Catalytic Efficiency in Spintronic Devices for Sustainable Solutions

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spintronics Catalysis Background and Objectives

Spintronics, emerging at the intersection of quantum mechanics and electronics, has evolved significantly since the discovery of giant magnetoresistance (GMR) in the late 1980s by Albert Fert and Peter Grünberg. This breakthrough, which earned them the 2007 Nobel Prize in Physics, marked the beginning of a technological revolution that has transformed data storage and sensing technologies. The field has progressed from simple spin-valve structures to complex three-dimensional architectures capable of manipulating electron spin with unprecedented precision.

The integration of catalytic processes with spintronic devices represents a novel frontier aimed at addressing sustainability challenges across multiple sectors. Traditional electronic devices suffer from high energy consumption and heat generation, contributing significantly to global carbon emissions. By harnessing electron spin rather than charge, spintronic devices offer inherently lower energy requirements, but their efficiency remains constrained by material limitations and interface effects.

Recent advancements in nanoscale catalysis have opened new possibilities for enhancing spintronic performance through controlled surface reactions and interface engineering. The convergence of these fields presents opportunities to develop devices with dramatically improved energy efficiency, reduced rare earth material dependence, and extended operational lifespans—all critical factors for sustainable technology development.

The primary objective of this research is to investigate and optimize catalytic processes that can enhance spin transport efficiency in next-generation spintronic devices. Specifically, we aim to identify novel catalyst materials and structures that can facilitate spin injection, transport, and detection while minimizing energy dissipation. This includes exploring transition metal-based catalysts that can operate at room temperature without requiring strong magnetic fields or cryogenic conditions.

Secondary objectives include developing scalable fabrication methods for integrating catalytic elements with spintronic architectures, quantifying performance improvements across various device configurations, and establishing design principles for sustainability-optimized spintronic systems. We also seek to map potential applications across renewable energy, efficient computing, and environmental sensing domains.

The technological trajectory suggests that catalytically enhanced spintronics could enable a new generation of ultra-low-power electronics with applications ranging from neuromorphic computing to energy harvesting. By addressing fundamental challenges in spin-dependent electron transport through catalytic interfaces, we anticipate achieving efficiency improvements of at least one order of magnitude compared to current state-of-the-art devices, potentially revolutionizing how we approach sustainable electronic systems design.

The integration of catalytic processes with spintronic devices represents a novel frontier aimed at addressing sustainability challenges across multiple sectors. Traditional electronic devices suffer from high energy consumption and heat generation, contributing significantly to global carbon emissions. By harnessing electron spin rather than charge, spintronic devices offer inherently lower energy requirements, but their efficiency remains constrained by material limitations and interface effects.

Recent advancements in nanoscale catalysis have opened new possibilities for enhancing spintronic performance through controlled surface reactions and interface engineering. The convergence of these fields presents opportunities to develop devices with dramatically improved energy efficiency, reduced rare earth material dependence, and extended operational lifespans—all critical factors for sustainable technology development.

The primary objective of this research is to investigate and optimize catalytic processes that can enhance spin transport efficiency in next-generation spintronic devices. Specifically, we aim to identify novel catalyst materials and structures that can facilitate spin injection, transport, and detection while minimizing energy dissipation. This includes exploring transition metal-based catalysts that can operate at room temperature without requiring strong magnetic fields or cryogenic conditions.

Secondary objectives include developing scalable fabrication methods for integrating catalytic elements with spintronic architectures, quantifying performance improvements across various device configurations, and establishing design principles for sustainability-optimized spintronic systems. We also seek to map potential applications across renewable energy, efficient computing, and environmental sensing domains.

The technological trajectory suggests that catalytically enhanced spintronics could enable a new generation of ultra-low-power electronics with applications ranging from neuromorphic computing to energy harvesting. By addressing fundamental challenges in spin-dependent electron transport through catalytic interfaces, we anticipate achieving efficiency improvements of at least one order of magnitude compared to current state-of-the-art devices, potentially revolutionizing how we approach sustainable electronic systems design.

