Fluoroantimonic Acid in the Progression of Catalytic Methods

JUN 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluoroantimonic Acid Evolution and Objectives

Fluoroantimonic acid, often referred to as the world's strongest superacid, has played a pivotal role in the evolution of catalytic methods. Its discovery in the 1960s marked a significant milestone in the field of acid catalysis, opening up new possibilities for chemical transformations that were previously unattainable. The development of this superacid has been driven by the need for more efficient and selective catalytic processes in various industries, particularly in petrochemicals and fine chemical synthesis.

The journey of fluoroantimonic acid began with the pioneering work of George A. Olah, who explored the potential of superacids in organic chemistry. His research laid the foundation for understanding the unique properties of this compound, which is formed by combining hydrogen fluoride (HF) and antimony pentafluoride (SbF5). The resulting acid exhibits an astounding ability to protonate even extremely weak bases, making it an exceptionally powerful tool in catalysis.

Over the decades, the applications of fluoroantimonic acid have expanded significantly. Initially used primarily in academic research, it has gradually found its way into industrial processes. The acid's extreme acidity allows for the activation of C-H and C-C bonds under milder conditions than traditional methods, leading to more energy-efficient and environmentally friendly catalytic processes.

The objectives in the progression of catalytic methods involving fluoroantimonic acid are multifaceted. Researchers aim to harness its immense catalytic power while addressing the challenges associated with its use, such as its highly corrosive nature and sensitivity to moisture. One key goal is to develop more stable and easily handled forms of the acid, potentially through the creation of supported catalysts or ionic liquids incorporating its active components.

Another important objective is to expand the scope of reactions that can be catalyzed by fluoroantimonic acid. This includes exploring its potential in asymmetric catalysis, where the acid's strong Lewis acidity could be exploited to create highly enantioselective transformations. Additionally, there is ongoing research into using fluoroantimonic acid for the activation of small molecules like methane, which could have significant implications for the energy sector.

The future trajectory of fluoroantimonic acid in catalytic methods is likely to focus on enhancing its selectivity and developing more sustainable processes. This may involve combining the acid with other catalytic systems, such as enzymes or transition metal complexes, to create hybrid catalysts with unique reactivity profiles. Furthermore, there is a growing interest in understanding the fundamental mechanisms of fluoroantimonic acid catalysis at the molecular level, which could lead to the rational design of new superacid catalysts with tailored properties.

The journey of fluoroantimonic acid began with the pioneering work of George A. Olah, who explored the potential of superacids in organic chemistry. His research laid the foundation for understanding the unique properties of this compound, which is formed by combining hydrogen fluoride (HF) and antimony pentafluoride (SbF5). The resulting acid exhibits an astounding ability to protonate even extremely weak bases, making it an exceptionally powerful tool in catalysis.

Over the decades, the applications of fluoroantimonic acid have expanded significantly. Initially used primarily in academic research, it has gradually found its way into industrial processes. The acid's extreme acidity allows for the activation of C-H and C-C bonds under milder conditions than traditional methods, leading to more energy-efficient and environmentally friendly catalytic processes.

The objectives in the progression of catalytic methods involving fluoroantimonic acid are multifaceted. Researchers aim to harness its immense catalytic power while addressing the challenges associated with its use, such as its highly corrosive nature and sensitivity to moisture. One key goal is to develop more stable and easily handled forms of the acid, potentially through the creation of supported catalysts or ionic liquids incorporating its active components.

Another important objective is to expand the scope of reactions that can be catalyzed by fluoroantimonic acid. This includes exploring its potential in asymmetric catalysis, where the acid's strong Lewis acidity could be exploited to create highly enantioselective transformations. Additionally, there is ongoing research into using fluoroantimonic acid for the activation of small molecules like methane, which could have significant implications for the energy sector.

The future trajectory of fluoroantimonic acid in catalytic methods is likely to focus on enhancing its selectivity and developing more sustainable processes. This may involve combining the acid with other catalytic systems, such as enzymes or transition metal complexes, to create hybrid catalysts with unique reactivity profiles. Furthermore, there is a growing interest in understanding the fundamental mechanisms of fluoroantimonic acid catalysis at the molecular level, which could lead to the rational design of new superacid catalysts with tailored properties.

