How to Apply Fluoroantimonic Acid in Innovative Synthesis?

JUN 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluoroantimonic Acid Background and Objectives

Fluoroantimonic acid, a superacid composed of a mixture of hydrogen fluoride (HF) and antimony pentafluoride (SbF5), has been a subject of intense scientific interest since its discovery in the 1960s. This compound holds the distinction of being the strongest known superacid, with an acidity level estimated to be over a quadrillion times stronger than pure sulfuric acid. Its extreme acidity is attributed to the formation of highly reactive protonated species in solution, which can protonate even very weak bases.

The development of fluoroantimonic acid marked a significant milestone in the field of acid chemistry and catalysis. Its unique properties have opened up new possibilities in organic synthesis and materials science. However, due to its extreme reactivity and corrosive nature, the practical applications of fluoroantimonic acid have been limited, primarily confined to specialized laboratory settings and industrial processes.

In recent years, there has been a growing interest in exploring innovative applications of fluoroantimonic acid in synthetic chemistry. The primary objective of this research is to harness the superacid's exceptional protonating ability to facilitate challenging chemical transformations that are difficult or impossible to achieve with conventional acid catalysts.

One of the key areas of focus is the activation of typically unreactive C-H bonds in hydrocarbons. Fluoroantimonic acid's ability to generate highly electrophilic species could potentially enable the functionalization of inert alkanes, opening up new pathways for the synthesis of complex organic molecules. Additionally, researchers are investigating its potential in promoting novel carbon-carbon bond formation reactions, which could lead to more efficient and atom-economical synthetic routes.

Another important objective is to develop safer and more controlled methods for handling and applying fluoroantimonic acid in synthesis. This includes exploring the use of supported or immobilized forms of the superacid, which could mitigate some of the handling challenges while retaining its exceptional reactivity. Researchers are also investigating the potential of ionic liquid systems incorporating fluoroantimonic acid, which could provide a more stable and easily manipulated reaction medium.

The application of fluoroantimonic acid in materials science is another area of growing interest. Its extreme acidity could potentially be utilized in the synthesis of novel polymers, nanostructured materials, and advanced ceramics. The ability to generate highly reactive intermediates under controlled conditions could lead to the development of materials with unique properties and applications.

As research in this field progresses, a key goal is to bridge the gap between the theoretical potential of fluoroantimonic acid and its practical applications in both academic and industrial settings. This involves not only expanding the scope of reactions where it can be effectively employed but also addressing the significant challenges associated with its use, including safety considerations, material compatibility, and scalability of processes.

The development of fluoroantimonic acid marked a significant milestone in the field of acid chemistry and catalysis. Its unique properties have opened up new possibilities in organic synthesis and materials science. However, due to its extreme reactivity and corrosive nature, the practical applications of fluoroantimonic acid have been limited, primarily confined to specialized laboratory settings and industrial processes.

In recent years, there has been a growing interest in exploring innovative applications of fluoroantimonic acid in synthetic chemistry. The primary objective of this research is to harness the superacid's exceptional protonating ability to facilitate challenging chemical transformations that are difficult or impossible to achieve with conventional acid catalysts.

One of the key areas of focus is the activation of typically unreactive C-H bonds in hydrocarbons. Fluoroantimonic acid's ability to generate highly electrophilic species could potentially enable the functionalization of inert alkanes, opening up new pathways for the synthesis of complex organic molecules. Additionally, researchers are investigating its potential in promoting novel carbon-carbon bond formation reactions, which could lead to more efficient and atom-economical synthetic routes.

Another important objective is to develop safer and more controlled methods for handling and applying fluoroantimonic acid in synthesis. This includes exploring the use of supported or immobilized forms of the superacid, which could mitigate some of the handling challenges while retaining its exceptional reactivity. Researchers are also investigating the potential of ionic liquid systems incorporating fluoroantimonic acid, which could provide a more stable and easily manipulated reaction medium.

The application of fluoroantimonic acid in materials science is another area of growing interest. Its extreme acidity could potentially be utilized in the synthesis of novel polymers, nanostructured materials, and advanced ceramics. The ability to generate highly reactive intermediates under controlled conditions could lead to the development of materials with unique properties and applications.

As research in this field progresses, a key goal is to bridge the gap between the theoretical potential of fluoroantimonic acid and its practical applications in both academic and industrial settings. This involves not only expanding the scope of reactions where it can be effectively employed but also addressing the significant challenges associated with its use, including safety considerations, material compatibility, and scalability of processes.

