How to Maximize Chemical Process Efficiency with Fluoroantimonic Acid?

JUN 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluoroantimonic Acid Background and Objectives

Fluoroantimonic acid, a superacid composed of a mixture of hydrogen fluoride (HF) and antimony pentafluoride (SbF5), has emerged as a powerful catalyst in various chemical processes. Its exceptional acidity, surpassing that of 100% sulfuric acid by over a trillion times, has garnered significant attention in the field of chemical engineering and industrial applications.

The development of fluoroantimonic acid can be traced back to the mid-20th century when researchers began exploring superacids for their unique properties. Its discovery marked a significant milestone in acid chemistry, opening up new possibilities for catalysis and chemical transformations that were previously unattainable.

Over the years, the understanding of fluoroantimonic acid's structure and behavior has evolved. Its extreme acidity is attributed to the formation of hexafluoroantimonate (SbF6-) ions, which are exceptionally weak conjugate bases. This property allows fluoroantimonic acid to protonate even very weak bases, making it an invaluable tool in organic synthesis and petrochemical processes.

The primary objective in maximizing chemical process efficiency with fluoroantimonic acid is to harness its exceptional catalytic properties while addressing the challenges associated with its use. These challenges include its highly corrosive nature, sensitivity to moisture, and the need for specialized handling and containment systems.

Current research aims to optimize the application of fluoroantimonic acid in various industrial processes, particularly in the petrochemical industry for isomerization, alkylation, and cracking reactions. The goal is to develop more efficient and selective catalytic systems that can operate under milder conditions, reducing energy consumption and improving product yields.

Another key objective is to explore novel applications of fluoroantimonic acid in emerging fields such as materials science and nanotechnology. Its ability to generate highly reactive carbocations opens up possibilities for synthesizing new materials with unique properties.

As environmental concerns grow, there is also a focus on developing greener alternatives or modified versions of fluoroantimonic acid that maintain its catalytic efficiency while reducing its environmental impact. This includes research into recyclable catalyst systems and the use of ionic liquids as reaction media.

The future trajectory of fluoroantimonic acid research is likely to involve interdisciplinary approaches, combining insights from chemistry, materials science, and engineering to push the boundaries of its applications. Advancements in computational chemistry and modeling are expected to play a crucial role in predicting and optimizing reaction conditions, further enhancing the efficiency of processes involving this superacid.

The development of fluoroantimonic acid can be traced back to the mid-20th century when researchers began exploring superacids for their unique properties. Its discovery marked a significant milestone in acid chemistry, opening up new possibilities for catalysis and chemical transformations that were previously unattainable.

Over the years, the understanding of fluoroantimonic acid's structure and behavior has evolved. Its extreme acidity is attributed to the formation of hexafluoroantimonate (SbF6-) ions, which are exceptionally weak conjugate bases. This property allows fluoroantimonic acid to protonate even very weak bases, making it an invaluable tool in organic synthesis and petrochemical processes.

The primary objective in maximizing chemical process efficiency with fluoroantimonic acid is to harness its exceptional catalytic properties while addressing the challenges associated with its use. These challenges include its highly corrosive nature, sensitivity to moisture, and the need for specialized handling and containment systems.

Current research aims to optimize the application of fluoroantimonic acid in various industrial processes, particularly in the petrochemical industry for isomerization, alkylation, and cracking reactions. The goal is to develop more efficient and selective catalytic systems that can operate under milder conditions, reducing energy consumption and improving product yields.

Another key objective is to explore novel applications of fluoroantimonic acid in emerging fields such as materials science and nanotechnology. Its ability to generate highly reactive carbocations opens up possibilities for synthesizing new materials with unique properties.

As environmental concerns grow, there is also a focus on developing greener alternatives or modified versions of fluoroantimonic acid that maintain its catalytic efficiency while reducing its environmental impact. This includes research into recyclable catalyst systems and the use of ionic liquids as reaction media.

