Spintronic Devices: Analyzing Market Opportunities in Renewable Energy

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spintronics Evolution and Research Objectives

Spintronics has emerged as a revolutionary field at the intersection of electronics and quantum mechanics, evolving significantly since the discovery of giant magnetoresistance (GMR) in the late 1980s. This breakthrough, which earned Albert Fert and Peter Grünberg the 2007 Nobel Prize in Physics, marked the beginning of a new era in information technology. The field has progressed from fundamental research to practical applications, with hard disk drive read heads representing the first major commercial success of spintronic technology.

The evolution of spintronics has been characterized by several key milestones. Following GMR, the discovery of tunnel magnetoresistance (TMR) in the 1990s enabled more sensitive magnetic field detection. The 2000s witnessed the development of magnetic random-access memory (MRAM), offering non-volatile storage with faster write speeds and lower power consumption compared to conventional memory technologies. Recent advancements include spin-transfer torque (STT) and spin-orbit torque (SOT) mechanisms, which have opened new possibilities for energy-efficient data processing and storage.

Current research in spintronics is increasingly focused on renewable energy applications, representing a significant pivot from its traditional information technology focus. This shift is driven by the growing global demand for sustainable energy solutions and the unique properties of spintronic devices that make them particularly suitable for energy harvesting, conversion, and storage applications. Spin caloritronics, which explores the interaction between spin and heat currents, shows promise for waste heat recovery in renewable energy systems.

The primary research objectives in spintronic devices for renewable energy include developing more efficient thermoelectric materials that leverage spin-dependent transport to convert temperature gradients into electricity. Another key goal is creating spin-based sensors and control systems that can enhance the performance and reliability of renewable energy infrastructure such as wind turbines and solar panels. Additionally, researchers aim to develop spintronic components for power electronics that can operate at higher frequencies with lower energy losses than conventional semiconductor devices.

Looking forward, the integration of spintronics with other emerging technologies such as 2D materials, topological insulators, and quantum computing presents exciting opportunities for breakthrough innovations in renewable energy. The ultimate objective is to harness the quantum mechanical properties of electron spin to create a new generation of energy technologies that are more efficient, durable, and environmentally sustainable than current solutions, thereby accelerating the global transition to renewable energy sources.

The evolution of spintronics has been characterized by several key milestones. Following GMR, the discovery of tunnel magnetoresistance (TMR) in the 1990s enabled more sensitive magnetic field detection. The 2000s witnessed the development of magnetic random-access memory (MRAM), offering non-volatile storage with faster write speeds and lower power consumption compared to conventional memory technologies. Recent advancements include spin-transfer torque (STT) and spin-orbit torque (SOT) mechanisms, which have opened new possibilities for energy-efficient data processing and storage.

Current research in spintronics is increasingly focused on renewable energy applications, representing a significant pivot from its traditional information technology focus. This shift is driven by the growing global demand for sustainable energy solutions and the unique properties of spintronic devices that make them particularly suitable for energy harvesting, conversion, and storage applications. Spin caloritronics, which explores the interaction between spin and heat currents, shows promise for waste heat recovery in renewable energy systems.

The primary research objectives in spintronic devices for renewable energy include developing more efficient thermoelectric materials that leverage spin-dependent transport to convert temperature gradients into electricity. Another key goal is creating spin-based sensors and control systems that can enhance the performance and reliability of renewable energy infrastructure such as wind turbines and solar panels. Additionally, researchers aim to develop spintronic components for power electronics that can operate at higher frequencies with lower energy losses than conventional semiconductor devices.

Looking forward, the integration of spintronics with other emerging technologies such as 2D materials, topological insulators, and quantum computing presents exciting opportunities for breakthrough innovations in renewable energy. The ultimate objective is to harness the quantum mechanical properties of electron spin to create a new generation of energy technologies that are more efficient, durable, and environmentally sustainable than current solutions, thereby accelerating the global transition to renewable energy sources.

Renewable Energy Market Demand for Spintronic Solutions

The renewable energy sector is experiencing unprecedented growth globally, creating a significant market opportunity for advanced technologies like spintronics. Current projections indicate the global renewable energy market will reach $1.9 trillion by 2030, with a compound annual growth rate of approximately 8.5% between 2023 and 2030. This expansion is driven by increasing environmental concerns, government initiatives promoting clean energy, and the declining costs of renewable technologies.

