to traditional vehicles remain a barrier for some consumers, although this gap is narrowing with economies of scale and technological improvements.

The competitive landscape of the EV long-distance travel market is dynamic, with traditional automakers and new entrants vying for market share. Companies that have successfully integrated blade battery technology into their vehicles have gained a competitive edge, offering improved range and charging speeds to consumers.

Looking ahead, the market is expected to continue its robust growth trajectory. Factors such as ongoing improvements in battery technology, expansion of fast-charging networks, and increasing consumer acceptance of EVs for long-distance travel will drive this growth. The blade battery technology is poised to play a pivotal role in shaping the future of this market, potentially revolutionizing the way consumers perceive and use electric vehicles for extended journeys.

Blade Battery Technology Status and Challenges

Blade battery technology has made significant strides in recent years, revolutionizing the landscape of electric vehicle (EV) energy storage. Developed by BYD, this innovative lithium iron phosphate (LFP) battery design has addressed several key challenges faced by traditional EV batteries, particularly in the context of long-distance travel.

The current status of blade battery technology showcases impressive advancements in energy density, safety, and longevity. These batteries boast a volumetric energy density up to 50% higher than conventional LFP batteries, allowing for increased range without compromising vehicle space. The unique cell-to-pack design eliminates the need for module housings, resulting in a more efficient use of space and improved overall energy density.

Safety has been a paramount concern in EV battery development, and blade batteries have made significant progress in this area. Their inherent stability and resistance to thermal runaway have been demonstrated through rigorous testing, including nail penetration tests. This enhanced safety profile is particularly crucial for long-distance travel, where battery reliability is of utmost importance.

Despite these advancements, blade battery technology still faces several challenges. One of the primary hurdles is the relatively lower energy density compared to some high-nickel NMC (Nickel Manganese Cobalt) batteries. While blade batteries offer improved safety and longevity, they still lag behind in terms of absolute energy storage capacity per unit weight, which can impact the overall range of EVs.

Another challenge lies in the charging speed of blade batteries. Although they have shown improvements in fast-charging capabilities, they still do not match the charging rates of some advanced lithium-ion chemistries. This limitation can affect the convenience of long-distance travel, potentially requiring more frequent or longer charging stops.

The manufacturing process of blade batteries also presents challenges. The precision required in producing the long, thin cells and integrating them into the pack structure demands advanced manufacturing techniques and quality control measures. Scaling up production while maintaining consistency and quality is an ongoing challenge for manufacturers.

Additionally, the long-term performance and degradation characteristics of blade batteries in real-world, long-distance travel scenarios are still being studied. While initial data is promising, more extensive field testing is needed to fully understand how these batteries perform over extended periods and multiple charge cycles in various climatic conditions.

Lastly, the integration of blade batteries into existing EV platforms and charging infrastructure poses both technical and logistical challenges. Automakers must adapt their vehicle designs to accommodate the unique form factor of blade batteries, and charging networks may need to optimize their systems to fully leverage the capabilities of this technology.

The current status of blade battery technology showcases impressive advancements in energy density, safety, and longevity. These batteries boast a volumetric energy density up to 50% higher than conventional LFP batteries, allowing for increased range without compromising vehicle space. The unique cell-to-pack design eliminates the need for module housings, resulting in a more efficient use of space and improved overall energy density.

Safety has been a paramount concern in EV battery development, and blade batteries have made significant progress in this area. Their inherent stability and resistance to thermal runaway have been demonstrated through rigorous testing, including nail penetration tests. This enhanced safety profile is particularly crucial for long-distance travel, where battery reliability is of utmost importance.

Despite these advancements, blade battery technology still faces several challenges. One of the primary hurdles is the relatively lower energy density compared to some high-nickel NMC (Nickel Manganese Cobalt) batteries. While blade batteries offer improved safety and longevity, they still lag behind in terms of absolute energy storage capacity per unit weight, which can impact the overall range of EVs.

Another challenge lies in the charging speed of blade batteries. Although they have shown improvements in fast-charging capabilities, they still do not match the charging rates of some advanced lithium-ion chemistries. This limitation can affect the convenience of long-distance travel, potentially requiring more frequent or longer charging stops.

The manufacturing process of blade batteries also presents challenges. The precision required in producing the long, thin cells and integrating them into the pack structure demands advanced manufacturing techniques and quality control measures. Scaling up production while maintaining consistency and quality is an ongoing challenge for manufacturers.

Additionally, the long-term performance and degradation characteristics of blade batteries in real-world, long-distance travel scenarios are still being studied. While initial data is promising, more extensive field testing is needed to fully understand how these batteries perform over extended periods and multiple charge cycles in various climatic conditions.

