Bolting And Gasket Creep: Tightness Retention Under Thermal Cycling

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bolting and Gasket Creep Fundamentals and Objectives

Bolting and gasket assemblies represent critical components in pressurized systems across numerous industries, including oil and gas, chemical processing, power generation, and aerospace. The phenomenon of creep—the time-dependent deformation of materials under constant stress—has been recognized as a significant challenge in maintaining joint integrity since the early 20th century. Historical developments in understanding creep behavior began with empirical observations in steam power applications, evolving through metallurgical advancements in the 1950s-1970s, and culminating in sophisticated computational models in recent decades.

The technical evolution of gasket materials has progressed from simple compressed fiber compositions to advanced multi-layer metallic designs and engineered elastomers with specialized fillers. Concurrently, bolting technology has advanced from basic carbon steel fasteners to high-performance alloys specifically engineered to resist creep deformation under elevated temperatures.

Thermal cycling—the repeated heating and cooling of a bolted joint—introduces complex mechanical behaviors that significantly exacerbate creep effects. This cyclical temperature variation causes differential expansion and contraction between dissimilar materials in the joint assembly, creating fluctuating stress distributions that accelerate relaxation phenomena and potentially compromise sealing integrity.

The fundamental mechanics underlying gasket creep involve viscoelastic and viscoplastic material responses, stress redistribution within the compressed gasket, and interfacial interactions between the gasket and flange surfaces. For bolting components, creep manifests primarily through gradual elongation under tensile loading, resulting in reduced clamping force over time. These mechanisms become particularly pronounced when operating temperatures approach or exceed 40% of the material's melting point (in Kelvin).

The primary technical objective of this investigation is to develop comprehensive predictive models for tightness retention in bolted gasket assemblies subjected to thermal cycling conditions. Specific goals include quantifying the relationship between thermal cycle parameters (temperature range, rate of change, dwell times) and the rate of preload loss, identifying optimal material combinations to minimize differential thermal expansion effects, and establishing design guidelines for maintaining joint integrity across diverse operating environments.

Additionally, this research aims to explore innovative approaches for real-time monitoring of bolt preload during thermal cycling, evaluate emerging gasket materials with enhanced creep resistance properties, and develop standardized testing methodologies that more accurately reflect real-world service conditions than current static testing protocols.

The technical evolution of gasket materials has progressed from simple compressed fiber compositions to advanced multi-layer metallic designs and engineered elastomers with specialized fillers. Concurrently, bolting technology has advanced from basic carbon steel fasteners to high-performance alloys specifically engineered to resist creep deformation under elevated temperatures.

Thermal cycling—the repeated heating and cooling of a bolted joint—introduces complex mechanical behaviors that significantly exacerbate creep effects. This cyclical temperature variation causes differential expansion and contraction between dissimilar materials in the joint assembly, creating fluctuating stress distributions that accelerate relaxation phenomena and potentially compromise sealing integrity.

The fundamental mechanics underlying gasket creep involve viscoelastic and viscoplastic material responses, stress redistribution within the compressed gasket, and interfacial interactions between the gasket and flange surfaces. For bolting components, creep manifests primarily through gradual elongation under tensile loading, resulting in reduced clamping force over time. These mechanisms become particularly pronounced when operating temperatures approach or exceed 40% of the material's melting point (in Kelvin).

The primary technical objective of this investigation is to develop comprehensive predictive models for tightness retention in bolted gasket assemblies subjected to thermal cycling conditions. Specific goals include quantifying the relationship between thermal cycle parameters (temperature range, rate of change, dwell times) and the rate of preload loss, identifying optimal material combinations to minimize differential thermal expansion effects, and establishing design guidelines for maintaining joint integrity across diverse operating environments.

Additionally, this research aims to explore innovative approaches for real-time monitoring of bolt preload during thermal cycling, evaluate emerging gasket materials with enhanced creep resistance properties, and develop standardized testing methodologies that more accurately reflect real-world service conditions than current static testing protocols.

Market Demand for Reliable Sealing Solutions

The global market for reliable sealing solutions has experienced significant growth over the past decade, driven primarily by stringent regulatory requirements across industries and increasing focus on operational safety and efficiency. Industries such as oil and gas, chemical processing, power generation, and aerospace have particularly stringent requirements for sealing integrity under varying thermal conditions.

