Challenges and Solutions in Blade Battery Thermal Management

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Blade Battery Thermal Management Background and Objectives

Blade batteries have emerged as a promising technology in the electric vehicle (EV) industry, offering enhanced safety, energy density, and space utilization. However, effective thermal management remains a critical challenge in their development and implementation. The evolution of blade battery technology can be traced back to the early 2010s when researchers began exploring new battery cell designs to improve energy density and safety in EVs.

As the automotive industry shifts towards electrification, the demand for high-performance, safe, and cost-effective battery solutions has intensified. Blade batteries, with their unique form factor and structural advantages, have gained significant attention in recent years. The primary objective of blade battery thermal management is to maintain optimal operating temperatures across the entire battery pack, ensuring consistent performance, longevity, and safety.

The technological trajectory of blade batteries has been marked by continuous improvements in cell chemistry, structural design, and thermal management strategies. Early iterations focused on optimizing the cell's internal structure to enhance heat dissipation. Subsequent developments have explored advanced cooling techniques, including liquid cooling systems and phase-change materials, to address the thermal challenges inherent in high-density battery packs.

Current research and development efforts in blade battery thermal management are driven by several key objectives. These include minimizing temperature gradients within the battery pack, reducing thermal runaway risks, extending battery life, and improving overall system efficiency. Additionally, there is a growing emphasis on developing thermal management solutions that are scalable, cost-effective, and compatible with mass production processes.

The evolution of blade battery technology is closely intertwined with advancements in materials science, thermal engineering, and battery management systems. Researchers and engineers are exploring innovative approaches such as intelligent thermal control algorithms, advanced thermal interface materials, and integrated cooling channels to enhance heat dissipation and temperature regulation.

As the EV market continues to expand, the importance of effective thermal management in blade batteries cannot be overstated. It plays a crucial role in addressing consumer concerns regarding battery safety, range anxiety, and charging times. Furthermore, optimized thermal management contributes to the overall performance and efficiency of electric vehicles, supporting the broader goals of sustainable transportation and reduced carbon emissions.

Looking ahead, the field of blade battery thermal management is poised for further innovation. Emerging trends include the development of predictive thermal management systems, the integration of artificial intelligence for real-time optimization, and the exploration of novel cooling technologies. These advancements aim to push the boundaries of battery performance while ensuring safety and reliability in diverse operating conditions.

As the automotive industry shifts towards electrification, the demand for high-performance, safe, and cost-effective battery solutions has intensified. Blade batteries, with their unique form factor and structural advantages, have gained significant attention in recent years. The primary objective of blade battery thermal management is to maintain optimal operating temperatures across the entire battery pack, ensuring consistent performance, longevity, and safety.

The technological trajectory of blade batteries has been marked by continuous improvements in cell chemistry, structural design, and thermal management strategies. Early iterations focused on optimizing the cell's internal structure to enhance heat dissipation. Subsequent developments have explored advanced cooling techniques, including liquid cooling systems and phase-change materials, to address the thermal challenges inherent in high-density battery packs.

Current research and development efforts in blade battery thermal management are driven by several key objectives. These include minimizing temperature gradients within the battery pack, reducing thermal runaway risks, extending battery life, and improving overall system efficiency. Additionally, there is a growing emphasis on developing thermal management solutions that are scalable, cost-effective, and compatible with mass production processes.

The evolution of blade battery technology is closely intertwined with advancements in materials science, thermal engineering, and battery management systems. Researchers and engineers are exploring innovative approaches such as intelligent thermal control algorithms, advanced thermal interface materials, and integrated cooling channels to enhance heat dissipation and temperature regulation.

As the EV market continues to expand, the importance of effective thermal management in blade batteries cannot be overstated. It plays a crucial role in addressing consumer concerns regarding battery safety, range anxiety, and charging times. Furthermore, optimized thermal management contributes to the overall performance and efficiency of electric vehicles, supporting the broader goals of sustainable transportation and reduced carbon emissions.

Looking ahead, the field of blade battery thermal management is poised for further innovation. Emerging trends include the development of predictive thermal management systems, the integration of artificial intelligence for real-time optimization, and the exploration of novel cooling technologies. These advancements aim to push the boundaries of battery performance while ensuring safety and reliability in diverse operating conditions.

