Alkyl Derivatives: Applications in Organic Chemistry

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkyl Derivatives Overview and Research Objectives

Alkyl derivatives have played a pivotal role in the evolution of organic chemistry, serving as fundamental building blocks for countless synthetic processes and applications. These compounds, characterized by their carbon-hydrogen bonds, have been the subject of extensive research and development over the past century. The field of alkyl derivatives has witnessed significant advancements, from basic structural studies to complex functional group manipulations, leading to their widespread use in various sectors of the chemical industry.

The primary objective of this research is to provide a comprehensive overview of the current state and future prospects of alkyl derivatives in organic chemistry. This investigation aims to explore the diverse applications of these compounds, ranging from their use as reagents in organic synthesis to their role as precursors in the production of pharmaceuticals, polymers, and fine chemicals. By examining the historical context and recent developments, we seek to identify emerging trends and potential areas for innovation in the utilization of alkyl derivatives.

One of the key focuses of this study is to analyze the versatility of alkyl derivatives in carbon-carbon bond formation reactions, which are crucial in the synthesis of complex organic molecules. We will examine various methodologies, including alkylation reactions, cross-coupling processes, and radical-mediated transformations, to highlight the breadth of synthetic possibilities offered by these compounds. Additionally, we aim to assess the impact of recent advances in catalysis and green chemistry on the application of alkyl derivatives, with particular emphasis on sustainable and environmentally friendly processes.

Furthermore, this research will delve into the role of alkyl derivatives in the development of functional materials, such as polymers, surfactants, and lubricants. We will explore how the structural modifications of alkyl groups influence the physical and chemical properties of these materials, leading to tailored applications in diverse industries. The investigation will also cover the use of alkyl derivatives in the field of medicinal chemistry, focusing on their importance in drug discovery and the synthesis of bioactive compounds.

As we progress through this study, we will address the challenges and limitations associated with the use of alkyl derivatives, including issues related to selectivity, reactivity, and environmental impact. By identifying these obstacles, we aim to stimulate discussion on potential solutions and future research directions. This comprehensive analysis will provide valuable insights for researchers, industry professionals, and policymakers, guiding future efforts in the development and application of alkyl derivatives in organic chemistry.

The primary objective of this research is to provide a comprehensive overview of the current state and future prospects of alkyl derivatives in organic chemistry. This investigation aims to explore the diverse applications of these compounds, ranging from their use as reagents in organic synthesis to their role as precursors in the production of pharmaceuticals, polymers, and fine chemicals. By examining the historical context and recent developments, we seek to identify emerging trends and potential areas for innovation in the utilization of alkyl derivatives.

One of the key focuses of this study is to analyze the versatility of alkyl derivatives in carbon-carbon bond formation reactions, which are crucial in the synthesis of complex organic molecules. We will examine various methodologies, including alkylation reactions, cross-coupling processes, and radical-mediated transformations, to highlight the breadth of synthetic possibilities offered by these compounds. Additionally, we aim to assess the impact of recent advances in catalysis and green chemistry on the application of alkyl derivatives, with particular emphasis on sustainable and environmentally friendly processes.

Furthermore, this research will delve into the role of alkyl derivatives in the development of functional materials, such as polymers, surfactants, and lubricants. We will explore how the structural modifications of alkyl groups influence the physical and chemical properties of these materials, leading to tailored applications in diverse industries. The investigation will also cover the use of alkyl derivatives in the field of medicinal chemistry, focusing on their importance in drug discovery and the synthesis of bioactive compounds.

As we progress through this study, we will address the challenges and limitations associated with the use of alkyl derivatives, including issues related to selectivity, reactivity, and environmental impact. By identifying these obstacles, we aim to stimulate discussion on potential solutions and future research directions. This comprehensive analysis will provide valuable insights for researchers, industry professionals, and policymakers, guiding future efforts in the development and application of alkyl derivatives in organic chemistry.

Market Analysis for Alkyl Derivative Applications

The market for alkyl derivatives in organic chemistry has experienced significant growth in recent years, driven by increasing demand across various industries. These versatile compounds find applications in pharmaceuticals, agrochemicals, polymers, and specialty chemicals, contributing to their expanding market presence.

