Catalytic Advancements with Fluoroantimonic Acid

JUN 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluoroantimonic Acid Catalysis: Background and Objectives

Fluoroantimonic acid, a superacid formed by combining hydrogen fluoride and antimony pentafluoride, has emerged as a powerful catalyst in various chemical processes. Its exceptional acidity, surpassing that of conventional acids, has revolutionized catalytic reactions in both academic research and industrial applications. The development of fluoroantimonic acid catalysis can be traced back to the mid-20th century, with significant advancements occurring in recent decades.

The evolution of fluoroantimonic acid catalysis has been driven by the increasing demand for more efficient and selective chemical transformations. Its unique properties, including extreme proton donating ability and strong Lewis acidity, have enabled the activation of traditionally unreactive substrates and the facilitation of challenging reactions. This has opened up new possibilities in organic synthesis, petrochemical processing, and materials science.

One of the key trends in fluoroantimonic acid catalysis is the exploration of its potential in green chemistry applications. Researchers are investigating ways to harness its catalytic power while minimizing environmental impact and improving overall process sustainability. This includes the development of recyclable catalyst systems and the optimization of reaction conditions to reduce waste generation.

Another significant trend is the integration of fluoroantimonic acid catalysis with other advanced technologies, such as flow chemistry and microreactor systems. These combinations aim to enhance reaction control, improve safety, and increase scalability, making fluoroantimonic acid catalysis more amenable to industrial-scale applications.

The primary objectives of current research in fluoroantimonic acid catalysis are multifaceted. First, there is a focus on expanding the scope of reactions that can be effectively catalyzed by fluoroantimonic acid, particularly in the areas of C-C bond formation, isomerization, and polymerization. Second, efforts are being made to develop more stable and easily handled forms of the acid, addressing the challenges associated with its corrosive nature and moisture sensitivity.

Additionally, researchers are working on elucidating the precise mechanistic details of fluoroantimonic acid-catalyzed reactions. This fundamental understanding is crucial for rational catalyst design and the development of more efficient and selective catalytic systems. The goal is to achieve greater control over reaction outcomes and to enable the prediction of reactivity patterns for novel substrates.

Furthermore, there is a growing interest in exploring the potential of fluoroantimonic acid in emerging fields such as nanotechnology and materials science. Its unique properties are being investigated for applications in surface modification, nanoparticle synthesis, and the development of advanced functional materials.

The evolution of fluoroantimonic acid catalysis has been driven by the increasing demand for more efficient and selective chemical transformations. Its unique properties, including extreme proton donating ability and strong Lewis acidity, have enabled the activation of traditionally unreactive substrates and the facilitation of challenging reactions. This has opened up new possibilities in organic synthesis, petrochemical processing, and materials science.

One of the key trends in fluoroantimonic acid catalysis is the exploration of its potential in green chemistry applications. Researchers are investigating ways to harness its catalytic power while minimizing environmental impact and improving overall process sustainability. This includes the development of recyclable catalyst systems and the optimization of reaction conditions to reduce waste generation.

Another significant trend is the integration of fluoroantimonic acid catalysis with other advanced technologies, such as flow chemistry and microreactor systems. These combinations aim to enhance reaction control, improve safety, and increase scalability, making fluoroantimonic acid catalysis more amenable to industrial-scale applications.

The primary objectives of current research in fluoroantimonic acid catalysis are multifaceted. First, there is a focus on expanding the scope of reactions that can be effectively catalyzed by fluoroantimonic acid, particularly in the areas of C-C bond formation, isomerization, and polymerization. Second, efforts are being made to develop more stable and easily handled forms of the acid, addressing the challenges associated with its corrosive nature and moisture sensitivity.

Additionally, researchers are working on elucidating the precise mechanistic details of fluoroantimonic acid-catalyzed reactions. This fundamental understanding is crucial for rational catalyst design and the development of more efficient and selective catalytic systems. The goal is to achieve greater control over reaction outcomes and to enable the prediction of reactivity patterns for novel substrates.

Furthermore, there is a growing interest in exploring the potential of fluoroantimonic acid in emerging fields such as nanotechnology and materials science. Its unique properties are being investigated for applications in surface modification, nanoparticle synthesis, and the development of advanced functional materials.