Industrial Demand Analysis

The industrial demand for fluoroantimonic acid in catalytic methods has been steadily increasing due to its exceptional strength as a superacid and its unique catalytic properties. This compound, often referred to as the world's strongest acid, has found significant applications in various sectors of the chemical industry, particularly in hydrocarbon processing and petrochemical production.

In the oil and gas industry, fluoroantimonic acid has shown remarkable potential in enhancing the efficiency of catalytic cracking processes. Its ability to promote isomerization and alkylation reactions has led to improved yields of high-octane gasoline components. This has resulted in a growing demand from refineries seeking to optimize their production processes and meet stringent fuel quality standards.

The pharmaceutical sector has also recognized the value of fluoroantimonic acid in catalytic methods. Its use in the synthesis of complex organic molecules, particularly in the production of certain active pharmaceutical ingredients (APIs), has opened new avenues for drug development. The acid's capacity to catalyze reactions under milder conditions and with higher selectivity has attracted significant interest from pharmaceutical companies looking to streamline their manufacturing processes.

In the field of polymer chemistry, fluoroantimonic acid has demonstrated promising applications in the production of specialty polymers. Its strong acidic properties enable the catalysis of polymerization reactions that were previously challenging or impossible with conventional acids. This has led to the development of novel materials with enhanced properties, driving demand from industries such as aerospace, automotive, and electronics.

The fine chemicals industry has also shown increasing interest in fluoroantimonic acid for its potential in catalyzing complex organic transformations. Its use in the synthesis of specialty chemicals, fragrances, and flavors has opened up new possibilities for product innovation and process optimization.

However, the industrial demand for fluoroantimonic acid is tempered by several factors. The extreme corrosiveness and reactivity of the acid pose significant handling and safety challenges, requiring specialized equipment and rigorous safety protocols. This has limited its widespread adoption, particularly in smaller-scale operations or facilities without advanced safety infrastructure.

Environmental concerns and regulatory pressures have also influenced the demand for fluoroantimonic acid. As industries face increasing scrutiny over their environmental impact, there is a growing push towards greener catalytic methods. This has led to research into alternative catalysts and processes that can achieve similar results with reduced environmental risks.

Despite these challenges, the unique capabilities of fluoroantimonic acid continue to drive its demand in specific high-value applications where its benefits outweigh the associated risks and costs. As research progresses and new applications emerge, the industrial demand for this powerful catalytic agent is expected to evolve, with potential growth in niche sectors balanced against the development of safer alternatives in more mainstream applications.

In the oil and gas industry, fluoroantimonic acid has shown remarkable potential in enhancing the efficiency of catalytic cracking processes. Its ability to promote isomerization and alkylation reactions has led to improved yields of high-octane gasoline components. This has resulted in a growing demand from refineries seeking to optimize their production processes and meet stringent fuel quality standards.

The pharmaceutical sector has also recognized the value of fluoroantimonic acid in catalytic methods. Its use in the synthesis of complex organic molecules, particularly in the production of certain active pharmaceutical ingredients (APIs), has opened new avenues for drug development. The acid's capacity to catalyze reactions under milder conditions and with higher selectivity has attracted significant interest from pharmaceutical companies looking to streamline their manufacturing processes.

In the field of polymer chemistry, fluoroantimonic acid has demonstrated promising applications in the production of specialty polymers. Its strong acidic properties enable the catalysis of polymerization reactions that were previously challenging or impossible with conventional acids. This has led to the development of novel materials with enhanced properties, driving demand from industries such as aerospace, automotive, and electronics.

The fine chemicals industry has also shown increasing interest in fluoroantimonic acid for its potential in catalyzing complex organic transformations. Its use in the synthesis of specialty chemicals, fragrances, and flavors has opened up new possibilities for product innovation and process optimization.

However, the industrial demand for fluoroantimonic acid is tempered by several factors. The extreme corrosiveness and reactivity of the acid pose significant handling and safety challenges, requiring specialized equipment and rigorous safety protocols. This has limited its widespread adoption, particularly in smaller-scale operations or facilities without advanced safety infrastructure.

Environmental concerns and regulatory pressures have also influenced the demand for fluoroantimonic acid. As industries face increasing scrutiny over their environmental impact, there is a growing push towards greener catalytic methods. This has led to research into alternative catalysts and processes that can achieve similar results with reduced environmental risks.

