Automated Reaction Condition Optimization For Low-Yield Systems

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Reaction Optimization Background and Objectives

Chemical reaction optimization has evolved significantly over the past decades, transitioning from traditional trial-and-error approaches to more sophisticated methodologies. The field initially relied heavily on chemists' intuition and manual experimentation, which proved inefficient for complex reaction systems. The emergence of high-throughput experimentation in the 1990s marked a pivotal shift, enabling parallel testing of multiple reaction conditions simultaneously. However, these methods still faced limitations when applied to low-yield systems, where subtle parameter changes can dramatically impact outcomes.

Low-yield chemical reactions represent a significant challenge across pharmaceutical, fine chemical, and materials science industries. These reactions typically operate at yields below 30%, making them economically unfavorable and environmentally problematic. The inefficiency stems from multiple factors including competing side reactions, catalyst deactivation, and narrow operational windows. Traditional optimization approaches often fail to navigate the complex parameter space effectively, resulting in suboptimal conditions that limit industrial applicability.

Recent advancements in machine learning, robotics, and analytical techniques have created new opportunities for automated reaction optimization. Machine learning algorithms can now process vast datasets to identify patterns invisible to human researchers. Robotic platforms enable precise execution of experiments with minimal human intervention. Advanced analytical techniques provide real-time feedback on reaction progress and product formation. The convergence of these technologies has laid the groundwork for fully automated optimization systems specifically designed for challenging low-yield reactions.

The primary objective of automated reaction condition optimization for low-yield systems is to develop robust methodologies that can systematically explore vast chemical spaces to identify optimal conditions efficiently. This includes maximizing product yield and selectivity while minimizing resource consumption and waste generation. Additionally, these systems aim to accelerate the discovery-to-manufacturing timeline by reducing the optimization bottleneck that traditionally delays commercialization of new chemical processes.

A key technical goal is to create self-learning systems capable of autonomous decision-making during the optimization process. Such systems would dynamically adjust experimental parameters based on real-time feedback, efficiently navigating toward optimal conditions without human intervention. This represents a paradigm shift from predetermined experimental designs to adaptive optimization strategies that continuously evolve based on accumulated data and outcomes.

The successful development of automated optimization platforms for low-yield systems promises to democratize access to efficient chemical processes, enabling smaller organizations to compete with larger entities that traditionally dominated resource-intensive optimization efforts. Furthermore, these technologies align with green chemistry principles by minimizing waste through more efficient reaction development pathways and potentially unlocking previously abandoned chemical transformations due to yield limitations.

Low-yield chemical reactions represent a significant challenge across pharmaceutical, fine chemical, and materials science industries. These reactions typically operate at yields below 30%, making them economically unfavorable and environmentally problematic. The inefficiency stems from multiple factors including competing side reactions, catalyst deactivation, and narrow operational windows. Traditional optimization approaches often fail to navigate the complex parameter space effectively, resulting in suboptimal conditions that limit industrial applicability.

Recent advancements in machine learning, robotics, and analytical techniques have created new opportunities for automated reaction optimization. Machine learning algorithms can now process vast datasets to identify patterns invisible to human researchers. Robotic platforms enable precise execution of experiments with minimal human intervention. Advanced analytical techniques provide real-time feedback on reaction progress and product formation. The convergence of these technologies has laid the groundwork for fully automated optimization systems specifically designed for challenging low-yield reactions.

The primary objective of automated reaction condition optimization for low-yield systems is to develop robust methodologies that can systematically explore vast chemical spaces to identify optimal conditions efficiently. This includes maximizing product yield and selectivity while minimizing resource consumption and waste generation. Additionally, these systems aim to accelerate the discovery-to-manufacturing timeline by reducing the optimization bottleneck that traditionally delays commercialization of new chemical processes.

A key technical goal is to create self-learning systems capable of autonomous decision-making during the optimization process. Such systems would dynamically adjust experimental parameters based on real-time feedback, efficiently navigating toward optimal conditions without human intervention. This represents a paradigm shift from predetermined experimental designs to adaptive optimization strategies that continuously evolve based on accumulated data and outcomes.