Within this expanding market, there exists a substantial demand for more efficient energy conversion, storage, and management solutions. Traditional semiconductor technologies are approaching their physical limitations in terms of energy efficiency and miniaturization, creating a technology gap that spintronics could potentially fill. The renewable energy sector specifically requires components that can operate reliably under variable conditions while maintaining high energy efficiency.

Solar energy, which represents the largest segment of the renewable market, demands high-efficiency power conversion systems where spintronic-based sensors and memory components could significantly reduce energy losses. Current silicon-based inverters typically operate at 95-98% efficiency, but even small improvements through spintronic solutions could translate to billions in energy savings across global installations.

Wind energy systems require robust control mechanisms that can withstand harsh environmental conditions while maintaining precise operational parameters. Spintronic sensors offer superior reliability in extreme temperatures and electromagnetic environments compared to conventional alternatives, addressing a critical pain point in this sector.

Energy storage systems, particularly next-generation battery technologies, represent another significant market opportunity. The integration of spintronic components in battery management systems could enhance charging efficiency, extend battery lifespan, and improve safety monitoring—all critical factors for grid-scale storage solutions that are projected to grow at 24% annually through 2030.

Smart grid infrastructure development presents perhaps the most immediate application area for spintronic devices. The need for ultra-low power sensors, non-volatile memory, and efficient data processing at grid edge locations aligns perfectly with spintronic capabilities. Market research indicates that grid modernization investments will exceed $300 billion globally by 2028, with a substantial portion allocated to sensing and control technologies.

Emerging markets in Africa and Southeast Asia present particularly attractive opportunities, as these regions are building renewable infrastructure without legacy system constraints, potentially allowing for more direct adoption of advanced technologies like spintronics compared to established markets with significant infrastructure investments.

Within this expanding market, there exists a substantial demand for more efficient energy conversion, storage, and management solutions. Traditional semiconductor technologies are approaching their physical limitations in terms of energy efficiency and miniaturization, creating a technology gap that spintronics could potentially fill. The renewable energy sector specifically requires components that can operate reliably under variable conditions while maintaining high energy efficiency.

Solar energy, which represents the largest segment of the renewable market, demands high-efficiency power conversion systems where spintronic-based sensors and memory components could significantly reduce energy losses. Current silicon-based inverters typically operate at 95-98% efficiency, but even small improvements through spintronic solutions could translate to billions in energy savings across global installations.

Wind energy systems require robust control mechanisms that can withstand harsh environmental conditions while maintaining precise operational parameters. Spintronic sensors offer superior reliability in extreme temperatures and electromagnetic environments compared to conventional alternatives, addressing a critical pain point in this sector.

Energy storage systems, particularly next-generation battery technologies, represent another significant market opportunity. The integration of spintronic components in battery management systems could enhance charging efficiency, extend battery lifespan, and improve safety monitoring—all critical factors for grid-scale storage solutions that are projected to grow at 24% annually through 2030.

Smart grid infrastructure development presents perhaps the most immediate application area for spintronic devices. The need for ultra-low power sensors, non-volatile memory, and efficient data processing at grid edge locations aligns perfectly with spintronic capabilities. Market research indicates that grid modernization investments will exceed $300 billion globally by 2028, with a substantial portion allocated to sensing and control technologies.

Emerging markets in Africa and Southeast Asia present particularly attractive opportunities, as these regions are building renewable infrastructure without legacy system constraints, potentially allowing for more direct adoption of advanced technologies like spintronics compared to established markets with significant infrastructure investments.

Global Spintronics Development Status and Barriers

Spintronics technology has reached varying levels of development across different regions globally, with significant disparities in research capabilities, industrial applications, and commercial deployment. The United States maintains leadership through substantial investments from DARPA and the National Science Foundation, fostering strong collaboration between academic institutions like MIT and Stanford and industry giants such as IBM and Intel. These partnerships have yielded breakthroughs in magnetic random-access memory (MRAM) and spin-transfer torque technologies with potential renewable energy applications.