In the pharmaceutical sector, alkyl derivatives play a crucial role in drug development and synthesis. They serve as building blocks for active pharmaceutical ingredients (APIs) and intermediates, enabling the creation of novel therapeutic compounds. The global pharmaceutical market's steady growth, coupled with the rising need for innovative drugs, has bolstered the demand for alkyl derivatives in this sector.

The agrochemical industry represents another substantial market for alkyl derivatives. These compounds are essential in the production of pesticides, herbicides, and fertilizers, contributing to improved crop yields and agricultural efficiency. As global food demand continues to rise, the agrochemical sector's reliance on alkyl derivatives is expected to increase, further driving market growth.

Polymer manufacturing is a key application area for alkyl derivatives, particularly in the production of plastics, resins, and synthetic rubbers. The automotive, packaging, and construction industries heavily rely on these materials, creating a sustained demand for alkyl derivatives. The growing emphasis on lightweight and durable materials in various sectors has further amplified the market potential for alkyl-derivative-based polymers.

The specialty chemicals industry utilizes alkyl derivatives in the production of surfactants, lubricants, and personal care products. The increasing consumer focus on eco-friendly and bio-based products has led to the development of novel alkyl derivatives from renewable sources, opening up new market opportunities.

Geographically, North America and Europe have traditionally been the largest markets for alkyl derivatives, owing to their well-established chemical and pharmaceutical industries. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by industrialization, population growth, and increasing disposable incomes in countries like China and India.

Market analysts project a compound annual growth rate (CAGR) for the global alkyl derivatives market in the mid-single digits over the next five years. This growth is attributed to the expanding applications in various end-use industries and the ongoing research and development efforts to discover new uses for these versatile compounds.

In the pharmaceutical sector, alkyl derivatives play a crucial role in drug development and synthesis. They serve as building blocks for active pharmaceutical ingredients (APIs) and intermediates, enabling the creation of novel therapeutic compounds. The global pharmaceutical market's steady growth, coupled with the rising need for innovative drugs, has bolstered the demand for alkyl derivatives in this sector.

The agrochemical industry represents another substantial market for alkyl derivatives. These compounds are essential in the production of pesticides, herbicides, and fertilizers, contributing to improved crop yields and agricultural efficiency. As global food demand continues to rise, the agrochemical sector's reliance on alkyl derivatives is expected to increase, further driving market growth.

Polymer manufacturing is a key application area for alkyl derivatives, particularly in the production of plastics, resins, and synthetic rubbers. The automotive, packaging, and construction industries heavily rely on these materials, creating a sustained demand for alkyl derivatives. The growing emphasis on lightweight and durable materials in various sectors has further amplified the market potential for alkyl-derivative-based polymers.

The specialty chemicals industry utilizes alkyl derivatives in the production of surfactants, lubricants, and personal care products. The increasing consumer focus on eco-friendly and bio-based products has led to the development of novel alkyl derivatives from renewable sources, opening up new market opportunities.

Geographically, North America and Europe have traditionally been the largest markets for alkyl derivatives, owing to their well-established chemical and pharmaceutical industries. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by industrialization, population growth, and increasing disposable incomes in countries like China and India.

Market analysts project a compound annual growth rate (CAGR) for the global alkyl derivatives market in the mid-single digits over the next five years. This growth is attributed to the expanding applications in various end-use industries and the ongoing research and development efforts to discover new uses for these versatile compounds.

Current Challenges in Alkyl Derivative Synthesis

The synthesis of alkyl derivatives in organic chemistry faces several significant challenges that hinder their widespread application and industrial-scale production. One of the primary obstacles is the control of selectivity in alkylation reactions. Achieving high regioselectivity and stereoselectivity remains difficult, especially when dealing with complex substrates or when aiming for specific isomers.

Another major challenge lies in the development of more environmentally friendly and sustainable alkylation methods. Traditional approaches often rely on toxic alkylating agents or harsh reaction conditions, which are not aligned with the principles of green chemistry. The search for safer, more atom-economical, and less energy-intensive processes is ongoing but has yet to yield universally applicable solutions.

The scalability of alkyl derivative synthesis poses a significant hurdle for industrial applications. Many laboratory-scale methods do not translate well to large-scale production due to issues such as heat transfer, mixing efficiency, and reagent handling. This gap between bench-top synthesis and industrial production often requires extensive process development and optimization.

