Auto-Calibration Routines For Robotic Liquid Handling In MAPs

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Robotic Liquid Handling Auto-Calibration Background and Objectives

Robotic liquid handling systems have evolved significantly over the past three decades, transforming from simple automated pipetting devices to sophisticated robotic platforms capable of executing complex laboratory protocols. The integration of Microfluidic Array Plates (MAPs) represents a pivotal advancement in this field, enabling higher throughput, reduced reagent consumption, and enhanced precision for various applications including drug discovery, genomics, and clinical diagnostics.

The evolution of liquid handling technology has been characterized by increasing levels of automation, miniaturization, and integration with other laboratory systems. Early systems focused primarily on replacing manual pipetting operations, while modern platforms incorporate advanced features such as real-time monitoring, error detection, and adaptive control mechanisms. Despite these advancements, calibration remains a persistent challenge that significantly impacts system performance and reliability.

Traditional calibration methods for robotic liquid handling systems typically involve time-consuming manual procedures that require specialized training and equipment. These methods often rely on gravimetric or photometric techniques that must be performed periodically, resulting in significant downtime and operational inefficiencies. The complexity of these procedures increases exponentially when working with MAPs due to their high-density microwell formats and unique fluidic properties.

The primary objective of developing auto-calibration routines for robotic liquid handling in MAPs is to establish autonomous, accurate, and efficient calibration processes that minimize human intervention while maximizing system performance. These routines aim to address critical parameters including volume accuracy, precision, liquid class optimization, and positional accuracy across the entire operational range of the system.

Secondary objectives include reducing calibration time by at least 70% compared to manual methods, enabling on-the-fly calibration during routine operations, and developing adaptive algorithms that can account for variations in environmental conditions, liquid properties, and consumable characteristics. Additionally, these routines should provide comprehensive data logging and traceability to support regulatory compliance in regulated environments.

The technological trajectory points toward the integration of machine learning and computer vision technologies to create self-learning systems capable of continuous optimization. Recent developments in sensor miniaturization, real-time feedback mechanisms, and artificial intelligence have created new opportunities for implementing sophisticated auto-calibration routines that were previously unattainable.

Achieving these objectives would represent a significant advancement in laboratory automation, potentially transforming workflow efficiency, data quality, and operational costs across multiple industries. The development of robust auto-calibration routines specifically designed for MAPs would address a critical gap in current technology and establish a foundation for next-generation liquid handling platforms.

The evolution of liquid handling technology has been characterized by increasing levels of automation, miniaturization, and integration with other laboratory systems. Early systems focused primarily on replacing manual pipetting operations, while modern platforms incorporate advanced features such as real-time monitoring, error detection, and adaptive control mechanisms. Despite these advancements, calibration remains a persistent challenge that significantly impacts system performance and reliability.

Traditional calibration methods for robotic liquid handling systems typically involve time-consuming manual procedures that require specialized training and equipment. These methods often rely on gravimetric or photometric techniques that must be performed periodically, resulting in significant downtime and operational inefficiencies. The complexity of these procedures increases exponentially when working with MAPs due to their high-density microwell formats and unique fluidic properties.

The primary objective of developing auto-calibration routines for robotic liquid handling in MAPs is to establish autonomous, accurate, and efficient calibration processes that minimize human intervention while maximizing system performance. These routines aim to address critical parameters including volume accuracy, precision, liquid class optimization, and positional accuracy across the entire operational range of the system.

Secondary objectives include reducing calibration time by at least 70% compared to manual methods, enabling on-the-fly calibration during routine operations, and developing adaptive algorithms that can account for variations in environmental conditions, liquid properties, and consumable characteristics. Additionally, these routines should provide comprehensive data logging and traceability to support regulatory compliance in regulated environments.

The technological trajectory points toward the integration of machine learning and computer vision technologies to create self-learning systems capable of continuous optimization. Recent developments in sensor miniaturization, real-time feedback mechanisms, and artificial intelligence have created new opportunities for implementing sophisticated auto-calibration routines that were previously unattainable.