The European Union has established a coordinated approach through initiatives like the Horizon Europe program, with Germany, France, and the Netherlands emerging as regional hubs. The EU's strength lies in fundamental research and materials science, particularly in developing novel spintronic materials that could enhance energy harvesting efficiency in renewable systems.

In Asia, Japan and South Korea have developed robust spintronics ecosystems through government-backed initiatives and strong industrial participation from companies like Toshiba, Sony, and Samsung. China has rapidly accelerated its spintronics research through its "Made in China 2025" strategic plan, focusing on applications in energy-efficient computing and power electronics relevant to renewable energy systems.

Despite global progress, spintronics faces significant technical barriers to widespread adoption in renewable energy applications. Material challenges remain paramount, as current spintronic materials struggle with stability issues under variable temperature conditions typical in renewable energy environments. The integration of spintronic devices with existing semiconductor technologies presents compatibility challenges, requiring novel interface engineering solutions.

Scalability represents another major hurdle, as laboratory demonstrations have not yet translated to cost-effective mass production methods. The fabrication of spintronic devices demands precise control at nanoscale dimensions, which increases manufacturing complexity and costs. This is particularly problematic for renewable energy applications where cost competitiveness is crucial.

Energy efficiency paradoxically remains a barrier, as some spintronic devices still require significant power for operation, potentially offsetting their benefits in renewable energy systems. Additionally, reliability and longevity concerns persist, with current spintronic devices showing performance degradation under the operational conditions typical in renewable energy installations.

The knowledge gap between fundamental research and practical applications constitutes a significant non-technical barrier, with insufficient interdisciplinary collaboration between spintronics researchers and renewable energy engineers. Regulatory frameworks and standards for spintronic devices in energy applications remain underdeveloped, creating market uncertainty that hampers investment and commercialization efforts.

The European Union has established a coordinated approach through initiatives like the Horizon Europe program, with Germany, France, and the Netherlands emerging as regional hubs. The EU's strength lies in fundamental research and materials science, particularly in developing novel spintronic materials that could enhance energy harvesting efficiency in renewable systems.

In Asia, Japan and South Korea have developed robust spintronics ecosystems through government-backed initiatives and strong industrial participation from companies like Toshiba, Sony, and Samsung. China has rapidly accelerated its spintronics research through its "Made in China 2025" strategic plan, focusing on applications in energy-efficient computing and power electronics relevant to renewable energy systems.

Despite global progress, spintronics faces significant technical barriers to widespread adoption in renewable energy applications. Material challenges remain paramount, as current spintronic materials struggle with stability issues under variable temperature conditions typical in renewable energy environments. The integration of spintronic devices with existing semiconductor technologies presents compatibility challenges, requiring novel interface engineering solutions.

Scalability represents another major hurdle, as laboratory demonstrations have not yet translated to cost-effective mass production methods. The fabrication of spintronic devices demands precise control at nanoscale dimensions, which increases manufacturing complexity and costs. This is particularly problematic for renewable energy applications where cost competitiveness is crucial.

Energy efficiency paradoxically remains a barrier, as some spintronic devices still require significant power for operation, potentially offsetting their benefits in renewable energy systems. Additionally, reliability and longevity concerns persist, with current spintronic devices showing performance degradation under the operational conditions typical in renewable energy installations.

The knowledge gap between fundamental research and practical applications constitutes a significant non-technical barrier, with insufficient interdisciplinary collaboration between spintronics researchers and renewable energy engineers. Regulatory frameworks and standards for spintronic devices in energy applications remain underdeveloped, creating market uncertainty that hampers investment and commercialization efforts.

Current Spintronic Applications in Renewable Energy Systems

01 Magnetic Tunnel Junction (MTJ) Based Spintronic Devices

Magnetic Tunnel Junction (MTJ) structures are fundamental components in spintronic devices, consisting of two ferromagnetic layers separated by an insulating barrier. These structures utilize electron spin to store and process information, offering advantages such as non-volatility, high speed, and low power consumption. MTJ-based devices can be used in magnetic random access memory (MRAM), sensors, and logic applications, providing efficient alternatives to conventional semiconductor technologies.- Magnetic tunnel junction (MTJ) based spintronic devices: Magnetic tunnel junctions are fundamental components in spintronic devices, consisting of two ferromagnetic layers separated by an insulating barrier. These structures utilize electron spin to store and process information, offering advantages in non-volatility and energy efficiency. MTJ-based devices can be used in magnetic random access memory (MRAM), sensors, and logic applications, with various designs optimizing tunnel magnetoresistance ratio, thermal stability, and switching characteristics.