Catalyst design and efficiency present another area of concern. While many catalytic systems have been developed for alkylation reactions, finding catalysts that combine high activity, selectivity, and stability remains challenging. Moreover, the high cost of some catalysts, particularly those based on precious metals, can limit their practical application in large-scale synthesis.

The formation of unwanted by-products during alkyl derivative synthesis is a persistent issue. Side reactions, such as over-alkylation or polymerization, can significantly reduce yield and complicate purification processes. Developing strategies to minimize these side reactions while maintaining high conversion rates is crucial for improving the overall efficiency of alkyl derivative production.

Lastly, the limited substrate scope of many alkylation methods restricts their versatility. Expanding the range of compatible functional groups and developing methods that can tolerate sensitive moieties would greatly enhance the utility of alkyl derivative synthesis in complex molecule construction and late-stage functionalization.

Addressing these challenges requires a multidisciplinary approach, combining advances in synthetic methodology, catalysis, process engineering, and green chemistry. Overcoming these hurdles will not only improve the synthesis of alkyl derivatives but also contribute to the broader field of organic synthesis and its applications in various industries.

Another major challenge lies in the development of more environmentally friendly and sustainable alkylation methods. Traditional approaches often rely on toxic alkylating agents or harsh reaction conditions, which are not aligned with the principles of green chemistry. The search for safer, more atom-economical, and less energy-intensive processes is ongoing but has yet to yield universally applicable solutions.

The scalability of alkyl derivative synthesis poses a significant hurdle for industrial applications. Many laboratory-scale methods do not translate well to large-scale production due to issues such as heat transfer, mixing efficiency, and reagent handling. This gap between bench-top synthesis and industrial production often requires extensive process development and optimization.

Catalyst design and efficiency present another area of concern. While many catalytic systems have been developed for alkylation reactions, finding catalysts that combine high activity, selectivity, and stability remains challenging. Moreover, the high cost of some catalysts, particularly those based on precious metals, can limit their practical application in large-scale synthesis.

The formation of unwanted by-products during alkyl derivative synthesis is a persistent issue. Side reactions, such as over-alkylation or polymerization, can significantly reduce yield and complicate purification processes. Developing strategies to minimize these side reactions while maintaining high conversion rates is crucial for improving the overall efficiency of alkyl derivative production.

Lastly, the limited substrate scope of many alkylation methods restricts their versatility. Expanding the range of compatible functional groups and developing methods that can tolerate sensitive moieties would greatly enhance the utility of alkyl derivative synthesis in complex molecule construction and late-stage functionalization.

Addressing these challenges requires a multidisciplinary approach, combining advances in synthetic methodology, catalysis, process engineering, and green chemistry. Overcoming these hurdles will not only improve the synthesis of alkyl derivatives but also contribute to the broader field of organic synthesis and its applications in various industries.

Current Synthetic Methods for Alkyl Derivatives

01 Synthesis of alkyl derivatives

Various methods for synthesizing alkyl derivatives are described, including reactions involving alkyl halides, alcohols, and other precursors. These processes often involve catalysts and specific reaction conditions to achieve desired alkyl derivatives with different functional groups.- Synthesis of alkyl derivatives: Various methods for synthesizing alkyl derivatives are described, including reactions involving alkyl halides, alcohols, and other precursors. These processes often involve catalysts and specific reaction conditions to achieve desired alkyl compounds.

- Applications in polymer chemistry: Alkyl derivatives play a significant role in polymer chemistry, being used as monomers, chain transfer agents, or modifiers. They can influence polymer properties such as solubility, thermal stability, and mechanical strength.

- Use in pharmaceutical compounds: Alkyl derivatives are important in pharmaceutical research and development. They are used to modify drug molecules, affecting their pharmacokinetics, bioavailability, and therapeutic efficacy. Some alkyl derivatives themselves possess pharmacological activity.

- Applications in surfactants and detergents: Alkyl derivatives are widely used in the production of surfactants and detergents. They can enhance the cleaning properties, foam stability, and biodegradability of these products. Different alkyl chain lengths can be used to tailor the properties for specific applications.

- Use in lubricants and fuel additives: Alkyl derivatives find applications in the formulation of lubricants and fuel additives. They can improve the viscosity index, thermal stability, and friction-reducing properties of lubricants. In fuels, they may act as octane boosters or detergents to keep engines clean.

