Blade Battery's Role in Decarbonizing Transportation Sectors

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Blade Battery Evolution

The evolution of Blade Battery technology represents a significant milestone in the quest for decarbonizing transportation sectors. Initially developed by BYD in 2020, this innovative lithium iron phosphate (LFP) battery design has rapidly gained traction due to its enhanced safety features and improved energy density.

The Blade Battery's journey began with a focus on addressing the inherent safety concerns associated with traditional lithium-ion batteries. By utilizing a unique cell-to-pack design, BYD engineers were able to create a more stable and resilient battery structure. This design eliminates the need for modules, allowing for a higher energy density and reduced risk of thermal runaway.

As the technology matured, subsequent iterations of the Blade Battery saw improvements in energy density and charging capabilities. The original version boasted an energy density of around 140 Wh/kg, which has since been increased to over 160 Wh/kg in more recent models. This progress has been crucial in extending the range of electric vehicles and making them more competitive with traditional internal combustion engine vehicles.

Another key aspect of the Blade Battery's evolution has been its adaptability to various vehicle types. Initially deployed in passenger cars, the technology has since been scaled to accommodate larger vehicles such as buses and trucks. This versatility has played a pivotal role in expanding the potential for decarbonization across different transportation sectors.

The manufacturing process for Blade Batteries has also undergone significant refinement. BYD has invested heavily in automated production lines, which have not only increased output capacity but also improved consistency and quality control. This scaling of production has been instrumental in reducing costs and making electric vehicles more accessible to a broader market.

In terms of charging technology, the Blade Battery has seen advancements in fast-charging capabilities. Recent versions can achieve an 80% charge in under 30 minutes, addressing one of the primary concerns of potential electric vehicle adopters. This improvement in charging speed has been crucial for the wider adoption of electric vehicles in both personal and commercial transportation sectors.

The environmental impact of Blade Battery production has also been a focus area for development. BYD has made strides in reducing the carbon footprint of the manufacturing process, implementing more sustainable practices and exploring the use of recycled materials. This holistic approach to sustainability aligns with the broader goals of decarbonization in the transportation industry.

The Blade Battery's journey began with a focus on addressing the inherent safety concerns associated with traditional lithium-ion batteries. By utilizing a unique cell-to-pack design, BYD engineers were able to create a more stable and resilient battery structure. This design eliminates the need for modules, allowing for a higher energy density and reduced risk of thermal runaway.

As the technology matured, subsequent iterations of the Blade Battery saw improvements in energy density and charging capabilities. The original version boasted an energy density of around 140 Wh/kg, which has since been increased to over 160 Wh/kg in more recent models. This progress has been crucial in extending the range of electric vehicles and making them more competitive with traditional internal combustion engine vehicles.

Another key aspect of the Blade Battery's evolution has been its adaptability to various vehicle types. Initially deployed in passenger cars, the technology has since been scaled to accommodate larger vehicles such as buses and trucks. This versatility has played a pivotal role in expanding the potential for decarbonization across different transportation sectors.

The manufacturing process for Blade Batteries has also undergone significant refinement. BYD has invested heavily in automated production lines, which have not only increased output capacity but also improved consistency and quality control. This scaling of production has been instrumental in reducing costs and making electric vehicles more accessible to a broader market.

In terms of charging technology, the Blade Battery has seen advancements in fast-charging capabilities. Recent versions can achieve an 80% charge in under 30 minutes, addressing one of the primary concerns of potential electric vehicle adopters. This improvement in charging speed has been crucial for the wider adoption of electric vehicles in both personal and commercial transportation sectors.

The environmental impact of Blade Battery production has also been a focus area for development. BYD has made strides in reducing the carbon footprint of the manufacturing process, implementing more sustainable practices and exploring the use of recycled materials. This holistic approach to sustainability aligns with the broader goals of decarbonization in the transportation industry.

EV Market Demand Analysis

The global electric vehicle (EV) market has been experiencing unprecedented growth, driven by increasing environmental awareness, government incentives, and technological advancements. The demand for EVs is closely tied to the development of advanced battery technologies, such as the Blade Battery, which plays a crucial role in decarbonizing transportation sectors.

In recent years, the EV market has shown remarkable expansion across various regions. China, the world's largest automotive market, has been at the forefront of EV adoption, with sales surpassing 3.3 million units in 2021. Europe has also witnessed significant growth, with EV sales reaching 2.3 million units in the same year. The United States, while lagging behind China and Europe, has shown promising growth with EV sales exceeding 600,000 units in 2021.