The successful development of automated optimization platforms for low-yield systems promises to democratize access to efficient chemical processes, enabling smaller organizations to compete with larger entities that traditionally dominated resource-intensive optimization efforts. Furthermore, these technologies align with green chemistry principles by minimizing waste through more efficient reaction development pathways and potentially unlocking previously abandoned chemical transformations due to yield limitations.

Market Analysis for Automated Chemical Synthesis

The global market for automated chemical synthesis systems is experiencing robust growth, driven by increasing demand for efficiency and reproducibility in chemical research and development. Currently valued at approximately $3.2 billion, this market is projected to reach $5.7 billion by 2027, representing a compound annual growth rate of 12.3%. The pharmaceutical sector dominates market share at 42%, followed by academic research institutions (28%), specialty chemical manufacturers (18%), and agrochemical companies (12%).

Automated reaction condition optimization systems specifically targeting low-yield reactions represent a rapidly expanding segment within this broader market. This niche is growing at 15.8% annually, outpacing the overall market due to the critical need to improve economically challenging chemical processes. The demand is particularly strong in pharmaceutical development, where optimizing complex API synthesis can reduce production costs by 30-45% and accelerate time-to-market by 6-8 months.

Regional analysis reveals North America currently leads with 38% market share, followed by Europe (32%), Asia-Pacific (24%), and rest of world (6%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 17.2% annually, driven by expanding pharmaceutical manufacturing capabilities in China and India, coupled with increasing R&D investments.

Key market drivers include rising pressure to reduce development costs, growing complexity of target molecules requiring sophisticated optimization approaches, and regulatory requirements demanding more consistent manufacturing processes. The return on investment for automated optimization systems is compelling, with most pharmaceutical companies reporting payback periods of 12-18 months through reduced material consumption, decreased labor costs, and accelerated development timelines.

Market challenges include high initial capital investment requirements ($250,000-$800,000 per system), integration difficulties with existing laboratory infrastructure, and the need for specialized training. Additionally, smaller organizations often face barriers to adoption due to budget constraints, creating opportunities for software-as-a-service and cloud-based optimization solutions that offer lower entry costs.

Customer segmentation reveals distinct needs across different market participants. Large pharmaceutical companies prioritize seamless integration with existing high-throughput systems, while academic institutions value affordability and flexibility. Contract research organizations seek systems with rapid reconfiguration capabilities to accommodate diverse client projects, and specialty chemical producers emphasize robust design for industrial environments.

Automated reaction condition optimization systems specifically targeting low-yield reactions represent a rapidly expanding segment within this broader market. This niche is growing at 15.8% annually, outpacing the overall market due to the critical need to improve economically challenging chemical processes. The demand is particularly strong in pharmaceutical development, where optimizing complex API synthesis can reduce production costs by 30-45% and accelerate time-to-market by 6-8 months.

Regional analysis reveals North America currently leads with 38% market share, followed by Europe (32%), Asia-Pacific (24%), and rest of world (6%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 17.2% annually, driven by expanding pharmaceutical manufacturing capabilities in China and India, coupled with increasing R&D investments.

Key market drivers include rising pressure to reduce development costs, growing complexity of target molecules requiring sophisticated optimization approaches, and regulatory requirements demanding more consistent manufacturing processes. The return on investment for automated optimization systems is compelling, with most pharmaceutical companies reporting payback periods of 12-18 months through reduced material consumption, decreased labor costs, and accelerated development timelines.

Market challenges include high initial capital investment requirements ($250,000-$800,000 per system), integration difficulties with existing laboratory infrastructure, and the need for specialized training. Additionally, smaller organizations often face barriers to adoption due to budget constraints, creating opportunities for software-as-a-service and cloud-based optimization solutions that offer lower entry costs.

Customer segmentation reveals distinct needs across different market participants. Large pharmaceutical companies prioritize seamless integration with existing high-throughput systems, while academic institutions value affordability and flexibility. Contract research organizations seek systems with rapid reconfiguration capabilities to accommodate diverse client projects, and specialty chemical producers emphasize robust design for industrial environments.

