Modelling Blade Battery Performance in Extreme Climates

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Blade Battery Evolution and Objectives

Blade batteries have emerged as a revolutionary technology in the energy storage sector, particularly for electric vehicles (EVs). The evolution of blade batteries can be traced back to the early 2010s when the need for safer, more efficient, and longer-lasting battery solutions became apparent in the rapidly growing EV market. Initially, the focus was on improving the energy density and safety of traditional lithium-ion batteries.

As the technology progressed, researchers and engineers identified the potential of lithium iron phosphate (LFP) chemistry combined with a novel structural design. This led to the development of blade batteries, which are characterized by their long, thin form factor and improved safety features. The primary objectives driving the evolution of blade batteries have been to enhance energy density, improve safety, extend battery life, and reduce production costs.

One of the key milestones in blade battery development was the introduction of cell-to-pack (CTP) technology. This innovation allowed for more efficient use of space within the battery pack, resulting in higher energy density and improved overall performance. The CTP approach also simplified the manufacturing process, contributing to cost reduction and increased production efficiency.

Another significant objective in blade battery evolution has been to address the inherent safety concerns associated with lithium-ion batteries. By utilizing LFP chemistry and implementing a more stable structural design, blade batteries have demonstrated superior resistance to thermal runaway and reduced risk of fire or explosion, even under extreme conditions.

The ongoing evolution of blade batteries is now focused on optimizing their performance across a wide range of environmental conditions. This includes addressing challenges such as extreme temperatures, which can significantly impact battery efficiency and longevity. The objective is to develop blade batteries that maintain consistent performance and safety standards in diverse climates, from arctic cold to tropical heat.

Modelling blade battery performance in extreme climates has become a critical aspect of this evolutionary process. Researchers are working to create sophisticated simulation models that can accurately predict battery behavior under various environmental stresses. These models aim to inform design improvements and operational strategies to ensure optimal performance and longevity in real-world applications.

Looking ahead, the objectives for blade battery technology include further improvements in energy density, faster charging capabilities, and enhanced integration with smart grid systems. Additionally, there is a growing focus on sustainability, with efforts to develop more environmentally friendly production processes and improve the recyclability of blade batteries at the end of their lifecycle.

As the technology progressed, researchers and engineers identified the potential of lithium iron phosphate (LFP) chemistry combined with a novel structural design. This led to the development of blade batteries, which are characterized by their long, thin form factor and improved safety features. The primary objectives driving the evolution of blade batteries have been to enhance energy density, improve safety, extend battery life, and reduce production costs.

One of the key milestones in blade battery development was the introduction of cell-to-pack (CTP) technology. This innovation allowed for more efficient use of space within the battery pack, resulting in higher energy density and improved overall performance. The CTP approach also simplified the manufacturing process, contributing to cost reduction and increased production efficiency.

Another significant objective in blade battery evolution has been to address the inherent safety concerns associated with lithium-ion batteries. By utilizing LFP chemistry and implementing a more stable structural design, blade batteries have demonstrated superior resistance to thermal runaway and reduced risk of fire or explosion, even under extreme conditions.

The ongoing evolution of blade batteries is now focused on optimizing their performance across a wide range of environmental conditions. This includes addressing challenges such as extreme temperatures, which can significantly impact battery efficiency and longevity. The objective is to develop blade batteries that maintain consistent performance and safety standards in diverse climates, from arctic cold to tropical heat.

Modelling blade battery performance in extreme climates has become a critical aspect of this evolutionary process. Researchers are working to create sophisticated simulation models that can accurately predict battery behavior under various environmental stresses. These models aim to inform design improvements and operational strategies to ensure optimal performance and longevity in real-world applications.

Looking ahead, the objectives for blade battery technology include further improvements in energy density, faster charging capabilities, and enhanced integration with smart grid systems. Additionally, there is a growing focus on sustainability, with efforts to develop more environmentally friendly production processes and improve the recyclability of blade batteries at the end of their lifecycle.

Market Analysis for Climate-Resilient EV Batteries

The market for climate-resilient EV batteries, particularly those designed to perform in extreme climates, is experiencing significant growth and transformation. This trend is driven by the increasing global demand for electric vehicles and the need for reliable battery performance across diverse environmental conditions. As climate change intensifies, regions previously considered moderate are now experiencing more frequent extreme weather events, expanding the market for robust battery solutions.