Despite these challenges, the unique capabilities of fluoroantimonic acid continue to drive its demand in specific high-value applications where its benefits outweigh the associated risks and costs. As research progresses and new applications emerge, the industrial demand for this powerful catalytic agent is expected to evolve, with potential growth in niche sectors balanced against the development of safer alternatives in more mainstream applications.

Technical Challenges and Limitations

Fluoroantimonic acid, despite its potential as a powerful catalyst in various chemical processes, faces several significant technical challenges and limitations that hinder its widespread adoption in industrial applications. One of the primary obstacles is its extreme corrosiveness and reactivity. This superacid is so potent that it can react with almost any substance, including glass and many metals, making containment and handling extremely difficult and dangerous. Specialized equipment made from materials like Teflon or certain alloys is required, significantly increasing operational costs and complexity.

The high reactivity of fluoroantimonic acid also poses challenges in terms of selectivity and control in catalytic reactions. While its strong acidity can accelerate many reactions, it may also lead to unwanted side reactions or over-reactions, potentially reducing yield and product purity. This lack of selectivity limits its applicability in fine chemical synthesis and other processes where precise control over reaction pathways is crucial.

Another significant limitation is the environmental and safety concerns associated with fluoroantimonic acid. Its production, handling, and disposal require stringent safety measures and specialized facilities. The acid's extreme toxicity and potential for generating harmful fumes pose serious risks to human health and the environment. These factors contribute to high operational costs and regulatory hurdles, making it less attractive for large-scale industrial use.

The stability of fluoroantimonic acid under various reaction conditions is another technical challenge. The acid can decompose or lose its catalytic activity under certain temperatures or in the presence of specific compounds. This instability can lead to inconsistent performance in catalytic processes and may require frequent regeneration or replacement of the catalyst, impacting process efficiency and economics.

Furthermore, the scalability of processes involving fluoroantimonic acid remains a significant hurdle. While it may show promising results in laboratory-scale experiments, translating these to industrial-scale operations presents numerous engineering and safety challenges. The need for specialized equipment, stringent safety protocols, and complex waste management systems makes scaling up fluoroantimonic acid-based processes technically demanding and economically challenging.

Lastly, the limited availability and high cost of fluoroantimonic acid and its precursors pose additional constraints. The production of this superacid requires specialized facilities and involves hazardous materials, contributing to its high cost. This economic factor, combined with the technical challenges, often makes alternative catalysts or processes more attractive for industrial applications, despite the potential advantages of fluoroantimonic acid in terms of reaction rates and efficiency.

The high reactivity of fluoroantimonic acid also poses challenges in terms of selectivity and control in catalytic reactions. While its strong acidity can accelerate many reactions, it may also lead to unwanted side reactions or over-reactions, potentially reducing yield and product purity. This lack of selectivity limits its applicability in fine chemical synthesis and other processes where precise control over reaction pathways is crucial.

Another significant limitation is the environmental and safety concerns associated with fluoroantimonic acid. Its production, handling, and disposal require stringent safety measures and specialized facilities. The acid's extreme toxicity and potential for generating harmful fumes pose serious risks to human health and the environment. These factors contribute to high operational costs and regulatory hurdles, making it less attractive for large-scale industrial use.

The stability of fluoroantimonic acid under various reaction conditions is another technical challenge. The acid can decompose or lose its catalytic activity under certain temperatures or in the presence of specific compounds. This instability can lead to inconsistent performance in catalytic processes and may require frequent regeneration or replacement of the catalyst, impacting process efficiency and economics.

Furthermore, the scalability of processes involving fluoroantimonic acid remains a significant hurdle. While it may show promising results in laboratory-scale experiments, translating these to industrial-scale operations presents numerous engineering and safety challenges. The need for specialized equipment, stringent safety protocols, and complex waste management systems makes scaling up fluoroantimonic acid-based processes technically demanding and economically challenging.

Lastly, the limited availability and high cost of fluoroantimonic acid and its precursors pose additional constraints. The production of this superacid requires specialized facilities and involves hazardous materials, contributing to its high cost. This economic factor, combined with the technical challenges, often makes alternative catalysts or processes more attractive for industrial applications, despite the potential advantages of fluoroantimonic acid in terms of reaction rates and efficiency.