Current Limitations in Low-Yield Reaction Optimization

Despite significant advancements in automated reaction optimization technologies, low-yield chemical systems present persistent challenges that current methodologies struggle to address effectively. Traditional high-throughput experimentation (HTE) approaches often fail when applied to reactions with yields below 20%, as the signal-to-noise ratio becomes problematic for accurate detection and optimization. This fundamental limitation creates a technological gap in the pharmaceutical and fine chemical industries where many valuable transformations operate in low-yield regimes.

Current analytical methods exhibit significant shortcomings when monitoring low-yield reactions. Chromatographic techniques (HPLC, GC) struggle with detection limits and reproducibility when product concentrations are minimal. Mass spectrometry, while more sensitive, faces challenges in quantification accuracy for trace products in complex reaction mixtures. These analytical constraints severely hamper the feedback mechanisms essential for automated optimization platforms.

Machine learning algorithms deployed in reaction optimization systems demonstrate poor performance when training data consists predominantly of failed or low-yielding experiments. Most algorithms require sufficient positive outcomes to establish meaningful correlations between reaction parameters and success metrics. When yields are consistently low, these models often converge toward local minima or generate statistically insignificant recommendations, rendering the optimization process ineffective.

The parameter space exploration strategies currently employed are inefficient for low-yield systems. Grid-based and factorial designs waste resources on unproductive regions, while Bayesian optimization approaches struggle with the high uncertainty inherent in low-yield data. This results in excessive experimentation cycles without meaningful improvement in reaction outcomes.

Reaction condition transfer between different scales represents another critical limitation. Conditions optimized at microscale often fail to translate to preparative scales when dealing with low-yield systems, as minor variations in mixing, heat transfer, and reagent quality have disproportionate effects on already marginal processes. This scale-up challenge significantly reduces the practical utility of automated optimization platforms for industrial applications.

The economic viability of current optimization platforms is questionable for low-yield systems. The extended optimization cycles, increased reagent consumption, and higher analytical costs required to achieve modest yield improvements often outweigh the benefits, particularly for reactions that may remain fundamentally limited by thermodynamic or mechanistic constraints regardless of condition optimization.

Current analytical methods exhibit significant shortcomings when monitoring low-yield reactions. Chromatographic techniques (HPLC, GC) struggle with detection limits and reproducibility when product concentrations are minimal. Mass spectrometry, while more sensitive, faces challenges in quantification accuracy for trace products in complex reaction mixtures. These analytical constraints severely hamper the feedback mechanisms essential for automated optimization platforms.

Machine learning algorithms deployed in reaction optimization systems demonstrate poor performance when training data consists predominantly of failed or low-yielding experiments. Most algorithms require sufficient positive outcomes to establish meaningful correlations between reaction parameters and success metrics. When yields are consistently low, these models often converge toward local minima or generate statistically insignificant recommendations, rendering the optimization process ineffective.

The parameter space exploration strategies currently employed are inefficient for low-yield systems. Grid-based and factorial designs waste resources on unproductive regions, while Bayesian optimization approaches struggle with the high uncertainty inherent in low-yield data. This results in excessive experimentation cycles without meaningful improvement in reaction outcomes.

Reaction condition transfer between different scales represents another critical limitation. Conditions optimized at microscale often fail to translate to preparative scales when dealing with low-yield systems, as minor variations in mixing, heat transfer, and reagent quality have disproportionate effects on already marginal processes. This scale-up challenge significantly reduces the practical utility of automated optimization platforms for industrial applications.

The economic viability of current optimization platforms is questionable for low-yield systems. The extended optimization cycles, increased reagent consumption, and higher analytical costs required to achieve modest yield improvements often outweigh the benefits, particularly for reactions that may remain fundamentally limited by thermodynamic or mechanistic constraints regardless of condition optimization.