The automotive industry is a primary driver of this market, with major manufacturers investing heavily in research and development to create batteries that can withstand temperature extremes. The focus on blade batteries, known for their high energy density and improved safety features, is particularly noteworthy in this context. These batteries are gaining traction due to their potential to maintain performance in challenging climatic conditions.

Market analysis indicates a growing consumer awareness of the importance of battery resilience in extreme climates. This awareness is translating into a willingness to pay premium prices for vehicles equipped with advanced, climate-resistant battery technology. The market is not limited to personal vehicles; commercial and public transportation sectors are also showing increased interest in these batteries, recognizing the need for reliable performance in varied environmental conditions.

Geographically, the market for climate-resilient EV batteries is expanding beyond traditional automotive strongholds. Emerging markets in regions with extreme climates, such as parts of the Middle East, Northern Europe, and equatorial countries, are becoming significant players in this sector. These areas are not only potential markets but also testing grounds for new battery technologies designed to withstand harsh environmental conditions.

The market is also being shaped by regulatory pressures and environmental policies. Governments worldwide are implementing stricter emissions standards and offering incentives for EV adoption, indirectly boosting the demand for advanced battery technologies. This regulatory landscape is encouraging innovation in battery design and manufacturing, with a focus on creating more resilient and efficient energy storage solutions.

Competition in this market is intensifying, with both established automotive companies and new entrants vying for market share. This competition is driving rapid technological advancements and pushing the boundaries of battery performance in extreme conditions. Collaborations between battery manufacturers, automotive companies, and research institutions are becoming more common, accelerating the pace of innovation in this field.

As the market for climate-resilient EV batteries continues to evolve, it is expected to play a crucial role in the broader transition to sustainable transportation. The ability to model and predict battery performance in extreme climates will be a key differentiator for companies in this space, influencing market dynamics and shaping future investment strategies in the EV industry.

The automotive industry is a primary driver of this market, with major manufacturers investing heavily in research and development to create batteries that can withstand temperature extremes. The focus on blade batteries, known for their high energy density and improved safety features, is particularly noteworthy in this context. These batteries are gaining traction due to their potential to maintain performance in challenging climatic conditions.

Market analysis indicates a growing consumer awareness of the importance of battery resilience in extreme climates. This awareness is translating into a willingness to pay premium prices for vehicles equipped with advanced, climate-resistant battery technology. The market is not limited to personal vehicles; commercial and public transportation sectors are also showing increased interest in these batteries, recognizing the need for reliable performance in varied environmental conditions.

Geographically, the market for climate-resilient EV batteries is expanding beyond traditional automotive strongholds. Emerging markets in regions with extreme climates, such as parts of the Middle East, Northern Europe, and equatorial countries, are becoming significant players in this sector. These areas are not only potential markets but also testing grounds for new battery technologies designed to withstand harsh environmental conditions.

The market is also being shaped by regulatory pressures and environmental policies. Governments worldwide are implementing stricter emissions standards and offering incentives for EV adoption, indirectly boosting the demand for advanced battery technologies. This regulatory landscape is encouraging innovation in battery design and manufacturing, with a focus on creating more resilient and efficient energy storage solutions.

Competition in this market is intensifying, with both established automotive companies and new entrants vying for market share. This competition is driving rapid technological advancements and pushing the boundaries of battery performance in extreme conditions. Collaborations between battery manufacturers, automotive companies, and research institutions are becoming more common, accelerating the pace of innovation in this field.

As the market for climate-resilient EV batteries continues to evolve, it is expected to play a crucial role in the broader transition to sustainable transportation. The ability to model and predict battery performance in extreme climates will be a key differentiator for companies in this space, influencing market dynamics and shaping future investment strategies in the EV industry.

Challenges in Extreme Climate Battery Performance

Modelling battery performance in extreme climates presents significant challenges due to the complex interplay between environmental factors and battery chemistry. One of the primary obstacles is accurately simulating the wide range of temperature fluctuations that batteries may encounter in real-world scenarios. Extreme heat and cold can dramatically affect battery capacity, charging efficiency, and overall lifespan.

In hot climates, elevated temperatures accelerate chemical reactions within the battery, potentially leading to thermal runaway and premature aging. Conversely, cold temperatures can significantly reduce battery performance by slowing down chemical processes and increasing internal resistance. These temperature-induced effects are particularly pronounced in blade batteries, which have a unique form factor that can influence heat distribution and dissipation.