Lastly, the integration of blade batteries into existing EV platforms and charging infrastructure poses both technical and logistical challenges. Automakers must adapt their vehicle designs to accommodate the unique form factor of blade batteries, and charging networks may need to optimize their systems to fully leverage the capabilities of this technology.

Current Blade Battery Solutions for EVs

01 Battery management for long-distance travel

Advanced battery management systems are crucial for long-distance travel in electric vehicles equipped with blade batteries. These systems optimize battery performance, monitor state of charge, and implement efficient charging strategies to maximize range and minimize charging stops during extended journeys.- Battery management for long-distance travel: Advanced battery management systems are crucial for optimizing the performance of blade batteries during long-distance travel. These systems monitor and control various parameters such as temperature, charge levels, and power distribution to ensure efficient energy usage and extend the driving range. Intelligent algorithms are employed to predict energy consumption based on route information and driving conditions.

- Thermal management of blade batteries: Effective thermal management is essential for maintaining optimal performance and longevity of blade batteries during long-distance travel. This includes advanced cooling systems, heat dissipation techniques, and temperature regulation mechanisms to prevent overheating and ensure consistent power output. Thermal management also contributes to faster charging capabilities and improved overall efficiency.

- Charging infrastructure for long-distance travel: Development of robust charging infrastructure is critical for supporting long-distance travel with blade batteries. This includes the implementation of fast-charging stations along major routes, smart charging systems that optimize charging times and power delivery, and integration with navigation systems to plan efficient charging stops during long journeys.

- Energy density and capacity improvements: Ongoing research focuses on enhancing the energy density and capacity of blade batteries to extend the driving range for long-distance travel. This involves developing new materials, improving cell design, and optimizing the battery pack configuration to maximize energy storage while minimizing weight and space requirements.

- Integration with vehicle systems for range optimization: Seamless integration of blade batteries with other vehicle systems is crucial for optimizing range during long-distance travel. This includes advanced energy recovery systems, intelligent power distribution, and adaptive driving modes that adjust vehicle performance based on battery status and travel conditions. Integration with navigation and route planning systems also helps in optimizing energy usage over long distances.

02 Thermal management of blade batteries

Effective thermal management is essential for maintaining optimal performance and longevity of blade batteries during long-distance travel. This includes cooling systems, heat dissipation techniques, and temperature monitoring to prevent overheating and ensure consistent power output over extended periods.Expand Specific Solutions03 Charging infrastructure for long-distance routes

Development of charging infrastructure along long-distance routes is critical for the successful implementation of blade battery technology in electric vehicles. This includes fast-charging stations, battery swap facilities, and intelligent route planning systems that consider charging stops.Expand Specific Solutions04 Energy density and capacity improvements

Ongoing research focuses on enhancing the energy density and capacity of blade batteries to extend the range of electric vehicles. This involves advancements in battery chemistry, cell design, and packaging to increase energy storage while maintaining the compact form factor of blade batteries.Expand Specific Solutions05 Integration with vehicle systems for range optimization

Seamless integration of blade batteries with vehicle systems such as regenerative braking, power electronics, and energy-efficient auxiliaries is crucial for optimizing range during long-distance travel. This integration allows for more efficient energy utilization and improved overall vehicle performance.Expand Specific Solutions

Key Players in Blade Battery and EV Industry

The competition landscape for blade battery technology in long-distance EV travel is evolving rapidly. The market is in its growth phase, with significant potential for expansion as EV adoption increases globally. Major players like Ford, GM, Hyundai, and Kia are investing heavily in this technology, recognizing its potential to address range anxiety concerns. Chinese companies such as Hefei Guoxuan and Svolt Energy are also making strides in blade battery development. The technology is approaching maturity, with companies like BYD (not listed) leading the way in commercialization. However, there's still room for innovation and improvement in energy density, charging speed, and cost-effectiveness, driving ongoing research and development efforts across the industry.

Hefei Guoxuan High-Tech Power Energy Co., Ltd.

Technical Solution: Guoxuan's Blade Battery technology significantly impacts long-distance travel in EVs by offering improved energy density and safety. The battery's unique design allows for more efficient space utilization, increasing energy density by up to 50% compared to traditional lithium-ion batteries[1]. This translates to extended driving ranges, crucial for long-distance travel. The Blade Battery's lithium iron phosphate (LFP) chemistry provides enhanced thermal stability and reduced risk of thermal runaway[2], addressing safety concerns during extended trips. Additionally, the battery's fast-charging capability enables 80% charge in just 30 minutes[3], minimizing downtime during long journeys.

Strengths: Higher energy density, improved safety, and fast charging capabilities. Weaknesses: LFP chemistry may have slightly lower energy density compared to some other lithium-ion chemistries, potentially limiting maximum range compared to some competitors.