Industrial Demand for Superacid Catalysts

The demand for superacid catalysts in industrial applications has been steadily growing, driven by the need for more efficient and environmentally friendly chemical processes. Fluoroantimonic acid, as one of the strongest known superacids, has garnered significant attention in various sectors due to its exceptional catalytic properties. The petroleum industry, in particular, has shown a keen interest in superacid catalysts for processes such as isomerization, alkylation, and cracking of hydrocarbons.

In the petrochemical sector, the use of superacid catalysts like fluoroantimonic acid has led to improved yields and selectivity in the production of high-octane gasoline components. This has resulted in a reduction of energy consumption and waste generation, aligning with the industry's push towards sustainability. The ability of these catalysts to operate at lower temperatures and pressures compared to traditional catalysts has also contributed to their increasing adoption.

The fine chemicals and pharmaceutical industries have also recognized the potential of superacid catalysts in synthesizing complex organic compounds. The unique ability of fluoroantimonic acid to catalyze reactions that are challenging or impossible with conventional acids has opened up new pathways for drug discovery and the production of specialty chemicals. This has led to a growing demand for superacid catalysts in these high-value sectors.

In the polymer industry, superacid catalysts have found applications in the production of high-performance materials. The use of fluoroantimonic acid and other superacids has enabled the synthesis of novel polymers with enhanced properties, such as improved thermal stability and chemical resistance. This has created new opportunities in industries ranging from aerospace to electronics, further driving the demand for these catalysts.

The environmental sector has also contributed to the increasing industrial demand for superacid catalysts. Their use in the treatment of industrial waste and the removal of pollutants from exhaust gases has gained traction. The superior catalytic activity of superacids allows for more efficient breakdown of recalcitrant compounds, addressing some of the most challenging environmental issues faced by industries today.

Despite the growing demand, the widespread adoption of superacid catalysts, particularly fluoroantimonic acid, faces challenges related to handling and safety concerns. The extreme corrosiveness and reactivity of these substances necessitate specialized equipment and stringent safety protocols. As a result, there is an ongoing effort to develop more stable and user-friendly superacid catalysts that retain the exceptional catalytic properties while mitigating the associated risks.

In the petrochemical sector, the use of superacid catalysts like fluoroantimonic acid has led to improved yields and selectivity in the production of high-octane gasoline components. This has resulted in a reduction of energy consumption and waste generation, aligning with the industry's push towards sustainability. The ability of these catalysts to operate at lower temperatures and pressures compared to traditional catalysts has also contributed to their increasing adoption.

The fine chemicals and pharmaceutical industries have also recognized the potential of superacid catalysts in synthesizing complex organic compounds. The unique ability of fluoroantimonic acid to catalyze reactions that are challenging or impossible with conventional acids has opened up new pathways for drug discovery and the production of specialty chemicals. This has led to a growing demand for superacid catalysts in these high-value sectors.

In the polymer industry, superacid catalysts have found applications in the production of high-performance materials. The use of fluoroantimonic acid and other superacids has enabled the synthesis of novel polymers with enhanced properties, such as improved thermal stability and chemical resistance. This has created new opportunities in industries ranging from aerospace to electronics, further driving the demand for these catalysts.

The environmental sector has also contributed to the increasing industrial demand for superacid catalysts. Their use in the treatment of industrial waste and the removal of pollutants from exhaust gases has gained traction. The superior catalytic activity of superacids allows for more efficient breakdown of recalcitrant compounds, addressing some of the most challenging environmental issues faced by industries today.

Despite the growing demand, the widespread adoption of superacid catalysts, particularly fluoroantimonic acid, faces challenges related to handling and safety concerns. The extreme corrosiveness and reactivity of these substances necessitate specialized equipment and stringent safety protocols. As a result, there is an ongoing effort to develop more stable and user-friendly superacid catalysts that retain the exceptional catalytic properties while mitigating the associated risks.

Current State and Challenges in Fluoroantimonic Acid Application

Fluoroantimonic acid, recognized as one of the strongest superacids, has garnered significant attention in the field of catalysis. The current state of its application is characterized by both promising advancements and notable challenges. In recent years, researchers have made substantial progress in harnessing the unique properties of this superacid for various catalytic processes.