Market Analysis for Superacid Applications

The market for superacid applications, particularly those involving fluoroantimonic acid, has shown significant growth potential in recent years. This powerful superacid, known for its extreme acidity and reactivity, has found increasing use in various industrial and research applications. The global superacid market, which includes fluoroantimonic acid, is driven by the growing demand for efficient catalysts in petrochemical processes and the need for advanced materials in electronics manufacturing.

In the petrochemical industry, fluoroantimonic acid has emerged as a valuable catalyst for alkylation reactions, isomerization processes, and the production of high-octane gasoline components. This sector represents a substantial portion of the superacid market, with refineries continuously seeking ways to improve fuel quality and production efficiency. The automotive industry's push for cleaner, more efficient fuels has further bolstered the demand for superacid catalysts in this sector.

The electronics industry has also become a significant consumer of fluoroantimonic acid, particularly in the production of semiconductors and advanced materials. As the demand for smaller, more powerful electronic devices continues to grow, the need for superacids in etching and cleaning processes has increased correspondingly. This trend is expected to continue as the Internet of Things (IoT) and 5G technologies drive further innovation in electronics manufacturing.

Research and development in materials science and organic synthesis represent another key market segment for fluoroantimonic acid. Its unique properties make it an invaluable tool for exploring new chemical reactions and developing novel compounds. Academic institutions and pharmaceutical companies are increasingly utilizing superacids in their research efforts, contributing to market growth.

Despite its potential, the market for fluoroantimonic acid faces challenges related to handling and safety concerns. The extreme reactivity of this superacid necessitates specialized equipment and stringent safety protocols, which can limit its adoption in some industries. However, ongoing research into safer handling methods and the development of more stable superacid formulations are expected to address these concerns and expand market opportunities.

Geographically, North America and Europe currently lead the superacid market, with established petrochemical and electronics industries driving demand. However, the Asia-Pacific region is expected to show the highest growth rate in the coming years, fueled by rapid industrialization and increasing investments in research and development.

In the petrochemical industry, fluoroantimonic acid has emerged as a valuable catalyst for alkylation reactions, isomerization processes, and the production of high-octane gasoline components. This sector represents a substantial portion of the superacid market, with refineries continuously seeking ways to improve fuel quality and production efficiency. The automotive industry's push for cleaner, more efficient fuels has further bolstered the demand for superacid catalysts in this sector.

The electronics industry has also become a significant consumer of fluoroantimonic acid, particularly in the production of semiconductors and advanced materials. As the demand for smaller, more powerful electronic devices continues to grow, the need for superacids in etching and cleaning processes has increased correspondingly. This trend is expected to continue as the Internet of Things (IoT) and 5G technologies drive further innovation in electronics manufacturing.

Research and development in materials science and organic synthesis represent another key market segment for fluoroantimonic acid. Its unique properties make it an invaluable tool for exploring new chemical reactions and developing novel compounds. Academic institutions and pharmaceutical companies are increasingly utilizing superacids in their research efforts, contributing to market growth.

Despite its potential, the market for fluoroantimonic acid faces challenges related to handling and safety concerns. The extreme reactivity of this superacid necessitates specialized equipment and stringent safety protocols, which can limit its adoption in some industries. However, ongoing research into safer handling methods and the development of more stable superacid formulations are expected to address these concerns and expand market opportunities.

Geographically, North America and Europe currently lead the superacid market, with established petrochemical and electronics industries driving demand. However, the Asia-Pacific region is expected to show the highest growth rate in the coming years, fueled by rapid industrialization and increasing investments in research and development.

Current Challenges in Fluoroantimonic Acid Synthesis

The synthesis and application of fluoroantimonic acid present several significant challenges that researchers and industry professionals must overcome. One of the primary obstacles is the extreme reactivity and corrosiveness of this superacid, which makes handling and storage exceptionally difficult. Conventional materials used in laboratory equipment and industrial processes are often inadequate to withstand the aggressive nature of fluoroantimonic acid, necessitating the development of specialized containment systems and handling protocols.

Another major challenge lies in controlling the reaction conditions during synthesis. Fluoroantimonic acid is typically produced by combining hydrogen fluoride with antimony pentafluoride, a process that requires precise temperature and pressure control. Even slight deviations can lead to undesired side reactions or compromised product quality. Maintaining consistent production parameters at scale remains a significant hurdle for industrial applications.