02 Applications in polymer chemistry

Alkyl derivatives play a significant role in polymer chemistry, being used as monomers, chain transfer agents, or modifiers. They can influence polymer properties such as molecular weight, branching, and functionality, leading to materials with tailored characteristics for specific applications.Expand Specific Solutions03 Use in pharmaceutical compounds

Alkyl derivatives are important in pharmaceutical research and development. They are used to modify drug molecules, affecting properties such as solubility, bioavailability, and pharmacokinetics. Some alkyl derivatives themselves may have therapeutic effects or serve as precursors for active pharmaceutical ingredients.Expand Specific Solutions04 Applications in surfactants and detergents

Alkyl derivatives are widely used in the formulation of surfactants and detergents. They can act as emulsifiers, wetting agents, or foaming agents, contributing to the cleaning and surface-active properties of various products in household and industrial applications.Expand Specific Solutions05 Use in agricultural chemicals

Alkyl derivatives find applications in the development of agricultural chemicals such as pesticides, herbicides, and plant growth regulators. They can be used to modify the properties of active ingredients, improving their efficacy, stability, or environmental profile in crop protection and management.Expand Specific Solutions

Key Players in Alkyl Derivative Industry

The applications of alkyl derivatives in organic chemistry represent a mature field with significant market size and ongoing research. The industry is in a consolidation phase, with major players like Shell, Bayer, Merck, and Eastman Chemical dominating the landscape. These companies have established strong research and development capabilities, driving technological advancements in alkyl derivative applications. The market is characterized by a mix of large multinational corporations and specialized chemical companies, each focusing on specific niches within the broader field. As the technology matures, companies are increasingly focusing on developing more efficient and sustainable processes for alkyl derivative production and application.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed innovative applications of alkyl derivatives in organic chemistry, focusing on improving fuel and lubricant performance. Their research includes the synthesis of novel alkyl-substituted aromatics for use as fuel additives, enhancing combustion efficiency and reducing emissions[1]. They have also explored the use of long-chain alkyl derivatives in lubricant formulations to improve viscosity index and thermal stability[2]. Shell's approach involves molecular modeling to predict structure-property relationships, enabling targeted design of alkyl derivatives for specific applications[3].

Strengths: Extensive R&D capabilities, global reach for implementation. Weaknesses: Primarily focused on petroleum-related applications, potentially limiting broader organic chemistry applications.

Bayer Intellectual Property GmbH

Technical Solution: Bayer has made significant strides in applying alkyl derivatives to crop protection and pharmaceutical development. In crop protection, they have developed novel alkyl-substituted heterocycles as effective fungicides, demonstrating improved uptake and systemic distribution in plants[4]. For pharmaceuticals, Bayer has utilized alkyl derivatives to enhance drug lipophilicity and membrane permeability, resulting in improved bioavailability of active compounds[5]. Their approach often involves rational design and high-throughput screening of alkylated analogs to optimize biological activity and physicochemical properties[6].

Strengths: Strong expertise in life sciences applications, robust patent portfolio. Weaknesses: May have less focus on industrial or materials science applications of alkyl derivatives.

Innovative Alkyl Derivative Reactions

Use of alkoxylated alkyl and alkenyl polyglycosides

PatentInactiveEP1803349A1

Innovation

- The use of alkoxylated alkyl and/or alkenyl polyglycosides as nonionic surfactants in agrochemical formulations, which can be easily incorporated and synergistically enhance the efficacy of herbicides and pesticides, particularly glyphosate, by modifying the alkyl and/or alkenyl radicals and their degree of polymerization.

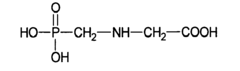

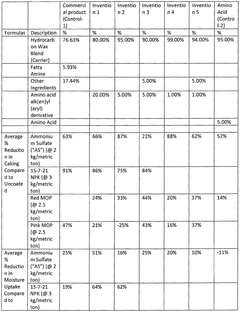

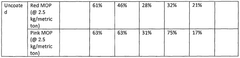

A compositon for Anti-caking and/or moisture reduction for fertilizers comprised of an amino acid ALK(EN)YL (ARYL) derivative

PatentWO2025128224A1

Innovation

- Incorporating an amino acid alk(en)yl (aryl) derivative into fertilizers as an anti-caking and moisture-resistant coating, which can be applied through various methods such as coatings, crystallization, granulation, or prilling, providing a biodegradable, biobased, and non-dangerous alternative.

