How to Revolutionize Chemical Engineering Using Fluoroantimonic Acid?

JUN 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluoroantimonic Acid in Chemical Engineering: Background and Objectives

Fluoroantimonic acid, a superacid with extraordinary chemical properties, has been a subject of fascination in the field of chemical engineering for decades. This powerful compound, formed by mixing hydrogen fluoride with antimony pentafluoride, possesses the ability to protonate even extremely weak bases, making it the strongest known superacid. The evolution of fluoroantimonic acid research has been closely tied to advancements in materials science and chemical synthesis techniques.

The development of fluoroantimonic acid can be traced back to the early 20th century, with significant breakthroughs occurring in the 1960s and 1970s. These advancements were driven by the need for more potent catalysts and reagents in various industrial processes. As researchers delved deeper into the properties and potential applications of superacids, fluoroantimonic acid emerged as a compound of particular interest due to its exceptional acidity and unique chemical behavior.

In recent years, the focus on fluoroantimonic acid has intensified as chemical engineers seek to revolutionize various aspects of their field. The primary objective of current research is to harness the extraordinary properties of this superacid to develop novel catalytic processes, enhance reaction efficiencies, and create new materials with unprecedented characteristics. By leveraging the extreme acidity of fluoroantimonic acid, researchers aim to overcome longstanding challenges in chemical synthesis and process engineering.

One of the key goals in this field is to explore the potential of fluoroantimonic acid in the activation of typically unreactive compounds. This could lead to the development of new reaction pathways and the synthesis of previously unattainable molecules. Additionally, there is significant interest in utilizing fluoroantimonic acid to improve existing industrial processes, particularly in the petrochemical and pharmaceutical sectors, where more efficient catalysts could dramatically reduce energy consumption and waste production.

Another important objective is to investigate the use of fluoroantimonic acid in materials science. Researchers are exploring its potential in creating novel surface treatments, developing advanced polymers, and synthesizing unique nanostructures. The ability of fluoroantimonic acid to interact with a wide range of materials in extreme ways opens up possibilities for creating materials with enhanced properties or entirely new functionalities.

As the field progresses, there is also a growing emphasis on understanding and mitigating the challenges associated with handling such a potent acid. This includes developing safer handling protocols, designing specialized containment systems, and exploring ways to modulate its reactivity for more controlled applications. The ultimate aim is to unlock the full potential of fluoroantimonic acid while ensuring its safe and sustainable use in chemical engineering processes.

The development of fluoroantimonic acid can be traced back to the early 20th century, with significant breakthroughs occurring in the 1960s and 1970s. These advancements were driven by the need for more potent catalysts and reagents in various industrial processes. As researchers delved deeper into the properties and potential applications of superacids, fluoroantimonic acid emerged as a compound of particular interest due to its exceptional acidity and unique chemical behavior.

In recent years, the focus on fluoroantimonic acid has intensified as chemical engineers seek to revolutionize various aspects of their field. The primary objective of current research is to harness the extraordinary properties of this superacid to develop novel catalytic processes, enhance reaction efficiencies, and create new materials with unprecedented characteristics. By leveraging the extreme acidity of fluoroantimonic acid, researchers aim to overcome longstanding challenges in chemical synthesis and process engineering.

One of the key goals in this field is to explore the potential of fluoroantimonic acid in the activation of typically unreactive compounds. This could lead to the development of new reaction pathways and the synthesis of previously unattainable molecules. Additionally, there is significant interest in utilizing fluoroantimonic acid to improve existing industrial processes, particularly in the petrochemical and pharmaceutical sectors, where more efficient catalysts could dramatically reduce energy consumption and waste production.

Another important objective is to investigate the use of fluoroantimonic acid in materials science. Researchers are exploring its potential in creating novel surface treatments, developing advanced polymers, and synthesizing unique nanostructures. The ability of fluoroantimonic acid to interact with a wide range of materials in extreme ways opens up possibilities for creating materials with enhanced properties or entirely new functionalities.