The demand for EVs is expected to continue its upward trajectory, with projections indicating a compound annual growth rate (CAGR) of over 25% from 2021 to 2028. This growth is driven by several factors, including stricter emissions regulations, falling battery costs, and improving charging infrastructure.

The Blade Battery, developed by BYD, addresses key consumer concerns regarding EV adoption, such as range anxiety and safety. Its innovative design allows for higher energy density, longer driving range, and enhanced safety features compared to traditional lithium-ion batteries. These improvements directly contribute to increased consumer confidence and, consequently, higher demand for EVs equipped with Blade Batteries.

Market analysis reveals that consumers are increasingly prioritizing safety and performance when considering EV purchases. The Blade Battery's ability to withstand extreme conditions and its reduced risk of thermal runaway align well with these consumer preferences, potentially driving higher adoption rates in the coming years.

Furthermore, the transportation sector's decarbonization efforts extend beyond personal vehicles. Commercial fleets, public transportation, and last-mile delivery services are actively seeking electric alternatives to reduce their carbon footprint. The Blade Battery's characteristics make it particularly suitable for these applications, potentially expanding its market reach and driving demand across various transportation segments.

As governments worldwide implement more stringent emissions regulations and set ambitious targets for EV adoption, the market demand for advanced battery technologies like the Blade Battery is expected to surge. Many countries have announced plans to phase out internal combustion engine vehicles in the coming decades, creating a substantial long-term market for EVs and their associated battery technologies.

In conclusion, the EV market demand analysis indicates a robust and growing market for advanced battery technologies like the Blade Battery. Its role in decarbonizing transportation sectors is significant, addressing key consumer concerns and aligning with global sustainability goals. As the EV market continues to expand, the demand for innovative battery solutions will likely intensify, positioning technologies like the Blade Battery at the forefront of the automotive industry's transformation.

In recent years, the EV market has shown remarkable expansion across various regions. China, the world's largest automotive market, has been at the forefront of EV adoption, with sales surpassing 3.3 million units in 2021. Europe has also witnessed significant growth, with EV sales reaching 2.3 million units in the same year. The United States, while lagging behind China and Europe, has shown promising growth with EV sales exceeding 600,000 units in 2021.

The demand for EVs is expected to continue its upward trajectory, with projections indicating a compound annual growth rate (CAGR) of over 25% from 2021 to 2028. This growth is driven by several factors, including stricter emissions regulations, falling battery costs, and improving charging infrastructure.

The Blade Battery, developed by BYD, addresses key consumer concerns regarding EV adoption, such as range anxiety and safety. Its innovative design allows for higher energy density, longer driving range, and enhanced safety features compared to traditional lithium-ion batteries. These improvements directly contribute to increased consumer confidence and, consequently, higher demand for EVs equipped with Blade Batteries.

Market analysis reveals that consumers are increasingly prioritizing safety and performance when considering EV purchases. The Blade Battery's ability to withstand extreme conditions and its reduced risk of thermal runaway align well with these consumer preferences, potentially driving higher adoption rates in the coming years.

Furthermore, the transportation sector's decarbonization efforts extend beyond personal vehicles. Commercial fleets, public transportation, and last-mile delivery services are actively seeking electric alternatives to reduce their carbon footprint. The Blade Battery's characteristics make it particularly suitable for these applications, potentially expanding its market reach and driving demand across various transportation segments.

As governments worldwide implement more stringent emissions regulations and set ambitious targets for EV adoption, the market demand for advanced battery technologies like the Blade Battery is expected to surge. Many countries have announced plans to phase out internal combustion engine vehicles in the coming decades, creating a substantial long-term market for EVs and their associated battery technologies.

In conclusion, the EV market demand analysis indicates a robust and growing market for advanced battery technologies like the Blade Battery. Its role in decarbonizing transportation sectors is significant, addressing key consumer concerns and aligning with global sustainability goals. As the EV market continues to expand, the demand for innovative battery solutions will likely intensify, positioning technologies like the Blade Battery at the forefront of the automotive industry's transformation.

Blade Battery Tech Status

Blade batteries have emerged as a promising technology in the quest for decarbonizing transportation sectors. Currently, these batteries are at the forefront of innovation in electric vehicle (EV) energy storage systems. Developed by BYD, a leading Chinese automotive manufacturer, blade batteries represent a significant advancement in lithium iron phosphate (LFP) battery technology.