Green Chemistry Aspects of Alkyl Derivatives

The integration of green chemistry principles into the applications of alkyl derivatives in organic chemistry has become increasingly important in recent years. This shift towards more sustainable practices aims to reduce the environmental impact of chemical processes while maintaining or improving their efficiency and effectiveness.

One of the key aspects of green chemistry in relation to alkyl derivatives is the development of safer and more environmentally friendly synthetic routes. Traditional methods for producing alkyl derivatives often involve the use of toxic reagents and generate significant amounts of waste. However, researchers have made substantial progress in developing alternative approaches that utilize renewable feedstocks, catalysts, and solvents.

Biocatalysis has emerged as a promising green chemistry strategy for the synthesis of alkyl derivatives. Enzymes, such as lipases and esterases, can catalyze various reactions involving alkyl groups under mild conditions, reducing energy consumption and minimizing the need for harsh chemicals. These biocatalytic processes often exhibit high selectivity and can be performed in aqueous media, further enhancing their environmental credentials.

The use of renewable resources as starting materials for alkyl derivative synthesis has gained traction in recent years. For instance, plant-based oils and fats can be transformed into valuable alkyl derivatives through various chemical and enzymatic processes. This approach not only reduces reliance on fossil-based feedstocks but also contributes to the circular economy by utilizing waste or by-products from other industries.

Green solvents play a crucial role in improving the sustainability of alkyl derivative applications. Supercritical carbon dioxide, ionic liquids, and deep eutectic solvents have been explored as alternatives to traditional organic solvents. These green solvents often allow for easier product separation and solvent recycling, reducing waste generation and improving overall process efficiency.

The principles of atom economy and waste minimization are being applied to optimize reactions involving alkyl derivatives. Researchers are developing new synthetic methodologies that maximize the incorporation of reactants into the final product, reducing the formation of by-products and improving overall yield. This approach not only enhances the sustainability of the processes but also often leads to cost savings and improved product quality.

In conclusion, the integration of green chemistry principles into the applications of alkyl derivatives in organic chemistry is driving innovation and sustainability in the field. By focusing on safer reagents, renewable feedstocks, biocatalysis, green solvents, and efficient synthetic methodologies, researchers are paving the way for more environmentally friendly and economically viable processes in the production and utilization of alkyl derivatives.

One of the key aspects of green chemistry in relation to alkyl derivatives is the development of safer and more environmentally friendly synthetic routes. Traditional methods for producing alkyl derivatives often involve the use of toxic reagents and generate significant amounts of waste. However, researchers have made substantial progress in developing alternative approaches that utilize renewable feedstocks, catalysts, and solvents.

Biocatalysis has emerged as a promising green chemistry strategy for the synthesis of alkyl derivatives. Enzymes, such as lipases and esterases, can catalyze various reactions involving alkyl groups under mild conditions, reducing energy consumption and minimizing the need for harsh chemicals. These biocatalytic processes often exhibit high selectivity and can be performed in aqueous media, further enhancing their environmental credentials.

The use of renewable resources as starting materials for alkyl derivative synthesis has gained traction in recent years. For instance, plant-based oils and fats can be transformed into valuable alkyl derivatives through various chemical and enzymatic processes. This approach not only reduces reliance on fossil-based feedstocks but also contributes to the circular economy by utilizing waste or by-products from other industries.

Green solvents play a crucial role in improving the sustainability of alkyl derivative applications. Supercritical carbon dioxide, ionic liquids, and deep eutectic solvents have been explored as alternatives to traditional organic solvents. These green solvents often allow for easier product separation and solvent recycling, reducing waste generation and improving overall process efficiency.

The principles of atom economy and waste minimization are being applied to optimize reactions involving alkyl derivatives. Researchers are developing new synthetic methodologies that maximize the incorporation of reactants into the final product, reducing the formation of by-products and improving overall yield. This approach not only enhances the sustainability of the processes but also often leads to cost savings and improved product quality.

In conclusion, the integration of green chemistry principles into the applications of alkyl derivatives in organic chemistry is driving innovation and sustainability in the field. By focusing on safer reagents, renewable feedstocks, biocatalysis, green solvents, and efficient synthetic methodologies, researchers are paving the way for more environmentally friendly and economically viable processes in the production and utilization of alkyl derivatives.