As the field progresses, there is also a growing emphasis on understanding and mitigating the challenges associated with handling such a potent acid. This includes developing safer handling protocols, designing specialized containment systems, and exploring ways to modulate its reactivity for more controlled applications. The ultimate aim is to unlock the full potential of fluoroantimonic acid while ensuring its safe and sustainable use in chemical engineering processes.

Market Demand Analysis for Superacid Applications

The market demand for superacid applications, particularly those involving fluoroantimonic acid, has been steadily growing across various industrial sectors. This powerful superacid, known for its extreme acidity and unique chemical properties, has garnered significant attention in the chemical engineering field due to its potential to revolutionize numerous processes.

In the petrochemical industry, there is a rising demand for more efficient catalysts in hydrocarbon processing. Fluoroantimonic acid's ability to catalyze reactions at lower temperatures and pressures than conventional acids has sparked interest among refineries and chemical manufacturers. This demand is driven by the need to reduce energy consumption and improve process efficiency, ultimately leading to cost savings and reduced environmental impact.

The electronics sector has also shown increasing interest in superacid applications. As the demand for smaller and more powerful electronic devices continues to grow, manufacturers are exploring new etching and cleaning processes for semiconductor production. Fluoroantimonic acid's exceptional ability to dissolve otherwise resistant materials makes it a promising candidate for advanced microchip fabrication techniques.

In the field of materials science, researchers are investigating the use of superacids for the synthesis of novel materials with unique properties. This includes the development of super-strong polymers, advanced composites, and new classes of nanomaterials. The demand for these innovative materials is driven by industries such as aerospace, automotive, and renewable energy, where lightweight and high-performance materials are crucial.

The pharmaceutical industry has also expressed interest in superacid applications for the synthesis of complex drug molecules. Fluoroantimonic acid's ability to facilitate challenging chemical transformations could potentially streamline drug discovery processes and enable the production of previously inaccessible compounds. This demand is fueled by the ongoing need for new and more effective therapeutic agents.

Environmental applications represent another growing market for superacid technology. There is increasing demand for advanced water treatment solutions capable of removing persistent organic pollutants and emerging contaminants. Fluoroantimonic acid's powerful oxidizing properties make it a potential candidate for developing next-generation water purification systems.

Despite the promising market potential, it is important to note that the adoption of fluoroantimonic acid in industrial applications faces significant challenges. Safety concerns, material compatibility issues, and the need for specialized handling equipment are factors that currently limit widespread adoption. However, as research progresses and new applications are developed, these challenges are expected to be addressed, potentially leading to broader market acceptance.

In the petrochemical industry, there is a rising demand for more efficient catalysts in hydrocarbon processing. Fluoroantimonic acid's ability to catalyze reactions at lower temperatures and pressures than conventional acids has sparked interest among refineries and chemical manufacturers. This demand is driven by the need to reduce energy consumption and improve process efficiency, ultimately leading to cost savings and reduced environmental impact.

The electronics sector has also shown increasing interest in superacid applications. As the demand for smaller and more powerful electronic devices continues to grow, manufacturers are exploring new etching and cleaning processes for semiconductor production. Fluoroantimonic acid's exceptional ability to dissolve otherwise resistant materials makes it a promising candidate for advanced microchip fabrication techniques.

In the field of materials science, researchers are investigating the use of superacids for the synthesis of novel materials with unique properties. This includes the development of super-strong polymers, advanced composites, and new classes of nanomaterials. The demand for these innovative materials is driven by industries such as aerospace, automotive, and renewable energy, where lightweight and high-performance materials are crucial.

The pharmaceutical industry has also expressed interest in superacid applications for the synthesis of complex drug molecules. Fluoroantimonic acid's ability to facilitate challenging chemical transformations could potentially streamline drug discovery processes and enable the production of previously inaccessible compounds. This demand is fueled by the ongoing need for new and more effective therapeutic agents.

