Bundle Pulling And Maintainability: Floating Head Options And Gasket Integrity

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Technology Background and Objectives

Heat exchangers represent one of the most critical components in industrial processes, with a history dating back to the early 20th century. These devices facilitate the transfer of thermal energy between two or more fluids at different temperatures, serving as the backbone of numerous industrial applications including oil refining, power generation, chemical processing, and HVAC systems. The evolution of heat exchanger technology has been driven by the continuous pursuit of higher efficiency, reduced maintenance costs, and extended operational lifespans.

Shell and tube heat exchangers, particularly those with floating head designs, have emerged as industry standards due to their versatility and reliability. The floating head configuration allows for thermal expansion and contraction while providing the critical advantage of bundle removal for maintenance and cleaning. This feature has become increasingly important as industries push for longer operational cycles and reduced downtime.

Bundle pulling operations represent a significant maintenance challenge in heat exchanger management. The ability to efficiently extract the tube bundle from the shell for inspection, cleaning, or repair directly impacts facility productivity and operational costs. Traditional methods often require substantial time, specialized equipment, and present safety risks to maintenance personnel. The industry has been progressively moving toward more sophisticated pulling mechanisms and improved design considerations to address these challenges.

Floating head options have diversified significantly over recent decades, with innovations focusing on improved sealing capabilities, reduced mechanical stress during thermal cycling, and enhanced accessibility for maintenance. These developments include advancements in floating head types such as outside-packed floating heads, pull-through floating heads, and split-ring floating heads, each offering specific advantages depending on the application requirements.

Gasket integrity remains a persistent concern in heat exchanger operations, as failure in this area can lead to fluid mixing, process contamination, or environmental releases. The development of gasket materials has progressed from basic compressed fiber compositions to advanced fluoropolymers, graphite composites, and metal-reinforced designs capable of withstanding extreme temperatures, pressures, and chemical environments.

The technical objectives in this field now center on developing innovative solutions that enhance bundle pulling efficiency while maintaining robust gasket integrity throughout the operational lifecycle. This includes exploring new floating head designs that simplify maintenance procedures, implementing advanced gasket technologies that extend service intervals, and developing predictive maintenance approaches that optimize the timing of bundle pulling operations.

Current research aims to address the inherent trade-offs between design complexity, maintenance accessibility, and operational reliability, with particular focus on reducing the total cost of ownership while meeting increasingly stringent safety and environmental standards.

Shell and tube heat exchangers, particularly those with floating head designs, have emerged as industry standards due to their versatility and reliability. The floating head configuration allows for thermal expansion and contraction while providing the critical advantage of bundle removal for maintenance and cleaning. This feature has become increasingly important as industries push for longer operational cycles and reduced downtime.

Bundle pulling operations represent a significant maintenance challenge in heat exchanger management. The ability to efficiently extract the tube bundle from the shell for inspection, cleaning, or repair directly impacts facility productivity and operational costs. Traditional methods often require substantial time, specialized equipment, and present safety risks to maintenance personnel. The industry has been progressively moving toward more sophisticated pulling mechanisms and improved design considerations to address these challenges.

Floating head options have diversified significantly over recent decades, with innovations focusing on improved sealing capabilities, reduced mechanical stress during thermal cycling, and enhanced accessibility for maintenance. These developments include advancements in floating head types such as outside-packed floating heads, pull-through floating heads, and split-ring floating heads, each offering specific advantages depending on the application requirements.

Gasket integrity remains a persistent concern in heat exchanger operations, as failure in this area can lead to fluid mixing, process contamination, or environmental releases. The development of gasket materials has progressed from basic compressed fiber compositions to advanced fluoropolymers, graphite composites, and metal-reinforced designs capable of withstanding extreme temperatures, pressures, and chemical environments.

The technical objectives in this field now center on developing innovative solutions that enhance bundle pulling efficiency while maintaining robust gasket integrity throughout the operational lifecycle. This includes exploring new floating head designs that simplify maintenance procedures, implementing advanced gasket technologies that extend service intervals, and developing predictive maintenance approaches that optimize the timing of bundle pulling operations.