Current market analysis indicates that the industrial gasket market is valued at approximately $9.5 billion globally, with a compound annual growth rate of 5.2% projected through 2028. Within this market, solutions specifically addressing thermal cycling challenges represent a rapidly growing segment, as traditional sealing technologies often fail to maintain tightness under fluctuating temperature conditions.

End-users across industries are increasingly demanding sealing solutions that can withstand thermal cycling while maintaining joint integrity. This demand is particularly pronounced in the petrochemical sector, where process temperature fluctuations can range from cryogenic to over 1000°C, creating significant challenges for conventional gasket materials and bolting systems.

Market research reveals that maintenance and downtime costs associated with leaking flanged joints exceed $2 billion annually across global industries. Approximately 60% of these failures are directly attributed to gasket creep and bolt relaxation during thermal cycling events. This represents a substantial opportunity for innovative solutions that can effectively address these technical challenges.

Regional analysis shows varying market demands, with North America and Europe focusing primarily on high-performance solutions that meet increasingly stringent environmental regulations. Meanwhile, the Asia-Pacific region demonstrates the fastest growth rate at 6.8% annually, driven by rapid industrialization and infrastructure development in countries like China and India.

Customer surveys indicate that plant operators are willing to pay premium prices for sealing solutions that demonstrably reduce maintenance frequency and extend service life under thermal cycling conditions. The return on investment for such solutions is typically realized within 6-18 months through reduced downtime, decreased product loss, and lower maintenance costs.

Market segmentation shows that metal-reinforced graphite gaskets currently dominate the high-temperature cycling applications with approximately 40% market share, followed by PTFE-based solutions at 25% and advanced ceramic composites at 15%. However, there remains significant unmet demand for solutions that can maintain tightness across broader temperature ranges while offering improved compression set resistance.

Current market analysis indicates that the industrial gasket market is valued at approximately $9.5 billion globally, with a compound annual growth rate of 5.2% projected through 2028. Within this market, solutions specifically addressing thermal cycling challenges represent a rapidly growing segment, as traditional sealing technologies often fail to maintain tightness under fluctuating temperature conditions.

End-users across industries are increasingly demanding sealing solutions that can withstand thermal cycling while maintaining joint integrity. This demand is particularly pronounced in the petrochemical sector, where process temperature fluctuations can range from cryogenic to over 1000°C, creating significant challenges for conventional gasket materials and bolting systems.

Market research reveals that maintenance and downtime costs associated with leaking flanged joints exceed $2 billion annually across global industries. Approximately 60% of these failures are directly attributed to gasket creep and bolt relaxation during thermal cycling events. This represents a substantial opportunity for innovative solutions that can effectively address these technical challenges.

Regional analysis shows varying market demands, with North America and Europe focusing primarily on high-performance solutions that meet increasingly stringent environmental regulations. Meanwhile, the Asia-Pacific region demonstrates the fastest growth rate at 6.8% annually, driven by rapid industrialization and infrastructure development in countries like China and India.

Customer surveys indicate that plant operators are willing to pay premium prices for sealing solutions that demonstrably reduce maintenance frequency and extend service life under thermal cycling conditions. The return on investment for such solutions is typically realized within 6-18 months through reduced downtime, decreased product loss, and lower maintenance costs.

Market segmentation shows that metal-reinforced graphite gaskets currently dominate the high-temperature cycling applications with approximately 40% market share, followed by PTFE-based solutions at 25% and advanced ceramic composites at 15%. However, there remains significant unmet demand for solutions that can maintain tightness across broader temperature ranges while offering improved compression set resistance.

Technical Challenges in Tightness Retention

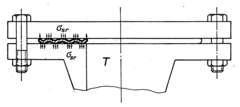

Maintaining tightness retention in bolted flange connections presents significant technical challenges, particularly under thermal cycling conditions. The primary issue stems from the differential thermal expansion rates between gaskets, bolts, and flanges. When subjected to temperature fluctuations, these components expand and contract at different rates, creating dynamic stress distributions that compromise the initial bolt preload and gasket compression.