Market Demand for Advanced EV Battery Systems

The electric vehicle (EV) market has experienced significant growth in recent years, driven by increasing environmental concerns, government incentives, and technological advancements. This growth has led to a surge in demand for advanced EV battery systems, particularly those with improved thermal management capabilities. The blade battery, a novel design in the EV battery landscape, has garnered attention for its potential to address several key challenges in battery performance and safety.

Market research indicates that consumers are increasingly prioritizing EVs with longer range, faster charging times, and enhanced safety features. These demands directly translate to the need for advanced battery systems that can deliver higher energy density, improved thermal stability, and longer lifespan. The blade battery's unique form factor and thermal management properties position it as a promising solution to meet these evolving market requirements.

In the context of thermal management, the blade battery design offers several advantages that align with market demands. Its thin, elongated structure allows for more efficient heat dissipation, addressing one of the primary concerns in EV battery performance and longevity. This improved thermal management capability can lead to faster charging speeds, reduced risk of thermal runaway, and potentially longer battery life – all of which are highly valued by consumers and automakers alike.

The market for EVs with advanced thermal management systems is expected to grow substantially in the coming years. This growth is driven not only by consumer demand but also by stringent regulatory requirements aimed at improving EV safety and performance. As a result, automakers are actively seeking battery technologies that can provide a competitive edge in these areas, creating a robust market for innovative solutions like the blade battery.

Furthermore, the increasing focus on sustainability in the automotive industry has led to a growing demand for battery systems that are not only high-performing but also more environmentally friendly. The blade battery's potential for improved resource utilization and enhanced recyclability aligns well with this market trend, potentially offering a competitive advantage to manufacturers who adopt this technology.

In conclusion, the market demand for advanced EV battery systems, particularly those with superior thermal management capabilities, is strong and growing. The blade battery's unique characteristics position it as a promising technology to meet these demands, potentially driving significant market interest and adoption in the coming years.

Market research indicates that consumers are increasingly prioritizing EVs with longer range, faster charging times, and enhanced safety features. These demands directly translate to the need for advanced battery systems that can deliver higher energy density, improved thermal stability, and longer lifespan. The blade battery's unique form factor and thermal management properties position it as a promising solution to meet these evolving market requirements.

In the context of thermal management, the blade battery design offers several advantages that align with market demands. Its thin, elongated structure allows for more efficient heat dissipation, addressing one of the primary concerns in EV battery performance and longevity. This improved thermal management capability can lead to faster charging speeds, reduced risk of thermal runaway, and potentially longer battery life – all of which are highly valued by consumers and automakers alike.

The market for EVs with advanced thermal management systems is expected to grow substantially in the coming years. This growth is driven not only by consumer demand but also by stringent regulatory requirements aimed at improving EV safety and performance. As a result, automakers are actively seeking battery technologies that can provide a competitive edge in these areas, creating a robust market for innovative solutions like the blade battery.

Furthermore, the increasing focus on sustainability in the automotive industry has led to a growing demand for battery systems that are not only high-performing but also more environmentally friendly. The blade battery's potential for improved resource utilization and enhanced recyclability aligns well with this market trend, potentially offering a competitive advantage to manufacturers who adopt this technology.

In conclusion, the market demand for advanced EV battery systems, particularly those with superior thermal management capabilities, is strong and growing. The blade battery's unique characteristics position it as a promising technology to meet these demands, potentially driving significant market interest and adoption in the coming years.

Current Challenges in Blade Battery Thermal Control

Blade batteries, known for their high energy density and compact design, face significant thermal management challenges that impact their performance, safety, and longevity. One of the primary issues is the uneven heat distribution within the battery pack. Due to the tightly packed cells in a blade configuration, heat tends to accumulate in the center, creating temperature gradients that can lead to thermal runaway and reduced overall efficiency.

Another critical challenge is the limited space for thermal management systems. The slim profile of blade batteries, while advantageous for vehicle design, restricts the implementation of traditional cooling methods. This constraint makes it difficult to incorporate adequate cooling channels or heat dissipation mechanisms, potentially compromising the battery's thermal stability during high-power charging and discharging cycles.

The high energy density of blade batteries also contributes to increased heat generation during operation. This heat buildup can accelerate battery degradation, reducing its lifespan and performance over time. Managing this excess heat effectively without compromising the battery's compact form factor remains a significant engineering challenge.