The current technical status of blade batteries showcases several key improvements over traditional lithium-ion batteries. Firstly, they offer enhanced safety features, with a notably reduced risk of thermal runaway and combustion. This is achieved through their unique cell-to-pack design, which eliminates the need for module housings and allows for more efficient space utilization within the battery pack.

In terms of energy density, blade batteries have made substantial progress. While LFP batteries have traditionally lagged behind nickel-based chemistries in this aspect, the blade battery design has narrowed this gap considerably. Current iterations of blade batteries boast energy densities approaching 160 Wh/kg at the pack level, a significant improvement over earlier LFP technologies.

Longevity is another area where blade batteries excel in their current state. These batteries demonstrate impressive cycle life, with some models capable of retaining over 90% of their original capacity after 3,000 charge-discharge cycles. This durability translates to extended vehicle range and reduced battery replacement needs over the lifetime of an EV.

From a manufacturing perspective, blade batteries benefit from a streamlined production process. The simplified structure allows for more efficient assembly and reduced production costs. This has positioned blade batteries as a competitive option for mass-market EVs, particularly in segments where cost-effectiveness is a primary concern.

However, challenges remain in the current technical landscape of blade batteries. While their energy density has improved, they still fall short of the highest-performing nickel-based lithium-ion batteries. This limitation may impact their suitability for certain high-performance or long-range EV applications.

Additionally, the technology's thermal management requirements, particularly in extreme climate conditions, present ongoing engineering challenges. Efforts are underway to optimize the battery's performance across a wider temperature range, which is crucial for global adoption in diverse climates.

In the context of decarbonizing transportation, the current status of blade battery technology offers significant promise. Their combination of safety, longevity, and cost-effectiveness makes them well-suited for a wide range of electric vehicles, from urban commuters to public transportation. As the technology continues to mature, it is expected to play an increasingly important role in accelerating the transition to sustainable transportation solutions.

The current technical status of blade batteries showcases several key improvements over traditional lithium-ion batteries. Firstly, they offer enhanced safety features, with a notably reduced risk of thermal runaway and combustion. This is achieved through their unique cell-to-pack design, which eliminates the need for module housings and allows for more efficient space utilization within the battery pack.

In terms of energy density, blade batteries have made substantial progress. While LFP batteries have traditionally lagged behind nickel-based chemistries in this aspect, the blade battery design has narrowed this gap considerably. Current iterations of blade batteries boast energy densities approaching 160 Wh/kg at the pack level, a significant improvement over earlier LFP technologies.

Longevity is another area where blade batteries excel in their current state. These batteries demonstrate impressive cycle life, with some models capable of retaining over 90% of their original capacity after 3,000 charge-discharge cycles. This durability translates to extended vehicle range and reduced battery replacement needs over the lifetime of an EV.

From a manufacturing perspective, blade batteries benefit from a streamlined production process. The simplified structure allows for more efficient assembly and reduced production costs. This has positioned blade batteries as a competitive option for mass-market EVs, particularly in segments where cost-effectiveness is a primary concern.

However, challenges remain in the current technical landscape of blade batteries. While their energy density has improved, they still fall short of the highest-performing nickel-based lithium-ion batteries. This limitation may impact their suitability for certain high-performance or long-range EV applications.

Additionally, the technology's thermal management requirements, particularly in extreme climate conditions, present ongoing engineering challenges. Efforts are underway to optimize the battery's performance across a wider temperature range, which is crucial for global adoption in diverse climates.

In the context of decarbonizing transportation, the current status of blade battery technology offers significant promise. Their combination of safety, longevity, and cost-effectiveness makes them well-suited for a wide range of electric vehicles, from urban commuters to public transportation. As the technology continues to mature, it is expected to play an increasingly important role in accelerating the transition to sustainable transportation solutions.

Blade Battery Solutions

01 Battery composition and structure for decarbonization

Innovative battery compositions and structures are developed to reduce carbon emissions. These include the use of advanced materials and novel designs that enhance energy efficiency and reduce the environmental impact of battery production and usage.- Blade battery manufacturing process optimization: Improving the manufacturing process of blade batteries to reduce carbon emissions. This includes optimizing production techniques, using more efficient equipment, and implementing energy-saving measures throughout the manufacturing line. These improvements can significantly reduce the carbon footprint of blade battery production.