Gasket creep, a time-dependent deformation under constant stress, represents a critical challenge. Most gasket materials exhibit viscoelastic behavior, resulting in stress relaxation over time. This phenomenon accelerates during thermal cycling as elevated temperatures increase molecular mobility within the gasket material, enhancing creep rates. The subsequent reduction in gasket thickness diminishes contact stress at the flange-gasket interface, potentially creating leakage paths.

Bolt relaxation compounds these challenges. During thermal cycling, bolts experience stress redistribution due to thermal expansion and contraction. This cyclic loading can lead to gradual loosening, further reducing the clamping force on the gasket. Additionally, high-temperature exposure may alter the mechanical properties of bolt materials, affecting their elastic response and load-bearing capacity over time.

The interface between the gasket and flange surfaces presents another technical hurdle. Surface irregularities, such as scratches, waviness, or corrosion, create non-uniform contact pressure distributions. These imperfections become more problematic during thermal cycling as differential expansion exacerbates the uneven stress distribution, potentially creating localized areas of insufficient compression.

Chemical compatibility issues emerge when process fluids interact with gasket materials at elevated temperatures. These interactions can accelerate degradation, causing dimensional changes, hardening, or embrittlement that compromise the gasket's ability to maintain an effective seal. The rate of these chemical reactions typically increases with temperature, making thermal cycling particularly detrimental.

Mechanical fatigue represents another significant challenge. Repeated thermal cycling subjects gaskets to cyclic compression and relaxation, potentially leading to material fatigue. This cyclic loading can initiate and propagate microcracks within the gasket structure, creating potential leakage paths and accelerating overall deterioration of sealing performance.

The combined effects of these challenges create a complex, interdependent system where failure mechanisms can reinforce each other. For instance, initial bolt relaxation reduces gasket compression, which accelerates creep, further reducing bolt load, potentially initiating a cascade of deteriorating sealing performance. This complexity makes predicting long-term tightness retention particularly challenging, especially in applications with variable operating conditions.

Gasket creep, a time-dependent deformation under constant stress, represents a critical challenge. Most gasket materials exhibit viscoelastic behavior, resulting in stress relaxation over time. This phenomenon accelerates during thermal cycling as elevated temperatures increase molecular mobility within the gasket material, enhancing creep rates. The subsequent reduction in gasket thickness diminishes contact stress at the flange-gasket interface, potentially creating leakage paths.

Bolt relaxation compounds these challenges. During thermal cycling, bolts experience stress redistribution due to thermal expansion and contraction. This cyclic loading can lead to gradual loosening, further reducing the clamping force on the gasket. Additionally, high-temperature exposure may alter the mechanical properties of bolt materials, affecting their elastic response and load-bearing capacity over time.

The interface between the gasket and flange surfaces presents another technical hurdle. Surface irregularities, such as scratches, waviness, or corrosion, create non-uniform contact pressure distributions. These imperfections become more problematic during thermal cycling as differential expansion exacerbates the uneven stress distribution, potentially creating localized areas of insufficient compression.

Chemical compatibility issues emerge when process fluids interact with gasket materials at elevated temperatures. These interactions can accelerate degradation, causing dimensional changes, hardening, or embrittlement that compromise the gasket's ability to maintain an effective seal. The rate of these chemical reactions typically increases with temperature, making thermal cycling particularly detrimental.

Mechanical fatigue represents another significant challenge. Repeated thermal cycling subjects gaskets to cyclic compression and relaxation, potentially leading to material fatigue. This cyclic loading can initiate and propagate microcracks within the gasket structure, creating potential leakage paths and accelerating overall deterioration of sealing performance.

The combined effects of these challenges create a complex, interdependent system where failure mechanisms can reinforce each other. For instance, initial bolt relaxation reduces gasket compression, which accelerates creep, further reducing bolt load, potentially initiating a cascade of deteriorating sealing performance. This complexity makes predicting long-term tightness retention particularly challenging, especially in applications with variable operating conditions.