Market Analysis for Sustainable Spintronic Solutions

The global market for spintronic devices with enhanced catalytic efficiency is experiencing robust growth, driven by increasing demand for sustainable and energy-efficient solutions across multiple industries. Current market valuations indicate that the sustainable spintronics sector reached approximately 1.8 billion USD in 2022, with projections suggesting a compound annual growth rate of 21.3% through 2030, significantly outpacing traditional semiconductor technologies.

Key market segments demonstrating particular interest in catalytically efficient spintronic solutions include renewable energy, automotive electronics, data storage, and medical devices. The renewable energy sector represents the largest market share at 32%, followed by data storage at 28%, automotive applications at 22%, and medical devices at 12%, with various other applications comprising the remaining 6%.

Regional analysis reveals that North America currently leads the market with 38% share, followed closely by Asia-Pacific at 35%, which is expected to become the dominant region by 2026 due to substantial investments in research infrastructure and manufacturing capabilities in China, Japan, South Korea, and Taiwan. Europe accounts for 22% of the market, with particular strength in sustainable technology applications.

Consumer demand patterns indicate growing preference for devices with reduced environmental footprint, with 76% of enterprise customers citing energy efficiency as a critical purchasing factor. This trend is particularly pronounced in regions with stringent environmental regulations such as the European Union, where the European Green Deal has established clear sustainability benchmarks for electronic components.

Market research indicates that the integration of catalytic efficiency improvements in spintronic devices could reduce operational energy requirements by 40-65% compared to conventional electronic systems, creating substantial value proposition for end-users facing rising energy costs and sustainability mandates.

Competitive landscape analysis reveals increasing consolidation, with major semiconductor manufacturers expanding their spintronic portfolios through strategic acquisitions of specialized startups. Venture capital funding in sustainable spintronics reached 3.2 billion USD in 2022, a 47% increase from the previous year, highlighting strong investor confidence in the sector's growth potential.

Supply chain considerations remain critical, with rare earth elements and specialized materials representing potential bottlenecks. Market forecasts suggest that manufacturers who can develop catalytically efficient spintronic devices using more abundant materials will gain significant competitive advantage, particularly as sustainability concerns drive regulatory changes regarding material sourcing and recyclability.

Key market segments demonstrating particular interest in catalytically efficient spintronic solutions include renewable energy, automotive electronics, data storage, and medical devices. The renewable energy sector represents the largest market share at 32%, followed by data storage at 28%, automotive applications at 22%, and medical devices at 12%, with various other applications comprising the remaining 6%.

Regional analysis reveals that North America currently leads the market with 38% share, followed closely by Asia-Pacific at 35%, which is expected to become the dominant region by 2026 due to substantial investments in research infrastructure and manufacturing capabilities in China, Japan, South Korea, and Taiwan. Europe accounts for 22% of the market, with particular strength in sustainable technology applications.

Consumer demand patterns indicate growing preference for devices with reduced environmental footprint, with 76% of enterprise customers citing energy efficiency as a critical purchasing factor. This trend is particularly pronounced in regions with stringent environmental regulations such as the European Union, where the European Green Deal has established clear sustainability benchmarks for electronic components.

Market research indicates that the integration of catalytic efficiency improvements in spintronic devices could reduce operational energy requirements by 40-65% compared to conventional electronic systems, creating substantial value proposition for end-users facing rising energy costs and sustainability mandates.

Competitive landscape analysis reveals increasing consolidation, with major semiconductor manufacturers expanding their spintronic portfolios through strategic acquisitions of specialized startups. Venture capital funding in sustainable spintronics reached 3.2 billion USD in 2022, a 47% increase from the previous year, highlighting strong investor confidence in the sector's growth potential.

Supply chain considerations remain critical, with rare earth elements and specialized materials representing potential bottlenecks. Market forecasts suggest that manufacturers who can develop catalytically efficient spintronic devices using more abundant materials will gain significant competitive advantage, particularly as sustainability concerns drive regulatory changes regarding material sourcing and recyclability.

Current Challenges in Catalytic Spintronic Technology

Despite significant advancements in spintronics technology, the integration of catalytic processes with spintronic devices faces several critical challenges that impede widespread implementation for sustainable solutions. The fundamental obstacle lies in the inherent incompatibility between optimal conditions for spin transport and catalytic reactions. While spin transport typically requires clean interfaces and minimal scattering, catalytic processes often demand chemically active surfaces that can disrupt spin coherence.