One of the primary areas of application is in the petrochemical industry, where fluoroantimonic acid has shown remarkable efficiency in catalyzing alkylation reactions. Its ability to protonate even weak bases has led to enhanced reaction rates and improved product yields. However, the widespread industrial adoption of this superacid faces significant hurdles due to its extreme corrosiveness and sensitivity to moisture.

The synthesis and handling of fluoroantimonic acid present considerable challenges. Its preparation typically involves the combination of hydrogen fluoride and antimony pentafluoride, both of which are highly reactive and hazardous substances. Ensuring the purity and stability of the acid during storage and use remains a critical concern for researchers and industry practitioners alike.

Safety considerations pose another major challenge in the application of fluoroantimonic acid. Its extreme acidity necessitates specialized containment materials and rigorous safety protocols. The development of safer handling methods and containment systems is an ongoing area of research, crucial for expanding its practical applications.

In the realm of organic synthesis, fluoroantimonic acid has demonstrated potential in facilitating challenging transformations. Its super-acidic nature enables the activation of typically unreactive substrates, opening new pathways in synthetic chemistry. However, controlling the selectivity of reactions in such a highly acidic environment remains a significant challenge.

Environmental concerns also present a substantial obstacle to the widespread use of fluoroantimonic acid. Its potential environmental impact, particularly in terms of waste disposal and accidental releases, necessitates the development of robust containment and neutralization strategies. This aspect has spurred research into more environmentally benign alternatives that can match its catalytic prowess.

Recent advancements in material science have led to the exploration of novel support materials for immobilizing fluoroantimonic acid. These efforts aim to create heterogeneous catalysts that retain the superacid's catalytic activity while mitigating its handling and corrosion issues. However, maintaining catalytic efficiency in such supported systems remains a challenge.

The scalability of processes involving fluoroantimonic acid is another area of ongoing research and development. While its effectiveness has been demonstrated in laboratory settings, translating these results to industrial-scale operations presents significant engineering challenges, particularly in terms of reactor design and process control.

One of the primary areas of application is in the petrochemical industry, where fluoroantimonic acid has shown remarkable efficiency in catalyzing alkylation reactions. Its ability to protonate even weak bases has led to enhanced reaction rates and improved product yields. However, the widespread industrial adoption of this superacid faces significant hurdles due to its extreme corrosiveness and sensitivity to moisture.

The synthesis and handling of fluoroantimonic acid present considerable challenges. Its preparation typically involves the combination of hydrogen fluoride and antimony pentafluoride, both of which are highly reactive and hazardous substances. Ensuring the purity and stability of the acid during storage and use remains a critical concern for researchers and industry practitioners alike.

Safety considerations pose another major challenge in the application of fluoroantimonic acid. Its extreme acidity necessitates specialized containment materials and rigorous safety protocols. The development of safer handling methods and containment systems is an ongoing area of research, crucial for expanding its practical applications.

In the realm of organic synthesis, fluoroantimonic acid has demonstrated potential in facilitating challenging transformations. Its super-acidic nature enables the activation of typically unreactive substrates, opening new pathways in synthetic chemistry. However, controlling the selectivity of reactions in such a highly acidic environment remains a significant challenge.

Environmental concerns also present a substantial obstacle to the widespread use of fluoroantimonic acid. Its potential environmental impact, particularly in terms of waste disposal and accidental releases, necessitates the development of robust containment and neutralization strategies. This aspect has spurred research into more environmentally benign alternatives that can match its catalytic prowess.

Recent advancements in material science have led to the exploration of novel support materials for immobilizing fluoroantimonic acid. These efforts aim to create heterogeneous catalysts that retain the superacid's catalytic activity while mitigating its handling and corrosion issues. However, maintaining catalytic efficiency in such supported systems remains a challenge.

The scalability of processes involving fluoroantimonic acid is another area of ongoing research and development. While its effectiveness has been demonstrated in laboratory settings, translating these results to industrial-scale operations presents significant engineering challenges, particularly in terms of reactor design and process control.