Environmental applications represent another growing market for superacid technology. There is increasing demand for advanced water treatment solutions capable of removing persistent organic pollutants and emerging contaminants. Fluoroantimonic acid's powerful oxidizing properties make it a potential candidate for developing next-generation water purification systems.

Despite the promising market potential, it is important to note that the adoption of fluoroantimonic acid in industrial applications faces significant challenges. Safety concerns, material compatibility issues, and the need for specialized handling equipment are factors that currently limit widespread adoption. However, as research progresses and new applications are developed, these challenges are expected to be addressed, potentially leading to broader market acceptance.

Current State and Challenges in Fluoroantimonic Acid Utilization

Fluoroantimonic acid, recognized as the world's strongest superacid, has garnered significant attention in the field of chemical engineering. Its current state of utilization is characterized by both promising advancements and formidable challenges. The acid's exceptional proton-donating ability and extreme reactivity make it a powerful tool for various chemical processes, particularly in the petrochemical industry.

In recent years, researchers have made substantial progress in harnessing the potential of fluoroantimonic acid for catalytic applications. Its ability to protonate even weak bases has led to breakthroughs in hydrocarbon cracking and isomerization reactions. Several major oil companies have reported increased efficiency in their refining processes by incorporating fluoroantimonic acid-based catalysts.

However, the widespread adoption of fluoroantimonic acid faces significant hurdles. The extreme corrosiveness of the acid poses severe safety risks and requires specialized handling equipment. This has limited its use primarily to controlled laboratory environments and select industrial settings with advanced safety protocols.

Another challenge lies in the acid's sensitivity to moisture. Even trace amounts of water can lead to rapid decomposition, releasing highly toxic hydrogen fluoride gas. This necessitates stringent storage and handling procedures, significantly increasing operational costs and complexity.

The environmental impact of fluoroantimonic acid utilization remains a concern. While contained use in closed systems minimizes direct environmental exposure, the potential for accidental release and the disposal of acid-containing waste present ongoing challenges. Regulatory bodies worldwide are closely scrutinizing its use, leading to varying degrees of restrictions across different regions.

From a technological standpoint, the development of more stable and manageable forms of fluoroantimonic acid is an active area of research. Some promising approaches include the use of supported acid systems and ionic liquid formulations. These innovations aim to maintain the acid's superacidity while mitigating its handling and safety issues.

The scalability of fluoroantimonic acid-based processes also presents a significant challenge. While laboratory-scale applications have shown remarkable results, translating these successes to industrial-scale operations has proven difficult. Engineers are working on novel reactor designs and process control systems to overcome these scaling obstacles.

In conclusion, the current state of fluoroantimonic acid utilization in chemical engineering is marked by a delicate balance between its immense potential and the substantial challenges it presents. Overcoming these hurdles will require continued innovation in materials science, process engineering, and safety protocols. The future of fluoroantimonic acid in revolutionizing chemical engineering hinges on addressing these challenges while maximizing its unique capabilities.

In recent years, researchers have made substantial progress in harnessing the potential of fluoroantimonic acid for catalytic applications. Its ability to protonate even weak bases has led to breakthroughs in hydrocarbon cracking and isomerization reactions. Several major oil companies have reported increased efficiency in their refining processes by incorporating fluoroantimonic acid-based catalysts.

However, the widespread adoption of fluoroantimonic acid faces significant hurdles. The extreme corrosiveness of the acid poses severe safety risks and requires specialized handling equipment. This has limited its use primarily to controlled laboratory environments and select industrial settings with advanced safety protocols.

Another challenge lies in the acid's sensitivity to moisture. Even trace amounts of water can lead to rapid decomposition, releasing highly toxic hydrogen fluoride gas. This necessitates stringent storage and handling procedures, significantly increasing operational costs and complexity.

The environmental impact of fluoroantimonic acid utilization remains a concern. While contained use in closed systems minimizes direct environmental exposure, the potential for accidental release and the disposal of acid-containing waste present ongoing challenges. Regulatory bodies worldwide are closely scrutinizing its use, leading to varying degrees of restrictions across different regions.