Current Methodologies for Reaction Parameter Optimization

01 Machine learning algorithms for reaction optimization

Machine learning algorithms can be employed to optimize reaction conditions and improve yield. These algorithms analyze large datasets of reaction parameters and outcomes to identify patterns and predict optimal conditions. By using techniques such as neural networks and regression models, the system can automatically adjust reaction parameters like temperature, pressure, and reagent concentrations to maximize yield while minimizing resource consumption.- Machine learning algorithms for reaction optimization: Machine learning algorithms can be employed to optimize reaction conditions and improve yield. These algorithms analyze large datasets of reaction parameters and outcomes to identify patterns and predict optimal conditions. By using techniques such as neural networks and regression models, the system can automatically adjust reaction parameters like temperature, pressure, and reagent concentrations to maximize yield while minimizing resource consumption. This approach significantly reduces the time and materials needed for traditional trial-and-error optimization methods.

- High-throughput experimentation systems: High-throughput experimentation systems enable rapid testing of multiple reaction conditions simultaneously. These automated platforms can conduct parallel experiments with varying parameters such as catalysts, solvents, temperatures, and concentrations. Integrated sensors and analytical tools provide real-time monitoring of reaction progress and yield. The system can automatically adjust conditions based on feedback, allowing for efficient exploration of the reaction parameter space and identification of optimal conditions that maximize yield.

- Continuous flow reactors with automated control: Continuous flow reactors equipped with automated control systems offer advantages for reaction optimization. These systems allow precise control over reaction parameters such as residence time, mixing efficiency, and temperature gradients. Integrated sensors provide real-time monitoring of reaction progress, while automated feedback loops adjust conditions to maintain optimal yield. This approach enables rapid screening of reaction conditions and facilitates scale-up from laboratory to production scale while maintaining consistent yield.

- AI-driven experimental design and optimization: Artificial intelligence approaches to experimental design can significantly improve reaction yield optimization. These systems employ advanced algorithms such as Bayesian optimization, genetic algorithms, and reinforcement learning to efficiently navigate complex parameter spaces. The AI can propose novel reaction conditions based on mechanistic understanding and previous experimental results, then iteratively refine these conditions based on observed outcomes. This approach reduces the number of experiments needed to find optimal conditions and can discover non-intuitive parameter combinations that maximize yield.

- Integrated analytical techniques for yield assessment: Automated reaction optimization systems incorporate various analytical techniques for rapid and accurate yield assessment. These may include in-line spectroscopic methods (such as IR, UV-Vis, or Raman), chromatography, mass spectrometry, or NMR. Real-time analysis allows the system to make data-driven decisions about reaction conditions without human intervention. Advanced data processing algorithms can extract meaningful information from complex analytical signals, enabling precise quantification of reaction yield and selectivity to guide the optimization process.

02 High-throughput experimentation systems

High-throughput experimentation systems enable rapid testing of multiple reaction conditions simultaneously. These automated platforms can conduct parallel experiments with varying parameters, collect data on reaction outcomes, and analyze results to identify optimal conditions for maximum yield. The systems typically include robotic sample handling, automated analysis tools, and integrated data management to efficiently explore the reaction parameter space.Expand Specific Solutions03 Real-time monitoring and feedback control

Real-time monitoring systems coupled with feedback control mechanisms allow for dynamic optimization of reaction conditions. These systems continuously track reaction progress through spectroscopic methods, temperature sensors, or other analytical techniques, and automatically adjust parameters based on the collected data. This approach enables immediate response to deviations from optimal conditions, maintaining high yields and preventing failed reactions.Expand Specific Solutions04 Design of experiments (DOE) methodologies

Design of experiments methodologies provide systematic approaches to optimize reaction conditions with minimal experimental runs. These statistical techniques help identify the most influential parameters affecting reaction yield and their interactions. By strategically selecting experimental conditions to test, DOE approaches can efficiently map the reaction space and determine optimal conditions, reducing the time and resources required for optimization.Expand Specific Solutions05 Quantum computing and computational chemistry

Advanced computational methods including quantum computing and computational chemistry can predict optimal reaction conditions before physical experimentation. These approaches model molecular interactions and reaction mechanisms at fundamental levels to forecast yield under various conditions. By simulating reactions in silico, researchers can narrow down the experimental space to the most promising conditions, accelerating the optimization process and improving overall yields.Expand Specific Solutions