Furthermore, the thermal behavior of blade batteries varies significantly under different operating conditions. Extreme temperatures, both hot and cold, can severely impact battery performance and safety. Developing a thermal management system that can adapt to these varying conditions while maintaining optimal battery temperature is crucial yet complex.

The integration of blade batteries into electric vehicles presents additional thermal control challenges. The battery pack must not only manage its internal heat but also withstand external heat sources from the vehicle's operation and environmental factors. This requires a holistic approach to thermal management that considers the entire vehicle system.

Lastly, the cost and complexity of implementing advanced thermal management solutions pose a significant challenge. Balancing the need for effective cooling with the economic constraints of mass production is a delicate task. Innovative, cost-effective thermal management solutions that can be scaled for large-scale manufacturing are in high demand but remain elusive.

Addressing these challenges requires a multifaceted approach, combining advanced materials science, innovative cooling technologies, and sophisticated thermal modeling. The development of more efficient heat dissipation methods, such as phase change materials or advanced liquid cooling systems, shows promise. However, their integration into the compact blade battery design without compromising energy density or increasing costs significantly remains a key area of ongoing research and development in the field of electric vehicle battery technology.

Another critical challenge is the limited space for thermal management systems. The slim profile of blade batteries, while advantageous for vehicle design, restricts the implementation of traditional cooling methods. This constraint makes it difficult to incorporate adequate cooling channels or heat dissipation mechanisms, potentially compromising the battery's thermal stability during high-power charging and discharging cycles.

The high energy density of blade batteries also contributes to increased heat generation during operation. This heat buildup can accelerate battery degradation, reducing its lifespan and performance over time. Managing this excess heat effectively without compromising the battery's compact form factor remains a significant engineering challenge.

Furthermore, the thermal behavior of blade batteries varies significantly under different operating conditions. Extreme temperatures, both hot and cold, can severely impact battery performance and safety. Developing a thermal management system that can adapt to these varying conditions while maintaining optimal battery temperature is crucial yet complex.

The integration of blade batteries into electric vehicles presents additional thermal control challenges. The battery pack must not only manage its internal heat but also withstand external heat sources from the vehicle's operation and environmental factors. This requires a holistic approach to thermal management that considers the entire vehicle system.

Lastly, the cost and complexity of implementing advanced thermal management solutions pose a significant challenge. Balancing the need for effective cooling with the economic constraints of mass production is a delicate task. Innovative, cost-effective thermal management solutions that can be scaled for large-scale manufacturing are in high demand but remain elusive.

Addressing these challenges requires a multifaceted approach, combining advanced materials science, innovative cooling technologies, and sophisticated thermal modeling. The development of more efficient heat dissipation methods, such as phase change materials or advanced liquid cooling systems, shows promise. However, their integration into the compact blade battery design without compromising energy density or increasing costs significantly remains a key area of ongoing research and development in the field of electric vehicle battery technology.

Existing Thermal Management Solutions for Blade Batteries

01 Cooling system design for blade batteries

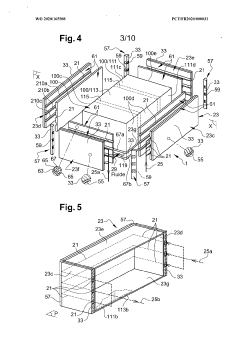

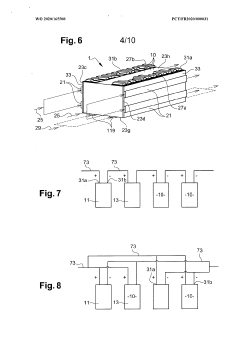

Innovative cooling system designs are implemented to manage the thermal output of blade batteries. These systems may include liquid cooling channels, heat pipes, or air cooling mechanisms integrated into the battery structure. The cooling systems are designed to efficiently dissipate heat, maintain optimal operating temperatures, and prevent thermal runaway.- Cooling system design for blade batteries: Blade batteries require efficient cooling systems to manage thermal issues. This includes the use of liquid cooling channels, heat pipes, or air cooling systems integrated into the battery pack design. These cooling systems help maintain optimal operating temperatures, improve battery performance, and extend lifespan.

- Temperature monitoring and control: Advanced temperature monitoring systems are implemented in blade batteries to continuously track thermal conditions. These systems use sensors and control algorithms to adjust cooling mechanisms in real-time, preventing overheating and ensuring safe operation across various charging and discharging scenarios.