Another challenge lies in modelling the impact of humidity and atmospheric pressure on battery performance. High humidity levels can lead to condensation and corrosion, affecting the battery's internal components and electrical connections. Atmospheric pressure variations, especially in high-altitude environments, can influence the battery's gas venting mechanisms and overall safety features.

The dynamic nature of extreme climates adds another layer of complexity to performance modelling. Rapid temperature changes, such as those experienced in desert environments with scorching days and frigid nights, can induce thermal stress on battery materials. This cyclic stress can lead to mechanical degradation over time, a factor that must be accurately represented in long-term performance models.

Furthermore, the interaction between extreme climate conditions and the battery management system (BMS) poses a significant modelling challenge. The BMS must adapt its control strategies to optimize battery performance and safety across a wide range of environmental conditions. Accurately predicting how these adaptive algorithms will behave under various extreme scenarios is crucial for developing robust battery systems.

Modelling the degradation of battery materials and components under prolonged exposure to extreme climates is another critical challenge. Factors such as electrolyte decomposition, electrode material changes, and separator degradation can all be accelerated or altered by extreme environmental conditions. Capturing these long-term effects in performance models requires a deep understanding of materials science and electrochemistry.

Lastly, validating battery performance models for extreme climates presents its own set of challenges. Conducting real-world tests across the full spectrum of possible environmental conditions is time-consuming and expensive. As a result, researchers must develop innovative methods to extrapolate limited test data to a broader range of scenarios while maintaining model accuracy and reliability.

In hot climates, elevated temperatures accelerate chemical reactions within the battery, potentially leading to thermal runaway and premature aging. Conversely, cold temperatures can significantly reduce battery performance by slowing down chemical processes and increasing internal resistance. These temperature-induced effects are particularly pronounced in blade batteries, which have a unique form factor that can influence heat distribution and dissipation.

Another challenge lies in modelling the impact of humidity and atmospheric pressure on battery performance. High humidity levels can lead to condensation and corrosion, affecting the battery's internal components and electrical connections. Atmospheric pressure variations, especially in high-altitude environments, can influence the battery's gas venting mechanisms and overall safety features.

The dynamic nature of extreme climates adds another layer of complexity to performance modelling. Rapid temperature changes, such as those experienced in desert environments with scorching days and frigid nights, can induce thermal stress on battery materials. This cyclic stress can lead to mechanical degradation over time, a factor that must be accurately represented in long-term performance models.

Furthermore, the interaction between extreme climate conditions and the battery management system (BMS) poses a significant modelling challenge. The BMS must adapt its control strategies to optimize battery performance and safety across a wide range of environmental conditions. Accurately predicting how these adaptive algorithms will behave under various extreme scenarios is crucial for developing robust battery systems.

Modelling the degradation of battery materials and components under prolonged exposure to extreme climates is another critical challenge. Factors such as electrolyte decomposition, electrode material changes, and separator degradation can all be accelerated or altered by extreme environmental conditions. Capturing these long-term effects in performance models requires a deep understanding of materials science and electrochemistry.

Lastly, validating battery performance models for extreme climates presents its own set of challenges. Conducting real-world tests across the full spectrum of possible environmental conditions is time-consuming and expensive. As a result, researchers must develop innovative methods to extrapolate limited test data to a broader range of scenarios while maintaining model accuracy and reliability.

Current Extreme Climate Battery Solutions

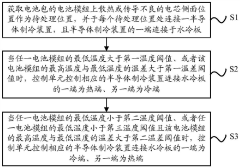

01 Battery Management System for Blade Batteries

Advanced battery management systems are crucial for optimizing blade battery performance. These systems monitor and control various parameters such as temperature, voltage, and current to ensure efficient operation and longevity of the battery. They also implement safety features to prevent overcharging, overheating, and other potential issues.- Battery Management System for Blade Batteries: Advanced battery management systems are crucial for optimizing blade battery performance. These systems monitor and control various parameters such as temperature, voltage, and current to ensure efficient operation and longevity of the battery. They also implement safety features to prevent overcharging, over-discharging, and thermal runaway.

- Thermal Management in Blade Batteries: Effective thermal management is essential for maintaining optimal blade battery performance. This includes innovative cooling systems, heat dissipation techniques, and temperature control mechanisms. Proper thermal management helps prevent capacity loss, extends battery life, and ensures consistent performance across various operating conditions.