Svolt Energy Technology Co., Ltd.

Technical Solution: Svolt's approach to enhancing long-distance EV travel focuses on their cobalt-free NMX battery technology. This innovation addresses key concerns for extended journeys, including energy density, safety, and cost. The NMX batteries offer an energy density of up to 350-400 Wh/kg[4], significantly improving the range of EVs. The removal of cobalt enhances safety by reducing the risk of thermal runaway, a critical factor for long trips. Svolt's batteries also feature advanced thermal management systems, maintaining optimal performance across various climates encountered during long-distance travel. The company's cell-to-pack (CTP) technology further increases energy density at the pack level, allowing for more efficient use of space and weight in EVs[5].

Strengths: High energy density, improved safety due to cobalt-free chemistry, and cost-effectiveness. Weaknesses: Relatively new technology with less real-world data compared to established battery types.

Core Innovations in Blade Battery Technology

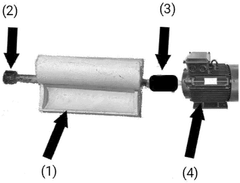

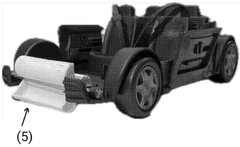

Design and manufacture of a system for charging the battery of electric vehicles that operates automatically without an external charging source

PatentWO2025150073A1

Innovation

- A system utilizing a wind turbine with an electric generator that generates energy from air pressure during vehicle movement to charge the battery autonomously, eliminating the need for external charging sources.

Charging Infrastructure for Long-Distance EV Travel

The development of blade batteries has significantly impacted long-distance travel in electric vehicles (EVs), necessitating a corresponding evolution in charging infrastructure. As EVs equipped with blade batteries become more prevalent on roads, the demand for efficient and widespread charging networks has intensified.

Charging infrastructure for long-distance EV travel requires a strategic approach to placement and capacity. High-power charging stations are being installed along major highways and interstates, typically spaced 100-150 miles apart to accommodate the range of most modern EVs. These stations are designed to deliver rapid charging, with many capable of providing up to 350 kW of power, allowing for substantial range replenishment in 15-30 minutes.

The integration of blade batteries in EVs has influenced the design of these charging stations. The improved energy density and faster charging capabilities of blade batteries mean that charging infrastructure must be capable of delivering higher power outputs. This has led to the development of more robust power delivery systems and cooling mechanisms at charging stations to handle the increased load and heat generation during rapid charging sessions.

To support long-distance travel, charging networks are also focusing on reliability and redundancy. Multiple charging points at each station ensure that even if one unit is out of service, EV drivers can still recharge their vehicles. Advanced monitoring systems are being implemented to predict maintenance needs and minimize downtime, crucial for maintaining the viability of long-distance EV travel.

User experience is another key consideration in the development of charging infrastructure for long-distance travel. Charging stations are increasingly being co-located with amenities such as restaurants, restrooms, and shopping areas, allowing drivers to make productive use of charging time. Mobile apps and in-vehicle navigation systems are being integrated with real-time charging station availability data, enabling drivers to plan their routes and charging stops more effectively.

The expansion of charging infrastructure is also addressing the challenge of "charging deserts" in rural and less populated areas. Governments and private companies are investing in the installation of charging stations in these regions to ensure comprehensive coverage for long-distance travelers. This expansion is critical for the widespread adoption of EVs and the feasibility of cross-country travel in electric vehicles.

As blade battery technology continues to advance, charging infrastructure is expected to evolve in tandem. Future developments may include even faster charging capabilities, wireless charging options for highway rest stops, and the integration of renewable energy sources to power charging stations, further enhancing the sustainability of long-distance EV travel.

Charging infrastructure for long-distance EV travel requires a strategic approach to placement and capacity. High-power charging stations are being installed along major highways and interstates, typically spaced 100-150 miles apart to accommodate the range of most modern EVs. These stations are designed to deliver rapid charging, with many capable of providing up to 350 kW of power, allowing for substantial range replenishment in 15-30 minutes.

The integration of blade batteries in EVs has influenced the design of these charging stations. The improved energy density and faster charging capabilities of blade batteries mean that charging infrastructure must be capable of delivering higher power outputs. This has led to the development of more robust power delivery systems and cooling mechanisms at charging stations to handle the increased load and heat generation during rapid charging sessions.

To support long-distance travel, charging networks are also focusing on reliability and redundancy. Multiple charging points at each station ensure that even if one unit is out of service, EV drivers can still recharge their vehicles. Advanced monitoring systems are being implemented to predict maintenance needs and minimize downtime, crucial for maintaining the viability of long-distance EV travel.