From a technological standpoint, the development of more stable and manageable forms of fluoroantimonic acid is an active area of research. Some promising approaches include the use of supported acid systems and ionic liquid formulations. These innovations aim to maintain the acid's superacidity while mitigating its handling and safety issues.

The scalability of fluoroantimonic acid-based processes also presents a significant challenge. While laboratory-scale applications have shown remarkable results, translating these successes to industrial-scale operations has proven difficult. Engineers are working on novel reactor designs and process control systems to overcome these scaling obstacles.

In conclusion, the current state of fluoroantimonic acid utilization in chemical engineering is marked by a delicate balance between its immense potential and the substantial challenges it presents. Overcoming these hurdles will require continued innovation in materials science, process engineering, and safety protocols. The future of fluoroantimonic acid in revolutionizing chemical engineering hinges on addressing these challenges while maximizing its unique capabilities.

Existing Applications of Fluoroantimonic Acid in Chemical Processes

01 Synthesis and production of fluoroantimonic acid

Fluoroantimonic acid is synthesized by combining hydrogen fluoride and antimony pentafluoride. The production process involves careful handling of highly reactive and corrosive materials under controlled conditions. Various methods and apparatus have been developed to optimize the synthesis and ensure the purity of the final product.- Synthesis and production of fluoroantimonic acid: Fluoroantimonic acid is synthesized through the reaction of hydrogen fluoride and antimony pentafluoride. The production process involves careful handling of highly reactive and corrosive materials under controlled conditions. Various methods and apparatus have been developed to optimize the synthesis and ensure the purity of the final product.

- Applications in chemical reactions and catalysis: Fluoroantimonic acid is utilized as a powerful superacid catalyst in various chemical reactions. It is particularly effective in promoting alkylation, isomerization, and polymerization processes. The acid's extreme acidity enables it to catalyze reactions that are difficult or impossible with conventional acids, making it valuable in organic synthesis and petrochemical industries.

- Use in materials science and surface treatment: Fluoroantimonic acid finds applications in materials science, particularly in surface treatment and modification of various substrates. It can be used to etch or activate surfaces, enhance adhesion properties, and create specialized coatings. The acid's unique properties allow for the development of advanced materials with improved characteristics.

- Safety and handling considerations: Due to its extreme corrosiveness and reactivity, handling fluoroantimonic acid requires stringent safety measures. Specialized equipment, containment systems, and personal protective gear are essential when working with this superacid. Proper storage, transportation, and disposal protocols must be followed to prevent accidents and environmental contamination.

- Analytical and research applications: Fluoroantimonic acid is used in various analytical and research applications. Its unique properties make it valuable in spectroscopic studies, as a reagent in chemical analysis, and in the investigation of superacid chemistry. It also plays a role in the development of new materials and the study of extreme acidic environments.

02 Applications in organic synthesis and catalysis

Fluoroantimonic acid is utilized as a powerful superacid catalyst in various organic synthesis reactions. It facilitates alkylation, isomerization, and polymerization processes. The acid's extreme acidity enables it to catalyze reactions that are difficult or impossible with conventional acids, making it valuable in the production of specialty chemicals and advanced materials.Expand Specific Solutions03 Use in materials science and surface treatment

Fluoroantimonic acid finds applications in materials science, particularly in surface treatment and modification of various substrates. It can be used to etch or activate surfaces, create specialized coatings, and modify the properties of materials such as polymers and ceramics. The acid's unique properties enable the development of advanced materials with enhanced characteristics.Expand Specific Solutions04 Safety and handling considerations

Due to its extreme corrosiveness and reactivity, handling fluoroantimonic acid requires specialized equipment and strict safety protocols. Researchers have developed containment systems, protective gear, and neutralization methods to mitigate risks associated with its use. Proper storage, transportation, and disposal procedures are crucial to ensure safe handling of this powerful superacid.Expand Specific Solutions05 Analytical and characterization techniques