The future trajectory of fluoroantimonic acid research is likely to involve interdisciplinary approaches, combining insights from chemistry, materials science, and engineering to push the boundaries of its applications. Advancements in computational chemistry and modeling are expected to play a crucial role in predicting and optimizing reaction conditions, further enhancing the efficiency of processes involving this superacid.

Industrial Demand Analysis

The industrial demand for fluoroantimonic acid in chemical process efficiency optimization has been steadily growing across various sectors. This superacid, known for its extreme acidity and powerful catalytic properties, has found applications in petrochemical refining, pharmaceutical synthesis, and advanced materials production.

In the petrochemical industry, fluoroantimonic acid has shown significant potential in enhancing the efficiency of hydrocarbon cracking processes. Its ability to catalyze isomerization and alkylation reactions at lower temperatures than conventional acids has led to reduced energy consumption and improved yield in fuel production. This has sparked interest among major oil and gas companies seeking to optimize their refining operations and reduce operational costs.

The pharmaceutical sector has also recognized the value of fluoroantimonic acid in streamlining complex organic synthesis pathways. Its strong protonating ability enables certain reactions to proceed more rapidly and selectively, potentially reducing the number of steps in drug manufacturing processes. This efficiency gain is particularly attractive to pharmaceutical companies facing pressure to accelerate drug development timelines and reduce production costs.

In the field of advanced materials, fluoroantimonic acid has demonstrated promise in the synthesis of high-performance polymers and specialty chemicals. Its unique properties allow for the creation of materials with enhanced thermal stability, chemical resistance, and mechanical strength. Industries such as aerospace, electronics, and automotive manufacturing are exploring the use of these advanced materials to improve product performance and durability.

The demand for fluoroantimonic acid is also driven by the growing emphasis on green chemistry and sustainable manufacturing practices. While the acid itself is highly corrosive and requires careful handling, its ability to catalyze reactions under milder conditions can lead to overall process improvements that align with sustainability goals. This includes reduced energy consumption, decreased waste generation, and improved atom economy in chemical transformations.

However, the industrial adoption of fluoroantimonic acid faces challenges related to safety concerns and material compatibility issues. The extreme corrosiveness of the acid necessitates specialized handling equipment and stringent safety protocols, which can increase implementation costs. As a result, there is a growing market for innovative containment solutions and process engineering services that can enable the safe and efficient use of fluoroantimonic acid in industrial settings.

Despite these challenges, the potential benefits of fluoroantimonic acid in maximizing chemical process efficiency continue to drive research and development efforts. Companies are investing in pilot projects and collaborating with academic institutions to explore novel applications and overcome technical barriers. This ongoing innovation is expected to further expand the industrial demand for fluoroantimonic acid and related technologies in the coming years.

In the petrochemical industry, fluoroantimonic acid has shown significant potential in enhancing the efficiency of hydrocarbon cracking processes. Its ability to catalyze isomerization and alkylation reactions at lower temperatures than conventional acids has led to reduced energy consumption and improved yield in fuel production. This has sparked interest among major oil and gas companies seeking to optimize their refining operations and reduce operational costs.

The pharmaceutical sector has also recognized the value of fluoroantimonic acid in streamlining complex organic synthesis pathways. Its strong protonating ability enables certain reactions to proceed more rapidly and selectively, potentially reducing the number of steps in drug manufacturing processes. This efficiency gain is particularly attractive to pharmaceutical companies facing pressure to accelerate drug development timelines and reduce production costs.

In the field of advanced materials, fluoroantimonic acid has demonstrated promise in the synthesis of high-performance polymers and specialty chemicals. Its unique properties allow for the creation of materials with enhanced thermal stability, chemical resistance, and mechanical strength. Industries such as aerospace, electronics, and automotive manufacturing are exploring the use of these advanced materials to improve product performance and durability.