The high toxicity of fluoroantimonic acid and its precursors poses substantial safety risks to personnel involved in its synthesis and use. Stringent safety measures and advanced protective equipment are essential, but these requirements often limit the accessibility of the acid for research and industrial purposes. Developing safer synthesis methods or finding less hazardous alternatives with similar superacidic properties is an ongoing area of research.

Environmental concerns also present challenges in fluoroantimonic acid synthesis. The production process and potential accidental releases can have severe environmental impacts, necessitating robust containment and disposal protocols. Regulatory compliance and waste management are critical aspects that must be addressed to ensure sustainable production and use of this superacid.

The limited stability of fluoroantimonic acid under ambient conditions further complicates its application in innovative synthesis. The acid rapidly decomposes when exposed to moisture or heat, making long-term storage and transportation problematic. This instability restricts its use in many potential applications and necessitates on-site production or specialized storage solutions.

Scaling up the synthesis of fluoroantimonic acid from laboratory to industrial quantities presents additional challenges. The highly exothermic nature of the reaction and the need for anhydrous conditions make large-scale production complex and potentially dangerous. Developing safe and efficient industrial-scale synthesis methods remains a significant obstacle to wider adoption of fluoroantimonic acid in innovative chemical processes.

Lastly, the high cost associated with the synthesis of fluoroantimonic acid, primarily due to the expensive precursors and specialized equipment required, limits its widespread use in research and industry. Finding more cost-effective synthesis routes or identifying alternative superacids with similar properties but lower production costs is crucial for expanding the application of these powerful catalysts in innovative synthesis.

Another major challenge lies in controlling the reaction conditions during synthesis. Fluoroantimonic acid is typically produced by combining hydrogen fluoride with antimony pentafluoride, a process that requires precise temperature and pressure control. Even slight deviations can lead to undesired side reactions or compromised product quality. Maintaining consistent production parameters at scale remains a significant hurdle for industrial applications.

The high toxicity of fluoroantimonic acid and its precursors poses substantial safety risks to personnel involved in its synthesis and use. Stringent safety measures and advanced protective equipment are essential, but these requirements often limit the accessibility of the acid for research and industrial purposes. Developing safer synthesis methods or finding less hazardous alternatives with similar superacidic properties is an ongoing area of research.

Environmental concerns also present challenges in fluoroantimonic acid synthesis. The production process and potential accidental releases can have severe environmental impacts, necessitating robust containment and disposal protocols. Regulatory compliance and waste management are critical aspects that must be addressed to ensure sustainable production and use of this superacid.

The limited stability of fluoroantimonic acid under ambient conditions further complicates its application in innovative synthesis. The acid rapidly decomposes when exposed to moisture or heat, making long-term storage and transportation problematic. This instability restricts its use in many potential applications and necessitates on-site production or specialized storage solutions.

Scaling up the synthesis of fluoroantimonic acid from laboratory to industrial quantities presents additional challenges. The highly exothermic nature of the reaction and the need for anhydrous conditions make large-scale production complex and potentially dangerous. Developing safe and efficient industrial-scale synthesis methods remains a significant obstacle to wider adoption of fluoroantimonic acid in innovative chemical processes.

Lastly, the high cost associated with the synthesis of fluoroantimonic acid, primarily due to the expensive precursors and specialized equipment required, limits its widespread use in research and industry. Finding more cost-effective synthesis routes or identifying alternative superacids with similar properties but lower production costs is crucial for expanding the application of these powerful catalysts in innovative synthesis.

Existing Fluoroantimonic Acid Synthesis Methods

01 Synthesis and production of fluoroantimonic acid

Fluoroantimonic acid is synthesized through the reaction of hydrogen fluoride and antimony pentafluoride. The production process involves careful handling of highly reactive and corrosive materials under controlled conditions. Specialized equipment and safety measures are required due to the extreme acidity and reactivity of the compound.- Synthesis and production of fluoroantimonic acid: Fluoroantimonic acid is synthesized through the reaction of hydrogen fluoride and antimony pentafluoride. The production process involves careful handling of highly reactive and corrosive materials under controlled conditions. Various methods and apparatus have been developed to optimize the synthesis and ensure the purity of the final product.

- Applications in catalysis and organic synthesis: Fluoroantimonic acid is utilized as a powerful superacid catalyst in various organic synthesis reactions. It facilitates alkylation, isomerization, and polymerization processes. The acid's extreme acidity enables it to catalyze reactions that are difficult or impossible with conventional acid catalysts, making it valuable in the production of specialty chemicals and advanced materials.

