How to Innovate Chemical Reactions with Fluoroantimonic Acid?

JUN 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluoroantimonic Acid: Background and Objectives

Fluoroantimonic acid, a superacid composed of a mixture of hydrogen fluoride (HF) and antimony pentafluoride (SbF5), stands as one of the strongest known acids in chemistry. Its discovery and development have revolutionized our understanding of acid-base chemistry and opened new avenues for chemical reactions and industrial processes.

The journey of fluoroantimonic acid began in the mid-20th century with the exploration of superacids. These compounds, defined as acids stronger than 100% sulfuric acid, pushed the boundaries of traditional acid chemistry. The culmination of this research led to the creation of fluoroantimonic acid, which exhibits an astounding ability to protonate even extremely weak bases.

The Hammett acidity function (H0) of fluoroantimonic acid is estimated to be as low as -28, making it billions of times stronger than sulfuric acid. This extreme acidity arises from the unique interaction between HF and SbF5, forming complex fluoroantimonates that can readily donate protons to substrates.

The primary objective in innovating chemical reactions with fluoroantimonic acid is to harness its exceptional protonating power for novel synthetic pathways and industrial applications. Researchers aim to exploit its ability to activate inert molecules, catalyze challenging transformations, and enable reactions that were previously thought impossible.

One key goal is to develop more efficient and selective catalytic systems using fluoroantimonic acid. This includes exploring its potential in petrochemical processes, such as isomerization and alkylation reactions, where its strong acidity could lead to improved yields and reduced energy consumption.

Another objective is to investigate the use of fluoroantimonic acid in materials science. Its ability to generate highly reactive carbocations opens up possibilities for creating new polymers, functionalized materials, and advanced composites with unique properties.

Researchers also aim to expand the application of fluoroantimonic acid in organic synthesis. By leveraging its extreme acidity, chemists hope to develop novel reaction pathways for the formation of carbon-carbon bonds, functional group transformations, and the synthesis of complex molecules.

Safety and handling considerations form a crucial aspect of the research objectives. Due to its highly corrosive and reactive nature, developing safer methodologies for using fluoroantimonic acid in laboratory and industrial settings is paramount. This includes exploring containment strategies, neutralization techniques, and the design of specialized equipment.

As we delve deeper into the potential of fluoroantimonic acid, the overarching goal is to push the boundaries of chemical reactivity and unlock new realms of synthetic possibilities. By understanding and controlling its unique properties, we aim to revolutionize various fields of chemistry and contribute to advancements in energy, materials, and pharmaceutical industries.

The journey of fluoroantimonic acid began in the mid-20th century with the exploration of superacids. These compounds, defined as acids stronger than 100% sulfuric acid, pushed the boundaries of traditional acid chemistry. The culmination of this research led to the creation of fluoroantimonic acid, which exhibits an astounding ability to protonate even extremely weak bases.

The Hammett acidity function (H0) of fluoroantimonic acid is estimated to be as low as -28, making it billions of times stronger than sulfuric acid. This extreme acidity arises from the unique interaction between HF and SbF5, forming complex fluoroantimonates that can readily donate protons to substrates.

The primary objective in innovating chemical reactions with fluoroantimonic acid is to harness its exceptional protonating power for novel synthetic pathways and industrial applications. Researchers aim to exploit its ability to activate inert molecules, catalyze challenging transformations, and enable reactions that were previously thought impossible.

One key goal is to develop more efficient and selective catalytic systems using fluoroantimonic acid. This includes exploring its potential in petrochemical processes, such as isomerization and alkylation reactions, where its strong acidity could lead to improved yields and reduced energy consumption.

Another objective is to investigate the use of fluoroantimonic acid in materials science. Its ability to generate highly reactive carbocations opens up possibilities for creating new polymers, functionalized materials, and advanced composites with unique properties.

Researchers also aim to expand the application of fluoroantimonic acid in organic synthesis. By leveraging its extreme acidity, chemists hope to develop novel reaction pathways for the formation of carbon-carbon bonds, functional group transformations, and the synthesis of complex molecules.

Safety and handling considerations form a crucial aspect of the research objectives. Due to its highly corrosive and reactive nature, developing safer methodologies for using fluoroantimonic acid in laboratory and industrial settings is paramount. This includes exploring containment strategies, neutralization techniques, and the design of specialized equipment.