The demand for fluoroantimonic acid is also driven by the growing emphasis on green chemistry and sustainable manufacturing practices. While the acid itself is highly corrosive and requires careful handling, its ability to catalyze reactions under milder conditions can lead to overall process improvements that align with sustainability goals. This includes reduced energy consumption, decreased waste generation, and improved atom economy in chemical transformations.

However, the industrial adoption of fluoroantimonic acid faces challenges related to safety concerns and material compatibility issues. The extreme corrosiveness of the acid necessitates specialized handling equipment and stringent safety protocols, which can increase implementation costs. As a result, there is a growing market for innovative containment solutions and process engineering services that can enable the safe and efficient use of fluoroantimonic acid in industrial settings.

Despite these challenges, the potential benefits of fluoroantimonic acid in maximizing chemical process efficiency continue to drive research and development efforts. Companies are investing in pilot projects and collaborating with academic institutions to explore novel applications and overcome technical barriers. This ongoing innovation is expected to further expand the industrial demand for fluoroantimonic acid and related technologies in the coming years.

Technical Challenges and Limitations

The use of fluoroantimonic acid in chemical processes presents significant technical challenges and limitations due to its extreme reactivity and corrosive nature. One of the primary obstacles is the difficulty in handling and containing this superacid. Conventional materials used in chemical processing equipment, such as stainless steel and glass, are rapidly degraded by fluoroantimonic acid, necessitating the use of specialized materials like fluoropolymers or certain noble metals. This requirement for exotic materials significantly increases the cost and complexity of process equipment design and maintenance.

Another major challenge is the precise control of reaction conditions when using fluoroantimonic acid. The superacid's extreme acidity can lead to unintended side reactions or rapid decomposition of desired products, making it challenging to achieve high selectivity and yield in chemical processes. Maintaining the desired stoichiometry and preventing unwanted protonation reactions require sophisticated process control systems and careful optimization of reaction parameters.

Safety considerations pose substantial limitations on the large-scale use of fluoroantimonic acid. Its highly corrosive and toxic nature demands stringent safety protocols, specialized personal protective equipment, and advanced containment systems. These requirements can significantly increase operational costs and complexity, potentially limiting the economic viability of processes utilizing this superacid.

The environmental impact of fluoroantimonic acid usage is another critical limitation. The acid's extreme reactivity with water and organic compounds makes waste treatment and disposal particularly challenging. Specialized neutralization and disposal procedures are necessary to prevent environmental contamination, adding further complexity and cost to chemical processes employing this superacid.

Scale-up of processes involving fluoroantimonic acid from laboratory to industrial scale presents unique engineering challenges. The heat generation and potential for runaway reactions associated with its use require careful thermal management strategies. Additionally, the need for specialized materials and equipment at larger scales can lead to significant capital expenditures and extended development timelines.

Regulatory compliance and worker safety concerns further constrain the widespread adoption of fluoroantimonic acid in industrial processes. Stringent regulations governing the transport, storage, and use of such hazardous materials can impose significant administrative burdens and operational restrictions on facilities employing this superacid.

Despite these challenges, ongoing research aims to address these limitations through the development of novel containment materials, improved process control strategies, and alternative reaction pathways that harness the unique properties of fluoroantimonic acid while mitigating its inherent risks and drawbacks.

Another major challenge is the precise control of reaction conditions when using fluoroantimonic acid. The superacid's extreme acidity can lead to unintended side reactions or rapid decomposition of desired products, making it challenging to achieve high selectivity and yield in chemical processes. Maintaining the desired stoichiometry and preventing unwanted protonation reactions require sophisticated process control systems and careful optimization of reaction parameters.

Safety considerations pose substantial limitations on the large-scale use of fluoroantimonic acid. Its highly corrosive and toxic nature demands stringent safety protocols, specialized personal protective equipment, and advanced containment systems. These requirements can significantly increase operational costs and complexity, potentially limiting the economic viability of processes utilizing this superacid.

The environmental impact of fluoroantimonic acid usage is another critical limitation. The acid's extreme reactivity with water and organic compounds makes waste treatment and disposal particularly challenging. Specialized neutralization and disposal procedures are necessary to prevent environmental contamination, adding further complexity and cost to chemical processes employing this superacid.

