Challenges in producing large-scale flexible AMOLED screens.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AMOLED Evolution and Objectives

Active-Matrix Organic Light-Emitting Diode (AMOLED) technology has revolutionized the display industry since its inception in the late 1990s. The evolution of AMOLED displays has been marked by significant advancements in picture quality, energy efficiency, and form factor flexibility. Initially developed for small-scale applications such as mobile devices, AMOLED technology has progressively expanded its reach to larger screens and more diverse applications.

The primary objective in AMOLED development has been to overcome the limitations of traditional LCD technology, particularly in terms of color reproduction, contrast ratios, and power consumption. AMOLED displays offer superior color accuracy, infinite contrast ratios, and lower power consumption, making them ideal for a wide range of devices from smartphones to televisions.

In recent years, the focus has shifted towards developing flexible and foldable AMOLED displays, presenting new challenges and opportunities. The ability to create bendable screens opens up possibilities for innovative device designs and user experiences. However, producing large-scale flexible AMOLED screens presents significant technical hurdles that researchers and manufacturers are actively working to overcome.

Key objectives in the evolution of AMOLED technology include improving manufacturing processes to increase yield rates and reduce production costs, enhancing the durability and lifespan of flexible displays, and scaling up the technology to accommodate larger screen sizes without compromising quality or performance.

Another critical goal is to address the inherent limitations of OLED materials, such as their susceptibility to degradation over time, particularly for blue OLEDs. Researchers are exploring new organic compounds and device architectures to improve the stability and longevity of AMOLED displays.

The development of flexible AMOLED screens also aims to overcome challenges related to the integration of touch sensors, protective layers, and other functional components into a bendable form factor. This includes creating new materials and manufacturing techniques that can maintain the display's flexibility while ensuring its durability and functionality.

As the industry moves towards larger flexible AMOLED screens, there is a growing emphasis on improving the uniformity of light emission across the entire display area, minimizing color shift at different viewing angles, and enhancing the overall visual experience for users.

In conclusion, the evolution of AMOLED technology and its objectives are driven by the vision of creating highly flexible, durable, and efficient large-scale displays that can revolutionize how we interact with visual information across various applications and industries.

The primary objective in AMOLED development has been to overcome the limitations of traditional LCD technology, particularly in terms of color reproduction, contrast ratios, and power consumption. AMOLED displays offer superior color accuracy, infinite contrast ratios, and lower power consumption, making them ideal for a wide range of devices from smartphones to televisions.

In recent years, the focus has shifted towards developing flexible and foldable AMOLED displays, presenting new challenges and opportunities. The ability to create bendable screens opens up possibilities for innovative device designs and user experiences. However, producing large-scale flexible AMOLED screens presents significant technical hurdles that researchers and manufacturers are actively working to overcome.

Key objectives in the evolution of AMOLED technology include improving manufacturing processes to increase yield rates and reduce production costs, enhancing the durability and lifespan of flexible displays, and scaling up the technology to accommodate larger screen sizes without compromising quality or performance.

Another critical goal is to address the inherent limitations of OLED materials, such as their susceptibility to degradation over time, particularly for blue OLEDs. Researchers are exploring new organic compounds and device architectures to improve the stability and longevity of AMOLED displays.

The development of flexible AMOLED screens also aims to overcome challenges related to the integration of touch sensors, protective layers, and other functional components into a bendable form factor. This includes creating new materials and manufacturing techniques that can maintain the display's flexibility while ensuring its durability and functionality.

As the industry moves towards larger flexible AMOLED screens, there is a growing emphasis on improving the uniformity of light emission across the entire display area, minimizing color shift at different viewing angles, and enhancing the overall visual experience for users.

In conclusion, the evolution of AMOLED technology and its objectives are driven by the vision of creating highly flexible, durable, and efficient large-scale displays that can revolutionize how we interact with visual information across various applications and industries.

Flexible Display Market Analysis

The flexible display market has experienced significant growth in recent years, driven by the increasing demand for innovative and portable electronic devices. This market segment encompasses various technologies, with AMOLED (Active-Matrix Organic Light-Emitting Diode) screens at the forefront due to their superior performance characteristics. The global flexible display market is expected to continue its upward trajectory, with major players in the consumer electronics industry investing heavily in research and development to overcome production challenges and bring large-scale flexible AMOLED screens to market.