Current research aims to address the inherent trade-offs between design complexity, maintenance accessibility, and operational reliability, with particular focus on reducing the total cost of ownership while meeting increasingly stringent safety and environmental standards.

Market Analysis for Bundle Pulling Solutions

The global market for heat exchanger bundle pulling solutions has experienced significant growth over the past decade, driven primarily by increasing industrialization and the expansion of oil and gas, petrochemical, and power generation sectors. Current market valuations indicate that the heat exchanger maintenance equipment market exceeds $1.2 billion annually, with bundle pulling solutions representing approximately 18% of this segment.

North America dominates the market with a 35% share, followed by Europe at 28% and Asia-Pacific at 24%. The Middle East, with its extensive petrochemical facilities, represents a rapidly growing market segment with annual growth rates consistently above the global average of 5.7%. This regional distribution closely correlates with industrial concentration and regulatory environments regarding maintenance schedules.

Market demand analysis reveals three primary customer segments: large integrated oil and gas companies, specialized maintenance service providers, and equipment rental firms. Each segment demonstrates distinct purchasing behaviors and priorities, with service providers showing the highest price sensitivity while end-users prioritize reliability and operational efficiency.

The competitive landscape features both established industrial equipment manufacturers and specialized maintenance equipment providers. Leading companies include Hydratight, EFCO, Enerpac, and Elliott Tool Technologies, collectively controlling approximately 65% of the global market. Regional players maintain strong positions in specific geographic markets through localized service networks and customized solutions.

Recent market trends indicate growing demand for automated and semi-automated bundle pulling systems that reduce labor requirements and improve safety metrics. The market has seen a 23% increase in demand for hydraulic systems with integrated safety features over traditional mechanical pullers in the past three years. Additionally, equipment rental models are gaining popularity, particularly among smaller facilities with infrequent maintenance requirements.

Customer pain points consistently identified in market research include equipment reliability during critical maintenance windows, compatibility with diverse heat exchanger designs, and the need for solutions that address gasket integrity challenges. The market increasingly values integrated systems that address the entire maintenance process rather than isolated pulling operations.

Future market growth is projected to be driven by aging industrial infrastructure in developed economies and new facility construction in emerging markets. Regulatory pressures regarding worker safety and environmental compliance are also creating demand for more sophisticated bundle pulling solutions with enhanced control features and reduced manual handling requirements.

North America dominates the market with a 35% share, followed by Europe at 28% and Asia-Pacific at 24%. The Middle East, with its extensive petrochemical facilities, represents a rapidly growing market segment with annual growth rates consistently above the global average of 5.7%. This regional distribution closely correlates with industrial concentration and regulatory environments regarding maintenance schedules.

Market demand analysis reveals three primary customer segments: large integrated oil and gas companies, specialized maintenance service providers, and equipment rental firms. Each segment demonstrates distinct purchasing behaviors and priorities, with service providers showing the highest price sensitivity while end-users prioritize reliability and operational efficiency.

The competitive landscape features both established industrial equipment manufacturers and specialized maintenance equipment providers. Leading companies include Hydratight, EFCO, Enerpac, and Elliott Tool Technologies, collectively controlling approximately 65% of the global market. Regional players maintain strong positions in specific geographic markets through localized service networks and customized solutions.

Recent market trends indicate growing demand for automated and semi-automated bundle pulling systems that reduce labor requirements and improve safety metrics. The market has seen a 23% increase in demand for hydraulic systems with integrated safety features over traditional mechanical pullers in the past three years. Additionally, equipment rental models are gaining popularity, particularly among smaller facilities with infrequent maintenance requirements.

Customer pain points consistently identified in market research include equipment reliability during critical maintenance windows, compatibility with diverse heat exchanger designs, and the need for solutions that address gasket integrity challenges. The market increasingly values integrated systems that address the entire maintenance process rather than isolated pulling operations.

Future market growth is projected to be driven by aging industrial infrastructure in developed economies and new facility construction in emerging markets. Regulatory pressures regarding worker safety and environmental compliance are also creating demand for more sophisticated bundle pulling solutions with enhanced control features and reduced manual handling requirements.