Achieving these objectives would represent a significant advancement in laboratory automation, potentially transforming workflow efficiency, data quality, and operational costs across multiple industries. The development of robust auto-calibration routines specifically designed for MAPs would address a critical gap in current technology and establish a foundation for next-generation liquid handling platforms.

Market Demand Analysis for Automated Liquid Handling Systems

The global market for automated liquid handling systems has experienced significant growth in recent years, driven primarily by the increasing demand for high-throughput screening in pharmaceutical and biotechnology research. The market value reached approximately $1.8 billion in 2022 and is projected to grow at a CAGR of 8.5% through 2028, highlighting the expanding need for precise and efficient liquid handling technologies.

Microfluidic Analysis Platforms (MAPs) represent a rapidly growing segment within this market, with particular demand coming from clinical diagnostics, genomics, and drug discovery applications. The COVID-19 pandemic has further accelerated this growth trajectory, as laboratories worldwide sought to increase testing capacity and automation capabilities to handle unprecedented sample volumes.

A key market driver is the growing emphasis on reproducibility in scientific research. Studies indicate that up to 70% of researchers have failed to reproduce another scientist's experiments, and over 50% have failed to reproduce their own experiments, often due to inconsistencies in manual liquid handling. This reproducibility crisis has intensified demand for automated systems with robust calibration capabilities.

Labor costs represent another significant market factor. In developed markets, laboratory technicians command salaries ranging from $45,000 to $75,000 annually. Automated liquid handling systems, despite their initial capital investment of $50,000 to $300,000 depending on complexity, offer substantial long-term cost savings by reducing labor requirements and human error.

The market specifically for auto-calibration routines in robotic liquid handling systems is emerging as a critical differentiator. End-users increasingly demand systems that can self-diagnose and self-calibrate to maintain accuracy over time. A survey of laboratory managers revealed that 82% consider calibration capabilities a "very important" or "critical" factor in purchasing decisions for new liquid handling equipment.

Geographically, North America dominates the market with approximately 40% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding research infrastructure in China, India, and South Korea.

By application segment, pharmaceutical and biotechnology companies account for the largest market share (45%), followed by academic and research institutions (30%), clinical diagnostics laboratories (15%), and other applications (10%). The pharmaceutical sector's demand is particularly focused on systems that can handle nanoliter volumes with high precision for drug discovery applications.

Microfluidic Analysis Platforms (MAPs) represent a rapidly growing segment within this market, with particular demand coming from clinical diagnostics, genomics, and drug discovery applications. The COVID-19 pandemic has further accelerated this growth trajectory, as laboratories worldwide sought to increase testing capacity and automation capabilities to handle unprecedented sample volumes.

A key market driver is the growing emphasis on reproducibility in scientific research. Studies indicate that up to 70% of researchers have failed to reproduce another scientist's experiments, and over 50% have failed to reproduce their own experiments, often due to inconsistencies in manual liquid handling. This reproducibility crisis has intensified demand for automated systems with robust calibration capabilities.

Labor costs represent another significant market factor. In developed markets, laboratory technicians command salaries ranging from $45,000 to $75,000 annually. Automated liquid handling systems, despite their initial capital investment of $50,000 to $300,000 depending on complexity, offer substantial long-term cost savings by reducing labor requirements and human error.

The market specifically for auto-calibration routines in robotic liquid handling systems is emerging as a critical differentiator. End-users increasingly demand systems that can self-diagnose and self-calibrate to maintain accuracy over time. A survey of laboratory managers revealed that 82% consider calibration capabilities a "very important" or "critical" factor in purchasing decisions for new liquid handling equipment.

Geographically, North America dominates the market with approximately 40% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding research infrastructure in China, India, and South Korea.

By application segment, pharmaceutical and biotechnology companies account for the largest market share (45%), followed by academic and research institutions (30%), clinical diagnostics laboratories (15%), and other applications (10%). The pharmaceutical sector's demand is particularly focused on systems that can handle nanoliter volumes with high precision for drug discovery applications.

Current Technical Challenges in MAPs Liquid Handling Calibration

Automated liquid handling systems in Microfluidic Analysis Platforms (MAPs) face several significant technical challenges in calibration processes that impede their widespread adoption and reliability. The primary challenge lies in achieving consistent accuracy across different liquid types with varying viscosities, surface tensions, and densities. Traditional calibration methods often rely on gravimetric analysis which, while precise for standard solutions, fails to account for the complex fluid dynamics of biological samples, resulting in volume dispensing errors that can reach up to 15% for viscous liquids.