- Blade Battery Cell Design and Structure: The design and structure of blade battery cells significantly impact their performance. This includes advancements in electrode materials, separator technology, and cell packaging. Improved cell design can lead to higher energy density, faster charging capabilities, and enhanced safety features.

- Performance Testing and Evaluation Methods: Developing sophisticated testing and evaluation methods is crucial for assessing and improving blade battery performance. This includes advanced diagnostic tools, performance prediction models, and accelerated aging tests. These methods help in identifying potential issues, optimizing battery design, and ensuring long-term reliability.

- Integration of Blade Batteries in Electric Vehicles: Optimizing the integration of blade batteries in electric vehicles is key to maximizing their performance. This involves designing efficient power distribution systems, implementing smart charging strategies, and developing vehicle-to-grid technologies. Proper integration ensures optimal energy utilization, extended driving range, and improved overall vehicle performance.

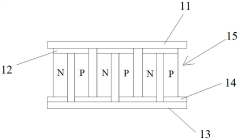

02 Thermal Management in Blade Batteries

Effective thermal management is essential for maintaining optimal blade battery performance. This includes innovative cooling systems and heat dissipation techniques to prevent overheating and ensure consistent performance across various operating conditions. Proper thermal management also contributes to extended battery life and improved safety.Expand Specific Solutions03 Blade Battery Cell Design and Configuration

The design and configuration of blade battery cells play a significant role in overall battery performance. This includes optimizing the cell structure, electrode materials, and electrolyte composition to enhance energy density, power output, and cycle life. Innovative cell designs also focus on improving safety features and reducing manufacturing costs.Expand Specific Solutions04 Performance Testing and Quality Control

Rigorous performance testing and quality control measures are implemented to ensure consistent and reliable blade battery performance. This involves comprehensive testing protocols for capacity, cycle life, safety, and environmental resilience. Advanced diagnostic tools and techniques are used to identify potential issues and maintain high-quality standards throughout the production process.Expand Specific Solutions05 Integration of Blade Batteries in Electric Vehicles

The integration of blade batteries in electric vehicles requires specialized design considerations to maximize performance and efficiency. This includes optimizing the battery pack layout, improving energy management systems, and enhancing the overall vehicle architecture to accommodate the unique characteristics of blade batteries. The focus is on achieving better range, faster charging, and improved vehicle dynamics.Expand Specific Solutions

Key Players in Blade Battery Manufacturing

The competitive landscape for modelling blade battery performance in extreme climates is evolving rapidly, reflecting the growing importance of electric vehicles and energy storage solutions. The market is in a growth phase, with increasing demand for high-performance batteries capable of withstanding diverse environmental conditions. Key players like LG Energy Solution, Tesla, and CATL are investing heavily in research and development to improve battery technology. The market size is expanding, driven by the automotive sector's shift towards electrification and the need for reliable energy storage systems. Technologically, companies are at various stages of maturity, with established firms like Sony and emerging players like Svolt Energy Technology competing to develop innovative solutions for extreme climate performance.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution's approach to modeling blade battery performance in extreme climates involves a combination of advanced materials science and sophisticated thermal management systems. The company utilizes proprietary electrolyte additives and electrode coatings that enhance battery stability across a wide temperature range. LG's modeling incorporates detailed electrochemical simulations that account for ion transport and electrode kinetics under various thermal conditions. The company's battery management system employs predictive algorithms that anticipate performance changes based on environmental factors and usage patterns[9]. LG also utilizes accelerated life testing methods to simulate long-term battery behavior in extreme climates, informing their modeling and design processes[10].

Strengths: Strong materials science foundation, comprehensive electrochemical modeling, and extensive manufacturing experience. Weaknesses: Potential for over-reliance on laboratory-based simulations versus real-world data in extreme conditions.

Robert Bosch GmbH

Technical Solution: Bosch's approach to modeling blade battery performance in extreme climates leverages its extensive experience in automotive systems and sensor technology. The company employs a multi-faceted modeling strategy that combines physical models with data-driven approaches. Bosch's system utilizes a network of high-precision temperature and current sensors to gather real-time data on battery conditions. This data feeds into advanced machine learning algorithms that predict battery behavior under various environmental stresses[7]. Bosch's modeling also incorporates aging factors and usage patterns to provide a comprehensive view of battery performance over time. The company's Battery in the Loop (BiL) simulation technology allows for virtual testing of batteries under extreme conditions, reducing development time and costs[8].