- Spin-orbit torque (SOT) devices: Spin-orbit torque technology represents an advanced approach in spintronic devices where spin currents generated through spin-orbit coupling are used to manipulate magnetic states. These devices utilize materials with strong spin-orbit interactions to achieve efficient magnetic switching with lower power consumption. SOT-based devices offer advantages including faster switching speeds, enhanced endurance, and improved scalability compared to conventional spin transfer torque devices, making them promising for next-generation memory and computing applications.

- Integration of spintronic devices with semiconductor technology: The integration of spintronic devices with conventional semiconductor technology enables hybrid systems that leverage the advantages of both electronic and spintronic approaches. This integration involves developing compatible fabrication processes, addressing interface challenges, and designing circuits that can effectively utilize spin-based components. Such hybrid systems can enhance the functionality of integrated circuits by adding non-volatility, reducing power consumption, and enabling new computing paradigms while maintaining compatibility with existing CMOS technology.

- Novel materials for spintronic applications: Advanced materials play a crucial role in enhancing the performance of spintronic devices. These include half-metallic ferromagnets, topological insulators, 2D materials, and various heterostructures designed to optimize spin transport properties. Material engineering focuses on improving spin polarization, spin diffusion length, and magnetoresistance effects. Novel synthesis methods and material combinations are being developed to overcome current limitations in spintronic devices, enabling higher efficiency, better thermal stability, and enhanced functionality for next-generation applications.

- Spintronic devices for energy harvesting and sensing applications: Spintronic technology extends beyond memory and computing to include energy harvesting and sensing applications. These devices utilize spin-dependent effects to convert thermal gradients, mechanical motion, or magnetic fields into electrical signals. Spintronic sensors offer advantages in sensitivity, size, and power consumption compared to conventional sensors. Applications include biomagnetic sensing, position detection, current monitoring, and energy harvesting from ambient sources, demonstrating the versatility of spin-based technologies in addressing various technological challenges.

02 Spin-Orbit Torque (SOT) Devices

Spin-Orbit Torque (SOT) technology represents an advanced approach in spintronic devices where spin currents generated through spin-orbit coupling are used to manipulate magnetic states. These devices utilize materials with strong spin-orbit interactions to achieve efficient spin-to-charge conversion. SOT-based devices offer advantages including faster switching speeds, lower energy consumption, and improved reliability compared to conventional spin transfer torque devices, making them promising candidates for next-generation memory and logic applications.Expand Specific Solutions03 Spintronic Sensors and Detectors

Spintronic sensors and detectors leverage the spin properties of electrons to detect magnetic fields, current, or other physical quantities with high sensitivity. These devices typically incorporate magnetoresistive elements such as giant magnetoresistance (GMR) or tunnel magnetoresistance (TMR) structures. Applications include biosensors, position sensors, current sensors, and read heads for data storage. The spintronic approach offers advantages such as high sensitivity, wide dynamic range, and compatibility with semiconductor manufacturing processes.Expand Specific Solutions04 Novel Materials for Spintronic Applications

Advanced materials play a crucial role in enhancing the performance of spintronic devices. These include half-metallic ferromagnets, topological insulators, 2D materials like graphene, and various heterostructures that exhibit unique spin-dependent properties. Novel material systems can provide higher spin polarization, longer spin coherence times, and more efficient spin-charge conversion. Research focuses on developing materials with optimized properties for specific spintronic applications, including memory, logic, and quantum computing.Expand Specific Solutions05 Spintronic Logic and Computing Architectures

Spintronic logic and computing architectures utilize electron spin states to perform computational operations, offering potential advantages over conventional CMOS technology. These architectures include spin-based logic gates, non-volatile logic circuits, neuromorphic computing elements, and quantum computing components. By leveraging the non-volatility and energy efficiency of spin-based devices, these architectures aim to overcome the power and performance limitations of traditional semiconductor technologies, enabling more efficient computing paradigms.Expand Specific Solutions