Temperature fluctuations present another substantial obstacle, as they can alter liquid properties and affect dispensing precision. Even minor temperature variations of 2-3°C can lead to volumetric discrepancies of 1-2%, which becomes critical when handling nanoliter volumes. Current systems lack robust temperature compensation mechanisms that can dynamically adjust calibration parameters in real-time.

Cross-contamination during calibration procedures remains problematic, particularly when transitioning between different reagents. Existing washing protocols are often insufficient for complete removal of residual liquids, leading to carryover that compromises experimental integrity. This issue is exacerbated in high-throughput environments where rapid processing is prioritized over thorough cleaning cycles.

The miniaturization trend in MAPs introduces additional calibration complexities. As dispensing volumes decrease to the nanoliter and picoliter range, the relative impact of evaporation, surface adsorption, and capillary forces increases dramatically. Current calibration methodologies struggle to account for these micro-scale phenomena, resulting in poor reproducibility for ultra-low volume dispensing operations.

Sensor integration presents both opportunities and challenges. While optical and capacitive sensors offer potential for real-time monitoring, their integration into calibration routines is hindered by signal-to-noise ratio issues and the need for frequent recalibration of the sensors themselves. The lack of standardized sensor interfaces further complicates the development of universal calibration protocols.

Software limitations constitute a significant barrier to advanced calibration. Many current platforms utilize proprietary software with closed architectures that restrict the implementation of machine learning algorithms for adaptive calibration. This prevents systems from learning from historical data and autonomously optimizing dispensing parameters based on observed performance patterns.

Finally, validation and traceability of calibration procedures remain challenging. The absence of universally accepted standards for microfluidic liquid handling makes it difficult to establish calibration benchmarks that ensure consistency across different laboratories and platforms. This lack of standardization impedes regulatory compliance and slows the clinical adoption of MAP technologies.

Temperature fluctuations present another substantial obstacle, as they can alter liquid properties and affect dispensing precision. Even minor temperature variations of 2-3°C can lead to volumetric discrepancies of 1-2%, which becomes critical when handling nanoliter volumes. Current systems lack robust temperature compensation mechanisms that can dynamically adjust calibration parameters in real-time.

Cross-contamination during calibration procedures remains problematic, particularly when transitioning between different reagents. Existing washing protocols are often insufficient for complete removal of residual liquids, leading to carryover that compromises experimental integrity. This issue is exacerbated in high-throughput environments where rapid processing is prioritized over thorough cleaning cycles.

The miniaturization trend in MAPs introduces additional calibration complexities. As dispensing volumes decrease to the nanoliter and picoliter range, the relative impact of evaporation, surface adsorption, and capillary forces increases dramatically. Current calibration methodologies struggle to account for these micro-scale phenomena, resulting in poor reproducibility for ultra-low volume dispensing operations.

Sensor integration presents both opportunities and challenges. While optical and capacitive sensors offer potential for real-time monitoring, their integration into calibration routines is hindered by signal-to-noise ratio issues and the need for frequent recalibration of the sensors themselves. The lack of standardized sensor interfaces further complicates the development of universal calibration protocols.

Software limitations constitute a significant barrier to advanced calibration. Many current platforms utilize proprietary software with closed architectures that restrict the implementation of machine learning algorithms for adaptive calibration. This prevents systems from learning from historical data and autonomously optimizing dispensing parameters based on observed performance patterns.

Finally, validation and traceability of calibration procedures remain challenging. The absence of universally accepted standards for microfluidic liquid handling makes it difficult to establish calibration benchmarks that ensure consistency across different laboratories and platforms. This lack of standardization impedes regulatory compliance and slows the clinical adoption of MAP technologies.