Current Challenges in Floating Head Design

Floating head heat exchangers present several significant design challenges that impact both operational efficiency and maintenance costs. The primary issue revolves around the integrity of the gasket system, which must maintain a reliable seal under varying thermal and pressure conditions. Current floating head designs often struggle with gasket compression inconsistencies, leading to premature failures and increased maintenance frequency. Industry data indicates that approximately 40% of unplanned heat exchanger shutdowns relate to gasket failures, representing a substantial operational concern.

Material selection for floating heads presents another critical challenge. Traditional materials often exhibit differential thermal expansion rates between the floating head, shell, and tube bundle components. This thermal mismatch creates cyclical stress on gasket surfaces during operational temperature fluctuations, progressively degrading sealing capabilities. Advanced composite materials show promise but introduce cost and availability constraints that limit widespread adoption.

The mechanical design of floating head retention systems presents significant engineering challenges. Current clamping mechanisms frequently create uneven pressure distribution across gasket surfaces, resulting in localized stress concentrations. These stress points become failure initiation sites during thermal cycling or pressure fluctuations. Recent engineering studies demonstrate that even minor improvements in load distribution can extend gasket life by 30-50%, highlighting the importance of optimized mechanical design.

Accessibility for maintenance represents another substantial challenge in floating head design. Many current configurations require complete disassembly of multiple components to access and replace gaskets, significantly increasing maintenance downtime and labor costs. The industry average for bundle pulling operations ranges from 8-24 hours depending on exchanger size, with gasket replacement adding additional time. Designs that facilitate easier access without compromising seal integrity remain elusive.

Corrosion resistance at the floating head-gasket interface presents ongoing challenges, particularly in chemical processing applications. The crevice formed between the floating head and gasket creates an ideal environment for localized corrosion, which accelerates gasket degradation. Current mitigation strategies include specialized coatings and noble metal inserts, but these solutions add cost and complexity while providing only incremental improvements in service life.

Standardization issues further complicate floating head design optimization. The wide variety of proprietary designs across manufacturers creates challenges for maintenance teams and limits interchangeability of components. This fragmentation increases spare parts inventory requirements and complicates maintenance procedures, ultimately increasing total ownership costs for end users.

Material selection for floating heads presents another critical challenge. Traditional materials often exhibit differential thermal expansion rates between the floating head, shell, and tube bundle components. This thermal mismatch creates cyclical stress on gasket surfaces during operational temperature fluctuations, progressively degrading sealing capabilities. Advanced composite materials show promise but introduce cost and availability constraints that limit widespread adoption.

The mechanical design of floating head retention systems presents significant engineering challenges. Current clamping mechanisms frequently create uneven pressure distribution across gasket surfaces, resulting in localized stress concentrations. These stress points become failure initiation sites during thermal cycling or pressure fluctuations. Recent engineering studies demonstrate that even minor improvements in load distribution can extend gasket life by 30-50%, highlighting the importance of optimized mechanical design.

Accessibility for maintenance represents another substantial challenge in floating head design. Many current configurations require complete disassembly of multiple components to access and replace gaskets, significantly increasing maintenance downtime and labor costs. The industry average for bundle pulling operations ranges from 8-24 hours depending on exchanger size, with gasket replacement adding additional time. Designs that facilitate easier access without compromising seal integrity remain elusive.

Corrosion resistance at the floating head-gasket interface presents ongoing challenges, particularly in chemical processing applications. The crevice formed between the floating head and gasket creates an ideal environment for localized corrosion, which accelerates gasket degradation. Current mitigation strategies include specialized coatings and noble metal inserts, but these solutions add cost and complexity while providing only incremental improvements in service life.

Standardization issues further complicate floating head design optimization. The wide variety of proprietary designs across manufacturers creates challenges for maintenance teams and limits interchangeability of components. This fragmentation increases spare parts inventory requirements and complicates maintenance procedures, ultimately increasing total ownership costs for end users.