As we delve deeper into the potential of fluoroantimonic acid, the overarching goal is to push the boundaries of chemical reactivity and unlock new realms of synthetic possibilities. By understanding and controlling its unique properties, we aim to revolutionize various fields of chemistry and contribute to advancements in energy, materials, and pharmaceutical industries.

Market Analysis for Superacid Applications

The market for superacid applications, particularly those involving fluoroantimonic acid, has shown significant growth potential in recent years. This powerful superacid, known for its extreme acidity and unique chemical properties, has found increasing use across various industrial sectors. The global superacid market, which includes fluoroantimonic acid, is experiencing steady expansion driven by advancements in chemical synthesis and materials science.

In the petrochemical industry, fluoroantimonic acid has emerged as a crucial catalyst for hydrocarbon cracking and isomerization processes. Its ability to facilitate these reactions under milder conditions than traditional catalysts has led to improved efficiency and reduced energy consumption in oil refining operations. This has resulted in a growing demand from major oil and gas companies seeking to optimize their production processes.

The electronics sector represents another key market for fluoroantimonic acid applications. As the demand for smaller, more powerful electronic devices continues to rise, manufacturers are exploring innovative etching techniques for semiconductor production. Fluoroantimonic acid's exceptional etching capabilities make it a promising candidate for developing next-generation microchips and advanced electronic components.

In the pharmaceutical industry, fluoroantimonic acid is gaining attention for its potential in synthesizing complex organic compounds. Its strong acidic properties enable unique chemical transformations that were previously challenging or impossible with conventional acids. This has opened new avenues for drug discovery and the development of novel pharmaceutical intermediates.

The materials science sector is also exploring fluoroantimonic acid applications, particularly in the production of advanced polymers and specialty chemicals. Its ability to catalyze polymerization reactions and facilitate the synthesis of high-performance materials has attracted interest from manufacturers of aerospace components, automotive parts, and industrial coatings.

Despite its promising applications, the market for fluoroantimonic acid faces challenges related to handling and safety concerns. The extreme corrosiveness and reactivity of this superacid necessitate specialized equipment and stringent safety protocols, which can limit its widespread adoption. However, ongoing research into safer handling methods and the development of more stable formulations are expected to address these concerns and further expand market opportunities.

As environmental regulations become increasingly stringent, there is a growing focus on developing greener chemical processes. This trend presents both challenges and opportunities for fluoroantimonic acid applications. While its use may face scrutiny in some areas, its potential to enable more efficient and less energy-intensive chemical reactions aligns with sustainability goals in others.

In the petrochemical industry, fluoroantimonic acid has emerged as a crucial catalyst for hydrocarbon cracking and isomerization processes. Its ability to facilitate these reactions under milder conditions than traditional catalysts has led to improved efficiency and reduced energy consumption in oil refining operations. This has resulted in a growing demand from major oil and gas companies seeking to optimize their production processes.

The electronics sector represents another key market for fluoroantimonic acid applications. As the demand for smaller, more powerful electronic devices continues to rise, manufacturers are exploring innovative etching techniques for semiconductor production. Fluoroantimonic acid's exceptional etching capabilities make it a promising candidate for developing next-generation microchips and advanced electronic components.

In the pharmaceutical industry, fluoroantimonic acid is gaining attention for its potential in synthesizing complex organic compounds. Its strong acidic properties enable unique chemical transformations that were previously challenging or impossible with conventional acids. This has opened new avenues for drug discovery and the development of novel pharmaceutical intermediates.

The materials science sector is also exploring fluoroantimonic acid applications, particularly in the production of advanced polymers and specialty chemicals. Its ability to catalyze polymerization reactions and facilitate the synthesis of high-performance materials has attracted interest from manufacturers of aerospace components, automotive parts, and industrial coatings.

Despite its promising applications, the market for fluoroantimonic acid faces challenges related to handling and safety concerns. The extreme corrosiveness and reactivity of this superacid necessitate specialized equipment and stringent safety protocols, which can limit its widespread adoption. However, ongoing research into safer handling methods and the development of more stable formulations are expected to address these concerns and further expand market opportunities.

As environmental regulations become increasingly stringent, there is a growing focus on developing greener chemical processes. This trend presents both challenges and opportunities for fluoroantimonic acid applications. While its use may face scrutiny in some areas, its potential to enable more efficient and less energy-intensive chemical reactions aligns with sustainability goals in others.

Current Challenges in Fluoroantimonic Acid Usage

Fluoroantimonic acid, known as the world's strongest superacid, presents significant challenges in its usage for chemical reactions. The primary obstacle lies in its extreme corrosiveness and reactivity, which severely limits the materials that can safely contain it. Traditional laboratory glassware and most metals are rapidly degraded by this powerful acid, necessitating the use of specialized containers made from fluoropolymers like Teflon.