Current Auto-Calibration Methodologies for Precision Dispensing

01 Self-calibration techniques for electronic systems

Self-calibration routines are implemented in electronic systems to automatically adjust parameters and ensure optimal performance without manual intervention. These techniques involve measuring system outputs against known references, calculating correction factors, and applying them to improve accuracy. Advanced algorithms can detect drift over time and make continuous adjustments to maintain calibration accuracy throughout the system's operational life.- Self-calibration techniques for electronic systems: Self-calibration routines can be implemented in electronic systems to automatically adjust parameters and improve calibration accuracy. These techniques often involve built-in test circuits that measure performance metrics and make real-time adjustments to compensate for variations in operating conditions, component tolerances, and environmental factors. Advanced algorithms can continuously monitor system performance and apply correction factors to maintain optimal calibration without manual intervention.

- Sensor calibration methods for improved measurement accuracy: Various methods are employed to enhance the calibration accuracy of sensors in measurement systems. These include reference-based calibration where sensors are compared against known standards, multi-point calibration techniques that characterize sensor response across operating ranges, and adaptive calibration algorithms that adjust for environmental conditions. These methods significantly improve measurement precision by reducing systematic errors and compensating for sensor drift over time.

- Automated calibration systems for laboratory equipment: Laboratory equipment employs automated calibration routines to ensure measurement accuracy and reliability. These systems utilize precision reference materials and standards to verify instrument performance and make necessary adjustments. The calibration processes often include verification steps, statistical analysis of results, and documentation of calibration parameters. Advanced systems can schedule calibration events, track calibration history, and alert users when recalibration is needed.

- Image processing calibration techniques: Image processing systems employ specialized calibration routines to ensure accurate color reproduction, geometric correction, and sensor alignment. These techniques include camera calibration to correct for lens distortion, color calibration using reference targets, and spatial calibration to ensure precise positioning. Automated algorithms can detect calibration patterns, extract calibration parameters, and apply corrections to improve image quality and measurement accuracy in applications ranging from machine vision to medical imaging.

- Signal processing calibration for communication systems: Communication systems utilize advanced calibration routines to optimize signal quality and transmission accuracy. These include techniques for calibrating transmitter and receiver components, compensating for channel distortions, and adjusting timing parameters. Adaptive algorithms continuously monitor signal quality metrics and make real-time adjustments to maintain optimal performance. Self-calibration procedures can compensate for temperature variations, component aging, and other factors that affect signal integrity.

02 Sensor calibration methods for improved measurement accuracy

Various methods are employed to calibrate sensors for enhanced measurement accuracy. These include comparison against reference standards, multi-point calibration techniques, and temperature compensation algorithms. The calibration routines can account for non-linearity, hysteresis, and environmental factors that affect sensor performance. Automated calibration sequences test sensors across their operational range to generate comprehensive correction maps that significantly improve measurement precision.Expand Specific Solutions03 Calibration systems for imaging and display devices

Auto-calibration routines for imaging and display devices ensure color accuracy, brightness uniformity, and geometric precision. These systems use optical feedback mechanisms to measure display output characteristics and apply corrections to compensate for manufacturing variations and aging effects. The calibration processes may involve pattern recognition, color space transformations, and pixel-by-pixel adjustments to achieve consistent visual performance across devices.Expand Specific Solutions04 Automated laboratory instrument calibration

Laboratory instruments employ sophisticated auto-calibration routines to maintain measurement accuracy for scientific and medical applications. These systems use standard reference materials to verify instrument response and automatically adjust parameters to compensate for drift. Calibration sequences may include multiple verification steps, statistical analysis of results, and fault detection algorithms to ensure reliable analytical performance. The calibration data is often stored for quality control and regulatory compliance purposes.Expand Specific Solutions05 Communication system calibration for signal integrity

Auto-calibration routines in communication systems optimize signal transmission parameters to maintain data integrity across varying conditions. These techniques include adaptive equalization, timing recovery, and impedance matching to compensate for channel characteristics and component variations. The calibration processes may operate continuously in the background, making real-time adjustments to maximize signal-to-noise ratio and minimize bit error rates. Advanced systems can predict and pre-compensate for expected variations to maintain consistent performance.Expand Specific Solutions

Key Industry Players in Robotic Liquid Handling Systems

The auto-calibration routines for robotic liquid handling in MAPs market is in its growth phase, with increasing adoption driven by laboratory automation demands. The market is projected to expand significantly as precision medicine and high-throughput screening applications grow. Technologically, the field shows varying maturity levels across players. Industry leaders like Tecan Trading AG and Opentrons Labworks have established robust calibration solutions, while companies such as Formulatrix and Brain Corp are advancing AI-driven calibration technologies. Academic institutions including South China University of Technology and University of Toronto are contributing fundamental research. The competitive landscape features both specialized liquid handling companies and broader robotics firms like OMRON and Robert Bosch, indicating convergence between laboratory automation and advanced robotics technologies.