Scale-up of processes involving fluoroantimonic acid from laboratory to industrial scale presents unique engineering challenges. The heat generation and potential for runaway reactions associated with its use require careful thermal management strategies. Additionally, the need for specialized materials and equipment at larger scales can lead to significant capital expenditures and extended development timelines.

Regulatory compliance and worker safety concerns further constrain the widespread adoption of fluoroantimonic acid in industrial processes. Stringent regulations governing the transport, storage, and use of such hazardous materials can impose significant administrative burdens and operational restrictions on facilities employing this superacid.

Despite these challenges, ongoing research aims to address these limitations through the development of novel containment materials, improved process control strategies, and alternative reaction pathways that harness the unique properties of fluoroantimonic acid while mitigating its inherent risks and drawbacks.

Current Efficiency Solutions

01 Catalytic applications of fluoroantimonic acid

Fluoroantimonic acid is utilized as a highly efficient catalyst in various chemical processes due to its strong acidity. It can catalyze reactions such as isomerization, alkylation, and polymerization, enhancing reaction rates and yields. The acid's efficiency stems from its ability to generate strong electrophiles and stabilize reactive intermediates.- Catalytic applications of fluoroantimonic acid: Fluoroantimonic acid is utilized as a highly efficient catalyst in various chemical processes due to its extreme acidity. It is particularly effective in promoting reactions such as isomerization, alkylation, and polymerization. The acid's strong catalytic properties allow for improved reaction rates and yields in industrial applications.

- Synthesis and preparation methods: Various methods have been developed for the synthesis and preparation of fluoroantimonic acid. These techniques focus on optimizing the production process to enhance the acid's efficiency and purity. Improved synthesis methods contribute to better quality and more cost-effective production of this powerful superacid.

- Applications in material processing: Fluoroantimonic acid finds applications in material processing, particularly in the treatment of surfaces and the modification of materials. Its high acidity and reactivity make it useful for etching, cleaning, and activating surfaces in various industries, including electronics and metallurgy.

- Safety and handling considerations: Due to its extreme corrosiveness and reactivity, special safety measures and handling procedures are necessary when working with fluoroantimonic acid. Research has been conducted to develop improved containment methods, protective equipment, and neutralization techniques to ensure safe usage in laboratory and industrial settings.

- Environmental impact and alternatives: Studies have been conducted on the environmental impact of fluoroantimonic acid and the development of more environmentally friendly alternatives. Research focuses on finding less hazardous substitutes that can provide similar levels of efficiency in various applications while minimizing ecological risks.

02 Synthesis and preparation methods

Efficient methods for synthesizing fluoroantimonic acid have been developed to improve its production and quality. These methods often involve the reaction of hydrogen fluoride with antimony pentafluoride under controlled conditions. Purification techniques and handling procedures are crucial due to the acid's extreme reactivity and corrosiveness.Expand Specific Solutions03 Applications in materials processing

Fluoroantimonic acid finds applications in materials processing, particularly in the etching and surface modification of various substrates. Its high acidity allows for efficient removal of oxide layers and other impurities, making it valuable in semiconductor manufacturing and nanotechnology. The acid's efficiency in these processes contributes to the production of high-quality materials and devices.Expand Specific Solutions04 Safety and handling considerations

Due to its extreme reactivity and corrosiveness, special safety measures and handling procedures are necessary when working with fluoroantimonic acid. This includes the use of specialized containment materials, personal protective equipment, and proper disposal methods. Efficient handling techniques have been developed to maximize the acid's utility while minimizing risks associated with its use.Expand Specific Solutions05 Environmental impact and alternatives

Research has been conducted on the environmental impact of fluoroantimonic acid and the development of more environmentally friendly alternatives. Efforts focus on finding compounds or processes that can match the efficiency of fluoroantimonic acid in various applications while reducing potential environmental hazards and improving sustainability.Expand Specific Solutions