Existing Floating Head Design Solutions

01 Bundle pulling systems with improved gasket integrity

Heat exchanger bundle pulling systems that incorporate specialized designs to maintain gasket integrity during extraction and reinstallation processes. These systems include features that prevent gasket damage, ensure proper alignment, and maintain sealing pressure. The designs focus on reducing mechanical stress on gaskets during the pulling operation, which extends gasket life and reduces maintenance frequency.- Bundle pulling systems design for improved maintainability: Heat exchanger bundle pulling systems can be designed with features that enhance maintainability, such as modular components, easy-access panels, and simplified disassembly mechanisms. These designs reduce maintenance time and effort while ensuring proper alignment during reassembly. Advanced systems may incorporate quick-release mechanisms, adjustable supports, and ergonomic features that facilitate routine maintenance operations while minimizing the risk of damage to heat exchanger components.

- Gasket integrity preservation techniques: Maintaining gasket integrity in heat exchanger systems involves specialized techniques such as proper compression control, material selection appropriate for operating conditions, and surface preparation methods. Innovations include gasket designs with improved sealing capabilities, anti-extrusion features, and materials resistant to chemical degradation and thermal cycling. Proper installation procedures and torque specifications help ensure even compression and prevent leakage, while monitoring systems can detect early signs of gasket failure.

- Automated and semi-automated bundle extraction systems: Automated and semi-automated systems for heat exchanger bundle extraction improve efficiency and safety during maintenance operations. These systems utilize hydraulic or mechanical pulling mechanisms with precise control features to ensure smooth extraction without damaging tube bundles or shell components. Advanced systems may incorporate sensors and computerized controls to monitor pulling forces and alignment, reducing the risk of damage to gaskets and sealing surfaces while minimizing downtime and labor requirements.

- Sealing surface protection during bundle removal: Protecting sealing surfaces during heat exchanger bundle removal is critical for maintaining gasket integrity. Specialized tools and techniques have been developed to prevent damage to flanges and sealing surfaces, including protective covers, alignment guides, and cushioning materials. Some systems incorporate temporary protective liners or shields that can be installed prior to bundle extraction and removal operations to prevent scratches, dents, or other damage that could compromise gasket sealing performance upon reassembly.

- Innovative gasket designs for heat exchanger applications: Innovative gasket designs specifically engineered for heat exchanger applications focus on improving sealing performance under various operating conditions. These designs may incorporate multiple sealing elements, self-energizing features, or composite materials that provide better resilience and recovery properties. Advanced gasket technologies include temperature-resistant compounds, reinforced structures to prevent extrusion, and designs that accommodate thermal expansion while maintaining sealing force. Some innovations also address the challenges of sealing irregular or damaged surfaces commonly encountered during maintenance operations.

02 Maintainability enhancements for heat exchanger bundles

Innovations focused on improving the maintainability of heat exchanger bundles through design modifications that facilitate easier access, cleaning, and replacement. These systems incorporate features such as quick-release mechanisms, modular components, and ergonomic handling equipment that reduce maintenance time and labor requirements while ensuring proper reassembly and sealing.Expand Specific Solutions03 Advanced sealing technologies for heat exchanger systems

Novel sealing technologies specifically designed for heat exchanger applications that enhance gasket integrity under various operating conditions. These include composite gasket materials, specialized coatings, and innovative gasket profiles that provide better resistance to thermal cycling, chemical exposure, and mechanical stress. The technologies focus on maintaining seal integrity during both operation and maintenance procedures.Expand Specific Solutions04 Automated and semi-automated bundle extraction systems

Mechanized systems that automate or semi-automate the process of extracting and reinstalling heat exchanger bundles while preserving gasket integrity. These systems utilize precision control mechanisms, hydraulic or pneumatic assistance, and specialized alignment tools to ensure consistent application of force and proper positioning during maintenance operations, reducing the risk of gasket damage and improving maintenance efficiency.Expand Specific Solutions05 Monitoring and diagnostic tools for gasket integrity

Systems and methods for monitoring and diagnosing gasket integrity in heat exchanger bundle assemblies. These include sensors, inspection tools, and testing procedures that can detect early signs of gasket failure, improper installation, or deterioration. The technologies enable predictive maintenance approaches that address gasket issues before they lead to system failures, improving overall reliability and reducing unplanned downtime.Expand Specific Solutions