Tecan Trading AG

Technical Solution: Tecan has developed advanced auto-calibration systems for their liquid handling platforms that utilize capacitive liquid level detection (cLLD) technology. Their Fluent and Freedom EVO platforms incorporate multi-channel verification (MCA) systems that automatically detect and compensate for variations in individual channel performance. The calibration routine employs gravimetric measurement with precision balances integrated into the workflow, allowing real-time verification of dispensed volumes as small as 0.5μL with CV values below 3%. Their patented technology includes automated tip detection and positioning systems that ensure precise alignment during calibration procedures. The system captures comprehensive calibration data across multiple parameters including liquid class characteristics, environmental conditions, and instrument-specific variables to create dynamic calibration models that adapt to changing conditions. Tecan's auto-calibration routines can be scheduled to run automatically during idle periods, minimizing workflow disruptions while maintaining compliance with regulatory standards.

Strengths: Industry-leading precision with documented accuracy across micro to milliliter volumes; comprehensive data management system for calibration history and compliance documentation; integration with laboratory information management systems (LIMS). Weaknesses: Higher initial investment compared to competitors; calibration routines can be time-consuming for high-throughput environments; requires specialized consumables for optimal performance.

Opentrons Labworks, Inc.

Technical Solution: Opentrons has pioneered an accessible approach to auto-calibration for liquid handling robots with their OT-2 platform. Their system employs computer vision and machine learning algorithms to automatically detect and calibrate pipette positions relative to labware. The calibration routine uses a camera mounted on the pipette head to identify reference points on deck positions, creating a spatial map that compensates for mechanical variations. Their Python-based calibration protocol allows users to define custom calibration sequences that can be integrated into experimental workflows. The system performs both positional calibration (XYZ coordinates) and volumetric calibration through iterative dispensing tests that measure and adjust for systematic errors. Opentrons' approach includes automatic tip detection and height sensing to prevent crashes and optimize liquid handling parameters. Their open-source calibration tools enable community-driven improvements and adaptations for specialized applications, making precise liquid handling more accessible to smaller laboratories.

Strengths: Cost-effective solution with open-source flexibility; user-friendly interface requiring minimal technical expertise; modular design allowing for component-specific calibration. Weaknesses: Lower precision compared to premium systems (typically 5-8% CV for volumes under 10μL); limited throughput capacity; fewer automated quality control features than enterprise-grade systems.

Core Patents and Innovations in Liquid Handling Calibration

Method for determining the position of a robotic arm in a liquid handling system, and a corresponding liquid handling system

PatentWO2018015545A1

Innovation

- The method involves using a measuring probe with a first electrode on the robot arm and a second electrode formed by the work surface or container, creating a measuring capacitor to detect impedance changes, allowing for the determination of reference coordinates and distances through capacitance measurements, enabling precise position calibration and ongoing calibration during system operation.

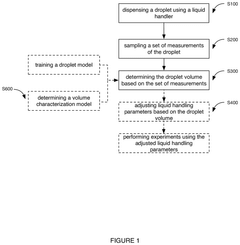

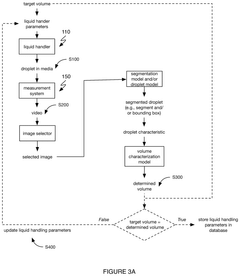

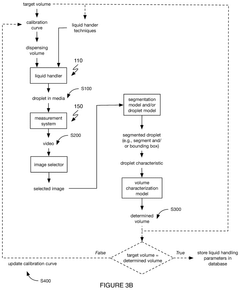

System and method for determining dispensing volume for a liquid handler

PatentPendingUS20250189552A1

Innovation

- A system and method that automatically calibrate a liquid handler by dispensing a droplet, sampling measurements, and determining the droplet volume using image-based estimation, which is agnostic to specific liquid handler specifications and can adjust liquid handling parameters for precise volume control.