Key Industry Players

The chemical process efficiency optimization using fluoroantimonic acid is in a nascent stage of development, with a growing market potential due to its super-acidic properties. The technology's maturity is still evolving, as evidenced by ongoing research at institutions like Central South University and Centre National de la Recherche Scientifique. Major players such as LANXESS Deutschland GmbH, DuPont de Nemours, Inc., and Air Products & Chemicals, Inc. are actively exploring applications, while companies like Solvay Specialty Polymers Italy SpA and 3M Innovative Properties Co. are focusing on innovative uses in materials science. The competitive landscape is diverse, with both academic institutions and industrial giants contributing to advancements in this field.

Bayer AG

Technical Solution: Bayer AG has developed a novel approach to maximize chemical process efficiency with fluoroantimonic acid. Their method involves using a specially designed reactor system that allows for precise control of reaction conditions. The system incorporates advanced materials resistant to the highly corrosive nature of fluoroantimonic acid, enabling longer operational times and reduced equipment degradation. Bayer's process also includes a sophisticated recycling mechanism that recovers and purifies the acid after each reaction cycle, significantly reducing waste and improving overall efficiency. Additionally, they have implemented a state-of-the-art monitoring system that uses real-time data analytics to optimize reaction parameters continuously.

Strengths: High efficiency, reduced waste, improved safety. Weaknesses: High initial investment, specialized equipment required.

DuPont de Nemours, Inc.

Technical Solution: DuPont has engineered an innovative process for maximizing efficiency when working with fluoroantimonic acid. Their approach centers on a proprietary catalyst system that enhances reaction rates while minimizing side products. The catalyst is designed to work synergistically with fluoroantimonic acid, allowing for milder reaction conditions and reduced energy consumption. DuPont's process also incorporates a novel heat exchange system that efficiently manages the exothermic nature of reactions involving fluoroantimonic acid, further improving overall process efficiency. The company has also developed specialized handling and storage solutions to ensure the safe and efficient use of this highly reactive acid throughout the entire production cycle.

Strengths: Enhanced reaction rates, energy efficiency, improved safety protocols. Weaknesses: Proprietary technology may limit widespread adoption, potential high costs.

Core Innovations in Process Optimization

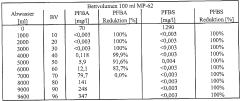

Treatment of waste water containing fluorinated acids or the salts thereof

PatentWO2011101342A1

Innovation

- The process involves using anion exchangers that are at least partially in the fluoride form, which are contacted with dilute aqueous solutions of fluorinated acids or their salts, allowing for effective binding and subsequent regeneration, with the anion exchanger being conditioned with hydrogen fluoride or fluoride anions to enhance selectivity and efficiency.

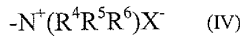

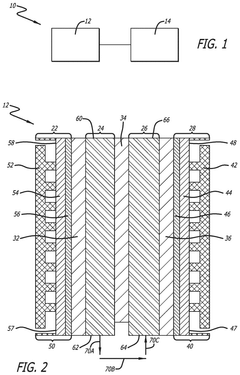

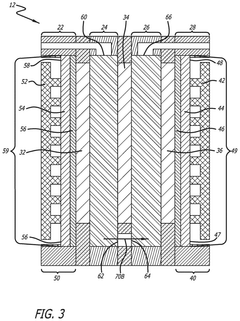

Methods and system for electrochemical production of formic acid from carbon dioxide

PatentPendingUS20250027208A1

Innovation

- The proposed electrochemical system incorporates a multi-compartment design with specific ion exchange membranes and a fluid flow path to separate and manage formate and hydronium ions effectively, enhancing faradaic efficiency by reducing formic acid crossover and maintaining optimal pH conditions.