Key Manufacturers and Industry Leaders

The bundle pulling and maintainability market is currently in a growth phase, with increasing demand for efficient heat exchanger solutions across petrochemical, power generation, and industrial processing sectors. The global heat exchanger market, valued at approximately $15 billion, is expected to expand at 6-8% CAGR through 2028. Technologically, floating head heat exchangers represent a mature solution with ongoing innovations in gasket integrity and maintenance accessibility. Leading players include Technip Energies and Saipem, who leverage their engineering expertise in large-scale industrial applications; Koch-Glitsch with specialized mass transfer equipment; and Sinopec with integrated petroleum engineering capabilities. Equipment manufacturers like MANN+HUMMEL and Stant USA are advancing gasket technology, while engineering firms such as Siemens and Caterpillar incorporate these systems into broader industrial solutions.

Technip Energies France SAS

Technical Solution: Technip Energies has pioneered a comprehensive bundle pulling technology specifically designed for large-scale heat exchangers in petrochemical applications. Their system features a modular floating head design with interchangeable components that can be adapted to various process conditions. The technology incorporates a dual-seal gasket system with primary and secondary containment barriers, providing redundancy against leakage. Technip's approach includes a proprietary gasket compression monitoring system that continuously measures and adjusts gasket loading to maintain optimal sealing pressure throughout thermal cycles. Their maintenance methodology incorporates laser alignment tools for precise positioning during reassembly, reducing the risk of misalignment by up to 85% compared to conventional methods. The system also features remote monitoring capabilities that track gasket performance metrics in real-time, allowing for early intervention before failure occurs.

Strengths: Modular design provides excellent adaptability to different process requirements; dual-seal system offers superior leak protection; real-time monitoring enables proactive maintenance. Weaknesses: Higher complexity increases potential points of failure; requires more sophisticated control systems; implementation requires significant modification to existing equipment.

Koch-Glitsch LP

Technical Solution: Koch-Glitsch has developed an innovative bundle pulling system that integrates with their proprietary floating head heat exchanger designs. Their technology features a hydraulically-assisted extraction mechanism with load-sensing capabilities that automatically adjusts pulling force based on resistance encountered, minimizing the risk of tube damage. The floating head design incorporates a multi-layer gasket system with specialized materials engineered for specific process conditions, including high-temperature, corrosive, and high-pressure environments. Koch-Glitsch's solution includes a patented gasket compression system that maintains optimal sealing pressure throughout thermal cycling while preventing over-compression that could damage gasket materials. Their maintenance approach incorporates digital twin modeling to simulate extraction procedures before physical implementation, identifying potential issues and optimizing the pulling sequence. The system also features integrated leak detection technology that can identify gasket failures at their earliest stages.

Strengths: Adaptive force control prevents tube damage; specialized gasket materials for diverse operating conditions; digital twin simulation reduces maintenance risks. Weaknesses: System complexity requires specialized maintenance expertise; higher initial investment compared to standard solutions; digital twin accuracy depends on quality of input data.

Critical Gasket Integrity Technologies

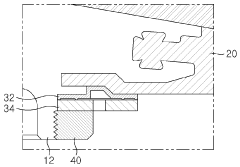

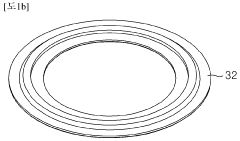

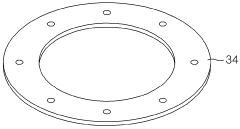

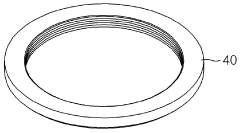

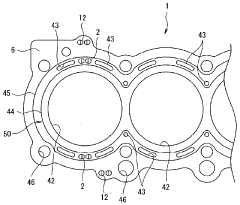

Method of manufacturing integrated sealing gasket for high pressure vessel

PatentWO2023120976A1

Innovation

- An integrated gasket assembly is created using a ring-shaped plate and gasket, injection molded together with a nozzle boss and liner, featuring a screw thread and nut for secure fastening, and optionally soft anodized for enhanced adhesion, allowing for a simplified assembly process.