- Thermal insulation and heat dissipation materials: Specialized materials are used in blade battery construction to enhance thermal management. This includes high-performance thermal insulation materials to prevent heat transfer between cells and heat-dissipating materials to efficiently remove excess heat from the battery pack.

- Battery pack layout optimization: The arrangement of cells within the blade battery pack is optimized to improve thermal management. This involves strategic placement of cooling elements, creating air flow channels, and designing the overall pack structure to facilitate even heat distribution and efficient cooling across all cells.

- Thermal management during charging and fast-charging: Specific thermal management strategies are employed during charging processes, especially for fast-charging scenarios. This includes pre-cooling systems, adaptive charging algorithms that consider thermal conditions, and integration with external cooling infrastructure at charging stations to manage heat generation during rapid energy transfer.

02 Thermal management materials and coatings

Advanced materials and coatings are utilized to enhance thermal management in blade batteries. These may include phase change materials, thermally conductive adhesives, or specialized coatings that improve heat dissipation. The materials are selected and applied to optimize thermal conductivity and heat distribution within the battery pack.Expand Specific Solutions03 Battery pack layout and thermal isolation

The arrangement and layout of blade batteries within the pack are optimized for thermal management. This includes strategic positioning of cells, incorporation of thermal barriers, and design of air flow paths. The layout aims to minimize heat transfer between cells and improve overall thermal efficiency of the battery system.Expand Specific Solutions04 Intelligent thermal management control systems

Advanced control systems are developed to actively manage the thermal conditions of blade batteries. These systems use sensors, algorithms, and predictive models to monitor temperature, adjust cooling mechanisms, and optimize battery performance. The intelligent controls help maintain ideal operating temperatures and extend battery life.Expand Specific Solutions05 Integration with vehicle thermal management

Blade battery thermal management systems are integrated with the overall vehicle thermal management. This approach allows for synergies between the battery cooling system and other vehicle systems, such as cabin climate control or powertrain cooling. The integration improves energy efficiency and overall thermal performance of the vehicle.Expand Specific Solutions

Key Players in Blade Battery and Thermal Management Industry

The blade battery thermal management sector is in a growth phase, with increasing market size driven by the rising demand for electric vehicles. The technology is maturing rapidly, but challenges remain in optimizing efficiency and safety. Key players like Contemporary Amperex Technology Co., Ltd. and LG Energy Solution Ltd. are leading innovation, while companies such as Svolt Energy Technology Co., Ltd. and Samsung SDI Co., Ltd. are also making significant contributions. The competitive landscape is characterized by intense R&D efforts, with both established automotive suppliers and specialized battery manufacturers vying for market share. As the technology evolves, collaboration between academia and industry, exemplified by partnerships with institutions like Beijing Institute of Technology, is becoming increasingly important for addressing complex thermal management issues.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL's blade battery thermal management system employs an innovative liquid cooling solution that circulates a coolant through channels integrated into the battery pack. This design allows for efficient heat dissipation across the entire battery surface, maintaining optimal operating temperatures. The system utilizes advanced thermal modeling and real-time temperature monitoring to adjust cooling intensity based on battery load and environmental conditions. CATL has also implemented a phase-change material (PCM) layer within the battery structure, which absorbs excess heat during high-load operations and releases it during cooler periods, further stabilizing temperature fluctuations[1][3].

Strengths: Excellent thermal efficiency, uniform temperature distribution, and adaptive cooling. Weaknesses: Increased complexity and potential for coolant leakage.

Svolt Energy Technology Co., Ltd.

Technical Solution: Svolt's approach to blade battery thermal management focuses on a multi-layered strategy. They employ a combination of air and liquid cooling systems, with a particular emphasis on their patented "honeycomb" structure within the battery pack. This structure maximizes surface area for heat exchange while minimizing weight. Svolt's system also incorporates intelligent thermal management algorithms that predict heat generation based on usage patterns and preemptively adjust cooling parameters. Additionally, they have developed a novel thermal interface material that enhances heat transfer between cells and cooling plates[2][4].

Strengths: Balanced approach combining air and liquid cooling, lightweight design. Weaknesses: Potential for increased manufacturing complexity due to intricate internal structures.