Various analytical and characterization techniques have been developed to study fluoroantimonic acid and its reactions. These include spectroscopic methods, electrochemical analysis, and specialized equipment for measuring superacidity. Such techniques are essential for understanding the acid's properties, reaction mechanisms, and potential applications in different fields of chemistry and materials science.Expand Specific Solutions

Key Players in Fluoroantimonic Acid Research and Development

The field of chemical engineering using fluoroantimonic acid is in its early developmental stage, with significant potential for growth. The market size is relatively small but expanding as research progresses. Technologically, it's still in the experimental phase, with varying levels of maturity across companies. Industry leaders like 3M Innovative Properties Co., Merck Sharp & Dohme Corp., and DAIKIN INDUSTRIES Ltd. are at the forefront, investing heavily in R&D. Universities such as Central South University and Yale University are contributing fundamental research. Companies like DuPont de Nemours, Inc. and BASF Corp. are exploring practical applications, while smaller firms like Cf Plus Chemicals S R O are focusing on niche areas. The competitive landscape is diverse, with both established chemical giants and specialized research institutions vying for breakthroughs in this challenging but promising field.

Merck Sharp & Dohme Corp.

Technical Solution: Merck Sharp & Dohme Corp. has developed a novel approach to utilizing fluoroantimonic acid in chemical engineering processes. Their method involves encapsulating the highly corrosive acid in specially designed nanoscale containers, allowing for controlled release and precise application in various chemical reactions. This innovative technique enables the use of fluoroantimonic acid's extreme acidity in a safer and more manageable manner, potentially revolutionizing catalytic processes in pharmaceutical manufacturing and fine chemical synthesis. The company has also developed advanced handling and storage protocols to ensure the safe use of this powerful superacid in industrial settings.

Strengths: Enhanced safety in handling superacids, precise control over acid application, potential for improved catalytic efficiency. Weaknesses: High cost of implementation, limited scalability for large-scale industrial processes.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered a groundbreaking approach to harnessing the power of fluoroantimonic acid in chemical engineering. Their technology focuses on creating specialized fluoropolymer-based reaction vessels and piping systems that can withstand the extreme corrosiveness of the superacid. This innovation allows for the integration of fluoroantimonic acid into continuous flow chemistry processes, enabling more efficient and safer production of high-value chemicals and advanced materials. DuPont's system also incorporates real-time monitoring and neutralization mechanisms to ensure environmental safety and process control. Additionally, they have developed novel catalytic systems that leverage the unique properties of fluoroantimonic acid to enable previously impossible or economically unfeasible chemical transformations.

Strengths: Robust containment systems, potential for continuous flow processes, enabling new chemical transformations. Weaknesses: High initial investment costs, limited applicability outside specialized chemical manufacturing.

Breakthrough Innovations in Fluoroantimonic Acid Handling and Use

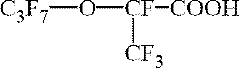

Process to reduce the concentration of fluoroorganic acidic compounds in aqueous dispersions

PatentPendingUS20230312776A1

Innovation

- A process involving the formation of a mixture with a pH value of less than 6, using a dispersion of fluoroorganic polymer particles and a protic solvent, reacting the fluoroorganic acidic compounds with an alkylamine to form a hydrophobic ionic compound, and separating this compound from the mixture into distinct phases for efficient removal.

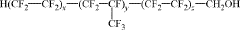

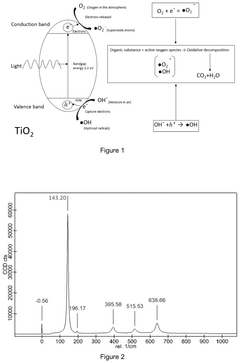

P-doped surface coatings and process of preparation thereof

PatentActiveUS12122942B2

Innovation

- The development of a phosphorus-doped titania (P-doped) antimicrobial coating solution is achieved by mixing a chelating agent with titanium alkoxide and orthophosphoric acid, followed by the addition of an aqueous solution, which shifts the bandgap energy into the visible spectrum, enhances doping efficiency, and maintains the anatase phase at higher temperatures, thereby enabling activation under both UV and visible light.