Strengths: Comprehensive sensor integration, advanced simulation capabilities, and extensive automotive industry experience. Weaknesses: Primary focus on supplying components rather than complete battery systems may limit full-scale implementation.

Core Innovations in Blade Battery Technology

Heat-augmented primary battery

PatentActiveUS11831044B2

Innovation

- Incorporating heat-generating materials, such as pyrotechnic thermites and phase change materials, to raise the temperature of primary batteries from ambient to higher levels, enabling discharge in low-temperature environments, with phase change materials acting as thermal buffers to maintain a benign surface temperature and protect against high thermal transients.

Battery pack thermal management system and method

PatentActiveCN113889684A

Innovation

- The semiconductor refrigeration device is installed on the side of the battery module where the heat dissipation or conduction is poor, and the water-cooling plate cooperates with the control unit to dynamically adjust the hot end and cold end of the semiconductor refrigeration device to achieve rapid cooling or Heating ensures even heat dissipation and heat transfer.

Environmental Impact Assessment

The environmental impact assessment of modelling blade battery performance in extreme climates is a crucial aspect of sustainable technology development. Extreme climates, characterized by temperature extremes, high humidity, or severe weather conditions, can significantly affect battery performance and longevity. This assessment aims to evaluate the potential environmental consequences of blade battery production, use, and disposal in such challenging environments.

Blade batteries, known for their high energy density and improved safety features, may require specialized materials and manufacturing processes to withstand extreme climates. The production of these batteries could lead to increased energy consumption and greenhouse gas emissions, particularly if additional protective measures are necessary for extreme climate resilience. However, the extended lifespan and improved performance of blade batteries in harsh conditions may offset these initial environmental costs over time.

In extreme cold climates, battery performance typically decreases due to reduced chemical reaction rates. This may lead to increased energy demand for battery heating systems, potentially resulting in higher overall energy consumption and associated emissions. Conversely, in extremely hot climates, the risk of thermal runaway and accelerated degradation of battery components increases, potentially shortening the battery's lifespan and necessitating more frequent replacements.

The environmental impact of blade batteries in extreme climates extends to their end-of-life management. Harsh conditions may accelerate battery degradation, leading to more frequent disposal and recycling needs. This could strain existing recycling infrastructure and potentially increase the risk of improper disposal, which may result in soil and water contamination if not managed correctly.

However, the improved performance of blade batteries in extreme climates could have positive environmental implications. By maintaining efficiency in challenging conditions, these batteries could reduce the need for backup power systems or frequent replacements, thereby decreasing overall resource consumption and waste generation. Additionally, their enhanced performance could support the adoption of renewable energy systems in remote or climatically challenging areas, contributing to reduced reliance on fossil fuels.

The assessment must also consider the potential for technological advancements in blade battery design specifically tailored for extreme climates. Innovations in thermal management, electrolyte composition, and protective coatings could mitigate some of the environmental concerns associated with battery performance in harsh conditions. These advancements may lead to more environmentally friendly production processes and improved recyclability, further reducing the overall environmental footprint of blade batteries in extreme climate applications.

Blade batteries, known for their high energy density and improved safety features, may require specialized materials and manufacturing processes to withstand extreme climates. The production of these batteries could lead to increased energy consumption and greenhouse gas emissions, particularly if additional protective measures are necessary for extreme climate resilience. However, the extended lifespan and improved performance of blade batteries in harsh conditions may offset these initial environmental costs over time.

In extreme cold climates, battery performance typically decreases due to reduced chemical reaction rates. This may lead to increased energy demand for battery heating systems, potentially resulting in higher overall energy consumption and associated emissions. Conversely, in extremely hot climates, the risk of thermal runaway and accelerated degradation of battery components increases, potentially shortening the battery's lifespan and necessitating more frequent replacements.

The environmental impact of blade batteries in extreme climates extends to their end-of-life management. Harsh conditions may accelerate battery degradation, leading to more frequent disposal and recycling needs. This could strain existing recycling infrastructure and potentially increase the risk of improper disposal, which may result in soil and water contamination if not managed correctly.