Consumer demand for flexible displays is primarily fueled by the desire for more durable, lightweight, and versatile devices. Smartphones and wearable technology are currently the primary applications for flexible displays, with potential expansion into automotive, aerospace, and healthcare sectors. The ability to create curved, foldable, and rollable screens opens up new possibilities for product design and user interaction, driving innovation across multiple industries.

Despite the promising market outlook, several factors are influencing the growth and adoption of flexible AMOLED technology. Production costs remain a significant barrier, as manufacturing large-scale flexible screens requires specialized equipment and processes. Yield rates for flexible displays are generally lower than those for rigid displays, contributing to higher production costs and limiting mass-market adoption. However, as manufacturing techniques improve and economies of scale are achieved, prices are expected to decrease, making flexible AMOLED screens more accessible to a broader range of consumers and applications.

The competitive landscape of the flexible display market is dominated by a few key players, primarily based in South Korea and China. These companies are investing heavily in production capacity and technological advancements to gain a competitive edge. As the market matures, we can expect to see increased competition and potentially new entrants, which may lead to accelerated innovation and more diverse product offerings.

Technological advancements in materials science and manufacturing processes are crucial for overcoming the challenges associated with producing large-scale flexible AMOLED screens. Researchers are exploring new substrate materials, encapsulation techniques, and production methods to improve durability, flexibility, and scalability. The development of more efficient and cost-effective production techniques will be essential for meeting the growing market demand and expanding the application range of flexible displays.

Consumer demand for flexible displays is primarily fueled by the desire for more durable, lightweight, and versatile devices. Smartphones and wearable technology are currently the primary applications for flexible displays, with potential expansion into automotive, aerospace, and healthcare sectors. The ability to create curved, foldable, and rollable screens opens up new possibilities for product design and user interaction, driving innovation across multiple industries.

Despite the promising market outlook, several factors are influencing the growth and adoption of flexible AMOLED technology. Production costs remain a significant barrier, as manufacturing large-scale flexible screens requires specialized equipment and processes. Yield rates for flexible displays are generally lower than those for rigid displays, contributing to higher production costs and limiting mass-market adoption. However, as manufacturing techniques improve and economies of scale are achieved, prices are expected to decrease, making flexible AMOLED screens more accessible to a broader range of consumers and applications.

The competitive landscape of the flexible display market is dominated by a few key players, primarily based in South Korea and China. These companies are investing heavily in production capacity and technological advancements to gain a competitive edge. As the market matures, we can expect to see increased competition and potentially new entrants, which may lead to accelerated innovation and more diverse product offerings.

Technological advancements in materials science and manufacturing processes are crucial for overcoming the challenges associated with producing large-scale flexible AMOLED screens. Researchers are exploring new substrate materials, encapsulation techniques, and production methods to improve durability, flexibility, and scalability. The development of more efficient and cost-effective production techniques will be essential for meeting the growing market demand and expanding the application range of flexible displays.

Flexible AMOLED Technical Hurdles

The production of large-scale flexible AMOLED screens presents several significant technical challenges that manufacturers must overcome. One of the primary hurdles is the development of flexible substrate materials that can withstand repeated bending and folding without compromising the display's performance or durability. Traditional glass substrates are rigid and brittle, making them unsuitable for flexible displays. Plastic substrates, while more flexible, often lack the thermal stability and barrier properties necessary for OLED fabrication.

Another major challenge lies in the thin-film transistor (TFT) backplane technology. Conventional amorphous silicon (a-Si) TFTs used in LCD displays lack the electron mobility required for OLED displays, especially when bent. Low-temperature polycrystalline silicon (LTPS) and oxide TFTs offer better performance but face difficulties in maintaining consistent electrical characteristics when flexed. The development of TFT materials and structures that can maintain stable performance under mechanical stress is crucial for flexible AMOLED production.

The deposition of organic materials and the encapsulation process also pose significant hurdles. Organic materials are sensitive to oxygen and moisture, which can degrade the OLED's performance and lifespan. Traditional encapsulation methods using rigid glass are not suitable for flexible displays. Thin-film encapsulation (TFE) technologies are being developed to provide adequate protection while maintaining flexibility, but achieving a perfect barrier against environmental factors remains challenging.

Scaling up the production of flexible AMOLED screens introduces additional complexities. Ensuring uniformity in the deposition of organic materials and TFTs across large areas is difficult, especially when dealing with flexible substrates that may deform during the manufacturing process. This can lead to inconsistencies in display performance and yield issues. Moreover, the handling and processing of large, flexible substrates require specialized equipment and techniques that differ significantly from those used in traditional rigid display production.