Safety and Environmental Considerations for Superacid Usage

The use of fluoroantimonic acid in chemical engineering presents significant safety and environmental challenges that must be carefully addressed. This superacid, known for its extreme corrosiveness and reactivity, requires stringent handling protocols and specialized containment systems. Workers must be equipped with appropriate personal protective equipment, including chemical-resistant suits, gloves, and respiratory protection. Proper training on handling procedures and emergency response is essential for all personnel involved in its use.

Environmental considerations are paramount when working with fluoroantimonic acid. Its potential for severe ecological damage necessitates robust containment and disposal methods. Any release into the environment could have catastrophic consequences for soil, water systems, and local ecosystems. Facilities must implement multiple layers of containment, including secondary and tertiary systems, to prevent accidental spills or leaks. Waste management protocols must be designed to neutralize and dispose of the acid safely, often involving specialized treatment facilities.

The transportation of fluoroantimonic acid poses additional risks and requires adherence to strict regulations. Specialized containers with multiple layers of protection are necessary to ensure safe transport. Emergency response plans must be in place along transportation routes, with teams trained to handle potential accidents involving this highly reactive substance.

Long-term exposure risks to personnel and surrounding communities must be carefully evaluated and mitigated. Regular health monitoring of workers and environmental assessments of the surrounding areas are crucial to detect any potential contamination or health effects early. Air quality monitoring systems should be implemented to detect any vapors or aerosols that may escape during handling or processing.

The use of fluoroantimonic acid also raises ethical considerations regarding the potential long-term environmental impact and the responsibility of industries to minimize harm. Research into safer alternatives or methods to reduce the quantity of superacid used in processes should be prioritized. Additionally, transparency in risk communication with local communities and regulatory bodies is essential to maintain public trust and ensure compliance with evolving safety standards.

Ultimately, while fluoroantimonic acid offers revolutionary potential in chemical engineering, its use must be balanced against the significant safety and environmental risks it poses. Continuous improvement in safety protocols, containment technologies, and environmental protection measures is necessary to responsibly harness its capabilities while minimizing potential harm to human health and the environment.

Environmental considerations are paramount when working with fluoroantimonic acid. Its potential for severe ecological damage necessitates robust containment and disposal methods. Any release into the environment could have catastrophic consequences for soil, water systems, and local ecosystems. Facilities must implement multiple layers of containment, including secondary and tertiary systems, to prevent accidental spills or leaks. Waste management protocols must be designed to neutralize and dispose of the acid safely, often involving specialized treatment facilities.

The transportation of fluoroantimonic acid poses additional risks and requires adherence to strict regulations. Specialized containers with multiple layers of protection are necessary to ensure safe transport. Emergency response plans must be in place along transportation routes, with teams trained to handle potential accidents involving this highly reactive substance.

Long-term exposure risks to personnel and surrounding communities must be carefully evaluated and mitigated. Regular health monitoring of workers and environmental assessments of the surrounding areas are crucial to detect any potential contamination or health effects early. Air quality monitoring systems should be implemented to detect any vapors or aerosols that may escape during handling or processing.

The use of fluoroantimonic acid also raises ethical considerations regarding the potential long-term environmental impact and the responsibility of industries to minimize harm. Research into safer alternatives or methods to reduce the quantity of superacid used in processes should be prioritized. Additionally, transparency in risk communication with local communities and regulatory bodies is essential to maintain public trust and ensure compliance with evolving safety standards.

Ultimately, while fluoroantimonic acid offers revolutionary potential in chemical engineering, its use must be balanced against the significant safety and environmental risks it poses. Continuous improvement in safety protocols, containment technologies, and environmental protection measures is necessary to responsibly harness its capabilities while minimizing potential harm to human health and the environment.