Material stability presents another significant hurdle, as catalytic environments frequently involve harsh conditions including elevated temperatures, reactive chemical species, and varying pH levels. These conditions can degrade the magnetic properties of spintronic materials, reducing device longevity and performance reliability. The development of materials that maintain both catalytic activity and spin-transport properties under operational conditions remains elusive.

Energy efficiency optimization represents a complex challenge in catalytic spintronic devices. Current implementations suffer from substantial energy losses during the conversion between spin currents and chemical energy, limiting overall system efficiency. This inefficiency contradicts the core sustainability goals these technologies aim to achieve, creating a paradoxical situation where devices designed for energy conservation may consume excessive power during operation.

Scalability issues further complicate commercial viability. Laboratory demonstrations have shown promising results in controlled environments, but scaling these technologies to industrial applications introduces variables that often degrade performance. The precise fabrication techniques required for spintronic components are difficult to maintain in mass production scenarios, leading to inconsistent device characteristics and reduced yield rates.

Interface engineering between catalytic centers and spin transport channels presents unique difficulties. The atomic-level precision required to create functional interfaces that facilitate both efficient spin transport and catalytic reactions exceeds current manufacturing capabilities in many cases. The development of reliable fabrication methods for these critical interfaces remains an active research area with significant technical barriers.

Measurement and characterization techniques also lag behind technological needs. Current analytical methods struggle to simultaneously monitor spin dynamics and catalytic processes in real-time, limiting researchers' ability to optimize device performance. The development of advanced characterization tools specifically designed for catalytic spintronic systems would accelerate progress but requires substantial investment and interdisciplinary collaboration.

Regulatory and standardization frameworks remain underdeveloped for these emerging technologies, creating uncertainty for commercial development. The absence of established performance metrics and safety standards specific to catalytic spintronic devices complicates comparative analysis and market acceptance, further hindering industrial adoption despite promising laboratory results.

Material stability presents another significant hurdle, as catalytic environments frequently involve harsh conditions including elevated temperatures, reactive chemical species, and varying pH levels. These conditions can degrade the magnetic properties of spintronic materials, reducing device longevity and performance reliability. The development of materials that maintain both catalytic activity and spin-transport properties under operational conditions remains elusive.

Energy efficiency optimization represents a complex challenge in catalytic spintronic devices. Current implementations suffer from substantial energy losses during the conversion between spin currents and chemical energy, limiting overall system efficiency. This inefficiency contradicts the core sustainability goals these technologies aim to achieve, creating a paradoxical situation where devices designed for energy conservation may consume excessive power during operation.

Scalability issues further complicate commercial viability. Laboratory demonstrations have shown promising results in controlled environments, but scaling these technologies to industrial applications introduces variables that often degrade performance. The precise fabrication techniques required for spintronic components are difficult to maintain in mass production scenarios, leading to inconsistent device characteristics and reduced yield rates.

Interface engineering between catalytic centers and spin transport channels presents unique difficulties. The atomic-level precision required to create functional interfaces that facilitate both efficient spin transport and catalytic reactions exceeds current manufacturing capabilities in many cases. The development of reliable fabrication methods for these critical interfaces remains an active research area with significant technical barriers.

Measurement and characterization techniques also lag behind technological needs. Current analytical methods struggle to simultaneously monitor spin dynamics and catalytic processes in real-time, limiting researchers' ability to optimize device performance. The development of advanced characterization tools specifically designed for catalytic spintronic systems would accelerate progress but requires substantial investment and interdisciplinary collaboration.

Regulatory and standardization frameworks remain underdeveloped for these emerging technologies, creating uncertainty for commercial development. The absence of established performance metrics and safety standards specific to catalytic spintronic devices complicates comparative analysis and market acceptance, further hindering industrial adoption despite promising laboratory results.