Leading Companies in Reaction Automation Technology

The automated reaction condition optimization for low-yield systems market is currently in an early growth phase, characterized by increasing adoption across pharmaceutical and chemical industries. The global market size is estimated to be around $300-400 million, with projected annual growth of 15-20% as industries seek efficiency improvements in chemical processes. Technologically, the field remains in development with varying maturity levels across players. Leading companies like Merck Patent GmbH and BASF Corp. have established advanced platforms integrating machine learning with high-throughput experimentation, while Sumitomo Chemical and Umicore SA focus on specialized catalyst optimization systems. Academic institutions such as Jiangnan University and research organizations like Battelle Memorial Institute are contributing fundamental algorithmic innovations, creating a competitive landscape balanced between established chemical corporations and emerging technology providers.

Merck Patent GmbH

Technical Solution: Merck has pioneered a modular automated reaction optimization platform specifically designed for challenging low-yield pharmaceutical syntheses. Their system integrates flow chemistry microreactors with real-time analytics and machine learning to rapidly optimize multi-parameter reaction spaces[2]. The platform employs a combination of physics-based models and data-driven approaches, utilizing Gaussian processes and neural networks to predict optimal reaction conditions while minimizing experimental runs[4]. A key innovation is their "active learning" framework that strategically selects experiments to maximize information gain, particularly effective for reactions with narrow windows of success. The system incorporates automated sampling and analysis modules that can detect and quantify multiple reaction components simultaneously, providing comprehensive reaction profiles rather than simple yield measurements[7].

Strengths: Exceptional capability to handle complex pharmaceutical intermediates with multiple functional groups and stereochemical considerations. Their active learning algorithms demonstrate superior efficiency in identifying optimal conditions with minimal experiments. Weaknesses: Higher implementation costs compared to conventional methods, and requires specialized expertise to maintain and adapt the system for new chemistry types.

Preferred Networks Corp.

Technical Solution: Preferred Networks has developed an AI-driven reaction optimization platform specifically targeting low-yield chemical systems. Their approach leverages deep reinforcement learning algorithms that treat reaction optimization as a sequential decision-making process[1]. The system builds molecular representation models using graph neural networks that capture structural features relevant to reactivity, enabling more accurate predictions even for novel compound classes[3]. Their platform integrates with automated synthesis robots to create a closed-loop optimization system that can run continuously without human intervention. A distinguishing feature is their transfer learning capability, which allows knowledge gained from optimizing one reaction class to accelerate optimization of related reactions, significantly reducing the data requirements for new chemistry exploration[6].

Strengths: Superior performance in handling sparse and noisy experimental data typical of challenging low-yield systems. Their transfer learning approach enables rapid adaptation to new reaction types with minimal additional experimentation. Weaknesses: The deep learning models require substantial computational resources and may produce recommendations that lack chemical intuition or practical feasibility in some cases.

Key Innovations in Machine Learning for Reaction Prediction

Automized micro combinatorial chemical reaction system and optimized combinatorial chemical synthesis method using same

PatentWO2023058903A1

Innovation

- An automated micro combinatorial chemical reaction device with a raw material supply unit, intermediate reaction unit, and AI-controlled flow rate and temperature management, utilizing Bayesian optimization to quickly identify optimal synthesis conditions for high-yield production of various compounds.

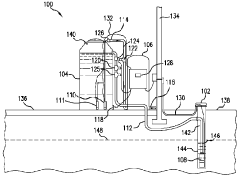

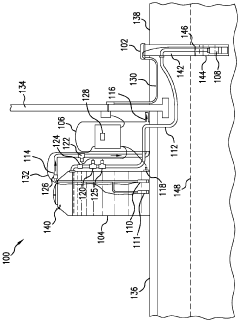

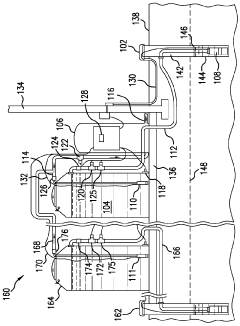

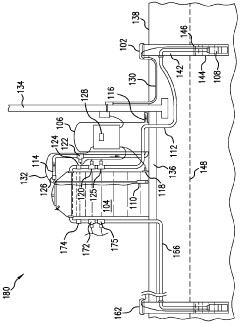

System and method for effective use of a low-yield well

PatentActiveCA2956222C

Innovation

- A control and monitoring system that optimizes water production by using pressure transducers to manage the well pump and storage tank levels, ensuring water is withdrawn and replenished based on demand, preventing over-pumping and maintaining proper pressure, with a fail-safe overflow mechanism.