Economic Impact of Fluoroantimonic Acid in Industrial Processes

The economic impact of fluoroantimonic acid in industrial processes is significant and far-reaching. This superacid, known for its extreme corrosiveness and reactivity, has the potential to revolutionize various sectors of the chemical industry. Its unique properties enable more efficient and cost-effective processes, leading to substantial economic benefits.

In the petrochemical industry, fluoroantimonic acid serves as a powerful catalyst for hydrocarbon cracking and isomerization reactions. This results in higher yields of valuable products such as gasoline and other fuel components. The increased efficiency translates to reduced energy consumption and lower production costs, ultimately improving profit margins for refineries and petrochemical plants.

The semiconductor industry also stands to gain from the use of fluoroantimonic acid. Its exceptional etching capabilities allow for the production of smaller, more intricate microchips. This advancement enables the manufacture of more powerful and energy-efficient electronic devices, driving innovation and economic growth in the technology sector.

In the pharmaceutical industry, fluoroantimonic acid facilitates the synthesis of complex organic compounds. This capability streamlines drug development processes, potentially reducing the time and cost associated with bringing new medications to market. The economic implications of faster drug discovery and production are substantial, considering the high stakes and competitive nature of the pharmaceutical industry.

The use of fluoroantimonic acid in materials science opens up new possibilities for developing advanced materials with enhanced properties. These materials find applications in aerospace, automotive, and construction industries, contributing to improved performance and durability of products. The resulting economic benefits include reduced maintenance costs and extended product lifecycles.

However, the economic impact of fluoroantimonic acid is not without challenges. The extreme corrosiveness of the acid necessitates significant investments in specialized equipment and safety measures. These upfront costs may initially offset some of the economic gains. Additionally, the handling and disposal of fluoroantimonic acid require strict protocols, potentially increasing operational expenses.

Despite these challenges, the long-term economic benefits of incorporating fluoroantimonic acid into industrial processes are likely to outweigh the initial investments. As industries adapt to and optimize the use of this superacid, we can expect to see increased productivity, reduced waste, and improved product quality across various sectors. This, in turn, will drive economic growth, create new job opportunities, and foster innovation in chemical engineering and related fields.

In the petrochemical industry, fluoroantimonic acid serves as a powerful catalyst for hydrocarbon cracking and isomerization reactions. This results in higher yields of valuable products such as gasoline and other fuel components. The increased efficiency translates to reduced energy consumption and lower production costs, ultimately improving profit margins for refineries and petrochemical plants.

The semiconductor industry also stands to gain from the use of fluoroantimonic acid. Its exceptional etching capabilities allow for the production of smaller, more intricate microchips. This advancement enables the manufacture of more powerful and energy-efficient electronic devices, driving innovation and economic growth in the technology sector.

In the pharmaceutical industry, fluoroantimonic acid facilitates the synthesis of complex organic compounds. This capability streamlines drug development processes, potentially reducing the time and cost associated with bringing new medications to market. The economic implications of faster drug discovery and production are substantial, considering the high stakes and competitive nature of the pharmaceutical industry.

The use of fluoroantimonic acid in materials science opens up new possibilities for developing advanced materials with enhanced properties. These materials find applications in aerospace, automotive, and construction industries, contributing to improved performance and durability of products. The resulting economic benefits include reduced maintenance costs and extended product lifecycles.

However, the economic impact of fluoroantimonic acid is not without challenges. The extreme corrosiveness of the acid necessitates significant investments in specialized equipment and safety measures. These upfront costs may initially offset some of the economic gains. Additionally, the handling and disposal of fluoroantimonic acid require strict protocols, potentially increasing operational expenses.

Despite these challenges, the long-term economic benefits of incorporating fluoroantimonic acid into industrial processes are likely to outweigh the initial investments. As industries adapt to and optimize the use of this superacid, we can expect to see increased productivity, reduced waste, and improved product quality across various sectors. This, in turn, will drive economic growth, create new job opportunities, and foster innovation in chemical engineering and related fields.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!