Current Catalytic Solutions

01 Synthesis and production of fluoroantimonic acid

Fluoroantimonic acid is synthesized through the reaction of hydrogen fluoride and antimony pentafluoride. The production process involves careful handling of highly reactive and corrosive materials under controlled conditions. Various methods and apparatus have been developed to optimize the synthesis and ensure the purity of the final product.- Synthesis and production of fluoroantimonic acid: Fluoroantimonic acid is synthesized by combining hydrogen fluoride and antimony pentafluoride. The production process involves careful handling of highly reactive and corrosive materials under controlled conditions. Various methods and apparatus have been developed to optimize the synthesis and ensure the purity of the final product.

- Applications in chemical reactions and catalysis: Fluoroantimonic acid is utilized as a powerful superacid catalyst in various chemical reactions. It is particularly effective in promoting alkylation, isomerization, and polymerization processes. The acid's extreme acidity enables it to catalyze reactions that are difficult or impossible with conventional acids.

- Use in materials science and surface treatment: Fluoroantimonic acid finds applications in materials science, particularly in surface treatment and modification of various substrates. It can be used to etch or activate surfaces, create specialized coatings, or modify the properties of materials such as polymers and ceramics.

- Safety and handling considerations: Due to its extreme reactivity and corrosiveness, fluoroantimonic acid requires specialized handling and storage procedures. Safety measures include the use of appropriate containment materials, personal protective equipment, and controlled environments. Proper disposal methods are crucial to prevent environmental contamination.

- Analytical and characterization techniques: Various analytical and characterization techniques have been developed to study fluoroantimonic acid and its reactions. These include spectroscopic methods, electrochemical analysis, and specialized equipment designed to handle highly acidic and reactive substances. Such techniques are essential for understanding the acid's properties and behavior in different applications.

02 Applications in organic synthesis and catalysis

Fluoroantimonic acid is utilized as a powerful superacid catalyst in various organic synthesis reactions. It facilitates alkylation, isomerization, and polymerization processes. The acid's extreme acidity enables it to catalyze reactions that are difficult or impossible with conventional acids, making it valuable in the production of specialty chemicals and advanced materials.Expand Specific Solutions03 Use in materials science and surface treatment

Fluoroantimonic acid finds applications in materials science, particularly in surface treatment and modification of various substrates. It can be used to etch or activate surfaces, enhance adhesion properties, and create specialized coatings. The acid's unique properties allow for the development of advanced materials with improved characteristics.Expand Specific Solutions04 Safety and handling considerations

Due to its extreme corrosiveness and reactivity, fluoroantimonic acid requires specialized handling and storage procedures. Safety measures include the use of appropriate containment materials, personal protective equipment, and controlled environments. Proper disposal methods and emergency response protocols are essential when working with this highly hazardous substance.Expand Specific Solutions05 Analytical and characterization techniques

Various analytical and characterization techniques have been developed to study fluoroantimonic acid and its reactions. These methods include spectroscopic analysis, electrochemical measurements, and specialized apparatus for handling and analyzing superacidic systems. Such techniques are crucial for understanding the acid's properties and optimizing its applications in research and industry.Expand Specific Solutions

Key Industry Players

The development of fluoroantimonic acid in catalytic methods is in a mature stage, with ongoing research and industrial applications. The market size for this technology is significant, driven by its potential in various chemical processes. Technologically, it has reached a high level of maturity, with companies like BASF Corp., Honeywell International Technologies Ltd., and China Petroleum & Chemical Corp. leading the field. These industry giants, along with research institutions such as Centre National de la Recherche Scientifique and The Regents of the University of California, are pushing the boundaries of fluoroantimonic acid applications. The competitive landscape is characterized by a mix of established chemical companies and innovative research centers, indicating a balance between commercial exploitation and fundamental scientific advancement in this area.

BASF Corp.

Technical Solution: BASF has developed a novel catalytic system utilizing fluoroantimonic acid as a super-acid catalyst for various organic transformations. Their approach involves the use of stabilized fluoroantimonic acid complexes, which allow for controlled reactivity in industrial-scale processes. This technology enables highly efficient and selective catalysis for reactions such as alkylation, isomerization, and polymerization under milder conditions compared to traditional acid catalysts.