- Use in materials science and surface treatments: Fluoroantimonic acid finds applications in materials science, particularly in surface treatments and modifications. It is used for etching and cleaning surfaces, especially in the semiconductor industry. The acid's strong protonating ability allows for the modification of various materials, enhancing their properties or preparing them for further processing.

- Safety and handling considerations: Due to its extreme corrosiveness and reactivity, special safety measures and handling procedures are required when working with fluoroantimonic acid. This includes the use of specialized containment materials, personal protective equipment, and strict protocols for storage, transport, and disposal. Proper training and safety systems are essential to prevent accidents and environmental contamination.

- Analytical and characterization methods: Various analytical techniques have been developed to characterize fluoroantimonic acid and its reactions. These methods include spectroscopic analyses, electrochemical measurements, and specialized titration procedures. Advanced characterization techniques are crucial for understanding the acid's behavior, determining its purity, and monitoring its performance in different applications.

02 Applications in organic synthesis and catalysis

Fluoroantimonic acid serves as a powerful superacid catalyst in various organic synthesis reactions. It is particularly useful in alkylation, isomerization, and polymerization processes. The extreme acidity of fluoroantimonic acid enables it to catalyze reactions that are difficult or impossible with conventional acids.Expand Specific Solutions03 Use in materials science and surface treatment

Fluoroantimonic acid finds applications in materials science for surface treatment and modification of various substrates. It can be used to etch or activate surfaces, create specialized coatings, or modify the properties of materials. The extreme reactivity of the acid allows for unique surface modifications that are challenging to achieve with other compounds.Expand Specific Solutions04 Safety considerations and handling procedures

Due to its extreme corrosiveness and reactivity, fluoroantimonic acid requires stringent safety measures and specialized handling procedures. This includes the use of specialized containment materials, personal protective equipment, and controlled environments. Proper disposal and neutralization methods are crucial to prevent environmental and safety hazards.Expand Specific Solutions05 Analytical and characterization techniques

Specialized analytical and characterization techniques are employed to study fluoroantimonic acid and its reactions. These may include spectroscopic methods, electrochemical analysis, and advanced computational modeling. The extreme nature of the compound necessitates adapted analytical approaches to accurately determine its properties and behavior in various chemical systems.Expand Specific Solutions

Key Players in Superacid Industry

The application of fluoroantimonic acid in innovative synthesis is an emerging field with significant potential. The market is in its early growth stage, characterized by increasing research and development activities. While the market size remains relatively small, it is expected to expand as new applications are discovered. The technology's maturity is still developing, with leading institutions like Central South University, Merck Sharp & Dohme Corp., and 3M Innovative Properties Co. driving advancements. Companies such as DAIKIN INDUSTRIES Ltd. and DuPont de Nemours, Inc. are also contributing to the field's progress. Academic institutions, including Oxford University and Yale University, are playing crucial roles in fundamental research, while industrial players focus on practical applications and commercialization opportunities.

Merck Sharp & Dohme Corp.

Technical Solution: Merck Sharp & Dohme Corp. has developed a novel approach to applying fluoroantimonic acid in innovative synthesis. Their method involves using a specially designed reactor system that can handle the extreme corrosiveness of fluoroantimonic acid. The process incorporates a unique containment system made of fluoropolymer materials resistant to the acid's reactivity. This allows for controlled reactions under precisely monitored conditions, enabling the synthesis of complex organic compounds that were previously challenging or impossible to produce. The company has also developed a proprietary neutralization and waste handling protocol to ensure safe disposal of reaction byproducts.

Strengths: Enables synthesis of previously inaccessible compounds, highly controlled reaction environment. Weaknesses: Expensive setup, strict safety protocols required, limited scalability.

3M Innovative Properties Co.

Technical Solution: 3M Innovative Properties Co. has pioneered a microfluidic platform for fluoroantimonic acid-based synthesis. Their technology utilizes a series of microscale channels and reaction chambers fabricated from acid-resistant materials. This system allows for precise control of reaction parameters such as temperature, pressure, and reactant ratios. The microfluidic approach enables rapid mixing and heat transfer, leading to more efficient and selective reactions. 3M has also developed a suite of in-line analytical tools for real-time monitoring of reaction progress, allowing for optimization of reaction conditions on the fly.