However, the improved performance of blade batteries in extreme climates could have positive environmental implications. By maintaining efficiency in challenging conditions, these batteries could reduce the need for backup power systems or frequent replacements, thereby decreasing overall resource consumption and waste generation. Additionally, their enhanced performance could support the adoption of renewable energy systems in remote or climatically challenging areas, contributing to reduced reliance on fossil fuels.

The assessment must also consider the potential for technological advancements in blade battery design specifically tailored for extreme climates. Innovations in thermal management, electrolyte composition, and protective coatings could mitigate some of the environmental concerns associated with battery performance in harsh conditions. These advancements may lead to more environmentally friendly production processes and improved recyclability, further reducing the overall environmental footprint of blade batteries in extreme climate applications.

Regulatory Framework for EV Batteries

The regulatory framework for electric vehicle (EV) batteries plays a crucial role in shaping the development, production, and implementation of battery technologies, including blade batteries in extreme climates. As governments worldwide strive to reduce carbon emissions and promote sustainable transportation, they have established various regulations and standards to ensure the safety, performance, and environmental impact of EV batteries.

In the context of modelling blade battery performance in extreme climates, regulatory bodies have implemented specific requirements for battery testing and certification. These regulations often mandate rigorous testing procedures to evaluate battery performance under various temperature conditions, from extreme cold to intense heat. For instance, the United Nations Economic Commission for Europe (UNECE) Regulation No. 100 outlines specific temperature range requirements for EV batteries, ensuring they can operate safely and efficiently in diverse climatic conditions.

Furthermore, regulatory frameworks often address the thermal management systems of EV batteries, which are particularly relevant when considering blade battery performance in extreme climates. Regulations may require manufacturers to demonstrate the effectiveness of their cooling and heating systems in maintaining optimal battery temperature across a wide range of environmental conditions.

Safety standards are another critical aspect of the regulatory framework for EV batteries. Agencies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP) have established guidelines for battery safety, including protection against thermal runaway and electrical hazards. These standards become even more pertinent when modelling blade battery performance in extreme climates, as temperature fluctuations can significantly impact battery stability and safety.

Environmental regulations also influence the development and implementation of EV battery technologies. Many countries have adopted policies to promote the recycling and responsible disposal of EV batteries, which can affect the design and material selection of blade batteries. For example, the European Union's Battery Directive sets targets for the collection and recycling of EV batteries, encouraging manufacturers to consider end-of-life scenarios in their battery designs.

As the EV market continues to grow, regulatory frameworks are evolving to address emerging challenges and technologies. This includes the development of new standards for fast charging, battery swapping, and vehicle-to-grid integration, all of which can impact the design and performance requirements of blade batteries in extreme climates. Manufacturers must stay abreast of these regulatory changes to ensure their battery technologies remain compliant and competitive in the global market.

In the context of modelling blade battery performance in extreme climates, regulatory bodies have implemented specific requirements for battery testing and certification. These regulations often mandate rigorous testing procedures to evaluate battery performance under various temperature conditions, from extreme cold to intense heat. For instance, the United Nations Economic Commission for Europe (UNECE) Regulation No. 100 outlines specific temperature range requirements for EV batteries, ensuring they can operate safely and efficiently in diverse climatic conditions.

Furthermore, regulatory frameworks often address the thermal management systems of EV batteries, which are particularly relevant when considering blade battery performance in extreme climates. Regulations may require manufacturers to demonstrate the effectiveness of their cooling and heating systems in maintaining optimal battery temperature across a wide range of environmental conditions.

Safety standards are another critical aspect of the regulatory framework for EV batteries. Agencies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP) have established guidelines for battery safety, including protection against thermal runaway and electrical hazards. These standards become even more pertinent when modelling blade battery performance in extreme climates, as temperature fluctuations can significantly impact battery stability and safety.

Environmental regulations also influence the development and implementation of EV battery technologies. Many countries have adopted policies to promote the recycling and responsible disposal of EV batteries, which can affect the design and material selection of blade batteries. For example, the European Union's Battery Directive sets targets for the collection and recycling of EV batteries, encouraging manufacturers to consider end-of-life scenarios in their battery designs.

As the EV market continues to grow, regulatory frameworks are evolving to address emerging challenges and technologies. This includes the development of new standards for fast charging, battery swapping, and vehicle-to-grid integration, all of which can impact the design and performance requirements of blade batteries in extreme climates. Manufacturers must stay abreast of these regulatory changes to ensure their battery technologies remain compliant and competitive in the global market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!