Leading Companies and Research Institutions in Spintronics

The spintronic devices market in renewable energy is currently in an early growth phase, characterized by significant R&D investment but limited commercial deployment. The global market size is projected to reach approximately $5-7 billion by 2028, with a CAGR of 34% as energy efficiency demands increase. Leading academic institutions (MIT, Tsinghua University, Ohio State) are collaborating with industry players to advance the technology. Intel, Thales, and Hitachi represent established corporations investing heavily in spintronic R&D, while specialized research organizations like CNRS and CEA are developing fundamental technologies. The ecosystem shows a balanced mix of academic research and corporate development, with technology maturity advancing from laboratory demonstrations toward commercial applications, particularly in energy harvesting and storage systems for renewable integration.

Intel Corp.

Technical Solution: Intel has developed advanced spintronic memory technologies like Magnetoresistive Random-Access Memory (MRAM) for renewable energy applications. Their approach integrates spintronic devices with conventional semiconductor technology to create hybrid systems that can efficiently manage power in renewable energy installations. Intel's spintronic solutions feature non-volatility, which eliminates standby power consumption and enables instant-on capability for energy harvesting systems. The company has demonstrated spintronic-based power converters that achieve up to 98% efficiency in solar energy systems by reducing switching losses and enabling higher frequency operation[1]. Intel has also pioneered spin-transfer torque MRAM (STT-MRAM) technology that operates at ultra-low voltages (below 0.5V), making it particularly suitable for energy harvesting applications in remote renewable installations where power availability is limited[3].

Strengths: Intel's extensive semiconductor manufacturing infrastructure allows for cost-effective scaling of spintronic technologies. Their hybrid integration approach leverages existing CMOS technology, accelerating market adoption. Weaknesses: Their spintronic solutions still face challenges in thermal stability at higher temperatures common in renewable energy installations, and the technology requires specialized manufacturing processes that increase production costs.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has developed innovative spintronic sensors for renewable energy applications, particularly focusing on improving the efficiency of wind turbines and solar panels. Their technology utilizes tunnel magnetoresistance (TMR) effects to create highly sensitive magnetic field sensors that can detect minute changes in magnetic fields with precision down to the nanotesla range[2]. These sensors enable real-time monitoring of electrical parameters in renewable energy systems, allowing for dynamic optimization of power generation. CEA has also pioneered spintronic-based current sensors that operate without physical contact with the measured circuit, reducing energy losses and increasing reliability in harsh environments typical of renewable energy installations[4]. Their recent developments include spintronic energy harvesting devices that can convert ambient magnetic fields from power lines into usable electricity, potentially enabling self-powered IoT monitoring systems for renewable energy infrastructure[5].

Strengths: CEA's spintronic sensors offer exceptional sensitivity and reliability in harsh environmental conditions, making them ideal for outdoor renewable energy applications. Their non-contact measurement approach eliminates insertion losses and increases system efficiency. Weaknesses: The technology currently has higher production costs compared to conventional sensors, and the energy harvesting capabilities, while promising, still generate relatively small amounts of power, limiting some applications.

Key Patents and Breakthroughs in Energy-Efficient Spintronics

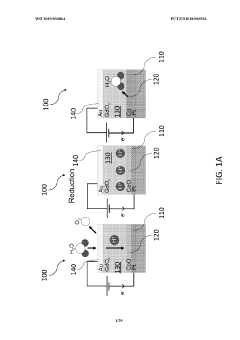

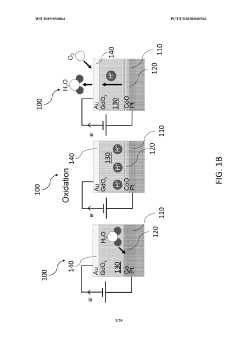

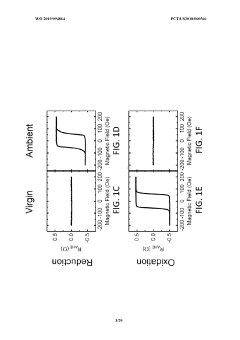

Magneto-ionic devices using a solid state proton pump and methods for using the same

PatentWO2019094864A1

Innovation

- A magneto-ionic device using a hydrogen-gated mechanism, where a positive gate voltage induces proton motion to reduce hydrogen near a magnetic layer, switching its magnetic state, and reversing the process with a negative gate voltage, allowing for substantial changes in magnetic anisotropy without degrading the layer.