- Recycling and reuse of battery materials: Developing efficient methods for recycling and reusing materials from blade batteries at the end of their lifecycle. This includes processes for recovering valuable metals and other components, which can be reused in new battery production, thereby reducing the need for raw material extraction and associated carbon emissions.

- Use of renewable energy in battery production: Incorporating renewable energy sources such as solar and wind power in the blade battery production process. This shift towards clean energy can significantly reduce the carbon emissions associated with battery manufacturing, contributing to overall decarbonization efforts.

- Advanced thermal management systems: Developing and implementing advanced thermal management systems for blade batteries. These systems can improve battery efficiency, extend lifespan, and reduce energy loss, all of which contribute to lower carbon emissions over the battery's lifecycle.

- Lightweight and eco-friendly battery materials: Researching and developing lightweight and environmentally friendly materials for blade battery construction. This includes exploring alternative electrode materials, electrolytes, and structural components that have a lower environmental impact and can improve the overall energy efficiency of the battery.

02 Recycling and reuse of battery components

Methods for recycling and reusing battery components are implemented to minimize waste and reduce the carbon footprint of battery production. This includes processes for recovering valuable materials from used batteries and repurposing them for new battery manufacturing.Expand Specific Solutions03 Green manufacturing processes for blade batteries

Environmentally friendly manufacturing processes are developed for blade batteries, focusing on reducing energy consumption and minimizing harmful emissions during production. This includes the use of renewable energy sources and optimization of production techniques.Expand Specific Solutions04 Integration of renewable energy in battery charging

Systems are designed to integrate renewable energy sources for charging blade batteries, reducing reliance on fossil fuels and decreasing overall carbon emissions associated with battery usage. This includes smart charging technologies and grid integration solutions.Expand Specific Solutions05 Carbon capture and utilization in battery production

Innovative methods for capturing and utilizing carbon dioxide during the battery production process are developed. These techniques aim to reduce the net carbon emissions of battery manufacturing while potentially improving battery performance.Expand Specific Solutions

Key EV Battery Players

The Blade Battery technology in decarbonizing transportation sectors is entering a competitive and rapidly evolving phase. The market is experiencing significant growth, driven by increasing demand for electric vehicles and sustainable energy solutions. Key players like Contemporary Amperex Technology Co., Ltd. and Svolt Energy Technology Co., Ltd. are at the forefront of this technology, with established companies such as Toyota and emerging players like Rivian and Northvolt also making significant strides. The technology's maturity is advancing quickly, with companies investing heavily in research and development to improve performance, safety, and cost-effectiveness. As the industry progresses, collaboration between automakers, battery manufacturers, and research institutions is becoming increasingly crucial for innovation and market expansion.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL's Blade Battery technology represents a significant advancement in lithium-ion battery design for electric vehicles. The Blade Battery utilizes LFP (lithium iron phosphate) chemistry in a novel cell-to-pack design, eliminating the need for module housing. This approach increases energy density by 50% compared to conventional LFP batteries[1]. The cells are arranged in a blade-like format, allowing for more efficient space utilization and improved thermal management. CATL claims the Blade Battery can achieve an energy density of up to 160Wh/kg at the pack level[2], which is competitive with some NMC (nickel manganese cobalt) batteries while offering superior safety characteristics. The battery has demonstrated exceptional safety performance, passing nail penetration tests without catching fire or exploding[3], addressing a critical concern in EV adoption.

Strengths: Superior safety performance, increased energy density, and improved space utilization. Weaknesses: Lower energy density compared to some high-nickel NMC batteries, potentially limiting long-range EV applications.

Svolt Energy Technology Co., Ltd.

Technical Solution: Svolt has developed a cobalt-free battery technology aimed at reducing dependency on scarce and ethically problematic cobalt resources. Their NMx batteries use nickel-manganese chemistry, offering a more sustainable alternative to traditional lithium-ion batteries. Svolt claims their cobalt-free batteries can achieve an energy density of up to 200 Wh/kg and a range of over 800 km in EVs[7]. The company has also introduced a "stacking" process for battery assembly, which improves energy density and reduces internal resistance. Svolt's batteries incorporate advanced safety features, including a ceramic coating on the separator to enhance thermal stability[8].

Strengths: Elimination of cobalt reduces ethical concerns and potential supply chain issues. Competitive energy density. Weaknesses: Relatively new technology with limited real-world performance data.