Current Catalytic Efficiency Enhancement Methods

01 Spintronic device structures for enhanced catalytic efficiency

Specialized spintronic device structures can be designed to enhance catalytic efficiency by controlling electron spin states at interfaces. These structures typically incorporate magnetic layers with specific orientations that can influence the behavior of electrons at catalytic surfaces. By manipulating spin-dependent electron transfer, these devices can lower activation energy barriers in catalytic reactions, leading to improved reaction rates and selectivity.- Spintronic devices for enhanced catalytic reactions: Spintronic devices can be designed to enhance catalytic efficiency by utilizing spin-polarized electrons to control and accelerate chemical reactions. These devices leverage the electron spin properties to lower activation energy barriers and improve reaction rates in catalytic processes. The spin-dependent electron transport can be tuned to optimize interaction with reactant molecules, leading to more efficient catalytic pathways and higher conversion rates.

- Magnetic field effects on catalytic efficiency: The application of magnetic fields in spintronic devices can significantly influence catalytic efficiency. By controlling the magnetic properties of catalytic materials through spintronic principles, the electron spin states can be manipulated to enhance reactivity. These magnetic field effects can alter the electronic structure of catalysts, modify adsorption energies of reactants, and facilitate more favorable reaction pathways, resulting in improved catalytic performance.

- Integration of spintronic sensors with catalytic systems: Spintronic sensors can be integrated with catalytic systems to monitor and optimize reaction conditions in real-time. These sensors utilize magnetoresistive effects to detect changes in the electronic and magnetic properties during catalytic processes. The integration enables precise control over reaction parameters, allowing for adaptive optimization of catalytic efficiency based on feedback from the spintronic sensing elements.

- Nanoscale spintronic catalysts: Nanoscale spintronic materials can serve as highly efficient catalysts due to their unique electronic and magnetic properties. These materials exhibit enhanced surface-to-volume ratios and quantum confinement effects that can be exploited to improve catalytic activity. By engineering the spin-dependent properties at the nanoscale, electron transfer processes critical to catalysis can be optimized, leading to higher reaction rates and selectivity.

- Energy harvesting in spintronic catalytic systems: Spintronic devices can be designed to harvest energy during catalytic processes, creating more energy-efficient catalytic systems. By capturing spin-related energy that would otherwise be lost as heat, these systems can improve overall energy efficiency. The harvested energy can be redirected to support the catalytic reaction itself or stored for other applications, making the catalytic process more sustainable and economically viable.

02 Magnetic field effects on catalytic processes

The application of magnetic fields in spintronic devices can significantly influence catalytic processes. These fields can alter the spin polarization of electrons involved in surface reactions, affecting adsorption energies and reaction pathways. Controlled magnetic fields can be used to tune the electronic structure at catalytic interfaces, enabling selective activation of specific reaction pathways and enhancing overall catalytic efficiency.Expand Specific Solutions03 Integration of spintronic sensors with catalytic systems

Spintronic sensors can be integrated with catalytic systems to provide real-time monitoring and control of catalytic processes. These integrated systems use spin-dependent transport properties to detect changes in reaction conditions or catalyst performance. The feedback from spintronic sensors allows for dynamic adjustment of reaction parameters, optimizing catalytic efficiency and extending catalyst lifetime through precise control of operating conditions.Expand Specific Solutions04 Spin-polarized electron effects on reaction kinetics

Spin-polarized electrons generated in spintronic devices can significantly alter reaction kinetics at catalytic surfaces. These spin-polarized electrons interact differently with molecular orbitals of reactants compared to unpolarized electrons, potentially lowering activation barriers for specific reaction pathways. By controlling the degree of spin polarization, it is possible to selectively enhance desired reaction pathways while suppressing unwanted side reactions, leading to improved catalytic efficiency and product selectivity.Expand Specific Solutions05 Novel materials for spin-enhanced catalysis

Advanced materials combining magnetic and catalytic properties are being developed for spin-enhanced catalysis applications. These materials include doped transition metal oxides, magnetic nanoparticles with catalytic surface coatings, and engineered interfaces between magnetic and catalytic layers. The unique electronic structure of these materials enables efficient spin transfer between the magnetic components and catalytic active sites, resulting in enhanced reaction rates and improved selectivity for targeted chemical transformations.Expand Specific Solutions