Innovative Approaches in Blade Battery Cooling Systems

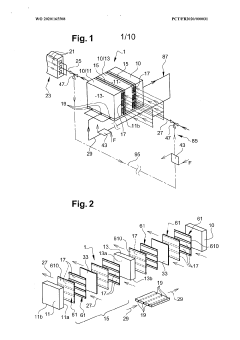

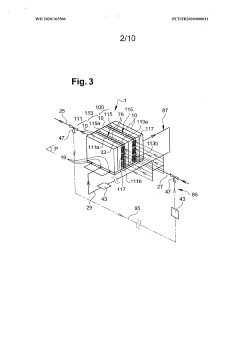

Battery Module, Battery Device, and Battery System Having Thermal Management Design

PatentPendingUS20240429488A1

Innovation

- A battery module and system design incorporating a thermal management system with a temperature control medium circulated through a system fluid circulation device, utilizing a heat exchange pipe that acts as both a heat exchange medium and current path, and an enclosure with high thermal insulation capabilities to maintain temperature uniformity and efficiency across battery cells.

Electric battery thermal management structure

PatentWO2020165508A1

Innovation

- A thermal management assembly with three distinct fluid circulation circuits: a first circuit between adjacent cells, a second circuit around the cell stack, and a third circuit on an alternate face, utilizing phase change materials and thermally conductive/insulating elements, along with valve control systems to manage fluid flow based on temperature and charge state data.

Safety Standards and Regulations for EV Battery Systems

The safety standards and regulations for electric vehicle (EV) battery systems have evolved significantly in response to the growing adoption of EVs and the need to ensure their safe operation. These standards address various aspects of battery design, manufacturing, testing, and performance, with a particular focus on thermal management and fire safety.

International organizations such as the Society of Automotive Engineers (SAE), the International Electrotechnical Commission (IEC), and the United Nations Economic Commission for Europe (UNECE) have developed comprehensive standards for EV battery systems. These include SAE J2929, which outlines safety requirements for lithium-ion battery packs in electric and hybrid vehicles, and IEC 62660, which specifies performance and life cycle testing for lithium-ion cells used in EVs.

Thermal management is a critical component of these safety standards, given its importance in preventing thermal runaway and ensuring optimal battery performance. Regulations typically require manufacturers to implement robust thermal management systems that can maintain battery temperature within safe operating ranges under various conditions, including extreme ambient temperatures and high-power charging scenarios.

Fire safety is another key focus area, with standards mandating the use of fire-resistant materials, thermal barriers, and venting systems to mitigate the risk of fire propagation within the battery pack. Additionally, regulations often require extensive testing protocols to evaluate battery behavior under abuse conditions, such as overcharging, short-circuiting, and mechanical impact.

Many countries have adopted or adapted these international standards into their national regulations. For instance, the United States National Highway Traffic Safety Administration (NHTSA) has incorporated elements of SAE J2929 into its Federal Motor Vehicle Safety Standards (FMVSS). Similarly, the European Union has developed the UN Regulation No. 100, which sets safety requirements for the electric power train of road vehicles.

As blade battery technology continues to advance, regulatory bodies are working to update existing standards and develop new ones to address the specific characteristics and potential risks associated with this design. This includes considerations for the unique thermal management challenges posed by the blade battery's compact and integrated structure.

Compliance with these safety standards and regulations is crucial for EV manufacturers and battery suppliers. It not only ensures the safety of consumers but also plays a significant role in building public trust in EV technology and supporting the broader adoption of electric vehicles in the global automotive market.

International organizations such as the Society of Automotive Engineers (SAE), the International Electrotechnical Commission (IEC), and the United Nations Economic Commission for Europe (UNECE) have developed comprehensive standards for EV battery systems. These include SAE J2929, which outlines safety requirements for lithium-ion battery packs in electric and hybrid vehicles, and IEC 62660, which specifies performance and life cycle testing for lithium-ion cells used in EVs.

Thermal management is a critical component of these safety standards, given its importance in preventing thermal runaway and ensuring optimal battery performance. Regulations typically require manufacturers to implement robust thermal management systems that can maintain battery temperature within safe operating ranges under various conditions, including extreme ambient temperatures and high-power charging scenarios.

Fire safety is another key focus area, with standards mandating the use of fire-resistant materials, thermal barriers, and venting systems to mitigate the risk of fire propagation within the battery pack. Additionally, regulations often require extensive testing protocols to evaluate battery behavior under abuse conditions, such as overcharging, short-circuiting, and mechanical impact.