User experience is another key consideration in the development of charging infrastructure for long-distance travel. Charging stations are increasingly being co-located with amenities such as restaurants, restrooms, and shopping areas, allowing drivers to make productive use of charging time. Mobile apps and in-vehicle navigation systems are being integrated with real-time charging station availability data, enabling drivers to plan their routes and charging stops more effectively.

The expansion of charging infrastructure is also addressing the challenge of "charging deserts" in rural and less populated areas. Governments and private companies are investing in the installation of charging stations in these regions to ensure comprehensive coverage for long-distance travelers. This expansion is critical for the widespread adoption of EVs and the feasibility of cross-country travel in electric vehicles.

As blade battery technology continues to advance, charging infrastructure is expected to evolve in tandem. Future developments may include even faster charging capabilities, wireless charging options for highway rest stops, and the integration of renewable energy sources to power charging stations, further enhancing the sustainability of long-distance EV travel.

Environmental Impact of Blade Battery Production

The production of Blade Batteries for electric vehicles (EVs) has significant environmental implications that must be carefully considered. These batteries, while offering advantages for long-distance travel in EVs, also present challenges in terms of their manufacturing process and overall lifecycle impact.

The extraction of raw materials for Blade Batteries, particularly lithium, cobalt, and nickel, can have substantial environmental consequences. Mining operations often lead to habitat destruction, soil erosion, and water pollution. However, the Blade Battery's design, which reduces the use of cobalt, helps mitigate some of these concerns compared to traditional lithium-ion batteries.

During the manufacturing phase, the production of Blade Batteries requires considerable energy input, contributing to greenhouse gas emissions if not sourced from renewable energy. The complex chemical processes involved in battery production also generate potentially hazardous waste materials that need proper management and disposal.

On the positive side, the Blade Battery's increased energy density and longer lifespan compared to conventional lithium-ion batteries mean that fewer batteries need to be produced over time for the same energy storage capacity. This reduction in overall battery production can lead to a decrease in the associated environmental impacts.

The use of Blade Batteries in EVs for long-distance travel indirectly contributes to reduced emissions from the transportation sector. As these batteries enable EVs to travel further on a single charge, they make electric vehicles more viable alternatives to internal combustion engine vehicles, potentially leading to a net positive environmental impact over their lifecycle.

End-of-life considerations for Blade Batteries are crucial from an environmental perspective. The recycling process for these batteries is complex but essential to recover valuable materials and prevent environmental contamination. Advancements in recycling technologies specific to Blade Batteries are necessary to maximize material recovery and minimize waste.

The environmental footprint of Blade Battery production also extends to water usage. The manufacturing process requires significant amounts of water, which can strain local water resources, particularly in water-scarce regions. Implementing water recycling and conservation measures in production facilities is essential to address this concern.

Lastly, the transportation of raw materials and finished Blade Batteries contributes to the overall environmental impact. Localizing production closer to end markets and optimizing supply chains can help reduce the carbon footprint associated with battery logistics.

The extraction of raw materials for Blade Batteries, particularly lithium, cobalt, and nickel, can have substantial environmental consequences. Mining operations often lead to habitat destruction, soil erosion, and water pollution. However, the Blade Battery's design, which reduces the use of cobalt, helps mitigate some of these concerns compared to traditional lithium-ion batteries.

During the manufacturing phase, the production of Blade Batteries requires considerable energy input, contributing to greenhouse gas emissions if not sourced from renewable energy. The complex chemical processes involved in battery production also generate potentially hazardous waste materials that need proper management and disposal.

On the positive side, the Blade Battery's increased energy density and longer lifespan compared to conventional lithium-ion batteries mean that fewer batteries need to be produced over time for the same energy storage capacity. This reduction in overall battery production can lead to a decrease in the associated environmental impacts.

The use of Blade Batteries in EVs for long-distance travel indirectly contributes to reduced emissions from the transportation sector. As these batteries enable EVs to travel further on a single charge, they make electric vehicles more viable alternatives to internal combustion engine vehicles, potentially leading to a net positive environmental impact over their lifecycle.

End-of-life considerations for Blade Batteries are crucial from an environmental perspective. The recycling process for these batteries is complex but essential to recover valuable materials and prevent environmental contamination. Advancements in recycling technologies specific to Blade Batteries are necessary to maximize material recovery and minimize waste.

The environmental footprint of Blade Battery production also extends to water usage. The manufacturing process requires significant amounts of water, which can strain local water resources, particularly in water-scarce regions. Implementing water recycling and conservation measures in production facilities is essential to address this concern.

Lastly, the transportation of raw materials and finished Blade Batteries contributes to the overall environmental impact. Localizing production closer to end markets and optimizing supply chains can help reduce the carbon footprint associated with battery logistics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!