Quality Assurance Standards for Automated Liquid Handling

Quality assurance standards for automated liquid handling systems in Microfluidic Array Plates (MAPs) have evolved significantly to address the critical need for precision and reliability in laboratory automation. These standards encompass comprehensive validation protocols that verify the accuracy, precision, and reproducibility of liquid transfers across multiple channels and wells. Industry benchmarks typically require volume accuracy within ±5% and precision (coefficient of variation) below 3% for volumes above 1μL, with more stringent requirements for critical applications.

The implementation of auto-calibration routines has necessitated the development of specialized quality control measures. These include gravimetric analysis using precision balances to verify dispensed volumes, photometric methods utilizing dye solutions to assess accuracy across multiple channels simultaneously, and fluorescence-based techniques that offer enhanced sensitivity for nanoliter-range dispensing. Regular performance verification schedules are mandated, with daily quick checks, weekly intermediate verifications, and monthly comprehensive calibrations.

Documentation requirements have become increasingly standardized, with automated liquid handlers requiring detailed maintenance logs, calibration certificates, and performance verification records. These documents must be maintained in compliance with laboratory accreditation standards such as ISO 17025 and industry-specific regulations like GLP (Good Laboratory Practice) and GMP (Good Manufacturing Practice).

Error detection and handling protocols constitute a critical component of quality assurance frameworks. Modern systems incorporate real-time monitoring of liquid levels, pressure sensors to detect clogging or air bubbles, and capacitive liquid level detection to ensure proper aspiration. Statistical process control methods are employed to identify trends before they result in out-of-specification performance, with automated alerts triggering when predefined thresholds are approached.

The integration of machine learning algorithms has enhanced quality assurance capabilities by enabling predictive maintenance and adaptive calibration schedules based on usage patterns and performance data. These systems can identify subtle deviations in dispensing patterns that might indicate impending mechanical issues or calibration drift, allowing for preemptive intervention.

Regulatory compliance frameworks vary by application field, with clinical diagnostics following CLIA and FDA requirements, pharmaceutical research adhering to 21 CFR Part 11 for electronic records, and academic research typically following institutional guidelines. The trend toward harmonization of these standards is evident in initiatives like the Artel Multichannel Verification System, which has become a de facto standard for performance verification across different platforms and manufacturers.

The implementation of auto-calibration routines has necessitated the development of specialized quality control measures. These include gravimetric analysis using precision balances to verify dispensed volumes, photometric methods utilizing dye solutions to assess accuracy across multiple channels simultaneously, and fluorescence-based techniques that offer enhanced sensitivity for nanoliter-range dispensing. Regular performance verification schedules are mandated, with daily quick checks, weekly intermediate verifications, and monthly comprehensive calibrations.

Documentation requirements have become increasingly standardized, with automated liquid handlers requiring detailed maintenance logs, calibration certificates, and performance verification records. These documents must be maintained in compliance with laboratory accreditation standards such as ISO 17025 and industry-specific regulations like GLP (Good Laboratory Practice) and GMP (Good Manufacturing Practice).

Error detection and handling protocols constitute a critical component of quality assurance frameworks. Modern systems incorporate real-time monitoring of liquid levels, pressure sensors to detect clogging or air bubbles, and capacitive liquid level detection to ensure proper aspiration. Statistical process control methods are employed to identify trends before they result in out-of-specification performance, with automated alerts triggering when predefined thresholds are approached.

The integration of machine learning algorithms has enhanced quality assurance capabilities by enabling predictive maintenance and adaptive calibration schedules based on usage patterns and performance data. These systems can identify subtle deviations in dispensing patterns that might indicate impending mechanical issues or calibration drift, allowing for preemptive intervention.

Regulatory compliance frameworks vary by application field, with clinical diagnostics following CLIA and FDA requirements, pharmaceutical research adhering to 21 CFR Part 11 for electronic records, and academic research typically following institutional guidelines. The trend toward harmonization of these standards is evident in initiatives like the Artel Multichannel Verification System, which has become a de facto standard for performance verification across different platforms and manufacturers.