Blade Battery Innovations

Reversible solid adsorption method and system utilizing waste heat for on-board recovery and storage of co2

PatentWO2012100149A1

Innovation

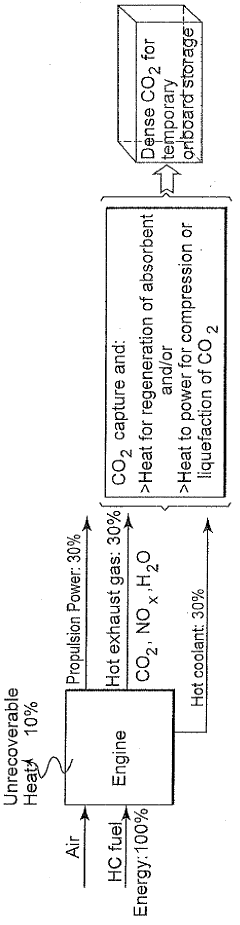

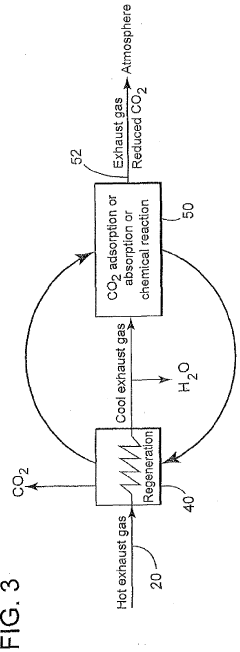

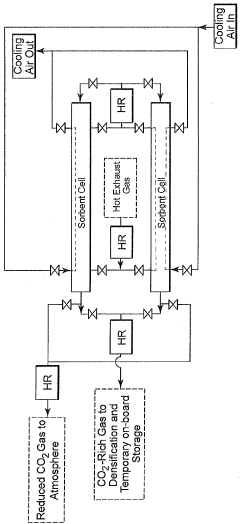

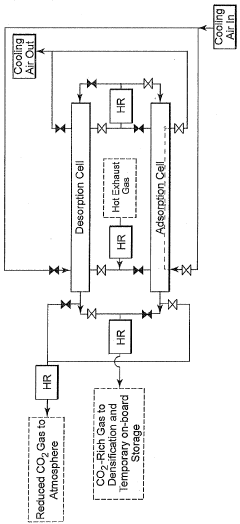

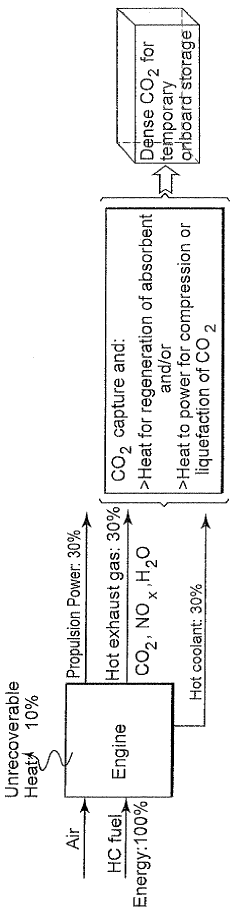

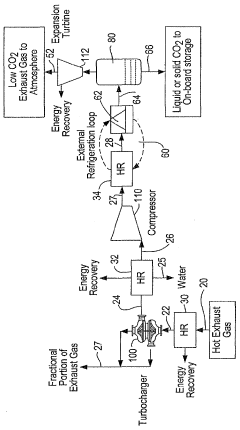

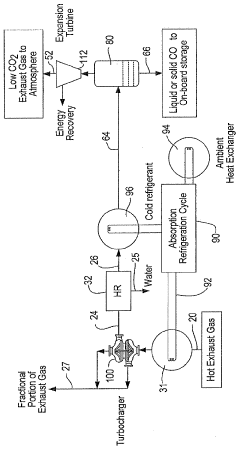

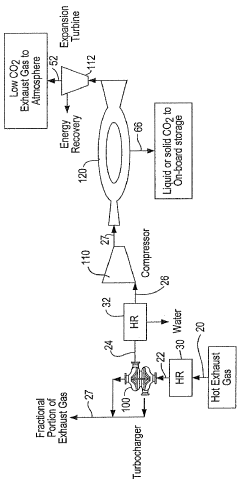

- A system utilizing waste heat from internal combustion engines for CO2 capture, regeneration, and densification, which includes an adsorption separation method, a heat exchanger for regeneration, and a compression zone for temporary on-board storage, leveraging waste heat to reduce energy costs and volume requirements.