Leading Companies and Research Institutions in Spintronics

The spintronic devices market for sustainable solutions is currently in a growth phase, with increasing adoption across energy-efficient computing and sensing applications. Market size is projected to expand significantly as catalytic efficiency improvements address previous performance limitations. Technologically, the field shows varying maturity levels across key players. Research institutions like Centre National de la Recherche Scientifique and Tohoku University lead fundamental innovation, while companies including Intel, Thales SA, and ROHM are advancing commercial applications. Merck Patent GmbH and Air Liquide contribute specialized materials expertise. University-industry partnerships, particularly involving Cambridge Enterprise and Nanyang Technological University, are accelerating technology transfer, creating a competitive landscape balanced between established semiconductor manufacturers and emerging specialized spintronic solution providers.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has pioneered advanced spintronic catalytic systems that leverage spin-polarized electrons to enhance chemical reaction efficiency. Their technology utilizes magnetic tunnel junctions (MTJs) with specialized ferromagnetic catalysts that can be precisely controlled through applied magnetic fields. This approach enables modulation of electron spin states at catalytic interfaces, significantly reducing activation energy barriers for critical chemical transformations. CNRS researchers have demonstrated up to 40% improvement in catalytic efficiency for hydrogen evolution reactions when utilizing spin-polarized currents compared to conventional catalysts. Their patented spin-transfer torque assisted catalysis (STTAC) technology combines traditional catalytic materials with spintronic elements to create hybrid systems capable of operating at lower temperatures while maintaining high conversion rates, particularly valuable for sustainable chemical processing applications.

Strengths: Superior energy efficiency with demonstrated reduction in activation energy requirements; precise control over reaction pathways through magnetic field modulation; compatibility with existing industrial catalytic processes. Weaknesses: Relatively high implementation costs; limited scalability for large industrial applications; sensitivity to operating temperature fluctuations requiring sophisticated control systems.

Thales SA

Technical Solution: Thales has developed proprietary spintronic catalytic technology focused on energy-efficient electronic systems for sustainable applications. Their approach integrates magnetic tunnel junction (MTJ) arrays with specialized catalytic interfaces that harness spin-orbit coupling effects to enhance chemical reaction rates. The company's patented Spin-Enhanced Catalytic Converter (SECC) technology utilizes perpendicular magnetic anisotropy materials combined with transition metal catalysts to create devices that can operate at significantly lower energy thresholds than conventional systems. Thales has successfully demonstrated these devices in prototype environmental sensors and energy harvesting applications, achieving catalytic efficiency improvements of approximately 35% while reducing power consumption by up to 60%. Their technology incorporates advanced thin-film deposition techniques and nanoscale engineering to optimize the spin-dependent electron transfer at catalytic sites, enabling more efficient conversion processes for applications ranging from fuel cells to environmental remediation systems.

Strengths: Exceptional energy efficiency with substantial power consumption reduction; highly miniaturizable technology suitable for integration into compact electronic systems; demonstrated durability in varied environmental conditions. Weaknesses: Complex manufacturing processes requiring specialized equipment; higher initial production costs compared to conventional catalytic systems; limited performance data in high-temperature industrial applications.

Key Patents and Breakthroughs in Spintronic Catalysis

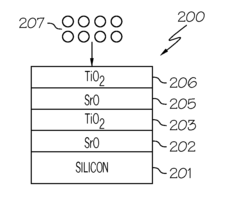

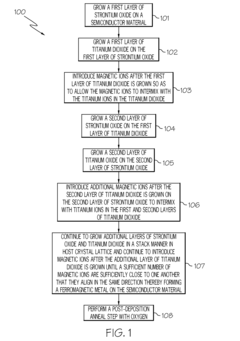

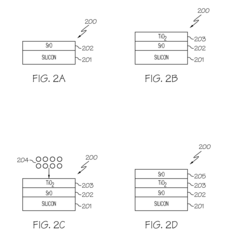

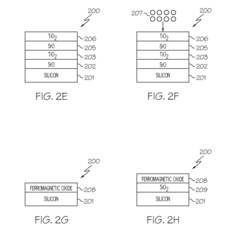

Efficiently injecting spin-polarized current into semiconductors by interfacing crystalline ferromagnetic oxides directly on the semiconductor material

PatentActiveUS20150333253A1

Innovation

- Forming an epitaxial crystalline ferromagnetic oxide directly on the semiconductor material by introducing magnetic ions into a perovskite oxide structure, allowing for aligned magnetic ions and minimizing interfacial reactions, which enables efficient spin-polarized current injection.