Strengths: Exceptional catalytic activity, improved selectivity, and reduced energy consumption. Weaknesses: High cost of fluoroantimonic acid, potential corrosion issues, and strict handling requirements due to its extreme reactivity.

Centre National de la Recherche Scientifique

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has made significant advancements in the fundamental understanding and application of fluoroantimonic acid in catalytic processes. Their research has focused on elucidating the mechanistic details of fluoroantimonic acid-catalyzed reactions and developing new methodologies for organic synthesis. CNRS scientists have successfully demonstrated the use of fluoroantimonic acid in novel C-C bond forming reactions and the activation of typically unreactive substrates, opening new avenues for synthetic chemistry.

Strengths: Cutting-edge fundamental research, potential for breakthrough discoveries, and development of new synthetic methodologies. Weaknesses: Challenges in translating academic research to industrial applications and potential safety concerns in laboratory settings.

Core Innovations in Fluoroantimonic Acid Catalysis

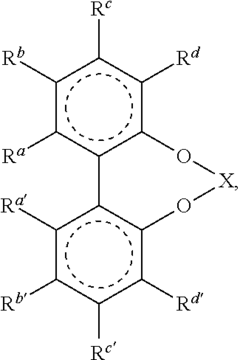

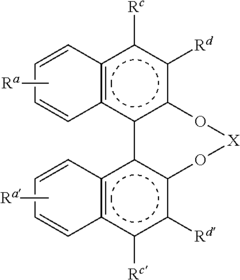

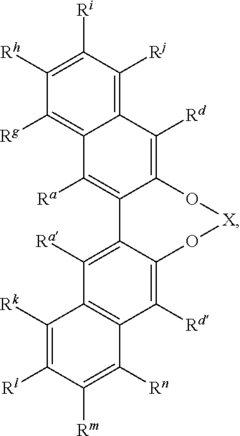

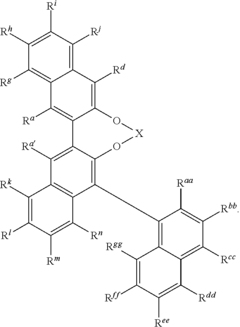

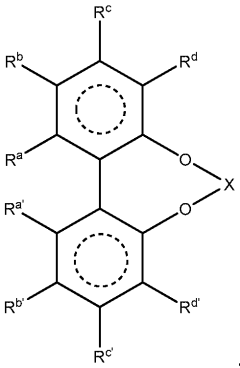

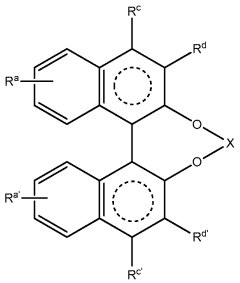

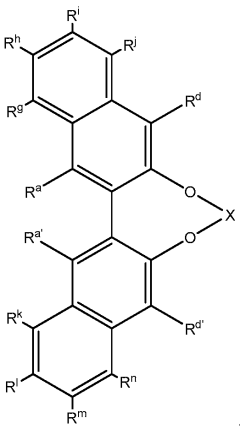

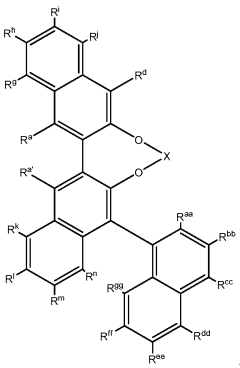

Asymmetric electrophilic fluorination using an anionic chiral phase-transfer catalyst

PatentActiveUS20140350253A1

Innovation

- Development of chiral anion phase-transfer catalysts that facilitate electrophilic addition reactions, allowing for enantioselective fluorination using stable and inexpensive reagents, and enabling the formation of fluorinated compounds that can be further functionalized.

Asymmetric electrophilic fluorination using an anionic chiral phase-transfer catalyst

PatentWO2013096971A1

Innovation

- Development of chiral anionic phase-transfer catalysts that facilitate enantioselective electrophilic addition reactions by forming soluble ion pairs with insoluble cationic electrophilic reagents, enabling efficient and enantiocontrolled C-F bond formation through electrophilic addition reactions.