Strengths: Excellent control over reaction parameters, efficient heat and mass transfer, potential for continuous flow processes. Weaknesses: Limited to small-scale synthesis, high initial investment costs.

Innovative Applications of Fluoroantimonic Acid

Method of fluorination by microwaves

PatentInactiveEP2189466A2

Innovation

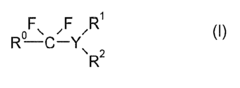

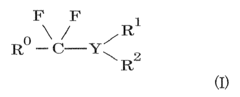

- A method involving fluorination of saccharides using specific fluorinating agents under thermal conditions or irradiation with microwave or electromagnetic waves, allowing for selective fluorination at specific positions within a wide temperature range, thereby overcoming the limitations of conventional methods.

Method for the production of [18f] fluoride-marked aromatic l-amino acids

PatentInactiveEP1663915A1

Innovation

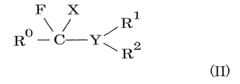

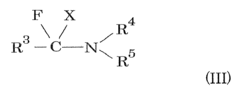

- A process involving nucleophilic substitution of a negatively charged [18F]fluoride ion with a suitable L-enantiomeric compound, followed by cleavage of protective groups, allowing for direct labeling and production of [18F]fluoro-L-phenylalanine derivatives in few steps, eliminating the need for enantiomer separation and achieving high stereochemical purity.

Safety and Handling Protocols

Fluoroantimonic acid, known as the world's strongest superacid, requires exceptionally stringent safety and handling protocols due to its extreme corrosiveness and reactivity. All operations involving this compound must be conducted in a specialized, inert atmosphere glovebox equipped with moisture and oxygen sensors. Personnel must wear full-body, chemical-resistant suits with self-contained breathing apparatus.

The acid must be stored in fluoropolymer containers, such as PTFE or PFA, as it reacts violently with glass and most metals. Double containment is essential, with the primary container placed within a secondary vessel to prevent accidental spills. Storage areas should be kept cool, dry, and well-ventilated, with strict access controls.

Handling procedures demand the use of specialized tools and equipment made from fluoropolymer materials. Transfer of the acid should be performed using gas-tight syringes or cannula techniques to minimize exposure. All reactions involving fluoroantimonic acid must be carried out in fluoropolymer-lined reactors or vessels designed to withstand extreme acidic conditions.

Neutralization and disposal of fluoroantimonic acid require careful planning and execution. The acid should never be disposed of directly into waste streams or sewers. Instead, it must be gradually neutralized using a cold, dilute solution of sodium or potassium hydroxide in a fluoropolymer vessel. The resulting mixture should then be treated as hazardous waste and disposed of according to local regulations.

Emergency response protocols must be established and regularly practiced. This includes having readily accessible eyewash stations, safety showers, and spill containment kits specifically designed for superacids. A detailed spill response plan should outline procedures for containment, neutralization, and proper disposal of any accidental releases.

Regular safety training and refresher courses are mandatory for all personnel working with or around fluoroantimonic acid. This training should cover proper handling techniques, personal protective equipment usage, emergency procedures, and the specific hazards associated with the compound. Strict adherence to these safety protocols is crucial to prevent potentially catastrophic incidents and ensure the safe application of fluoroantimonic acid in innovative synthesis processes.

The acid must be stored in fluoropolymer containers, such as PTFE or PFA, as it reacts violently with glass and most metals. Double containment is essential, with the primary container placed within a secondary vessel to prevent accidental spills. Storage areas should be kept cool, dry, and well-ventilated, with strict access controls.

Handling procedures demand the use of specialized tools and equipment made from fluoropolymer materials. Transfer of the acid should be performed using gas-tight syringes or cannula techniques to minimize exposure. All reactions involving fluoroantimonic acid must be carried out in fluoropolymer-lined reactors or vessels designed to withstand extreme acidic conditions.

Neutralization and disposal of fluoroantimonic acid require careful planning and execution. The acid should never be disposed of directly into waste streams or sewers. Instead, it must be gradually neutralized using a cold, dilute solution of sodium or potassium hydroxide in a fluoropolymer vessel. The resulting mixture should then be treated as hazardous waste and disposed of according to local regulations.

Emergency response protocols must be established and regularly practiced. This includes having readily accessible eyewash stations, safety showers, and spill containment kits specifically designed for superacids. A detailed spill response plan should outline procedures for containment, neutralization, and proper disposal of any accidental releases.