Existing Catalytic Solutions Using Fluoroantimonic Acid

01 Advancements in catalytic processes using fluoroantimonic acid

Recent developments have improved the efficiency and selectivity of catalytic reactions using fluoroantimonic acid. These advancements include optimized reaction conditions, novel reactor designs, and enhanced catalyst recovery methods, leading to increased yields and reduced environmental impact in various industrial applications.- Advancements in catalytic applications: Fluoroantimonic acid has shown significant advancements in catalytic applications, particularly in organic synthesis and petrochemical processes. Its super-acidic properties enable it to catalyze various reactions, including isomerization, alkylation, and cracking, with improved efficiency and selectivity compared to traditional catalysts.

- Novel synthesis methods for fluoroantimonic acid: Recent developments have focused on improving the synthesis methods for fluoroantimonic acid, aiming to enhance its purity, stability, and handling safety. These advancements include new precursor materials, optimized reaction conditions, and innovative purification techniques, resulting in higher-quality catalysts for industrial applications.

- Enhanced catalyst support systems: Research has led to the development of advanced support systems for fluoroantimonic acid catalysts, improving their stability, recyclability, and ease of handling. These support systems include novel porous materials, nanostructured substrates, and composite materials that enhance the catalytic performance while mitigating the corrosive nature of the acid.

- Application in polymer chemistry: Fluoroantimonic acid has found new applications in polymer chemistry, particularly in the synthesis of high-performance polymers and the modification of existing polymers. Its strong acidic properties enable unique polymerization reactions and polymer transformations that were previously challenging or impossible with conventional catalysts.

- Environmental and safety improvements: Significant efforts have been made to address the environmental and safety concerns associated with fluoroantimonic acid catalysis. These advancements include the development of containment systems, neutralization methods, and safer handling protocols, as well as the exploration of less hazardous alternatives that maintain similar catalytic activity.

02 Novel applications of fluoroantimonic acid in organic synthesis

Researchers have discovered new applications for fluoroantimonic acid in organic synthesis, particularly in the formation of carbon-carbon bonds and the activation of inert substrates. These findings have expanded the scope of reactions that can be catalyzed by this superacid, opening up possibilities for the synthesis of complex molecules and pharmaceutical intermediates.Expand Specific Solutions03 Improved handling and safety measures for fluoroantimonic acid

Significant progress has been made in developing safer handling procedures and containment systems for fluoroantimonic acid. These advancements include the design of corrosion-resistant materials, specialized storage containers, and improved personal protective equipment, enhancing the safety of researchers and industrial workers dealing with this highly reactive superacid.Expand Specific Solutions04 Enhanced characterization techniques for fluoroantimonic acid catalysis

New analytical methods and instrumentation have been developed to better understand the mechanism of fluoroantimonic acid catalysis at the molecular level. These techniques include advanced spectroscopic methods, in-situ monitoring, and computational modeling, providing valuable insights into reaction intermediates and transition states.Expand Specific Solutions05 Eco-friendly alternatives and modifications to fluoroantimonic acid catalysts

Research efforts have focused on developing more environmentally friendly alternatives to traditional fluoroantimonic acid catalysts. These include the use of supported catalysts, ionic liquids, and modified versions of the superacid with reduced toxicity and improved recyclability, addressing concerns about the environmental impact of fluoroantimonic acid in industrial processes.Expand Specific Solutions

Key Players in Fluoroantimonic Acid Research and Production

The field of catalytic advancements using fluoroantimonic acid is in a nascent stage of development, characterized by intense research and innovation. The market size is relatively small but growing rapidly, driven by potential applications in petrochemicals, pharmaceuticals, and materials science. The technology's maturity is still evolving, with key players like BASF Corp., ExxonMobil Chemical Patents, Inc., and Dow Global Technologies LLC leading industrial applications. Academic institutions such as Massachusetts Institute of Technology and California Institute of Technology are contributing significantly to fundamental research. Companies like Saudi Arabian Oil Co. and China Petroleum & Chemical Corp. are exploring applications in the energy sector, while pharmaceutical giants like Novartis AG are investigating potential uses in drug synthesis.