Current Methodologies for Thermal Cycling Resistance

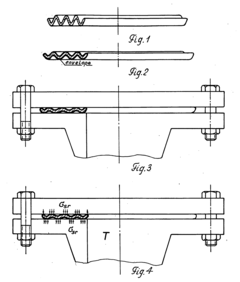

01 Gasket design for improved tightness retention

Specialized gasket designs can significantly improve tightness retention in bolting systems. These designs include features such as multiple sealing elements, composite materials, and optimized cross-sections that maintain sealing pressure even under thermal cycling or vibration. Some gaskets incorporate metal inserts or reinforcements to prevent relaxation and creep over time, while others use elastomeric or graphite facings to accommodate surface irregularities while maintaining seal integrity.- Gasket design for improved tightness retention: Specialized gasket designs can significantly enhance tightness retention in bolting systems. These designs incorporate features such as multi-layered structures, resilient materials, and optimized compression characteristics that maintain sealing force over time despite thermal cycling and mechanical stress. Some designs include self-energizing elements that respond to pressure changes, while others utilize composite materials that combine elasticity with resistance to creep and relaxation.

- Bolt tensioning and load distribution techniques: Advanced bolt tensioning techniques ensure optimal and uniform load distribution across gasket surfaces, critical for maintaining tightness retention. These methods include controlled torque application, tension monitoring systems, and sequential tightening procedures that prevent uneven compression. Some systems incorporate load-indicating devices that provide visual confirmation of proper bolt tension, while others employ hydraulic tensioners for precise and consistent bolt loading that minimizes relaxation over time.

- Anti-relaxation fastener technologies: Specialized fastener technologies designed to resist relaxation help maintain joint integrity in bolting and gasket systems. These include fasteners with modified thread profiles, locking mechanisms, and materials engineered to minimize creep under sustained loads. Some designs incorporate elastic elements that compensate for minor relaxation, while others feature mechanical locking systems that prevent rotation once the desired tension is achieved, ensuring long-term tightness retention even under vibration and thermal cycling.

- Environmental and thermal compensation systems: Systems designed to compensate for environmental factors and thermal expansion/contraction cycles are essential for maintaining gasket tightness. These include thermally responsive elements that adjust tension as temperatures change, pressure-compensating designs that respond to system pressure fluctuations, and materials engineered to maintain consistent properties across wide temperature ranges. Some systems incorporate flexible elements that accommodate differential thermal expansion between components while maintaining sealing force.

- Monitoring and maintenance technologies for joint integrity: Advanced monitoring and maintenance technologies help ensure continued tightness retention in bolting and gasket systems. These include ultrasonic bolt tension monitors, thermal imaging systems for detecting leakage, and smart sensors that provide real-time data on joint conditions. Some systems incorporate predictive maintenance algorithms that analyze performance trends to anticipate potential failures, while others feature accessible inspection points that allow for periodic verification of gasket compression and bolt tension without system disassembly.

02 Bolt tensioning and load distribution techniques

Proper bolt tensioning and load distribution are critical for maintaining tightness in gasketed joints. Advanced techniques include sequential tightening patterns, controlled torque application, and tension monitoring systems that ensure uniform compression of the gasket. Some systems employ hydraulic tensioners or ultrasonic measurement tools to achieve precise preload values. Proper load distribution across multiple fasteners prevents localized stress concentrations that could lead to gasket failure or leakage over time.Expand Specific Solutions03 Self-energizing and pressure-activated sealing systems

Self-energizing and pressure-activated sealing systems utilize the internal pressure of the contained fluid to enhance sealing performance. These systems feature specially designed gaskets or seals that deform under pressure to increase contact force against sealing surfaces. The design allows for initial sealing at lower bolt loads while maintaining tightness as system pressure fluctuates. This approach is particularly effective in high-pressure applications where traditional gaskets might fail due to relaxation or creep.Expand Specific Solutions04 Anti-vibration and anti-loosening fastener technologies

Anti-vibration and anti-loosening technologies prevent bolt relaxation in dynamic environments. These include specialized thread designs, locking washers, chemical thread lockers, and mechanical locking mechanisms that maintain bolt tension despite vibration or thermal cycling. Some systems incorporate spring elements that compensate for minor relaxation, while others use double-nut arrangements or prevailing torque features. These technologies are essential for maintaining gasket compression and preventing leakage in applications subject to movement or vibration.Expand Specific Solutions05 Monitoring and compensation systems for joint integrity