The integration of touch functionality into flexible AMOLED displays presents another set of challenges. Conventional touch sensors based on indium tin oxide (ITO) are not sufficiently flexible for these applications. Alternative materials and structures, such as metal mesh or silver nanowire networks, are being explored, but each comes with its own set of trade-offs in terms of optical transparency, conductivity, and flexibility.

Lastly, the development of flexible electronics and interconnects that can withstand repeated bending without failure is critical. This includes not only the display components but also the driving circuits and power management systems. Creating reliable, flexible interconnects that can maintain electrical connectivity under various bending conditions is essential for the overall functionality and durability of flexible AMOLED devices.

Another major challenge lies in the thin-film transistor (TFT) backplane technology. Conventional amorphous silicon (a-Si) TFTs used in LCD displays lack the electron mobility required for OLED displays, especially when bent. Low-temperature polycrystalline silicon (LTPS) and oxide TFTs offer better performance but face difficulties in maintaining consistent electrical characteristics when flexed. The development of TFT materials and structures that can maintain stable performance under mechanical stress is crucial for flexible AMOLED production.

The deposition of organic materials and the encapsulation process also pose significant hurdles. Organic materials are sensitive to oxygen and moisture, which can degrade the OLED's performance and lifespan. Traditional encapsulation methods using rigid glass are not suitable for flexible displays. Thin-film encapsulation (TFE) technologies are being developed to provide adequate protection while maintaining flexibility, but achieving a perfect barrier against environmental factors remains challenging.

Scaling up the production of flexible AMOLED screens introduces additional complexities. Ensuring uniformity in the deposition of organic materials and TFTs across large areas is difficult, especially when dealing with flexible substrates that may deform during the manufacturing process. This can lead to inconsistencies in display performance and yield issues. Moreover, the handling and processing of large, flexible substrates require specialized equipment and techniques that differ significantly from those used in traditional rigid display production.

The integration of touch functionality into flexible AMOLED displays presents another set of challenges. Conventional touch sensors based on indium tin oxide (ITO) are not sufficiently flexible for these applications. Alternative materials and structures, such as metal mesh or silver nanowire networks, are being explored, but each comes with its own set of trade-offs in terms of optical transparency, conductivity, and flexibility.

Lastly, the development of flexible electronics and interconnects that can withstand repeated bending without failure is critical. This includes not only the display components but also the driving circuits and power management systems. Creating reliable, flexible interconnects that can maintain electrical connectivity under various bending conditions is essential for the overall functionality and durability of flexible AMOLED devices.

Current Large-Scale Production Methods

01 Flexible AMOLED display structure

Flexible AMOLED screens incorporate specialized structures to enable bending and folding while maintaining display quality. These structures may include flexible substrates, thin-film encapsulation layers, and bendable electrode materials to achieve the desired flexibility without compromising performance.- Flexible AMOLED display structure: Flexible AMOLED screens incorporate specialized structures to enable bending and folding while maintaining display quality. These structures may include flexible substrates, thin-film encapsulation layers, and bendable electrode materials to achieve the desired flexibility without compromising performance.

- Scaling techniques for flexible AMOLED screens: Various scaling techniques are employed to manufacture flexible AMOLED screens in different sizes. These may involve adjusting pixel densities, optimizing circuit layouts, and developing scalable manufacturing processes to produce screens of varying dimensions while maintaining consistent quality and performance.

- Flexible AMOLED driver circuits: Specialized driver circuits are designed to accommodate the unique requirements of flexible AMOLED displays. These circuits may incorporate flexible printed circuit boards, stretchable interconnects, and adaptive driving schemes to ensure proper operation across various bending states and screen sizes.

- Flexible AMOLED screen protection: Protective measures are implemented to safeguard flexible AMOLED screens from damage during bending and everyday use. These may include specialized coating materials, multi-layer protection films, and innovative encapsulation techniques to enhance durability and longevity of the flexible displays.

- Flexible AMOLED screen manufacturing processes: Advanced manufacturing processes are developed to produce flexible AMOLED screens at scale. These processes may involve roll-to-roll fabrication techniques, low-temperature deposition methods, and innovative patterning technologies to enable efficient and cost-effective production of flexible displays in various sizes.