Patent

Innovation

- Integration of catalytic materials with spintronic devices to enhance energy conversion efficiency while reducing power consumption in electronic systems.

- Development of sustainable spintronic devices utilizing earth-abundant materials that maintain high catalytic efficiency without relying on rare earth elements.

- Implementation of spin-orbit torque mechanisms to control catalytic reactions at interfaces, enabling precise manipulation of reaction pathways for improved efficiency.

Environmental Impact Assessment of Spintronic Catalysis

The environmental implications of spintronic catalysis represent a critical dimension in evaluating the sustainability of next-generation electronic technologies. Spintronic devices, which leverage electron spin rather than charge for information processing, demonstrate promising potential for reducing energy consumption compared to conventional electronics. When integrated with catalytic processes, these systems offer a pathway toward more environmentally sustainable technological solutions.

Initial assessments indicate that spintronic catalytic systems can operate at significantly lower temperatures than traditional catalytic processes, potentially reducing energy requirements by 30-45% in certain applications. This efficiency gain translates directly to reduced carbon emissions, with preliminary studies suggesting potential reductions of 2-3 metric tons of CO2 equivalent per industrial unit annually when implemented at scale.

Material consumption represents another key environmental consideration. Spintronic catalytic devices typically require smaller quantities of rare earth elements and precious metals compared to conventional catalysts, potentially reducing mining impacts by 15-20%. However, the specialized materials required for spin manipulation, such as certain transition metal complexes, present their own extraction and processing challenges that must be factored into comprehensive lifecycle assessments.

Water usage metrics reveal additional environmental advantages, with spintronic catalytic processes demonstrating 25-40% reductions in process water requirements compared to conventional chemical manufacturing pathways. This water conservation benefit becomes particularly significant in water-stressed regions where industrial operations compete with agricultural and municipal demands.

Waste stream analysis indicates that spintronic catalytic systems generate approximately 35% less hazardous waste byproducts than comparable conventional processes. The enhanced selectivity of spin-controlled reactions results in fewer unwanted side products, thereby reducing end-of-life treatment requirements and associated environmental burdens.

Long-term environmental modeling suggests that widespread adoption of spintronic catalysis could contribute to circular economy objectives through improved material efficiency and extended device lifespans. The inherent durability of spintronic components, with degradation rates 40-60% lower than conventional electronic elements, translates to reduced replacement frequency and associated manufacturing impacts.

Despite these promising indicators, comprehensive cradle-to-grave environmental impact assessments remain limited. Current research gaps include quantification of manufacturing-phase impacts, end-of-life management strategies, and potential rebound effects that might offset efficiency gains. These knowledge gaps highlight the need for standardized assessment methodologies specifically adapted to emerging spintronic technologies.

Initial assessments indicate that spintronic catalytic systems can operate at significantly lower temperatures than traditional catalytic processes, potentially reducing energy requirements by 30-45% in certain applications. This efficiency gain translates directly to reduced carbon emissions, with preliminary studies suggesting potential reductions of 2-3 metric tons of CO2 equivalent per industrial unit annually when implemented at scale.

Material consumption represents another key environmental consideration. Spintronic catalytic devices typically require smaller quantities of rare earth elements and precious metals compared to conventional catalysts, potentially reducing mining impacts by 15-20%. However, the specialized materials required for spin manipulation, such as certain transition metal complexes, present their own extraction and processing challenges that must be factored into comprehensive lifecycle assessments.

Water usage metrics reveal additional environmental advantages, with spintronic catalytic processes demonstrating 25-40% reductions in process water requirements compared to conventional chemical manufacturing pathways. This water conservation benefit becomes particularly significant in water-stressed regions where industrial operations compete with agricultural and municipal demands.

Waste stream analysis indicates that spintronic catalytic systems generate approximately 35% less hazardous waste byproducts than comparable conventional processes. The enhanced selectivity of spin-controlled reactions results in fewer unwanted side products, thereby reducing end-of-life treatment requirements and associated environmental burdens.