Advanced monitoring and compensation systems continuously assess and maintain joint integrity. These include embedded sensors that measure bolt tension or gasket compression in real-time, allowing for early detection of potential leakage. Some systems incorporate automatic tensioning mechanisms that adjust bolt load to compensate for relaxation or thermal effects. Digital monitoring solutions can track joint performance over time, enabling predictive maintenance and preventing catastrophic failures. These technologies are particularly valuable in critical applications where joint failure could have severe consequences.Expand Specific Solutions

Key Industry Players and Manufacturers

The bolting and gasket creep technology market is currently in a growth phase, with increasing demand driven by industrial applications requiring reliable sealing solutions under thermal cycling conditions. The global gasket market is estimated to reach $70-80 billion by 2025, with specialized thermal cycling applications representing a significant segment. Technologically, the field shows varying maturity levels across different solution types. Industry leaders like W.L. Gore & Associates and Ishikawa Gasket have developed advanced materials with superior creep resistance, while companies such as NICHIAS, Tenneco, and Uchiyama Manufacturing are focusing on specialized automotive applications. Traditional players including Federal-Mogul and Illinois Tool Works continue to enhance conventional gasket technologies, while emerging competitors like Eagle Industry and Oiles Corp are introducing innovative composite materials designed specifically for extreme thermal cycling environments.

Ishikawa Gasket KK

Technical Solution: Ishikawa Gasket has developed the Metal Edge Molding (MEM) gasket technology specifically addressing bolt load retention during thermal cycling. Their approach integrates a stainless steel core with proprietary elastomer compounds featuring variable stiffness zones. The metal edge provides mechanical stops that prevent over-compression while maintaining optimal contact pressure during temperature fluctuations. Their patented "Stress Optimization Layer" redistributes bolt load dynamically as temperatures change, compensating for thermal expansion differences between fasteners and flanged components. Ishikawa's gaskets incorporate micro-embossments on the sealing surface that create localized high-pressure zones, maintaining sealing integrity even as bolt tension decreases over time. Their latest generation products feature nano-particle reinforced elastomers that demonstrate up to 30% improved creep resistance compared to conventional materials.

Strengths: Excellent performance in automotive applications with severe thermal cycling; proprietary elastomer formulations with superior aging resistance; innovative metal-elastomer interface design that prevents extrusion. Weaknesses: More complex manufacturing process increases production costs; requires specialized installation procedures; limited chemical compatibility range compared to pure metal gaskets.

Eagle Industry Co. Ltd.

Technical Solution: Eagle Industry has developed the "Thermal-Adaptive Sealing System" (TASS) specifically addressing bolt load retention during thermal cycling. Their technology utilizes a combination of specially processed metal substrates with proprietary surface treatments that create micro-scale energy absorption zones. These zones act as mechanical buffers, compensating for dimensional changes during thermal expansion and contraction. Eagle's gaskets incorporate gradient-density materials that provide different compression characteristics across the gasket face, optimizing both initial sealing and long-term retention. Their patented "Stress Equilibrium Design" distributes bolt load evenly across the entire sealing interface, preventing localized stress concentrations that accelerate creep. Eagle Industry has also pioneered advanced finite element analysis techniques that allow precise prediction of gasket behavior under specific thermal cycling conditions, enabling customized designs for critical applications.

Strengths: Exceptional performance in high-pressure hydraulic and pneumatic systems; excellent vibration resistance; precise engineering tailored to specific application requirements; comprehensive testing capabilities. Weaknesses: Higher cost due to specialized manufacturing processes; longer lead times for custom designs; requires careful handling during installation to prevent damage to precision surfaces.

Critical Patents in Creep-Resistant Materials

High temperature negative creep gasket and manufacturing same

PatentInactiveUS20090134587A1

Innovation

- A gasket with a corrugated core made from high-temperature Shape Memory Alloys (SMAs) that exhibits a 'negative creep' effect, where the core is deformed and shape-memorized to recover its initial shape at high operating temperatures, generating reactive stresses that counteract creep and provide a continuous, leak-tight seal.

Molybdenum disilicide matrix composites reinforced with refractory metal fibers

PatentInactiveUS5281565A

Innovation

- Incorporating particulate materials such as silicon carbide, silicon nitride, or boron nitride into the molybdenum disilicide matrix to modify its thermal expansion coefficient, combined with continuous refractory metal fibers like tungsten or molybdenum, to reduce thermal stress and enhance mechanical properties.