Direct densification method and system utilizing waste heat for on-board recovery and storage of co2 from motor vehicle internal combustion engine exhaust gases

PatentWO2012100157A1

Innovation

- A system and method for on-board CO2 capture and storage utilizing a waste heat recovery zone, densification zone, separation zone, and storage zone, where waste heat from the engine is used to cool, compress, and liquefy CO2, reducing its volume for temporary storage, and incorporating thermoelectric devices, absorption refrigeration cycles, and subsonic nozzles for efficient phase change and separation.

Environmental Impact

The adoption of Blade Batteries in the transportation sector has significant potential to reduce environmental impacts associated with conventional lithium-ion batteries. Blade Batteries, developed by BYD, utilize lithium iron phosphate (LFP) chemistry and a unique structural design that enhances safety and energy density while reducing the environmental footprint of battery production and use.

One of the primary environmental benefits of Blade Batteries is their improved energy density, which allows for longer driving ranges and reduced battery weight. This translates to lower energy consumption during vehicle operation, contributing to overall emissions reduction in the transportation sector. Additionally, the LFP chemistry used in Blade Batteries eliminates the need for cobalt, a material associated with ethical and environmental concerns in its mining and processing.

The manufacturing process of Blade Batteries also presents environmental advantages. The simplified cell structure and efficient production methods result in lower energy consumption during manufacturing compared to traditional lithium-ion batteries. This reduction in energy use during production contributes to a lower carbon footprint for electric vehicles equipped with Blade Batteries.

Furthermore, the enhanced safety features of Blade Batteries, including improved thermal management and reduced risk of thermal runaway, contribute to a longer lifespan and reduced likelihood of premature battery replacement. This extended lifecycle reduces the overall environmental impact associated with battery production and disposal.

The recyclability of Blade Batteries is another crucial factor in their environmental impact. The LFP chemistry used in these batteries is more easily recyclable than some other lithium-ion chemistries, potentially leading to a more circular economy approach in battery production and reducing the demand for raw materials extraction.

In terms of end-of-life management, Blade Batteries offer promising opportunities for second-life applications. Their robust design and stable chemistry make them suitable for stationary energy storage systems after their useful life in vehicles has ended. This repurposing extends the overall lifecycle of the batteries, further reducing waste and environmental impact.

As the transportation sector continues to electrify, the widespread adoption of Blade Batteries could play a significant role in reducing greenhouse gas emissions. By enabling more efficient and longer-range electric vehicles, these batteries contribute to the displacement of internal combustion engine vehicles, leading to substantial reductions in tailpipe emissions and overall carbon footprint of the transportation sector.

One of the primary environmental benefits of Blade Batteries is their improved energy density, which allows for longer driving ranges and reduced battery weight. This translates to lower energy consumption during vehicle operation, contributing to overall emissions reduction in the transportation sector. Additionally, the LFP chemistry used in Blade Batteries eliminates the need for cobalt, a material associated with ethical and environmental concerns in its mining and processing.

The manufacturing process of Blade Batteries also presents environmental advantages. The simplified cell structure and efficient production methods result in lower energy consumption during manufacturing compared to traditional lithium-ion batteries. This reduction in energy use during production contributes to a lower carbon footprint for electric vehicles equipped with Blade Batteries.

Furthermore, the enhanced safety features of Blade Batteries, including improved thermal management and reduced risk of thermal runaway, contribute to a longer lifespan and reduced likelihood of premature battery replacement. This extended lifecycle reduces the overall environmental impact associated with battery production and disposal.

The recyclability of Blade Batteries is another crucial factor in their environmental impact. The LFP chemistry used in these batteries is more easily recyclable than some other lithium-ion chemistries, potentially leading to a more circular economy approach in battery production and reducing the demand for raw materials extraction.

In terms of end-of-life management, Blade Batteries offer promising opportunities for second-life applications. Their robust design and stable chemistry make them suitable for stationary energy storage systems after their useful life in vehicles has ended. This repurposing extends the overall lifecycle of the batteries, further reducing waste and environmental impact.