02 Scaling techniques for flexible AMOLED displays

Various scaling techniques are employed to manufacture flexible AMOLED displays in different sizes. These methods involve adjusting pixel densities, optimizing circuit layouts, and developing scalable manufacturing processes to produce screens of varying dimensions while maintaining consistent quality and performance.Expand Specific Solutions03 Flexible AMOLED driver circuits

Specialized driver circuits are designed for flexible AMOLED displays to accommodate bending and folding. These circuits may include flexible printed circuit boards, stretchable interconnects, and adaptive driving schemes to ensure stable performance across different screen configurations.Expand Specific Solutions04 Flexible AMOLED touch integration

Integration of touch functionality in flexible AMOLED screens requires innovative approaches to maintain touch sensitivity and accuracy during bending. This may involve the use of flexible touch sensors, advanced algorithms for touch detection in curved surfaces, and novel materials for transparent conductive layers.Expand Specific Solutions05 Durability and lifespan of flexible AMOLED screens

Enhancing the durability and lifespan of flexible AMOLED screens is crucial for their widespread adoption. This involves developing protective layers, stress-resistant materials, and advanced encapsulation techniques to prevent damage from repeated bending and environmental factors, ensuring long-term reliability and performance.Expand Specific Solutions

Key Flexible AMOLED Manufacturers

The production of large-scale flexible AMOLED screens presents significant challenges in a rapidly evolving market. The industry is in a growth phase, with increasing demand for flexible displays in smartphones, wearables, and automotive applications. The global flexible AMOLED market is expanding, driven by consumer preferences for innovative form factors. Technologically, while progress has been made, achieving consistent quality and yield rates at scale remains challenging. Companies like Samsung Display, LG Display, and BOE Technology are at the forefront, investing heavily in R&D and production capabilities. However, other players such as China Star Optoelectronics and Visionox are also making strides, intensifying competition in this high-stakes field.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced flexible AMOLED technology using LTPO (Low-Temperature Polycrystalline Oxide) backplanes[1]. Their solution incorporates a unique pixel compensation algorithm to address non-uniformity issues in large screens[2]. BOE has also pioneered the use of inkjet-printed OLED materials, which allows for more efficient material usage and potentially lower production costs for large screens[3]. To enhance flexibility and durability, BOE employs a proprietary thin-film encapsulation technique that provides superior moisture and oxygen barrier properties[4]. Additionally, BOE has developed a novel touch integration method that reduces the overall thickness of flexible displays while maintaining sensitivity[5].

Strengths: Advanced LTPO technology, efficient material usage, superior encapsulation. Weaknesses: Potential yield issues with large-scale production, higher initial investment costs.

Everdisplay Optronics (Shanghai) Co., Ltd.

Technical Solution: Everdisplay has developed a flexible AMOLED solution utilizing LTPS (Low-Temperature Poly-Silicon) backplane technology, which provides high electron mobility and uniform performance across large display areas[1]. They have implemented a proprietary compensation algorithm to address non-uniformity issues in OLED aging, crucial for maintaining image quality in large flexible screens[2]. Everdisplay's approach includes a novel flexible substrate material that offers improved dimensional stability during the manufacturing process, enhancing yield rates for large-scale production[3]. To improve touch functionality, Everdisplay has developed an in-cell touch solution specifically designed for flexible displays, reducing overall thickness and enhancing sensitivity[4]. Additionally, they employ a hybrid encapsulation technology that combines inorganic and organic layers to provide superior moisture barrier properties while maintaining flexibility in large screens[5].

Strengths: High-performance LTPS backplane, advanced compensation algorithms, innovative flexible substrate. Weaknesses: Less established presence in very large display market, potential challenges in scaling up production capacity.

Breakthrough Flexible AMOLED Patents

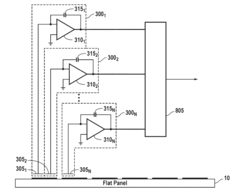

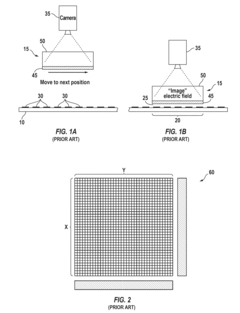

Direct detect sensor for flat panel displays

PatentActiveUS20100045334A1

Innovation

- A linear array of sensors with actively driven sensing electrodes and feedback circuits that maintain a fixed bias voltage, allowing for continuous scanning and improved sensitivity by minimizing the effect of parasitic capacitances, and enabling detection of defects like weak shorts and leaking transistors.