Safety Considerations in Alkyl Derivative Handling

The handling of alkyl derivatives in organic chemistry requires strict adherence to safety protocols due to their potential hazards. These compounds often possess high flammability, volatility, and reactivity, necessitating careful management throughout their use in laboratory and industrial settings.

Personal protective equipment (PPE) is essential when working with alkyl derivatives. This includes wearing appropriate gloves resistant to organic solvents, safety goggles or face shields to protect against splashes, and lab coats to prevent skin contact. In some cases, respiratory protection may be necessary, especially when dealing with volatile or toxic alkyl compounds.

Proper ventilation is crucial to minimize exposure to vapors and fumes. All operations involving alkyl derivatives should be conducted in well-ventilated areas, preferably under fume hoods. This helps prevent the accumulation of potentially harmful or flammable vapors in the workspace.

Storage and handling of alkyl derivatives demand special attention. These compounds should be kept in tightly sealed containers in cool, dry areas away from sources of heat, sparks, or open flames. Segregation from incompatible materials, such as strong oxidizers or acids, is vital to prevent dangerous reactions.

Spill control measures must be in place when working with alkyl derivatives. Appropriate absorbent materials and spill kits should be readily available. In case of a spill, immediate containment and proper disposal procedures must be followed to minimize environmental impact and safety risks.

Fire safety is a critical consideration due to the flammable nature of many alkyl derivatives. Fire extinguishers suitable for organic solvent fires should be easily accessible. Additionally, proper grounding and bonding procedures should be employed during transfer operations to prevent static electricity buildup and potential ignition.

Waste disposal of alkyl derivatives and related materials requires careful management. These compounds should never be disposed of down drains or in regular trash. Instead, they must be collected in designated waste containers and disposed of through approved chemical waste disposal channels.

Training and education play a crucial role in ensuring safe handling of alkyl derivatives. All personnel working with these compounds should receive comprehensive training on their properties, associated hazards, proper handling techniques, and emergency procedures. Regular refresher courses and safety briefings can help maintain awareness and compliance with safety protocols.

Emergency response planning is essential when dealing with alkyl derivatives. This includes having clearly defined procedures for chemical spills, fires, and personal exposure incidents. Emergency shower and eyewash stations should be readily available and regularly maintained.

Personal protective equipment (PPE) is essential when working with alkyl derivatives. This includes wearing appropriate gloves resistant to organic solvents, safety goggles or face shields to protect against splashes, and lab coats to prevent skin contact. In some cases, respiratory protection may be necessary, especially when dealing with volatile or toxic alkyl compounds.

Proper ventilation is crucial to minimize exposure to vapors and fumes. All operations involving alkyl derivatives should be conducted in well-ventilated areas, preferably under fume hoods. This helps prevent the accumulation of potentially harmful or flammable vapors in the workspace.

Storage and handling of alkyl derivatives demand special attention. These compounds should be kept in tightly sealed containers in cool, dry areas away from sources of heat, sparks, or open flames. Segregation from incompatible materials, such as strong oxidizers or acids, is vital to prevent dangerous reactions.

Spill control measures must be in place when working with alkyl derivatives. Appropriate absorbent materials and spill kits should be readily available. In case of a spill, immediate containment and proper disposal procedures must be followed to minimize environmental impact and safety risks.

Fire safety is a critical consideration due to the flammable nature of many alkyl derivatives. Fire extinguishers suitable for organic solvent fires should be easily accessible. Additionally, proper grounding and bonding procedures should be employed during transfer operations to prevent static electricity buildup and potential ignition.

Waste disposal of alkyl derivatives and related materials requires careful management. These compounds should never be disposed of down drains or in regular trash. Instead, they must be collected in designated waste containers and disposed of through approved chemical waste disposal channels.

Training and education play a crucial role in ensuring safe handling of alkyl derivatives. All personnel working with these compounds should receive comprehensive training on their properties, associated hazards, proper handling techniques, and emergency procedures. Regular refresher courses and safety briefings can help maintain awareness and compliance with safety protocols.

Emergency response planning is essential when dealing with alkyl derivatives. This includes having clearly defined procedures for chemical spills, fires, and personal exposure incidents. Emergency shower and eyewash stations should be readily available and regularly maintained.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!