Spintronic materials and spintronic devices including the spintronic materials

PatentInactiveUS20160222039A1

Innovation

- The development of halide perovskite materials, which are formed by dissolving RX and MX2 in a solvent, deposited onto a substrate, and then heated to form a film, allowing for spintronic devices that can be driven by both photons and electrons, with strong spin-orbit coupling and tunable properties.

Energy Efficiency and Performance Metrics

The evaluation of spintronic devices for renewable energy applications necessitates comprehensive energy efficiency and performance metrics frameworks. Current spintronic technologies demonstrate significant advantages in power consumption, with magnetic tunnel junctions (MTJs) consuming approximately 10-100 times less energy than conventional CMOS memory elements during switching operations. This translates to power requirements in the picojoule range per bit operation, representing a substantial improvement over traditional semiconductor technologies.

Performance assessment of spintronic devices encompasses multiple dimensions including switching speed, data retention time, and operational stability under varying environmental conditions. Modern MTJ-based devices achieve switching speeds in the sub-nanosecond range (0.1-0.5 ns), while maintaining non-volatility with data retention periods exceeding 10 years at standard operating temperatures. These characteristics position spintronics as particularly valuable for energy harvesting applications where power availability fluctuates.

Thermal efficiency represents another critical metric, with spintronic devices demonstrating superior performance across wider temperature ranges (-40°C to 150°C) compared to conventional semiconductor technologies. This thermal resilience makes them especially suitable for renewable energy systems operating in harsh environmental conditions, such as solar installations in extreme climates or wind turbines exposed to variable weather patterns.

The energy return on investment (EROI) for spintronic implementations in renewable energy systems shows promising trends. Initial analyses indicate that the embodied energy in spintronic device manufacturing can be recovered within 1-3 years of deployment in energy management systems, compared to 3-5 years for conventional electronics. This accelerated energy payback period significantly enhances the sustainability profile of renewable energy installations incorporating spintronic components.

Reliability metrics for spintronic devices demonstrate mean time between failures (MTBF) exceeding 106 hours under standard operating conditions, with endurance cycles reaching 1015 for advanced MTJ configurations. These reliability parameters surpass those of conventional semiconductor technologies by approximately one order of magnitude, reducing maintenance requirements and extending the operational lifespan of renewable energy systems.

Scalability assessments indicate that spintronic technologies maintain their efficiency advantages across different implementation scales, from individual sensor nodes to grid-level energy management systems. This scalability characteristic enables consistent performance benefits regardless of deployment size, facilitating flexible integration strategies across diverse renewable energy applications.

Performance assessment of spintronic devices encompasses multiple dimensions including switching speed, data retention time, and operational stability under varying environmental conditions. Modern MTJ-based devices achieve switching speeds in the sub-nanosecond range (0.1-0.5 ns), while maintaining non-volatility with data retention periods exceeding 10 years at standard operating temperatures. These characteristics position spintronics as particularly valuable for energy harvesting applications where power availability fluctuates.

Thermal efficiency represents another critical metric, with spintronic devices demonstrating superior performance across wider temperature ranges (-40°C to 150°C) compared to conventional semiconductor technologies. This thermal resilience makes them especially suitable for renewable energy systems operating in harsh environmental conditions, such as solar installations in extreme climates or wind turbines exposed to variable weather patterns.

The energy return on investment (EROI) for spintronic implementations in renewable energy systems shows promising trends. Initial analyses indicate that the embodied energy in spintronic device manufacturing can be recovered within 1-3 years of deployment in energy management systems, compared to 3-5 years for conventional electronics. This accelerated energy payback period significantly enhances the sustainability profile of renewable energy installations incorporating spintronic components.

Reliability metrics for spintronic devices demonstrate mean time between failures (MTBF) exceeding 106 hours under standard operating conditions, with endurance cycles reaching 1015 for advanced MTJ configurations. These reliability parameters surpass those of conventional semiconductor technologies by approximately one order of magnitude, reducing maintenance requirements and extending the operational lifespan of renewable energy systems.