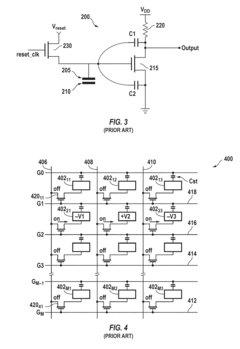

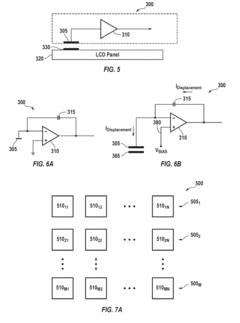

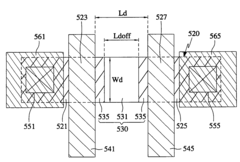

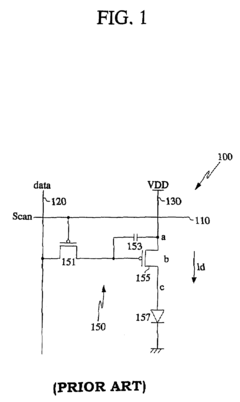

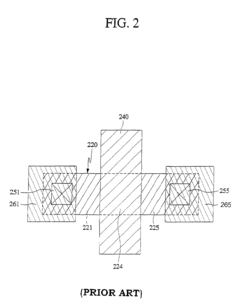

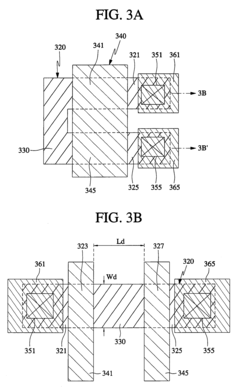

Flat panel display

PatentInactiveUS7283110B2

Innovation

- The implementation of transistors with varying resistance values, including multiple gates and offset regions with different doping concentrations or shapes, to control the current flowing through organic electroluminescent devices, thereby regulating the luminance and extending the device's life cycle.

Supply Chain and Material Challenges

The production of large-scale flexible AMOLED screens presents significant challenges in terms of supply chain and material sourcing. One of the primary obstacles is the limited availability of specialized materials required for these advanced displays. Flexible substrates, such as polyimide films, are crucial components that demand precise manufacturing processes and stringent quality control. The scarcity of suppliers capable of producing these materials at scale and to the required specifications creates bottlenecks in the production pipeline.

Another critical challenge lies in the sourcing of organic light-emitting materials. These compounds are essential for the OLED technology that underpins AMOLED displays. The development and production of high-performance, stable organic materials suitable for flexible applications require extensive research and development efforts. The limited number of suppliers capable of producing these materials to the necessary standards further complicates the supply chain.

The manufacturing of thin-film transistors (TFTs) for flexible AMOLED screens also poses significant material challenges. Traditional silicon-based TFTs are not suitable for flexible displays, necessitating the use of alternative materials such as low-temperature polycrystalline silicon (LTPS) or indium gallium zinc oxide (IGZO). The production of these materials at scale, while maintaining consistent quality and performance, remains a considerable hurdle.

Encapsulation materials present another critical supply chain challenge. Flexible AMOLED screens require advanced barrier films to protect the sensitive organic layers from moisture and oxygen. The development and production of these high-performance barrier materials involve complex processes and specialized equipment, limiting the number of suppliers capable of meeting the industry's demands.

The global nature of the supply chain for flexible AMOLED screens introduces additional complexities. Key materials and components are often sourced from different regions, making the production process vulnerable to geopolitical tensions, trade disputes, and logistical disruptions. This geographical dispersion of the supply chain can lead to increased costs, longer lead times, and potential quality control issues.

Furthermore, the rapid pace of technological advancement in the field of flexible displays creates a constant need for new and improved materials. This dynamic environment puts pressure on suppliers to continuously innovate and adapt their production processes, which can lead to temporary shortages or quality inconsistencies as new materials are introduced and scaled up.

Another critical challenge lies in the sourcing of organic light-emitting materials. These compounds are essential for the OLED technology that underpins AMOLED displays. The development and production of high-performance, stable organic materials suitable for flexible applications require extensive research and development efforts. The limited number of suppliers capable of producing these materials to the necessary standards further complicates the supply chain.

The manufacturing of thin-film transistors (TFTs) for flexible AMOLED screens also poses significant material challenges. Traditional silicon-based TFTs are not suitable for flexible displays, necessitating the use of alternative materials such as low-temperature polycrystalline silicon (LTPS) or indium gallium zinc oxide (IGZO). The production of these materials at scale, while maintaining consistent quality and performance, remains a considerable hurdle.

Encapsulation materials present another critical supply chain challenge. Flexible AMOLED screens require advanced barrier films to protect the sensitive organic layers from moisture and oxygen. The development and production of these high-performance barrier materials involve complex processes and specialized equipment, limiting the number of suppliers capable of meeting the industry's demands.