W. R. Grace & Co.-Conn.

Technical Solution: W. R. Grace has developed a proprietary fluoroantimonic acid-based catalyst system for use in hydrocarbon cracking and isomerization processes. Their technology incorporates the super-acidic properties of fluoroantimonic acid into a zeolite framework, creating a highly active and selective catalyst. This catalyst system is designed to operate at lower temperatures compared to conventional catalysts, resulting in improved energy efficiency and reduced coke formation in refinery operations.

Strengths: Enhanced catalytic activity, improved selectivity, and energy efficiency in hydrocarbon processing. Weaknesses: Potential for rapid deactivation due to moisture sensitivity, requires stringent process control.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed an advanced catalytic reforming process utilizing a fluoroantimonic acid-modified platinum catalyst. This innovative catalyst system combines the super-acidic properties of fluoroantimonic acid with the hydrogenation/dehydrogenation capabilities of platinum. The result is a highly efficient catalyst for the production of high-octane gasoline components and aromatic compounds. The process operates at lower pressures and temperatures compared to conventional reforming, leading to improved energy efficiency and reduced equipment costs.

Strengths: Higher yield of valuable products, improved energy efficiency, and reduced operating costs. Weaknesses: Catalyst sensitivity to contaminants, potential corrosion issues in process equipment.

Core Innovations in Fluoroantimonic Acid Catalysis

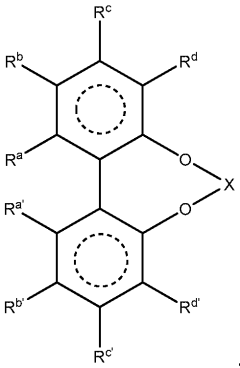

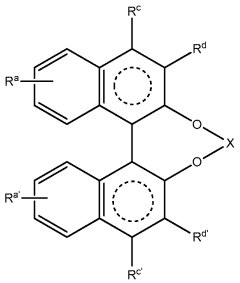

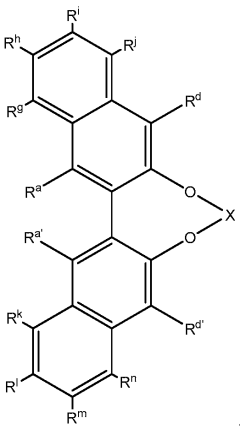

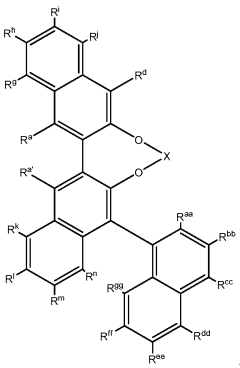

Asymmetric electrophilic fluorination using an anionic chiral phase-transfer catalyst

PatentWO2013096971A1

Innovation

- Development of chiral anionic phase-transfer catalysts that facilitate enantioselective electrophilic addition reactions by forming soluble ion pairs with insoluble cationic electrophilic reagents, enabling efficient and enantiocontrolled C-F bond formation through electrophilic addition reactions.

Curing compositions for fluoropolymers

PatentInactiveUS20120065321A1

Innovation

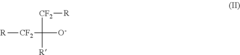

- Development of a catalyst composition comprising a cation and anion, specifically an organo onium, that is essentially free of hydrocarbon-containing alcohol, allowing for improved rheology control and reduced scorch in fluoroelastomers, particularly through the use of anions like tetra-alkylammonium 2-phenyl-1,1,1,3,3,3 hexafluoroisopropanoate, which effectively generates triazine crosslinks in perfluoroelastomers.

Safety and Handling Protocols for Fluoroantimonic Acid

Fluoroantimonic acid, known as the world's strongest superacid, requires stringent safety measures and handling protocols due to its extreme corrosiveness and reactivity. The primary concern when working with this substance is its ability to react violently with water and most organic compounds, necessitating specialized containment and handling procedures.

Personal protective equipment (PPE) is crucial when handling fluoroantimonic acid. Workers must wear fully encapsulating chemical-resistant suits, including gloves, boots, and face shields. The suit material should be specifically rated for fluoroantimonic acid resistance, as standard lab coats or nitrile gloves are inadequate. Respiratory protection, such as a self-contained breathing apparatus (SCBA), is essential to prevent inhalation of toxic fumes.