The handling and storage of fluoroantimonic acid pose considerable safety risks. Its highly hygroscopic nature means it reacts violently with water, producing dangerous fumes and heat. This property complicates its storage and requires stringent moisture-free conditions, adding complexity to experimental setups and industrial processes.

Another significant challenge is the difficulty in controlling reactions involving fluoroantimonic acid. Its extreme acidity can lead to unintended side reactions or rapid decomposition of organic compounds, making it challenging to achieve selective transformations. This lack of selectivity limits its applicability in fine chemical synthesis and pharmaceutical manufacturing.

The environmental impact of fluoroantimonic acid usage is also a major concern. Its production and disposal require specialized facilities and procedures to prevent contamination of air, water, and soil. The potential for accidental release poses severe risks to ecosystems and human health, necessitating rigorous safety protocols and containment measures.

Scale-up of reactions involving fluoroantimonic acid from laboratory to industrial scale presents numerous engineering challenges. The need for corrosion-resistant equipment and precise control systems significantly increases production costs. Moreover, the large-scale handling of such a hazardous substance requires extensive safety measures and specialized training for personnel.

The limited availability and high cost of fluoroantimonic acid further restrict its widespread use in chemical research and industry. Its production involves complex processes and hazardous precursors, making it economically unfeasible for many applications. This scarcity hampers extensive research into potential novel applications and reaction methodologies.

Lastly, the regulatory landscape surrounding the use of fluoroantimonic acid is complex and often restrictive. Stringent safety regulations and permitting requirements can make it challenging for researchers and industries to incorporate this superacid into their processes, limiting innovation and exploration of its full potential in chemical synthesis.

The handling and storage of fluoroantimonic acid pose considerable safety risks. Its highly hygroscopic nature means it reacts violently with water, producing dangerous fumes and heat. This property complicates its storage and requires stringent moisture-free conditions, adding complexity to experimental setups and industrial processes.

Another significant challenge is the difficulty in controlling reactions involving fluoroantimonic acid. Its extreme acidity can lead to unintended side reactions or rapid decomposition of organic compounds, making it challenging to achieve selective transformations. This lack of selectivity limits its applicability in fine chemical synthesis and pharmaceutical manufacturing.

The environmental impact of fluoroantimonic acid usage is also a major concern. Its production and disposal require specialized facilities and procedures to prevent contamination of air, water, and soil. The potential for accidental release poses severe risks to ecosystems and human health, necessitating rigorous safety protocols and containment measures.

Scale-up of reactions involving fluoroantimonic acid from laboratory to industrial scale presents numerous engineering challenges. The need for corrosion-resistant equipment and precise control systems significantly increases production costs. Moreover, the large-scale handling of such a hazardous substance requires extensive safety measures and specialized training for personnel.

The limited availability and high cost of fluoroantimonic acid further restrict its widespread use in chemical research and industry. Its production involves complex processes and hazardous precursors, making it economically unfeasible for many applications. This scarcity hampers extensive research into potential novel applications and reaction methodologies.

Lastly, the regulatory landscape surrounding the use of fluoroantimonic acid is complex and often restrictive. Stringent safety regulations and permitting requirements can make it challenging for researchers and industries to incorporate this superacid into their processes, limiting innovation and exploration of its full potential in chemical synthesis.

Existing Chemical Reaction Innovations with Fluoroantimonic Acid

01 Synthesis and production of fluoroantimonic acid

Fluoroantimonic acid is synthesized by combining hydrogen fluoride and antimony pentafluoride. The production process involves careful handling of these highly reactive compounds under controlled conditions. Various methods and apparatus have been developed to optimize the synthesis and ensure the purity of the resulting superacid.- Synthesis and properties of fluoroantimonic acid: Fluoroantimonic acid is a superacid formed by combining hydrogen fluoride (HF) and antimony pentafluoride (SbF5). It is known for its extremely high acidity and unique chemical properties. The synthesis process and characterization of its properties are crucial for understanding its potential applications in various fields.

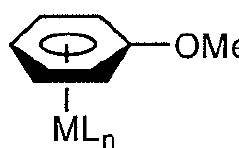

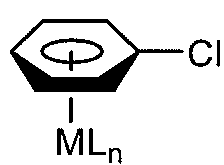

- Applications in organic synthesis and catalysis: Fluoroantimonic acid serves as a powerful catalyst in various organic synthesis reactions due to its strong acidity. It can catalyze alkylation, isomerization, and polymerization reactions. The acid's ability to generate highly reactive carbocations makes it valuable in the production of certain hydrocarbons and polymers.