Safety and Handling Protocols

Fluoroantimonic acid, being one of the strongest known superacids, requires exceptionally stringent safety and handling protocols to maximize chemical process efficiency while ensuring the protection of personnel and equipment. The primary consideration is the acid's extreme reactivity and corrosiveness, which necessitates specialized containment systems made of materials resistant to its effects, such as Teflon or fluorinated polymers.

Personal protective equipment (PPE) is crucial when working with fluoroantimonic acid. This includes fully encapsulating chemical-resistant suits, gloves, and boots made from compatible materials. Respiratory protection is mandatory, with self-contained breathing apparatus (SCBA) being the preferred choice due to the acid's ability to produce toxic fumes.

Proper ventilation systems are essential in any facility handling fluoroantimonic acid. These systems should be designed to rapidly remove and neutralize any vapors or fumes that may be generated during use or in case of accidental release. Emergency shower and eyewash stations must be readily accessible in all areas where the acid is handled or stored.

Storage protocols for fluoroantimonic acid are equally critical. The acid must be kept in tightly sealed, compatible containers in a cool, dry, and well-ventilated area. Due to its extreme reactivity with water, it should be stored away from any potential sources of moisture. Regular inspections of storage areas and containers are necessary to detect any signs of degradation or leakage.

Training is a fundamental aspect of safety protocols. All personnel involved in handling fluoroantimonic acid must undergo comprehensive training on its properties, hazards, and proper handling techniques. This training should be regularly updated and include practical exercises in emergency response procedures.

Spill response protocols must be well-established and rehearsed. This includes having appropriate neutralizing agents on hand, such as sodium bicarbonate or calcium carbonate, and specialized spill containment equipment. A detailed emergency response plan should be in place, outlining evacuation procedures and steps for containment and cleanup.

To maximize efficiency while maintaining safety, process design should incorporate principles of inherent safety. This may include minimizing the quantities of fluoroantimonic acid used, employing closed-loop systems to reduce exposure risks, and implementing robust process control systems to monitor and manage reaction conditions precisely.

Regular safety audits and risk assessments are essential to ensure that all protocols remain effective and up-to-date. These should include thorough reviews of handling procedures, equipment integrity, and emergency response readiness. Continuous improvement of safety measures based on these assessments is crucial for maintaining the highest standards of safety in chemical processes involving fluoroantimonic acid.

Personal protective equipment (PPE) is crucial when working with fluoroantimonic acid. This includes fully encapsulating chemical-resistant suits, gloves, and boots made from compatible materials. Respiratory protection is mandatory, with self-contained breathing apparatus (SCBA) being the preferred choice due to the acid's ability to produce toxic fumes.

Proper ventilation systems are essential in any facility handling fluoroantimonic acid. These systems should be designed to rapidly remove and neutralize any vapors or fumes that may be generated during use or in case of accidental release. Emergency shower and eyewash stations must be readily accessible in all areas where the acid is handled or stored.

Storage protocols for fluoroantimonic acid are equally critical. The acid must be kept in tightly sealed, compatible containers in a cool, dry, and well-ventilated area. Due to its extreme reactivity with water, it should be stored away from any potential sources of moisture. Regular inspections of storage areas and containers are necessary to detect any signs of degradation or leakage.

Training is a fundamental aspect of safety protocols. All personnel involved in handling fluoroantimonic acid must undergo comprehensive training on its properties, hazards, and proper handling techniques. This training should be regularly updated and include practical exercises in emergency response procedures.

Spill response protocols must be well-established and rehearsed. This includes having appropriate neutralizing agents on hand, such as sodium bicarbonate or calcium carbonate, and specialized spill containment equipment. A detailed emergency response plan should be in place, outlining evacuation procedures and steps for containment and cleanup.

To maximize efficiency while maintaining safety, process design should incorporate principles of inherent safety. This may include minimizing the quantities of fluoroantimonic acid used, employing closed-loop systems to reduce exposure risks, and implementing robust process control systems to monitor and manage reaction conditions precisely.