Safety and Handling Protocols

Fluoroantimonic acid, being one of the strongest known superacids, requires exceptionally stringent safety and handling protocols. The extreme corrosiveness and reactivity of this compound necessitate specialized equipment and highly trained personnel for its manipulation. All operations involving fluoroantimonic acid must be conducted in a dedicated, well-ventilated fume hood equipped with acid-resistant materials and emergency safety systems.

Personal protective equipment (PPE) is crucial when working with fluoroantimonic acid. Operators must wear fully encapsulating chemical-resistant suits, including acid-resistant gloves, boots, and face shields. Respiratory protection with supplied air or self-contained breathing apparatus (SCBA) is mandatory due to the potential for toxic fume generation.

Storage of fluoroantimonic acid demands specialized containers made of materials resistant to both hydrofluoric acid and antimony pentafluoride, such as polytetrafluoroethylene (PTFE) or certain fluoropolymers. These containers must be kept in a cool, dry, and well-ventilated area, away from incompatible materials and sources of heat or ignition. Regular inspections of storage facilities and containers are essential to detect any signs of degradation or leakage.

Transportation of fluoroantimonic acid requires compliance with strict regulations for hazardous materials. It must be packaged in UN-approved containers with appropriate labeling and documentation. Only authorized personnel should handle the transport, and emergency response plans must be in place along the entire transportation route.

Disposal of fluoroantimonic acid and related waste materials presents significant challenges. Neutralization processes must be carefully controlled and conducted by experts in specialized facilities. The resulting waste must be treated as hazardous and disposed of according to local, state, and federal regulations.

Emergency response procedures for spills or exposures to fluoroantimonic acid must be well-established and regularly practiced. This includes immediate evacuation protocols, containment strategies, and decontamination procedures. Specialized spill kits designed for superacids should be readily available in all areas where the acid is used or stored.

Training programs for personnel working with fluoroantimonic acid should be comprehensive and ongoing. These programs must cover proper handling techniques, emergency procedures, and the use of all relevant safety equipment. Regular refresher courses and safety drills are essential to maintain a high level of preparedness and competence among staff.

Given the extreme hazards associated with fluoroantimonic acid, its use in catalytic methods requires a thorough risk assessment and the implementation of rigorous safety protocols. The potential benefits of its application must be carefully weighed against the inherent risks and the resources required for safe handling and management.

Personal protective equipment (PPE) is crucial when working with fluoroantimonic acid. Operators must wear fully encapsulating chemical-resistant suits, including acid-resistant gloves, boots, and face shields. Respiratory protection with supplied air or self-contained breathing apparatus (SCBA) is mandatory due to the potential for toxic fume generation.

Storage of fluoroantimonic acid demands specialized containers made of materials resistant to both hydrofluoric acid and antimony pentafluoride, such as polytetrafluoroethylene (PTFE) or certain fluoropolymers. These containers must be kept in a cool, dry, and well-ventilated area, away from incompatible materials and sources of heat or ignition. Regular inspections of storage facilities and containers are essential to detect any signs of degradation or leakage.

Transportation of fluoroantimonic acid requires compliance with strict regulations for hazardous materials. It must be packaged in UN-approved containers with appropriate labeling and documentation. Only authorized personnel should handle the transport, and emergency response plans must be in place along the entire transportation route.

Disposal of fluoroantimonic acid and related waste materials presents significant challenges. Neutralization processes must be carefully controlled and conducted by experts in specialized facilities. The resulting waste must be treated as hazardous and disposed of according to local, state, and federal regulations.

Emergency response procedures for spills or exposures to fluoroantimonic acid must be well-established and regularly practiced. This includes immediate evacuation protocols, containment strategies, and decontamination procedures. Specialized spill kits designed for superacids should be readily available in all areas where the acid is used or stored.

Training programs for personnel working with fluoroantimonic acid should be comprehensive and ongoing. These programs must cover proper handling techniques, emergency procedures, and the use of all relevant safety equipment. Regular refresher courses and safety drills are essential to maintain a high level of preparedness and competence among staff.

Given the extreme hazards associated with fluoroantimonic acid, its use in catalytic methods requires a thorough risk assessment and the implementation of rigorous safety protocols. The potential benefits of its application must be carefully weighed against the inherent risks and the resources required for safe handling and management.