- Use in materials science and surface treatments: Fluoroantimonic acid finds applications in materials science, particularly in surface treatments and modifications. It can be used to etch or modify surfaces of various materials, including metals and semiconductors. The acid's strong protonating ability allows for unique surface chemistry applications.

- Safety considerations and handling procedures: Due to its extreme acidity and reactivity, fluoroantimonic acid requires special safety considerations and handling procedures. This includes the use of specialized containment materials, personal protective equipment, and strict protocols for storage and disposal. Understanding these safety aspects is crucial for its safe use in research and industrial settings.

- Analytical applications and detection methods: Fluoroantimonic acid has potential applications in analytical chemistry. Its unique properties can be utilized in certain analytical techniques or as a reagent for detecting specific compounds. Development of methods for detecting and quantifying fluoroantimonic acid itself is also an area of interest, particularly for environmental and safety monitoring.

02 Applications in chemical reactions and catalysis

Fluoroantimonic acid is utilized as a powerful catalyst in various chemical reactions due to its extremely high acidity. It is particularly effective in promoting reactions such as isomerization, alkylation, and polymerization of hydrocarbons. The superacid's catalytic properties are exploited in industrial processes and organic synthesis.Expand Specific Solutions03 Material compatibility and storage

Due to its highly corrosive nature, fluoroantimonic acid requires specialized materials for handling and storage. Research has been conducted on developing compatible materials, such as fluoropolymers and certain alloys, that can withstand the acid's aggressive properties. Proper containment and storage methods are crucial for safe handling and preventing environmental contamination.Expand Specific Solutions04 Safety measures and environmental considerations

Handling fluoroantimonic acid requires strict safety protocols due to its extreme reactivity and corrosiveness. Research has focused on developing safety measures, protective equipment, and containment systems to minimize risks associated with its use. Environmental impact assessments and disposal methods have also been studied to ensure responsible use of this powerful superacid.Expand Specific Solutions05 Analytical applications and detection methods

Fluoroantimonic acid has found applications in analytical chemistry and materials characterization. Research has been conducted on developing methods for detecting and quantifying the acid, as well as utilizing its properties for analyzing complex chemical mixtures. These analytical techniques contribute to advancements in various scientific fields and industrial processes.Expand Specific Solutions

Key Players in Superacid Research and Industry

The innovation of chemical reactions using fluoroantimonic acid is in a nascent stage of development, with significant potential for growth. The market size for this technology is expanding as industries seek more efficient and powerful catalysts. While the technology is still evolving, several key players are driving advancements. Universities like The Regents of the University of California, Yale University, and Central South University are conducting fundamental research. Industry leaders such as DuPont de Nemours, Inc., DAIKIN INDUSTRIES Ltd., and 3M Innovative Properties Co. are exploring practical applications. The technology's maturity varies across sectors, with some companies like Merck Sharp & Dohme Corp. and Evonik Operations GmbH focusing on specific applications in pharmaceuticals and specialty chemicals, indicating a gradual progression towards commercial viability.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a novel approach to utilizing fluoroantimonic acid in chemical reactions. Their method involves a controlled environment where the acid is contained in specially designed fluoropolymer vessels. This allows for precise manipulation of reaction conditions, including temperature and pressure. DuPont's innovation lies in their ability to harness the superacidity of fluoroantimonic acid while mitigating its extreme corrosiveness through advanced material science and engineering.

Strengths: Unparalleled reaction rates, ability to catalyze previously impossible reactions. Weaknesses: Extreme safety precautions required, high cost of specialized equipment.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin has pioneered a technique for using fluoroantimonic acid in the synthesis of high-performance fluoropolymers. Their approach involves a two-step process where the acid is used to generate highly reactive intermediates, which are then rapidly polymerized under controlled conditions. This method allows for the creation of fluoropolymers with unique properties, such as enhanced chemical resistance and thermal stability, that were previously unattainable.

Strengths: Production of novel materials with superior properties, potential for new applications in extreme environments. Weaknesses: Complex process control, potential environmental concerns.