Integration Capabilities with Laboratory Information Systems

The integration of auto-calibration routines for robotic liquid handling in Microfluidic Array Plates (MAPs) with Laboratory Information Management Systems (LIMS) represents a critical advancement in laboratory automation. Seamless connectivity between these systems enables real-time data exchange, enhancing both operational efficiency and experimental reproducibility. Modern integration frameworks utilize standardized protocols such as HL7, ASTM, and REST APIs to establish robust communication channels between calibration systems and LIMS platforms.

Data synchronization mechanisms ensure that calibration parameters, validation results, and system performance metrics are automatically recorded and associated with specific experimental workflows. This bidirectional communication allows calibration routines to access historical data from LIMS to establish baseline performance expectations, while simultaneously feeding calibration outcomes back to the LIMS for comprehensive documentation and traceability. Such integration significantly reduces manual data entry requirements and associated transcription errors.

Middleware solutions have emerged as effective bridges between proprietary robotic liquid handling systems and diverse LIMS environments. These integration layers abstract the complexity of different communication protocols and data formats, providing standardized interfaces that facilitate plug-and-play connectivity. Notable examples include Thermo Fisher's Integration Manager and Beckman Coulter's DART (Data Acquisition and Reporting Tool), which offer pre-configured connectors for popular LIMS platforms.

Security considerations play a paramount role in these integrations, particularly in regulated environments. Implementations typically incorporate authentication mechanisms, data encryption, audit trails, and electronic signatures to maintain compliance with regulations such as 21 CFR Part 11 and GDPR. These security measures ensure that calibration data maintains its integrity throughout the information lifecycle.

The integration architecture commonly follows either a centralized model, where a master LIMS orchestrates all calibration activities, or a distributed model featuring autonomous calibration routines that periodically synchronize with the LIMS. Cloud-based integration solutions are gaining popularity, offering scalability and accessibility advantages while introducing additional considerations regarding data sovereignty and network reliability.

Return on investment analyses indicate that laboratories implementing integrated auto-calibration systems experience approximately 30% reduction in documentation effort and up to 25% improvement in instrument utilization through optimized maintenance scheduling. These efficiency gains translate directly to increased throughput and enhanced data quality, particularly in high-throughput screening applications utilizing MAPs technology.

Data synchronization mechanisms ensure that calibration parameters, validation results, and system performance metrics are automatically recorded and associated with specific experimental workflows. This bidirectional communication allows calibration routines to access historical data from LIMS to establish baseline performance expectations, while simultaneously feeding calibration outcomes back to the LIMS for comprehensive documentation and traceability. Such integration significantly reduces manual data entry requirements and associated transcription errors.

Middleware solutions have emerged as effective bridges between proprietary robotic liquid handling systems and diverse LIMS environments. These integration layers abstract the complexity of different communication protocols and data formats, providing standardized interfaces that facilitate plug-and-play connectivity. Notable examples include Thermo Fisher's Integration Manager and Beckman Coulter's DART (Data Acquisition and Reporting Tool), which offer pre-configured connectors for popular LIMS platforms.

Security considerations play a paramount role in these integrations, particularly in regulated environments. Implementations typically incorporate authentication mechanisms, data encryption, audit trails, and electronic signatures to maintain compliance with regulations such as 21 CFR Part 11 and GDPR. These security measures ensure that calibration data maintains its integrity throughout the information lifecycle.

The integration architecture commonly follows either a centralized model, where a master LIMS orchestrates all calibration activities, or a distributed model featuring autonomous calibration routines that periodically synchronize with the LIMS. Cloud-based integration solutions are gaining popularity, offering scalability and accessibility advantages while introducing additional considerations regarding data sovereignty and network reliability.

Return on investment analyses indicate that laboratories implementing integrated auto-calibration systems experience approximately 30% reduction in documentation effort and up to 25% improvement in instrument utilization through optimized maintenance scheduling. These efficiency gains translate directly to increased throughput and enhanced data quality, particularly in high-throughput screening applications utilizing MAPs technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!