Environmental Impact Assessment

The use of fluoroantimonic acid in catalytic methods raises significant environmental concerns due to its highly corrosive and reactive nature. This superacid, composed of a mixture of hydrogen fluoride and antimony pentafluoride, poses severe risks to ecosystems and human health if not properly managed. Its extreme acidity can cause rapid degradation of organic matter, potentially leading to soil and water contamination if released into the environment.

The production and handling of fluoroantimonic acid require stringent safety measures to prevent accidental releases. Even small spills can result in the emission of toxic fumes, particularly hydrogen fluoride, which can cause severe respiratory issues and long-term health effects in exposed populations. The acid's ability to react violently with water further complicates containment and cleanup efforts in case of environmental contamination.

In aquatic ecosystems, the introduction of fluoroantimonic acid could lead to drastic pH changes, potentially causing mass die-offs of fish and other aquatic organisms. The acid's fluoride component may also contribute to the bioaccumulation of fluoride in aquatic food chains, affecting organisms at various trophic levels. Terrestrial ecosystems are equally at risk, with potential impacts including soil acidification, vegetation damage, and disruption of microbial communities essential for nutrient cycling.

The environmental fate of fluoroantimonic acid and its breakdown products in different environmental matrices requires thorough investigation. The persistence of antimony compounds in the environment is of particular concern, as they can have long-lasting effects on soil and water quality. Additionally, the potential for fluoroantimonic acid to mobilize heavy metals in contaminated soils could exacerbate existing pollution issues.

Mitigation strategies for the environmental risks associated with fluoroantimonic acid in catalytic processes should focus on closed-loop systems, advanced containment technologies, and the development of less hazardous alternatives. Implementing robust waste management protocols and emergency response plans is crucial for minimizing the environmental impact of accidental releases. Furthermore, ongoing monitoring of air, water, and soil quality in areas where fluoroantimonic acid is used or produced is essential for early detection of potential contamination.

As research into catalytic methods progresses, there is a growing emphasis on green chemistry principles to reduce the environmental footprint of industrial processes. This includes exploring alternatives to fluoroantimonic acid that offer similar catalytic efficiency with reduced environmental risks. Developing more environmentally benign superacids or entirely new catalytic approaches could significantly mitigate the potential ecological impacts associated with the use of fluoroantimonic acid in industrial applications.

The production and handling of fluoroantimonic acid require stringent safety measures to prevent accidental releases. Even small spills can result in the emission of toxic fumes, particularly hydrogen fluoride, which can cause severe respiratory issues and long-term health effects in exposed populations. The acid's ability to react violently with water further complicates containment and cleanup efforts in case of environmental contamination.

In aquatic ecosystems, the introduction of fluoroantimonic acid could lead to drastic pH changes, potentially causing mass die-offs of fish and other aquatic organisms. The acid's fluoride component may also contribute to the bioaccumulation of fluoride in aquatic food chains, affecting organisms at various trophic levels. Terrestrial ecosystems are equally at risk, with potential impacts including soil acidification, vegetation damage, and disruption of microbial communities essential for nutrient cycling.

The environmental fate of fluoroantimonic acid and its breakdown products in different environmental matrices requires thorough investigation. The persistence of antimony compounds in the environment is of particular concern, as they can have long-lasting effects on soil and water quality. Additionally, the potential for fluoroantimonic acid to mobilize heavy metals in contaminated soils could exacerbate existing pollution issues.

Mitigation strategies for the environmental risks associated with fluoroantimonic acid in catalytic processes should focus on closed-loop systems, advanced containment technologies, and the development of less hazardous alternatives. Implementing robust waste management protocols and emergency response plans is crucial for minimizing the environmental impact of accidental releases. Furthermore, ongoing monitoring of air, water, and soil quality in areas where fluoroantimonic acid is used or produced is essential for early detection of potential contamination.

As research into catalytic methods progresses, there is a growing emphasis on green chemistry principles to reduce the environmental footprint of industrial processes. This includes exploring alternatives to fluoroantimonic acid that offer similar catalytic efficiency with reduced environmental risks. Developing more environmentally benign superacids or entirely new catalytic approaches could significantly mitigate the potential ecological impacts associated with the use of fluoroantimonic acid in industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!