Breakthrough Reactions Enabled by Fluoroantimonic Acid

Fluorination method

PatentInactiveUS20220160905A1

Innovation

- A new process involving a difluorocarbene source, 18F-fluoride, and sulfur dioxide (SO2) is developed to produce 18F-trifluoromethanesulfinate quickly and reliably, enabling direct 18F-trifluoromethylation of aromatic groups in peptides and proteins through electrophilic radical chemistry.

Catalytic radiofluorination

PatentWO2008022319A2

Innovation

- A catalytic radiofluorination method using anhydrous potassium fluoride and crown ethers, such as Kryptofix, which allows for the substitution of leaving groups in alkyl, cycloalkyl, and aryl compounds without the need for activating groups, enabling the production of fluorine-18 labeled compounds like piperazine and phosphonium salts for improved imaging agents.

Safety and Handling Protocols for Fluoroantimonic Acid

Fluoroantimonic acid is one of the strongest known superacids, with a Hammett acidity function of -31.3. Its extreme corrosiveness and reactivity necessitate stringent safety measures and specialized handling protocols. When working with this compound, researchers must prioritize personal protection equipment (PPE) including fully encapsulating chemical-resistant suits, gloves, and face shields. All operations involving fluoroantimonic acid should be conducted in a fume hood with proper ventilation systems to prevent exposure to toxic fumes.

Due to its highly reactive nature, fluoroantimonic acid must be stored in containers made of materials resistant to hydrofluoric acid, such as PTFE (Teflon) or PFA (perfluoroalkoxy alkanes). Glass, metal, and most plastics are unsuitable for storage or handling. The acid should be kept in tightly sealed containers in a cool, dry area away from sources of heat or ignition. Regular inspections of storage areas and containers are crucial to detect any signs of leakage or degradation.

In case of accidental exposure or spills, immediate decontamination procedures must be initiated. This includes flushing affected areas with copious amounts of water and seeking immediate medical attention. Specialized neutralizing agents, such as calcium gluconate gel, should be readily available in laboratories working with fluoroantimonic acid. Spill response kits containing appropriate absorbents and neutralizers must be accessible in all areas where the acid is used or stored.

Proper waste disposal is critical when dealing with fluoroantimonic acid. Neutralization should be performed carefully, typically using a base such as sodium hydroxide, before disposal. The neutralized waste must still be treated as hazardous and disposed of according to local regulations. All equipment that comes into contact with the acid must be thoroughly decontaminated before cleaning or disposal.

Training is a crucial aspect of safety protocols for fluoroantimonic acid. All personnel working with or in proximity to the acid must undergo comprehensive safety training, including proper handling techniques, emergency response procedures, and the use of PPE. Regular refresher courses and safety drills should be conducted to maintain a high level of preparedness.

Implementing a buddy system for laboratory work involving fluoroantimonic acid is highly recommended. This ensures that no researcher works alone with the compound and that immediate assistance is available in case of an emergency. Additionally, establishing clear communication protocols and emergency response plans is essential for minimizing risks and ensuring rapid action in the event of an incident.

Due to its highly reactive nature, fluoroantimonic acid must be stored in containers made of materials resistant to hydrofluoric acid, such as PTFE (Teflon) or PFA (perfluoroalkoxy alkanes). Glass, metal, and most plastics are unsuitable for storage or handling. The acid should be kept in tightly sealed containers in a cool, dry area away from sources of heat or ignition. Regular inspections of storage areas and containers are crucial to detect any signs of leakage or degradation.

In case of accidental exposure or spills, immediate decontamination procedures must be initiated. This includes flushing affected areas with copious amounts of water and seeking immediate medical attention. Specialized neutralizing agents, such as calcium gluconate gel, should be readily available in laboratories working with fluoroantimonic acid. Spill response kits containing appropriate absorbents and neutralizers must be accessible in all areas where the acid is used or stored.

Proper waste disposal is critical when dealing with fluoroantimonic acid. Neutralization should be performed carefully, typically using a base such as sodium hydroxide, before disposal. The neutralized waste must still be treated as hazardous and disposed of according to local regulations. All equipment that comes into contact with the acid must be thoroughly decontaminated before cleaning or disposal.

Training is a crucial aspect of safety protocols for fluoroantimonic acid. All personnel working with or in proximity to the acid must undergo comprehensive safety training, including proper handling techniques, emergency response procedures, and the use of PPE. Regular refresher courses and safety drills should be conducted to maintain a high level of preparedness.

Implementing a buddy system for laboratory work involving fluoroantimonic acid is highly recommended. This ensures that no researcher works alone with the compound and that immediate assistance is available in case of an emergency. Additionally, establishing clear communication protocols and emergency response plans is essential for minimizing risks and ensuring rapid action in the event of an incident.