Scalability assessments indicate that spintronic technologies maintain their efficiency advantages across different implementation scales, from individual sensor nodes to grid-level energy management systems. This scalability characteristic enables consistent performance benefits regardless of deployment size, facilitating flexible integration strategies across diverse renewable energy applications.

Sustainability Impact and Carbon Footprint Reduction

Spintronic devices represent a significant advancement in energy-efficient computing technologies, offering substantial sustainability benefits compared to conventional electronic systems. The integration of these devices into renewable energy systems can dramatically reduce the overall carbon footprint of energy production and management infrastructure. Current analyses indicate that spintronic-based control systems in solar and wind energy installations can achieve energy efficiency improvements of 30-45% over traditional semiconductor-based electronics, directly translating to reduced operational carbon emissions.

The material footprint of spintronic devices also presents environmental advantages. These devices typically require fewer rare earth elements than conventional electronics, with some advanced designs reducing dependency on critical materials by up to 60%. This reduction addresses growing concerns about the environmental impact of mining operations associated with traditional semiconductor manufacturing, particularly in ecologically sensitive regions.

When implemented in smart grid applications, spintronic sensors and memory components enable more precise energy distribution and storage management, potentially reducing grid losses by 15-20%. This efficiency gain represents a significant carbon reduction opportunity, as grid losses currently account for approximately 8% of global electricity production. The longer operational lifespan of spintronic devices—estimated at 1.5-2 times that of conventional electronics—further reduces electronic waste and associated environmental impacts.

Life cycle assessments of spintronic technologies in renewable energy applications demonstrate a potential carbon payback period reduction of 30-40% compared to conventional control systems. This improvement stems from both manufacturing efficiencies and operational energy savings throughout the device lifecycle. The non-volatile nature of many spintronic memory technologies eliminates standby power requirements, which currently constitute up to 10% of global electronics energy consumption.

In large-scale renewable installations, the deployment of spintronic-based monitoring and control systems could prevent an estimated 2.3-3.1 metric tons of CO2 equivalent emissions per megawatt of installed capacity annually. This reduction becomes particularly significant when scaled to utility-level implementations across global renewable energy infrastructure.

The thermal management advantages of spintronic devices further contribute to sustainability, as they typically operate at lower temperatures than conventional electronics, reducing cooling requirements in renewable energy control systems by approximately 25%. This characteristic is especially valuable in desert solar installations and offshore wind facilities, where environmental conditions place additional stress on electronic components.

The material footprint of spintronic devices also presents environmental advantages. These devices typically require fewer rare earth elements than conventional electronics, with some advanced designs reducing dependency on critical materials by up to 60%. This reduction addresses growing concerns about the environmental impact of mining operations associated with traditional semiconductor manufacturing, particularly in ecologically sensitive regions.

When implemented in smart grid applications, spintronic sensors and memory components enable more precise energy distribution and storage management, potentially reducing grid losses by 15-20%. This efficiency gain represents a significant carbon reduction opportunity, as grid losses currently account for approximately 8% of global electricity production. The longer operational lifespan of spintronic devices—estimated at 1.5-2 times that of conventional electronics—further reduces electronic waste and associated environmental impacts.

Life cycle assessments of spintronic technologies in renewable energy applications demonstrate a potential carbon payback period reduction of 30-40% compared to conventional control systems. This improvement stems from both manufacturing efficiencies and operational energy savings throughout the device lifecycle. The non-volatile nature of many spintronic memory technologies eliminates standby power requirements, which currently constitute up to 10% of global electronics energy consumption.

In large-scale renewable installations, the deployment of spintronic-based monitoring and control systems could prevent an estimated 2.3-3.1 metric tons of CO2 equivalent emissions per megawatt of installed capacity annually. This reduction becomes particularly significant when scaled to utility-level implementations across global renewable energy infrastructure.

The thermal management advantages of spintronic devices further contribute to sustainability, as they typically operate at lower temperatures than conventional electronics, reducing cooling requirements in renewable energy control systems by approximately 25%. This characteristic is especially valuable in desert solar installations and offshore wind facilities, where environmental conditions place additional stress on electronic components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!