Material Science Advancements for High-Temperature Applications

Recent advancements in material science have significantly contributed to solving challenges related to bolting and gasket creep under thermal cycling conditions. High-temperature applications in industries such as aerospace, power generation, and petrochemical processing demand materials that can maintain structural integrity and sealing capabilities despite extreme temperature fluctuations.

Superalloys based on nickel, cobalt, and iron have undergone substantial development, with enhanced grain boundary strengthening mechanisms that resist deformation at elevated temperatures. These materials now incorporate precise distributions of gamma prime (γ') and gamma double prime (γ'') precipitates, which effectively block dislocation movement even at temperatures exceeding 800°C, dramatically reducing creep rates in bolting applications.

Ceramic matrix composites (CMCs) represent another breakthrough, combining ceramic fibers within ceramic matrices to create materials with exceptional thermal stability and mechanical strength. Silicon carbide (SiC) and aluminum oxide (Al₂O₃) based CMCs have demonstrated remarkable resistance to thermal cycling, maintaining dimensional stability where traditional metal alloys would experience significant creep deformation.

For gasket applications, advanced graphite composites reinforced with nano-scale additives have emerged as leading solutions. These materials incorporate graphene platelets and carbon nanotubes that create a complex network structure, enhancing both compressive strength and recovery properties. The resulting gaskets maintain sealing force even after hundreds of thermal cycles between ambient and 650°C temperatures.

Surface engineering technologies have also evolved to address high-temperature interface challenges. Thermal barrier coatings (TBCs) utilizing yttria-stabilized zirconia (YSZ) with engineered porosity profiles now protect underlying bolt materials while accommodating thermal expansion differentials. These coatings effectively reduce the thermal gradient experienced by the fastener, minimizing thermal fatigue and associated creep mechanisms.

Computational materials science has accelerated development through predictive modeling of creep behavior under complex thermal cycling conditions. Machine learning algorithms now accurately forecast material performance by analyzing microstructural evolution during thermal cycling, enabling designers to optimize material selection before physical testing begins.

Hybrid material systems combining metallic and ceramic components have shown particular promise for extreme environments. These systems strategically place different materials to leverage their respective strengths while mitigating weaknesses, resulting in bolting systems that maintain clamping force through hundreds of thermal cycles between cryogenic and elevated temperatures.

Superalloys based on nickel, cobalt, and iron have undergone substantial development, with enhanced grain boundary strengthening mechanisms that resist deformation at elevated temperatures. These materials now incorporate precise distributions of gamma prime (γ') and gamma double prime (γ'') precipitates, which effectively block dislocation movement even at temperatures exceeding 800°C, dramatically reducing creep rates in bolting applications.

Ceramic matrix composites (CMCs) represent another breakthrough, combining ceramic fibers within ceramic matrices to create materials with exceptional thermal stability and mechanical strength. Silicon carbide (SiC) and aluminum oxide (Al₂O₃) based CMCs have demonstrated remarkable resistance to thermal cycling, maintaining dimensional stability where traditional metal alloys would experience significant creep deformation.

For gasket applications, advanced graphite composites reinforced with nano-scale additives have emerged as leading solutions. These materials incorporate graphene platelets and carbon nanotubes that create a complex network structure, enhancing both compressive strength and recovery properties. The resulting gaskets maintain sealing force even after hundreds of thermal cycles between ambient and 650°C temperatures.

Surface engineering technologies have also evolved to address high-temperature interface challenges. Thermal barrier coatings (TBCs) utilizing yttria-stabilized zirconia (YSZ) with engineered porosity profiles now protect underlying bolt materials while accommodating thermal expansion differentials. These coatings effectively reduce the thermal gradient experienced by the fastener, minimizing thermal fatigue and associated creep mechanisms.

Computational materials science has accelerated development through predictive modeling of creep behavior under complex thermal cycling conditions. Machine learning algorithms now accurately forecast material performance by analyzing microstructural evolution during thermal cycling, enabling designers to optimize material selection before physical testing begins.