Storage of fluoroantimonic acid requires specialized containers made of materials resistant to its corrosive properties. Polytetrafluoroethylene (PTFE) or perfluoroalkoxy alkane (PFA) containers are commonly used. These containers must be sealed tightly and stored in a cool, dry area away from incompatible materials, particularly water and organic substances. Secondary containment is necessary to prevent spills from spreading.

Handling procedures must be conducted in a designated area with proper ventilation systems. Fume hoods equipped with acid-resistant liners and scrubbers are essential for containing and neutralizing any vapors. All equipment used in handling fluoroantimonic acid, including pipettes and transfer vessels, must be made of compatible materials and thoroughly cleaned after use.

Emergency response protocols are critical. Spill kits specifically designed for superacids should be readily available. These kits typically include neutralizing agents, absorbent materials, and disposal containers. Personnel must be trained in spill response procedures, including proper neutralization techniques and disposal methods. Eye wash stations and safety showers should be easily accessible in case of accidental exposure.

Waste disposal of fluoroantimonic acid and related materials requires specialized procedures. Neutralization is typically performed using a carefully controlled addition of a base, such as sodium hydroxide, in a designated waste treatment area. The resulting neutralized solution must still be handled as hazardous waste and disposed of according to local regulations.

Training and documentation are essential components of safety protocols. All personnel working with or around fluoroantimonic acid must undergo comprehensive training on its properties, hazards, and proper handling techniques. Standard operating procedures (SOPs) should be developed and regularly reviewed, detailing step-by-step processes for all activities involving the acid. Maintaining accurate records of usage, storage, and disposal is crucial for regulatory compliance and safety audits.

Personal protective equipment (PPE) is crucial when handling fluoroantimonic acid. Workers must wear fully encapsulating chemical-resistant suits, including gloves, boots, and face shields. The suit material should be specifically rated for fluoroantimonic acid resistance, as standard lab coats or nitrile gloves are inadequate. Respiratory protection, such as a self-contained breathing apparatus (SCBA), is essential to prevent inhalation of toxic fumes.

Storage of fluoroantimonic acid requires specialized containers made of materials resistant to its corrosive properties. Polytetrafluoroethylene (PTFE) or perfluoroalkoxy alkane (PFA) containers are commonly used. These containers must be sealed tightly and stored in a cool, dry area away from incompatible materials, particularly water and organic substances. Secondary containment is necessary to prevent spills from spreading.

Handling procedures must be conducted in a designated area with proper ventilation systems. Fume hoods equipped with acid-resistant liners and scrubbers are essential for containing and neutralizing any vapors. All equipment used in handling fluoroantimonic acid, including pipettes and transfer vessels, must be made of compatible materials and thoroughly cleaned after use.

Emergency response protocols are critical. Spill kits specifically designed for superacids should be readily available. These kits typically include neutralizing agents, absorbent materials, and disposal containers. Personnel must be trained in spill response procedures, including proper neutralization techniques and disposal methods. Eye wash stations and safety showers should be easily accessible in case of accidental exposure.

Waste disposal of fluoroantimonic acid and related materials requires specialized procedures. Neutralization is typically performed using a carefully controlled addition of a base, such as sodium hydroxide, in a designated waste treatment area. The resulting neutralized solution must still be handled as hazardous waste and disposed of according to local regulations.

Training and documentation are essential components of safety protocols. All personnel working with or around fluoroantimonic acid must undergo comprehensive training on its properties, hazards, and proper handling techniques. Standard operating procedures (SOPs) should be developed and regularly reviewed, detailing step-by-step processes for all activities involving the acid. Maintaining accurate records of usage, storage, and disposal is crucial for regulatory compliance and safety audits.

Environmental Impact of Fluoroantimonic Acid Usage

The environmental impact of fluoroantimonic acid usage is a critical concern in catalytic advancements. This superacid, known for its extreme corrosiveness and reactivity, poses significant challenges to environmental safety and sustainability. Its production, handling, and disposal require stringent protocols to prevent potential ecological damage.