As the transportation sector continues to electrify, the widespread adoption of Blade Batteries could play a significant role in reducing greenhouse gas emissions. By enabling more efficient and longer-range electric vehicles, these batteries contribute to the displacement of internal combustion engine vehicles, leading to substantial reductions in tailpipe emissions and overall carbon footprint of the transportation sector.

Policy & Regulations

The regulatory landscape surrounding blade batteries and their role in decarbonizing transportation sectors is rapidly evolving. Governments worldwide are implementing policies to accelerate the transition to electric vehicles (EVs) and reduce carbon emissions in the transportation sector. These policies often include incentives for EV adoption, stringent emissions standards, and mandates for phasing out internal combustion engine vehicles.

In the European Union, the European Green Deal sets ambitious targets for reducing greenhouse gas emissions, with a goal of achieving climate neutrality by 2050. This includes plans to reduce transport emissions by 90% by 2050 compared to 1990 levels. The EU has also proposed banning the sale of new petrol and diesel cars by 2035, which will significantly boost the demand for electric vehicles and, consequently, advanced battery technologies like blade batteries.

China, a leader in EV adoption and battery technology, has implemented a dual-credit policy that requires automakers to produce a certain percentage of new energy vehicles. The country has also set targets for EV sales to reach 20% of all new car sales by 2025 and 40% by 2030. These policies have driven significant investment in battery technology and manufacturing, including advancements in blade batteries.

In the United States, the Biden administration has set a target for 50% of all new vehicle sales to be electric by 2030. The recently passed Inflation Reduction Act includes substantial incentives for EV purchases and domestic battery production, which could accelerate the adoption of advanced battery technologies like blade batteries.

Many countries are also implementing regulations to ensure the sustainability and ethical sourcing of battery materials. The EU's proposed Battery Regulation aims to create a circular economy for batteries, including requirements for recycling, carbon footprint declarations, and due diligence in supply chains. These regulations will likely influence the development and production of blade batteries, encouraging manufacturers to focus on sustainability and recyclability.

Safety regulations are another critical aspect of battery policy. As blade batteries offer improved safety features compared to traditional lithium-ion batteries, they may benefit from evolving safety standards. Regulatory bodies like the UN Global Technical Regulation on Electric Vehicle Safety are continuously updating their guidelines to address the unique characteristics of new battery technologies.

As blade batteries continue to demonstrate their potential in improving EV range, safety, and sustainability, policymakers may introduce specific regulations or incentives to promote their adoption. This could include targeted research funding, tax credits for manufacturers, or preferential treatment in government procurement programs for vehicles equipped with blade batteries.

In the European Union, the European Green Deal sets ambitious targets for reducing greenhouse gas emissions, with a goal of achieving climate neutrality by 2050. This includes plans to reduce transport emissions by 90% by 2050 compared to 1990 levels. The EU has also proposed banning the sale of new petrol and diesel cars by 2035, which will significantly boost the demand for electric vehicles and, consequently, advanced battery technologies like blade batteries.

China, a leader in EV adoption and battery technology, has implemented a dual-credit policy that requires automakers to produce a certain percentage of new energy vehicles. The country has also set targets for EV sales to reach 20% of all new car sales by 2025 and 40% by 2030. These policies have driven significant investment in battery technology and manufacturing, including advancements in blade batteries.

In the United States, the Biden administration has set a target for 50% of all new vehicle sales to be electric by 2030. The recently passed Inflation Reduction Act includes substantial incentives for EV purchases and domestic battery production, which could accelerate the adoption of advanced battery technologies like blade batteries.

Many countries are also implementing regulations to ensure the sustainability and ethical sourcing of battery materials. The EU's proposed Battery Regulation aims to create a circular economy for batteries, including requirements for recycling, carbon footprint declarations, and due diligence in supply chains. These regulations will likely influence the development and production of blade batteries, encouraging manufacturers to focus on sustainability and recyclability.

Safety regulations are another critical aspect of battery policy. As blade batteries offer improved safety features compared to traditional lithium-ion batteries, they may benefit from evolving safety standards. Regulatory bodies like the UN Global Technical Regulation on Electric Vehicle Safety are continuously updating their guidelines to address the unique characteristics of new battery technologies.

As blade batteries continue to demonstrate their potential in improving EV range, safety, and sustainability, policymakers may introduce specific regulations or incentives to promote their adoption. This could include targeted research funding, tax credits for manufacturers, or preferential treatment in government procurement programs for vehicles equipped with blade batteries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!