Hybrid material systems combining metallic and ceramic components have shown particular promise for extreme environments. These systems strategically place different materials to leverage their respective strengths while mitigating weaknesses, resulting in bolting systems that maintain clamping force through hundreds of thermal cycles between cryogenic and elevated temperatures.

Safety Standards and Compliance Requirements

Compliance with safety standards is paramount in bolting and gasket applications, particularly those subjected to thermal cycling conditions. The American Society of Mechanical Engineers (ASME) has established comprehensive guidelines through ASME Section VIII and ASME B16.20, which specifically address pressure vessel design and metallic gasket requirements for pipe flanges. These standards outline critical parameters for material selection, installation procedures, and maintenance protocols to ensure joint integrity under varying temperature conditions.

The European Pressure Equipment Directive (PED 2014/68/EU) provides another regulatory framework that manufacturers must adhere to when designing bolted joints for pressure-containing equipment. This directive emphasizes risk assessment methodologies and requires thorough documentation of material properties, particularly those related to creep resistance and thermal stability.

Industry-specific standards such as API 6A and API 6FB for oil and gas applications introduce additional requirements for high-temperature service and fire testing. These standards mandate rigorous qualification testing that simulates thermal cycling conditions to verify long-term sealing performance. The testing protocols typically involve multiple heating and cooling cycles while monitoring leakage rates to ensure they remain within acceptable limits.

Environmental regulations also influence compliance requirements, with the EPA's Method 21 and LDAR (Leak Detection and Repair) programs establishing permissible fugitive emission levels. These regulations have driven innovation in gasket materials and bolting techniques designed to maintain tightness throughout thermal fluctuations, as environmental non-compliance can result in significant penalties.

For nuclear applications, the standards are even more stringent, with 10 CFR Part 50 and ASME Section III providing detailed requirements for components subjected to thermal transients. These standards mandate extensive qualification testing, material traceability, and comprehensive documentation of all bolted connections.

International Organization for Standardization (ISO) has developed ISO 13709/API 610 for centrifugal pumps and ISO 15848 for industrial valves, both addressing fugitive emissions and tightness retention under varying operating conditions. These standards have been widely adopted across industries and serve as benchmarks for evaluating bolting and gasket performance.

Compliance verification typically involves a combination of design validation through finite element analysis (FEA), prototype testing under simulated service conditions, and field monitoring during operation. Third-party certification bodies such as TÜV, Lloyd's Register, and DNV GL often provide independent verification of compliance with applicable standards, adding another layer of quality assurance for critical applications.

The European Pressure Equipment Directive (PED 2014/68/EU) provides another regulatory framework that manufacturers must adhere to when designing bolted joints for pressure-containing equipment. This directive emphasizes risk assessment methodologies and requires thorough documentation of material properties, particularly those related to creep resistance and thermal stability.

Industry-specific standards such as API 6A and API 6FB for oil and gas applications introduce additional requirements for high-temperature service and fire testing. These standards mandate rigorous qualification testing that simulates thermal cycling conditions to verify long-term sealing performance. The testing protocols typically involve multiple heating and cooling cycles while monitoring leakage rates to ensure they remain within acceptable limits.

Environmental regulations also influence compliance requirements, with the EPA's Method 21 and LDAR (Leak Detection and Repair) programs establishing permissible fugitive emission levels. These regulations have driven innovation in gasket materials and bolting techniques designed to maintain tightness throughout thermal fluctuations, as environmental non-compliance can result in significant penalties.

For nuclear applications, the standards are even more stringent, with 10 CFR Part 50 and ASME Section III providing detailed requirements for components subjected to thermal transients. These standards mandate extensive qualification testing, material traceability, and comprehensive documentation of all bolted connections.

International Organization for Standardization (ISO) has developed ISO 13709/API 610 for centrifugal pumps and ISO 15848 for industrial valves, both addressing fugitive emissions and tightness retention under varying operating conditions. These standards have been widely adopted across industries and serve as benchmarks for evaluating bolting and gasket performance.

Compliance verification typically involves a combination of design validation through finite element analysis (FEA), prototype testing under simulated service conditions, and field monitoring during operation. Third-party certification bodies such as TÜV, Lloyd's Register, and DNV GL often provide independent verification of compliance with applicable standards, adding another layer of quality assurance for critical applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!