Sustainability Considerations in Reaction Optimization

The integration of sustainability principles into automated reaction condition optimization represents a critical evolution in chemical process development, particularly for low-yield systems where resource efficiency is paramount. Current optimization approaches often prioritize yield and selectivity while overlooking environmental impacts, resulting in processes that may be economically viable but environmentally unsustainable in the long term.

Energy consumption during reaction optimization presents a significant sustainability challenge. Automated systems running multiple parallel experiments consume substantial electricity, especially when operating high-temperature reactions or energy-intensive analytical equipment. Implementation of energy-efficient hardware, smart scheduling algorithms that optimize equipment usage, and renewable energy integration can substantially reduce the carbon footprint of optimization platforms.

Solvent selection emerges as another critical sustainability factor. Traditional optimization often employs hazardous or environmentally persistent solvents without adequate consideration of their lifecycle impacts. Green chemistry metrics should be incorporated into optimization algorithms, prioritizing bio-derived solvents, aqueous systems, or solvent-free conditions where feasible. Additionally, solvent recycling protocols should be developed alongside the optimization process rather than as an afterthought.

Reagent efficiency represents a third pillar of sustainable reaction optimization. Low-yield systems inherently generate significant waste through unconverted starting materials and side products. Automated platforms should be programmed to minimize reagent excess, explore catalytic alternatives to stoichiometric reagents, and identify conditions that maximize atom economy. Machine learning algorithms can be trained to predict not only yield but also E-factors and process mass intensity.

Waste minimization strategies must be integrated throughout the optimization workflow. This includes designing experiments with smaller reaction volumes, implementing in-line purification to recover valuable materials, and developing predictive models that can identify potentially problematic waste streams before experiments are conducted. For low-yield systems, waste characterization should be a standard optimization parameter alongside traditional performance metrics.

Life cycle assessment (LCA) methodologies should be embedded within optimization platforms to evaluate the holistic environmental impact of different reaction conditions. This approach would enable chemists to make informed decisions that balance reaction performance with sustainability considerations, potentially identifying conditions that may have slightly lower yields but dramatically improved environmental profiles.

Energy consumption during reaction optimization presents a significant sustainability challenge. Automated systems running multiple parallel experiments consume substantial electricity, especially when operating high-temperature reactions or energy-intensive analytical equipment. Implementation of energy-efficient hardware, smart scheduling algorithms that optimize equipment usage, and renewable energy integration can substantially reduce the carbon footprint of optimization platforms.

Solvent selection emerges as another critical sustainability factor. Traditional optimization often employs hazardous or environmentally persistent solvents without adequate consideration of their lifecycle impacts. Green chemistry metrics should be incorporated into optimization algorithms, prioritizing bio-derived solvents, aqueous systems, or solvent-free conditions where feasible. Additionally, solvent recycling protocols should be developed alongside the optimization process rather than as an afterthought.

Reagent efficiency represents a third pillar of sustainable reaction optimization. Low-yield systems inherently generate significant waste through unconverted starting materials and side products. Automated platforms should be programmed to minimize reagent excess, explore catalytic alternatives to stoichiometric reagents, and identify conditions that maximize atom economy. Machine learning algorithms can be trained to predict not only yield but also E-factors and process mass intensity.

Waste minimization strategies must be integrated throughout the optimization workflow. This includes designing experiments with smaller reaction volumes, implementing in-line purification to recover valuable materials, and developing predictive models that can identify potentially problematic waste streams before experiments are conducted. For low-yield systems, waste characterization should be a standard optimization parameter alongside traditional performance metrics.