Regular safety audits and risk assessments are essential to ensure that all protocols remain effective and up-to-date. These should include thorough reviews of handling procedures, equipment integrity, and emergency response readiness. Continuous improvement of safety measures based on these assessments is crucial for maintaining the highest standards of safety in chemical processes involving fluoroantimonic acid.

Environmental Impact Assessment

The use of fluoroantimonic acid in chemical processes necessitates a comprehensive environmental impact assessment due to its highly corrosive and reactive nature. This superacid poses significant risks to ecosystems and human health if not properly managed. Its potential for environmental contamination is severe, as even small releases can cause extensive damage to soil, water bodies, and air quality.

In aquatic environments, fluoroantimonic acid can drastically alter pH levels, leading to the destruction of aquatic life and long-term ecological imbalances. The acid's ability to react violently with water makes it particularly hazardous near water sources. Soil contamination is another critical concern, as the acid can render large areas infertile and unsuitable for plant growth, potentially disrupting entire food chains.

Air pollution is a significant risk, especially during production and handling processes. The acid can release toxic fumes, including hydrogen fluoride and antimony compounds, which can cause severe respiratory issues and other health problems in both humans and animals. Long-term exposure to these emissions may lead to chronic health conditions in surrounding communities.

The production and disposal of fluoroantimonic acid also present environmental challenges. Manufacturing processes require stringent safety measures to prevent accidental releases, while disposal must adhere to strict protocols to avoid environmental contamination. The acid's extreme reactivity means that neutralization and treatment processes are complex and potentially hazardous in themselves.

Considering these factors, any industrial application of fluoroantimonic acid must implement robust containment systems, advanced air filtration technologies, and comprehensive emergency response plans. Regular environmental monitoring around production and usage sites is essential to detect and mitigate any potential leaks or emissions promptly.

The regulatory landscape surrounding fluoroantimonic acid use is increasingly stringent, with many jurisdictions imposing strict controls on its production, transport, and application. Companies must navigate complex compliance requirements, including detailed environmental impact studies, regular audits, and transparent reporting of safety measures and incident responses.

In conclusion, while fluoroantimonic acid offers significant potential for enhancing chemical process efficiency, its environmental impact cannot be overstated. Any implementation must carefully balance the benefits against the substantial environmental risks, with a focus on developing innovative safety technologies and sustainable practices to minimize its ecological footprint.

In aquatic environments, fluoroantimonic acid can drastically alter pH levels, leading to the destruction of aquatic life and long-term ecological imbalances. The acid's ability to react violently with water makes it particularly hazardous near water sources. Soil contamination is another critical concern, as the acid can render large areas infertile and unsuitable for plant growth, potentially disrupting entire food chains.

Air pollution is a significant risk, especially during production and handling processes. The acid can release toxic fumes, including hydrogen fluoride and antimony compounds, which can cause severe respiratory issues and other health problems in both humans and animals. Long-term exposure to these emissions may lead to chronic health conditions in surrounding communities.

The production and disposal of fluoroantimonic acid also present environmental challenges. Manufacturing processes require stringent safety measures to prevent accidental releases, while disposal must adhere to strict protocols to avoid environmental contamination. The acid's extreme reactivity means that neutralization and treatment processes are complex and potentially hazardous in themselves.

Considering these factors, any industrial application of fluoroantimonic acid must implement robust containment systems, advanced air filtration technologies, and comprehensive emergency response plans. Regular environmental monitoring around production and usage sites is essential to detect and mitigate any potential leaks or emissions promptly.

The regulatory landscape surrounding fluoroantimonic acid use is increasingly stringent, with many jurisdictions imposing strict controls on its production, transport, and application. Companies must navigate complex compliance requirements, including detailed environmental impact studies, regular audits, and transparent reporting of safety measures and incident responses.

In conclusion, while fluoroantimonic acid offers significant potential for enhancing chemical process efficiency, its environmental impact cannot be overstated. Any implementation must carefully balance the benefits against the substantial environmental risks, with a focus on developing innovative safety technologies and sustainable practices to minimize its ecological footprint.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!