Environmental Impact and Sustainability Considerations

The use of fluoroantimonic acid in chemical reactions raises significant environmental and sustainability concerns due to its extreme corrosiveness and reactivity. As one of the strongest known superacids, it poses severe risks to ecosystems and human health if released into the environment. The production, handling, and disposal of fluoroantimonic acid require stringent safety measures and specialized containment systems to prevent contamination of soil, water, and air.

The environmental impact of fluoroantimonic acid extends beyond its direct effects. Its synthesis involves the use of hydrofluoric acid and antimony pentafluoride, both of which have their own environmental implications. The production process generates hazardous waste and emissions that must be carefully managed to minimize ecological damage. Furthermore, the energy-intensive nature of manufacturing and maintaining the necessary containment infrastructure contributes to increased carbon footprint and resource consumption.

Sustainability considerations for innovations involving fluoroantimonic acid must address the entire lifecycle of the chemical, from production to disposal. Developing closed-loop systems for its use in chemical reactions can help mitigate environmental risks by reducing the need for fresh acid production and minimizing waste. Additionally, research into alternative catalysts or reaction pathways that achieve similar results with less hazardous materials could significantly improve the sustainability profile of related chemical processes.

The potential for accidental release and long-term environmental persistence of fluoroantimonic acid and its byproducts necessitates robust risk assessment and management strategies. This includes developing comprehensive emergency response plans, implementing advanced monitoring systems, and investing in remediation technologies for contaminated sites. Regulatory frameworks must also evolve to address the unique challenges posed by superacids in industrial applications.

Innovations in chemical reactions using fluoroantimonic acid should prioritize green chemistry principles, aiming to reduce the overall environmental footprint of processes. This may involve exploring ways to decrease the required acid concentration, improve reaction efficiency to minimize waste generation, or develop novel recycling techniques for spent acid. Additionally, research into bio-based or renewable precursors for superacid synthesis could contribute to a more sustainable supply chain.

Ultimately, the environmental and sustainability considerations surrounding fluoroantimonic acid underscore the need for a holistic approach to innovation in this field. Balancing the potential benefits of enhanced chemical reactions against the environmental risks requires ongoing collaboration between chemists, environmental scientists, and sustainability experts. As research progresses, it is crucial to continuously reassess and improve the ecological impact of fluoroantimonic acid applications, ensuring that technological advancements do not come at the cost of environmental degradation.

The environmental impact of fluoroantimonic acid extends beyond its direct effects. Its synthesis involves the use of hydrofluoric acid and antimony pentafluoride, both of which have their own environmental implications. The production process generates hazardous waste and emissions that must be carefully managed to minimize ecological damage. Furthermore, the energy-intensive nature of manufacturing and maintaining the necessary containment infrastructure contributes to increased carbon footprint and resource consumption.

Sustainability considerations for innovations involving fluoroantimonic acid must address the entire lifecycle of the chemical, from production to disposal. Developing closed-loop systems for its use in chemical reactions can help mitigate environmental risks by reducing the need for fresh acid production and minimizing waste. Additionally, research into alternative catalysts or reaction pathways that achieve similar results with less hazardous materials could significantly improve the sustainability profile of related chemical processes.

The potential for accidental release and long-term environmental persistence of fluoroantimonic acid and its byproducts necessitates robust risk assessment and management strategies. This includes developing comprehensive emergency response plans, implementing advanced monitoring systems, and investing in remediation technologies for contaminated sites. Regulatory frameworks must also evolve to address the unique challenges posed by superacids in industrial applications.

Innovations in chemical reactions using fluoroantimonic acid should prioritize green chemistry principles, aiming to reduce the overall environmental footprint of processes. This may involve exploring ways to decrease the required acid concentration, improve reaction efficiency to minimize waste generation, or develop novel recycling techniques for spent acid. Additionally, research into bio-based or renewable precursors for superacid synthesis could contribute to a more sustainable supply chain.

Ultimately, the environmental and sustainability considerations surrounding fluoroantimonic acid underscore the need for a holistic approach to innovation in this field. Balancing the potential benefits of enhanced chemical reactions against the environmental risks requires ongoing collaboration between chemists, environmental scientists, and sustainability experts. As research progresses, it is crucial to continuously reassess and improve the ecological impact of fluoroantimonic acid applications, ensuring that technological advancements do not come at the cost of environmental degradation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!