Many countries have adopted or adapted these international standards into their national regulations. For instance, the United States National Highway Traffic Safety Administration (NHTSA) has incorporated elements of SAE J2929 into its Federal Motor Vehicle Safety Standards (FMVSS). Similarly, the European Union has developed the UN Regulation No. 100, which sets safety requirements for the electric power train of road vehicles.

As blade battery technology continues to advance, regulatory bodies are working to update existing standards and develop new ones to address the specific characteristics and potential risks associated with this design. This includes considerations for the unique thermal management challenges posed by the blade battery's compact and integrated structure.

Compliance with these safety standards and regulations is crucial for EV manufacturers and battery suppliers. It not only ensures the safety of consumers but also plays a significant role in building public trust in EV technology and supporting the broader adoption of electric vehicles in the global automotive market.

Environmental Impact of Blade Battery Thermal Management

The environmental impact of blade battery thermal management systems is a critical consideration in the development and deployment of electric vehicles (EVs). These systems play a crucial role in maintaining optimal battery performance and longevity, but their operation can have significant environmental implications.

One of the primary environmental concerns associated with blade battery thermal management is energy consumption. The cooling and heating processes required to maintain ideal battery temperatures consume additional energy, potentially reducing the overall efficiency of the EV. This increased energy demand may lead to higher electricity consumption, which, depending on the energy source, could result in increased greenhouse gas emissions.

Water usage is another important environmental factor to consider. Some thermal management systems employ liquid cooling methods that require substantial amounts of water. In regions facing water scarcity, this could pose a significant environmental challenge and strain local water resources.

The production and disposal of thermal management components also contribute to the environmental footprint of blade batteries. Manufacturing processes for specialized cooling systems, heat exchangers, and thermal interface materials may involve energy-intensive procedures and the use of potentially harmful chemicals. Additionally, the end-of-life disposal or recycling of these components presents challenges in terms of waste management and resource recovery.

However, it is essential to note that effective thermal management systems can significantly extend battery life, reducing the frequency of battery replacements and associated environmental impacts of battery production and disposal. This long-term benefit may offset some of the immediate environmental costs associated with thermal management systems.

Innovations in thermal management technologies are actively addressing these environmental concerns. The development of more efficient cooling methods, such as phase change materials and advanced air cooling systems, aims to reduce energy consumption and minimize the use of water and other resources. Furthermore, research into biodegradable and recyclable materials for thermal management components is progressing, potentially mitigating end-of-life environmental impacts.

As the EV industry continues to evolve, balancing the performance benefits of blade battery thermal management with environmental sustainability remains a key challenge. Future advancements in this field will likely focus on developing more eco-friendly thermal management solutions that minimize resource consumption and environmental impact while maintaining optimal battery performance and longevity.

One of the primary environmental concerns associated with blade battery thermal management is energy consumption. The cooling and heating processes required to maintain ideal battery temperatures consume additional energy, potentially reducing the overall efficiency of the EV. This increased energy demand may lead to higher electricity consumption, which, depending on the energy source, could result in increased greenhouse gas emissions.

Water usage is another important environmental factor to consider. Some thermal management systems employ liquid cooling methods that require substantial amounts of water. In regions facing water scarcity, this could pose a significant environmental challenge and strain local water resources.

The production and disposal of thermal management components also contribute to the environmental footprint of blade batteries. Manufacturing processes for specialized cooling systems, heat exchangers, and thermal interface materials may involve energy-intensive procedures and the use of potentially harmful chemicals. Additionally, the end-of-life disposal or recycling of these components presents challenges in terms of waste management and resource recovery.

However, it is essential to note that effective thermal management systems can significantly extend battery life, reducing the frequency of battery replacements and associated environmental impacts of battery production and disposal. This long-term benefit may offset some of the immediate environmental costs associated with thermal management systems.

Innovations in thermal management technologies are actively addressing these environmental concerns. The development of more efficient cooling methods, such as phase change materials and advanced air cooling systems, aims to reduce energy consumption and minimize the use of water and other resources. Furthermore, research into biodegradable and recyclable materials for thermal management components is progressing, potentially mitigating end-of-life environmental impacts.

As the EV industry continues to evolve, balancing the performance benefits of blade battery thermal management with environmental sustainability remains a key challenge. Future advancements in this field will likely focus on developing more eco-friendly thermal management solutions that minimize resource consumption and environmental impact while maintaining optimal battery performance and longevity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!