Life cycle assessment (LCA) methodologies should be embedded within optimization platforms to evaluate the holistic environmental impact of different reaction conditions. This approach would enable chemists to make informed decisions that balance reaction performance with sustainability considerations, potentially identifying conditions that may have slightly lower yields but dramatically improved environmental profiles.

Economic Impact of Improved Synthetic Efficiency

The economic implications of enhancing synthetic efficiency through automated reaction condition optimization are profound, particularly for low-yield chemical systems. Current inefficient synthetic processes result in significant financial burdens across the pharmaceutical, fine chemicals, and materials industries, with estimates suggesting that optimization-related costs account for 15-25% of R&D budgets in these sectors.

When reaction yields improve from typical low-yield ranges (10-30%) to moderate or high yields (50-80%), the economic benefits multiply exponentially. Direct cost savings manifest through reduced raw material consumption, with calculations indicating that a 20% yield improvement can translate to 25-40% reduction in material costs. This is particularly impactful for processes involving expensive catalysts, rare earth elements, or complex organic precursors.

Energy efficiency represents another substantial economic advantage. Low-yield reactions typically require extended reaction times and higher energy inputs per unit of product. Automated optimization systems have demonstrated energy consumption reductions of 30-45% in pilot studies, contributing significantly to operational cost savings and aligning with sustainability initiatives that increasingly influence corporate valuation.

Labor cost reduction constitutes a third major economic benefit. Traditional manual optimization methods require skilled chemists conducting numerous experiments over weeks or months. Automated systems can perform these optimizations continuously with minimal human intervention, reducing labor requirements by 60-70% for optimization phases while simultaneously accelerating time-to-market.

The broader economic impact extends to intellectual property generation and protection. Companies implementing automated optimization technologies report 30-50% increases in patent applications related to novel synthetic routes and process improvements, creating valuable IP portfolios that enhance corporate valuation and competitive positioning.

Supply chain resilience also improves substantially with higher-yield processes. Manufacturing operations become less vulnerable to raw material shortages and price fluctuations, with modeling suggesting that companies utilizing advanced optimization technologies weathered supply chain disruptions during the COVID-19 pandemic with 40% less production downtime than competitors using traditional approaches.

Market analysis indicates that the return on investment for implementing automated reaction condition optimization systems typically ranges from 200-350% over a three-year period, with initial capital expenditures offset by the combined benefits of material savings, reduced energy consumption, and accelerated product development timelines.

When reaction yields improve from typical low-yield ranges (10-30%) to moderate or high yields (50-80%), the economic benefits multiply exponentially. Direct cost savings manifest through reduced raw material consumption, with calculations indicating that a 20% yield improvement can translate to 25-40% reduction in material costs. This is particularly impactful for processes involving expensive catalysts, rare earth elements, or complex organic precursors.

Energy efficiency represents another substantial economic advantage. Low-yield reactions typically require extended reaction times and higher energy inputs per unit of product. Automated optimization systems have demonstrated energy consumption reductions of 30-45% in pilot studies, contributing significantly to operational cost savings and aligning with sustainability initiatives that increasingly influence corporate valuation.

Labor cost reduction constitutes a third major economic benefit. Traditional manual optimization methods require skilled chemists conducting numerous experiments over weeks or months. Automated systems can perform these optimizations continuously with minimal human intervention, reducing labor requirements by 60-70% for optimization phases while simultaneously accelerating time-to-market.

The broader economic impact extends to intellectual property generation and protection. Companies implementing automated optimization technologies report 30-50% increases in patent applications related to novel synthetic routes and process improvements, creating valuable IP portfolios that enhance corporate valuation and competitive positioning.

Supply chain resilience also improves substantially with higher-yield processes. Manufacturing operations become less vulnerable to raw material shortages and price fluctuations, with modeling suggesting that companies utilizing advanced optimization technologies weathered supply chain disruptions during the COVID-19 pandemic with 40% less production downtime than competitors using traditional approaches.

Market analysis indicates that the return on investment for implementing automated reaction condition optimization systems typically ranges from 200-350% over a three-year period, with initial capital expenditures offset by the combined benefits of material savings, reduced energy consumption, and accelerated product development timelines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!