Regular safety training and refresher courses are mandatory for all personnel working with or around fluoroantimonic acid. This training should cover proper handling techniques, personal protective equipment usage, emergency procedures, and the specific hazards associated with the compound. Strict adherence to these safety protocols is crucial to prevent potentially catastrophic incidents and ensure the safe application of fluoroantimonic acid in innovative synthesis processes.

Environmental Impact Assessment

The application of fluoroantimonic acid in innovative synthesis processes raises significant environmental concerns due to its highly corrosive and reactive nature. This superacid, composed of a mixture of hydrogen fluoride and antimony pentafluoride, poses severe risks to ecosystems and human health if not properly managed.

Potential environmental impacts of fluoroantimonic acid usage include air pollution, water contamination, and soil degradation. The acid's volatile components can release toxic fumes, contributing to air quality deterioration and potentially harming local flora and fauna. Accidental spills or improper disposal may lead to water source contamination, affecting aquatic life and drinking water supplies. Soil exposed to fluoroantimonic acid can experience long-term pH changes, impacting soil fertility and microbial communities.

To mitigate these risks, stringent containment and handling protocols are essential. Advanced containment systems, such as specialized reaction vessels and storage tanks made of materials resistant to superacids, must be employed. Proper ventilation systems with scrubbers are crucial to prevent the release of harmful vapors into the atmosphere. Wastewater treatment facilities equipped to neutralize and remove fluoride and antimony compounds are necessary to prevent water pollution.

Emergency response plans and personnel training are critical components of environmental risk management when working with fluoroantimonic acid. Rapid response protocols for spills and leaks, including neutralization procedures and containment strategies, must be in place. Regular environmental monitoring, including air quality assessments and water testing, should be conducted to detect any potential contamination early.

The lifecycle assessment of fluoroantimonic acid usage in synthesis processes must consider the environmental impact of its production, transportation, use, and disposal. Sustainable alternatives and process optimizations should be explored to minimize the quantity of acid required and reduce the overall environmental footprint of the synthesis operations.

Regulatory compliance is another crucial aspect of environmental impact assessment. Adherence to local, national, and international environmental regulations governing the use of hazardous substances is mandatory. This includes proper documentation, reporting, and obtaining necessary permits for handling and disposing of fluoroantimonic acid and its byproducts.

Research into greener alternatives and process improvements should be prioritized to reduce reliance on fluoroantimonic acid where possible. This may include exploring less hazardous catalysts, developing novel reaction pathways, or implementing closed-loop systems that minimize waste generation and maximize resource efficiency.

Potential environmental impacts of fluoroantimonic acid usage include air pollution, water contamination, and soil degradation. The acid's volatile components can release toxic fumes, contributing to air quality deterioration and potentially harming local flora and fauna. Accidental spills or improper disposal may lead to water source contamination, affecting aquatic life and drinking water supplies. Soil exposed to fluoroantimonic acid can experience long-term pH changes, impacting soil fertility and microbial communities.

To mitigate these risks, stringent containment and handling protocols are essential. Advanced containment systems, such as specialized reaction vessels and storage tanks made of materials resistant to superacids, must be employed. Proper ventilation systems with scrubbers are crucial to prevent the release of harmful vapors into the atmosphere. Wastewater treatment facilities equipped to neutralize and remove fluoride and antimony compounds are necessary to prevent water pollution.

Emergency response plans and personnel training are critical components of environmental risk management when working with fluoroantimonic acid. Rapid response protocols for spills and leaks, including neutralization procedures and containment strategies, must be in place. Regular environmental monitoring, including air quality assessments and water testing, should be conducted to detect any potential contamination early.

The lifecycle assessment of fluoroantimonic acid usage in synthesis processes must consider the environmental impact of its production, transportation, use, and disposal. Sustainable alternatives and process optimizations should be explored to minimize the quantity of acid required and reduce the overall environmental footprint of the synthesis operations.

Regulatory compliance is another crucial aspect of environmental impact assessment. Adherence to local, national, and international environmental regulations governing the use of hazardous substances is mandatory. This includes proper documentation, reporting, and obtaining necessary permits for handling and disposing of fluoroantimonic acid and its byproducts.

Research into greener alternatives and process improvements should be prioritized to reduce reliance on fluoroantimonic acid where possible. This may include exploring less hazardous catalysts, developing novel reaction pathways, or implementing closed-loop systems that minimize waste generation and maximize resource efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!