The global nature of the supply chain for flexible AMOLED screens introduces additional complexities. Key materials and components are often sourced from different regions, making the production process vulnerable to geopolitical tensions, trade disputes, and logistical disruptions. This geographical dispersion of the supply chain can lead to increased costs, longer lead times, and potential quality control issues.

Furthermore, the rapid pace of technological advancement in the field of flexible displays creates a constant need for new and improved materials. This dynamic environment puts pressure on suppliers to continuously innovate and adapt their production processes, which can lead to temporary shortages or quality inconsistencies as new materials are introduced and scaled up.

Environmental Impact of Flex Displays

The environmental impact of flexible AMOLED displays is a critical consideration in the development and adoption of this technology. As these displays become more prevalent in consumer electronics, their lifecycle environmental footprint becomes increasingly significant. The production process of flexible AMOLED screens involves the use of various materials, including rare earth elements and precious metals, which can have substantial environmental implications in terms of resource extraction and processing.

One of the primary environmental concerns is the energy-intensive manufacturing process of flexible AMOLED displays. The production of these screens requires high-temperature processes and clean room environments, leading to significant energy consumption and associated carbon emissions. Additionally, the use of organic materials in AMOLED technology presents challenges in terms of disposal and recycling at the end of the product's life cycle.

Water usage is another critical environmental factor in the production of flexible AMOLED screens. The manufacturing process requires ultra-pure water for cleaning and processing, potentially straining local water resources in production areas. Moreover, the chemicals used in the fabrication process can lead to water pollution if not properly managed and treated.

However, flexible AMOLED displays also offer potential environmental benefits. Their flexibility and durability can lead to longer-lasting devices, potentially reducing electronic waste. The thin and lightweight nature of these displays may also contribute to more energy-efficient devices, as they require less power to operate compared to traditional rigid displays.

The recyclability of flexible AMOLED screens is an area of ongoing research and development. While the organic materials used in these displays pose recycling challenges, advancements in recycling technologies are being made to address these issues. Improved recycling methods could significantly reduce the environmental impact of these displays over their lifecycle.

As the technology evolves, manufacturers are increasingly focusing on developing more environmentally friendly production processes for flexible AMOLED displays. This includes efforts to reduce energy consumption, minimize water usage, and explore alternative materials that have less environmental impact. The industry is also working on improving the efficiency of these displays, which could lead to reduced power consumption in devices using this technology.

In conclusion, while flexible AMOLED displays present certain environmental challenges, particularly in their production phase, they also offer potential benefits in terms of device longevity and energy efficiency. The ongoing efforts to improve manufacturing processes and recyclability are crucial in mitigating the environmental impact of this emerging technology.

One of the primary environmental concerns is the energy-intensive manufacturing process of flexible AMOLED displays. The production of these screens requires high-temperature processes and clean room environments, leading to significant energy consumption and associated carbon emissions. Additionally, the use of organic materials in AMOLED technology presents challenges in terms of disposal and recycling at the end of the product's life cycle.

Water usage is another critical environmental factor in the production of flexible AMOLED screens. The manufacturing process requires ultra-pure water for cleaning and processing, potentially straining local water resources in production areas. Moreover, the chemicals used in the fabrication process can lead to water pollution if not properly managed and treated.

However, flexible AMOLED displays also offer potential environmental benefits. Their flexibility and durability can lead to longer-lasting devices, potentially reducing electronic waste. The thin and lightweight nature of these displays may also contribute to more energy-efficient devices, as they require less power to operate compared to traditional rigid displays.

The recyclability of flexible AMOLED screens is an area of ongoing research and development. While the organic materials used in these displays pose recycling challenges, advancements in recycling technologies are being made to address these issues. Improved recycling methods could significantly reduce the environmental impact of these displays over their lifecycle.

As the technology evolves, manufacturers are increasingly focusing on developing more environmentally friendly production processes for flexible AMOLED displays. This includes efforts to reduce energy consumption, minimize water usage, and explore alternative materials that have less environmental impact. The industry is also working on improving the efficiency of these displays, which could lead to reduced power consumption in devices using this technology.

In conclusion, while flexible AMOLED displays present certain environmental challenges, particularly in their production phase, they also offer potential benefits in terms of device longevity and energy efficiency. The ongoing efforts to improve manufacturing processes and recyclability are crucial in mitigating the environmental impact of this emerging technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!