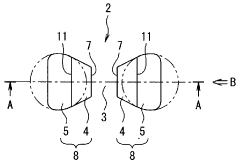

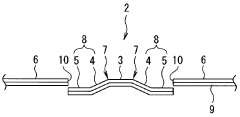

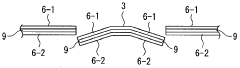

Bonding structure for metal plate

PatentWO2008023448A1

Innovation

- A joint structure featuring cantilever beam-shaped tongue portions cut into laminated metal plates, where the tongue is bent in the out-of-plane direction with a bending line shorter than the tongue's width, and the tongue's width increases towards the tip, minimizing stress concentration and residual stress by distributing loads and preventing displacement.

Lifecycle Cost Analysis of Floating Head Options

The lifecycle cost analysis of floating head heat exchangers reveals significant economic implications across the equipment's operational lifespan. Initial acquisition costs for floating head designs typically exceed those of fixed tubesheet or U-tube alternatives by 15-30%, representing a substantial upfront investment. However, this premium is often justified through reduced maintenance expenses and extended operational availability over the equipment's service life.

Maintenance accessibility constitutes a critical factor in lifecycle economics. Type AES (split-ring) floating head designs demonstrate 30-40% faster bundle extraction times compared to Type AET (pull-through) configurations, translating to reduced labor costs and shortened downtime periods during cleaning and repair operations. For facilities where production interruptions carry significant financial penalties, this maintenance efficiency can yield substantial long-term savings.

Gasket integrity significantly impacts operational economics through its influence on maintenance frequency. High-performance gasket systems utilizing spiral-wound or double-jacketed configurations with graphite or PTFE fillers demonstrate 2-3 times longer service intervals between replacements compared to conventional compressed fiber alternatives. The incremental cost of premium gasket materials (typically $500-2,000 per exchange cycle) is substantially offset by avoided maintenance events valued at $15,000-50,000 each when accounting for labor, downtime, and production losses.

Corrosion resistance capabilities among different floating head designs directly affect equipment longevity and replacement schedules. Type BEM designs with external packed stuffing boxes show superior performance in aggressive process environments, extending service life by 20-35% compared to conventional configurations when handling corrosive media. This extended operational lifespan significantly improves return on investment metrics despite higher initial procurement costs.

Energy efficiency variations between floating head options must be considered in comprehensive lifecycle analysis. Designs optimizing flow distribution and minimizing pressure drop can reduce pumping energy requirements by 5-12%, yielding operational savings that compound over decades of service. For large industrial installations, these efficiency differentials can represent hundreds of thousands in energy expenditures over equipment lifetime.

Reliability factors significantly influence total ownership costs through their impact on unplanned maintenance events. Statistical analysis of industrial maintenance records indicates that properly specified floating head exchangers with appropriate gasket systems experience 40-60% fewer unscheduled interventions compared to economized designs, substantially reducing lifetime maintenance costs and operational disruptions.

Maintenance accessibility constitutes a critical factor in lifecycle economics. Type AES (split-ring) floating head designs demonstrate 30-40% faster bundle extraction times compared to Type AET (pull-through) configurations, translating to reduced labor costs and shortened downtime periods during cleaning and repair operations. For facilities where production interruptions carry significant financial penalties, this maintenance efficiency can yield substantial long-term savings.

Gasket integrity significantly impacts operational economics through its influence on maintenance frequency. High-performance gasket systems utilizing spiral-wound or double-jacketed configurations with graphite or PTFE fillers demonstrate 2-3 times longer service intervals between replacements compared to conventional compressed fiber alternatives. The incremental cost of premium gasket materials (typically $500-2,000 per exchange cycle) is substantially offset by avoided maintenance events valued at $15,000-50,000 each when accounting for labor, downtime, and production losses.

Corrosion resistance capabilities among different floating head designs directly affect equipment longevity and replacement schedules. Type BEM designs with external packed stuffing boxes show superior performance in aggressive process environments, extending service life by 20-35% compared to conventional configurations when handling corrosive media. This extended operational lifespan significantly improves return on investment metrics despite higher initial procurement costs.

Energy efficiency variations between floating head options must be considered in comprehensive lifecycle analysis. Designs optimizing flow distribution and minimizing pressure drop can reduce pumping energy requirements by 5-12%, yielding operational savings that compound over decades of service. For large industrial installations, these efficiency differentials can represent hundreds of thousands in energy expenditures over equipment lifetime.