Fluoroantimonic acid's high reactivity can lead to severe contamination of soil and water systems if released into the environment. Even minute quantities can cause long-lasting ecological disruptions, affecting pH levels and potentially harming flora and fauna. The acid's ability to react with a wide range of substances increases the risk of secondary pollutants forming, further complicating environmental remediation efforts.

Air pollution is another significant concern associated with fluoroantimonic acid usage. Volatile components and reaction by-products can contribute to atmospheric contamination, potentially impacting air quality and human health in surrounding areas. The emission of fluorine-containing compounds is particularly worrisome due to their persistence in the environment and potential for long-range transport.

Water resources are especially vulnerable to fluoroantimonic acid contamination. Given its extreme acidity, even small spills can drastically alter aquatic ecosystems, leading to mass mortality of aquatic life and long-term habitat degradation. The acid's ability to dissolve many materials also raises concerns about leaching of heavy metals and other toxic substances from containment vessels or surrounding structures.

Waste management presents a significant challenge in fluoroantimonic acid applications. Neutralization and disposal of acid residues require specialized facilities and techniques to ensure environmental safety. The potential for acid-containing waste to react with other materials in disposal sites poses ongoing risks that necessitate careful long-term monitoring and management strategies.

The use of fluoroantimonic acid in industrial processes also raises concerns about resource depletion and energy consumption. The production of this superacid and its precursors involves energy-intensive processes and the use of non-renewable resources, contributing to broader environmental impacts associated with industrial chemical production.

Efforts to mitigate the environmental impact of fluoroantimonic acid usage focus on developing safer handling protocols, improving containment technologies, and exploring alternative catalysts with lower environmental risks. Research into green chemistry alternatives and process intensification aims to reduce the reliance on such aggressive reagents while maintaining catalytic efficiency.

Regulatory frameworks play a crucial role in managing the environmental risks associated with fluoroantimonic acid. Stringent guidelines for its production, transport, use, and disposal are essential to minimize potential ecological damage. International cooperation is necessary to ensure consistent standards and practices across different regions, given the global nature of chemical industries and environmental concerns.

Fluoroantimonic acid's high reactivity can lead to severe contamination of soil and water systems if released into the environment. Even minute quantities can cause long-lasting ecological disruptions, affecting pH levels and potentially harming flora and fauna. The acid's ability to react with a wide range of substances increases the risk of secondary pollutants forming, further complicating environmental remediation efforts.

Air pollution is another significant concern associated with fluoroantimonic acid usage. Volatile components and reaction by-products can contribute to atmospheric contamination, potentially impacting air quality and human health in surrounding areas. The emission of fluorine-containing compounds is particularly worrisome due to their persistence in the environment and potential for long-range transport.

Water resources are especially vulnerable to fluoroantimonic acid contamination. Given its extreme acidity, even small spills can drastically alter aquatic ecosystems, leading to mass mortality of aquatic life and long-term habitat degradation. The acid's ability to dissolve many materials also raises concerns about leaching of heavy metals and other toxic substances from containment vessels or surrounding structures.

Waste management presents a significant challenge in fluoroantimonic acid applications. Neutralization and disposal of acid residues require specialized facilities and techniques to ensure environmental safety. The potential for acid-containing waste to react with other materials in disposal sites poses ongoing risks that necessitate careful long-term monitoring and management strategies.

The use of fluoroantimonic acid in industrial processes also raises concerns about resource depletion and energy consumption. The production of this superacid and its precursors involves energy-intensive processes and the use of non-renewable resources, contributing to broader environmental impacts associated with industrial chemical production.

Efforts to mitigate the environmental impact of fluoroantimonic acid usage focus on developing safer handling protocols, improving containment technologies, and exploring alternative catalysts with lower environmental risks. Research into green chemistry alternatives and process intensification aims to reduce the reliance on such aggressive reagents while maintaining catalytic efficiency.

Regulatory frameworks play a crucial role in managing the environmental risks associated with fluoroantimonic acid. Stringent guidelines for its production, transport, use, and disposal are essential to minimize potential ecological damage. International cooperation is necessary to ensure consistent standards and practices across different regions, given the global nature of chemical industries and environmental concerns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!