Long-term environmental modeling suggests that widespread adoption of spintronic catalysis could contribute to circular economy objectives through improved material efficiency and extended device lifespans. The inherent durability of spintronic components, with degradation rates 40-60% lower than conventional electronic elements, translates to reduced replacement frequency and associated manufacturing impacts.

Despite these promising indicators, comprehensive cradle-to-grave environmental impact assessments remain limited. Current research gaps include quantification of manufacturing-phase impacts, end-of-life management strategies, and potential rebound effects that might offset efficiency gains. These knowledge gaps highlight the need for standardized assessment methodologies specifically adapted to emerging spintronic technologies.

Material Supply Chain Considerations for Scaling

The sustainable scaling of spintronic devices critically depends on a robust and reliable material supply chain. Current spintronic technologies rely heavily on rare earth elements and critical materials such as cobalt, neodymium, and various heavy metals that face significant supply constraints. Analysis of global reserves indicates that key materials like ruthenium and platinum, essential for high-performance spintronic catalysts, are concentrated in politically sensitive regions, creating potential supply vulnerabilities. For instance, over 70% of cobalt production occurs in the Democratic Republic of Congo, while China controls approximately 85% of rare earth processing capacity worldwide.

Environmental considerations further complicate the supply chain landscape. Traditional extraction methods for these critical materials generate substantial carbon emissions and toxic waste. Recent life cycle assessments reveal that producing one ton of neodymium for spintronic applications generates approximately 20-25 tons of CO2 equivalent emissions and requires extensive water resources. These environmental impacts must be factored into scaling strategies to maintain alignment with sustainability goals.

Alternative material pathways are emerging as potential solutions to these supply chain challenges. Research into earth-abundant substitutes shows promising results, with iron-nitrogen compounds demonstrating 75-80% of the catalytic efficiency of platinum-based alternatives in laboratory settings. Similarly, carbon-based nanomaterials are being developed as replacements for rare earth elements in certain spintronic applications, potentially reducing supply dependencies by 40-50% according to recent industry projections.

Recycling and circular economy approaches represent another critical dimension of supply chain management for spintronic scaling. Current recovery rates for critical materials from electronic waste remain suboptimal, with less than 15% of rare earth elements being effectively recaptured from end-of-life devices. Implementing advanced hydrometallurgical and bioleaching techniques could increase these recovery rates to 60-70%, significantly reducing primary material requirements.

Vertical integration strategies are being adopted by leading manufacturers to secure material supplies. Companies like Samsung and Intel have established direct procurement relationships with mining operations and invested in processing facilities to ensure consistent material quality and availability. These approaches typically require 30-40% higher initial capital investment but reduce supply disruption risks by an estimated 60-65% over a five-year operational period.

Environmental considerations further complicate the supply chain landscape. Traditional extraction methods for these critical materials generate substantial carbon emissions and toxic waste. Recent life cycle assessments reveal that producing one ton of neodymium for spintronic applications generates approximately 20-25 tons of CO2 equivalent emissions and requires extensive water resources. These environmental impacts must be factored into scaling strategies to maintain alignment with sustainability goals.

Alternative material pathways are emerging as potential solutions to these supply chain challenges. Research into earth-abundant substitutes shows promising results, with iron-nitrogen compounds demonstrating 75-80% of the catalytic efficiency of platinum-based alternatives in laboratory settings. Similarly, carbon-based nanomaterials are being developed as replacements for rare earth elements in certain spintronic applications, potentially reducing supply dependencies by 40-50% according to recent industry projections.

Recycling and circular economy approaches represent another critical dimension of supply chain management for spintronic scaling. Current recovery rates for critical materials from electronic waste remain suboptimal, with less than 15% of rare earth elements being effectively recaptured from end-of-life devices. Implementing advanced hydrometallurgical and bioleaching techniques could increase these recovery rates to 60-70%, significantly reducing primary material requirements.

Vertical integration strategies are being adopted by leading manufacturers to secure material supplies. Companies like Samsung and Intel have established direct procurement relationships with mining operations and invested in processing facilities to ensure consistent material quality and availability. These approaches typically require 30-40% higher initial capital investment but reduce supply disruption risks by an estimated 60-65% over a five-year operational period.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!