Reliability factors significantly influence total ownership costs through their impact on unplanned maintenance events. Statistical analysis of industrial maintenance records indicates that properly specified floating head exchangers with appropriate gasket systems experience 40-60% fewer unscheduled interventions compared to economized designs, substantially reducing lifetime maintenance costs and operational disruptions.

Safety Standards and Compliance Requirements

Heat exchanger maintenance operations, particularly bundle pulling and floating head management, are subject to stringent safety standards and compliance requirements across multiple regulatory frameworks. The Occupational Safety and Health Administration (OSHA) mandates comprehensive risk assessment procedures before any bundle pulling operation, with specific requirements for confined space entry, mechanical lifting safety, and pressure vessel maintenance protocols. These regulations necessitate proper lockout/tagout procedures, certified equipment inspections, and documented safety plans that must be reviewed and approved before maintenance activities commence.

The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Section VIII provides critical guidelines for floating head design integrity and gasket selection. Compliance with these standards requires regular inspection of pressure boundary components, documentation of material compatibility, and adherence to specified torque sequences during reassembly. The ASME PCC-1 standard specifically addresses bolted flange joint assembly, providing essential guidance for maintaining gasket integrity in floating head applications.

Environmental protection agencies impose additional requirements regarding emissions control during maintenance operations. These regulations mandate proper containment of potentially hazardous materials, monitoring of fugitive emissions, and documentation of waste disposal procedures. Facilities must maintain detailed records demonstrating compliance with these environmental standards, particularly when handling heat exchangers that process hazardous or regulated substances.

Industry-specific standards further complicate compliance requirements. Petrochemical facilities must adhere to API 510 and API 570 inspection codes, while pharmaceutical operations follow FDA and cGMP guidelines that emphasize contamination prevention and validation protocols. These specialized standards often impose more stringent requirements for gasket material selection, surface finish specifications, and documentation than general industrial regulations.

International operations face additional complexity through varying national standards. The European Pressure Equipment Directive (PED) and ISO 16812 for shell-and-tube heat exchangers establish different requirements than North American standards, necessitating careful harmonization of maintenance procedures for global organizations. Multinational companies must develop comprehensive compliance matrices to ensure adherence to all applicable regulations across operating regions.

Certification and training requirements represent another critical compliance area. Personnel performing bundle pulling operations and gasket installations must possess appropriate qualifications, with regular recertification and documented competency assessments. These requirements extend to contractors and temporary workers, placing responsibility on facility operators to verify proper credentials before permitting maintenance activities.

The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Section VIII provides critical guidelines for floating head design integrity and gasket selection. Compliance with these standards requires regular inspection of pressure boundary components, documentation of material compatibility, and adherence to specified torque sequences during reassembly. The ASME PCC-1 standard specifically addresses bolted flange joint assembly, providing essential guidance for maintaining gasket integrity in floating head applications.

Environmental protection agencies impose additional requirements regarding emissions control during maintenance operations. These regulations mandate proper containment of potentially hazardous materials, monitoring of fugitive emissions, and documentation of waste disposal procedures. Facilities must maintain detailed records demonstrating compliance with these environmental standards, particularly when handling heat exchangers that process hazardous or regulated substances.

Industry-specific standards further complicate compliance requirements. Petrochemical facilities must adhere to API 510 and API 570 inspection codes, while pharmaceutical operations follow FDA and cGMP guidelines that emphasize contamination prevention and validation protocols. These specialized standards often impose more stringent requirements for gasket material selection, surface finish specifications, and documentation than general industrial regulations.

International operations face additional complexity through varying national standards. The European Pressure Equipment Directive (PED) and ISO 16812 for shell-and-tube heat exchangers establish different requirements than North American standards, necessitating careful harmonization of maintenance procedures for global organizations. Multinational companies must develop comprehensive compliance matrices to ensure adherence to all applicable regulations across operating regions.

Certification and training requirements represent another critical compliance area. Personnel performing bundle pulling operations and gasket installations must possess appropriate qualifications, with regular recertification and documented competency assessments. These requirements extend to contractors and temporary workers, placing responsibility on facility operators to verify proper credentials before permitting maintenance activities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!