Characterizing Moisture Impact on PETG Film Expansion

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG Film Moisture Sensitivity Background

Polyethylene terephthalate glycol (PETG) film has gained significant attention in various industries due to its unique properties and versatile applications. As a modified version of PET, PETG offers improved clarity, toughness, and chemical resistance, making it an ideal choice for packaging, medical devices, and industrial applications. However, one of the critical challenges in utilizing PETG film is its sensitivity to moisture, which can significantly impact its dimensional stability and overall performance.

The moisture sensitivity of PETG film stems from its chemical structure and manufacturing process. PETG is a copolyester that incorporates glycol into its polymer chain, resulting in a more amorphous structure compared to standard PET. This amorphous nature allows for greater flexibility and impact resistance but also increases the material's susceptibility to moisture absorption. When exposed to humid environments or direct contact with water, PETG film can absorb moisture, leading to various dimensional and physical changes.

Understanding the moisture impact on PETG film expansion is crucial for ensuring product quality, optimizing manufacturing processes, and predicting long-term performance in different environmental conditions. The expansion of PETG film due to moisture absorption can manifest in several ways, including swelling, warping, and changes in mechanical properties. These dimensional changes can be particularly problematic in applications requiring precise tolerances or in multi-layer structures where differential expansion between layers can lead to delamination or other structural issues.

The extent of moisture-induced expansion in PETG film is influenced by several factors, including the film's thickness, manufacturing conditions, and environmental exposure. Thicker films generally exhibit slower moisture absorption rates but may experience more significant dimensional changes over time. The manufacturing process, particularly the cooling rate and orientation during extrusion, can affect the film's crystallinity and, consequently, its moisture sensitivity. Environmental factors such as temperature, relative humidity, and exposure duration play critical roles in determining the rate and extent of moisture absorption and subsequent expansion.

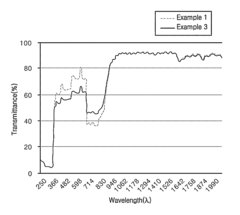

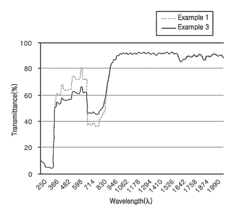

Characterizing the moisture impact on PETG film expansion involves a multifaceted approach, combining experimental measurements, analytical techniques, and predictive modeling. Researchers and industry professionals employ various methods to quantify moisture absorption rates, dimensional changes, and alterations in mechanical properties. These include gravimetric analysis, optical measurements, mechanical testing, and advanced spectroscopic techniques. Understanding these characteristics is essential for developing effective moisture barrier coatings, optimizing storage conditions, and designing products that can withstand varying environmental conditions.

As the demand for PETG film continues to grow across diverse applications, addressing its moisture sensitivity becomes increasingly important. This challenge presents opportunities for innovation in material science, coating technologies, and process engineering. By thoroughly characterizing the moisture impact on PETG film expansion, manufacturers and end-users can develop strategies to mitigate moisture-related issues, enhance product performance, and expand the range of applications for this versatile material.

The moisture sensitivity of PETG film stems from its chemical structure and manufacturing process. PETG is a copolyester that incorporates glycol into its polymer chain, resulting in a more amorphous structure compared to standard PET. This amorphous nature allows for greater flexibility and impact resistance but also increases the material's susceptibility to moisture absorption. When exposed to humid environments or direct contact with water, PETG film can absorb moisture, leading to various dimensional and physical changes.

Understanding the moisture impact on PETG film expansion is crucial for ensuring product quality, optimizing manufacturing processes, and predicting long-term performance in different environmental conditions. The expansion of PETG film due to moisture absorption can manifest in several ways, including swelling, warping, and changes in mechanical properties. These dimensional changes can be particularly problematic in applications requiring precise tolerances or in multi-layer structures where differential expansion between layers can lead to delamination or other structural issues.

The extent of moisture-induced expansion in PETG film is influenced by several factors, including the film's thickness, manufacturing conditions, and environmental exposure. Thicker films generally exhibit slower moisture absorption rates but may experience more significant dimensional changes over time. The manufacturing process, particularly the cooling rate and orientation during extrusion, can affect the film's crystallinity and, consequently, its moisture sensitivity. Environmental factors such as temperature, relative humidity, and exposure duration play critical roles in determining the rate and extent of moisture absorption and subsequent expansion.

Characterizing the moisture impact on PETG film expansion involves a multifaceted approach, combining experimental measurements, analytical techniques, and predictive modeling. Researchers and industry professionals employ various methods to quantify moisture absorption rates, dimensional changes, and alterations in mechanical properties. These include gravimetric analysis, optical measurements, mechanical testing, and advanced spectroscopic techniques. Understanding these characteristics is essential for developing effective moisture barrier coatings, optimizing storage conditions, and designing products that can withstand varying environmental conditions.

As the demand for PETG film continues to grow across diverse applications, addressing its moisture sensitivity becomes increasingly important. This challenge presents opportunities for innovation in material science, coating technologies, and process engineering. By thoroughly characterizing the moisture impact on PETG film expansion, manufacturers and end-users can develop strategies to mitigate moisture-related issues, enhance product performance, and expand the range of applications for this versatile material.

Market Analysis for Moisture-Resistant PETG Films

The market for moisture-resistant PETG films is experiencing significant growth, driven by increasing demand across various industries. PETG (Polyethylene Terephthalate Glycol-modified) films are widely used in packaging, labeling, and industrial applications due to their excellent clarity, durability, and chemical resistance. However, the impact of moisture on PETG film expansion has been a persistent challenge, creating a strong market need for moisture-resistant variants.

The packaging industry represents the largest market segment for moisture-resistant PETG films. With the rise of e-commerce and the need for robust packaging solutions, there is a growing demand for films that can withstand varying humidity conditions during storage and transportation. The food and beverage sector, in particular, requires packaging materials that maintain their integrity and prevent moisture ingress, preserving product quality and extending shelf life.

In the electronics industry, moisture-resistant PETG films are gaining traction for protecting sensitive components and printed circuit boards. As electronic devices become more compact and sophisticated, the need for reliable moisture barriers has intensified. This trend is further amplified by the expansion of the Internet of Things (IoT) and the increasing use of electronics in harsh environments.

The medical and pharmaceutical sectors also present significant market opportunities for moisture-resistant PETG films. These industries require packaging materials that can maintain sterility and protect drugs and medical devices from moisture contamination. The ongoing global health concerns have further accelerated the demand for high-performance packaging solutions in these sectors.

Geographically, Asia-Pacific is expected to be the fastest-growing market for moisture-resistant PETG films, driven by rapid industrialization, increasing disposable incomes, and changing consumer preferences. North America and Europe remain significant markets, with a focus on innovative and sustainable packaging solutions.

The market is characterized by intense competition among key players, including Eastman Chemical Company, SK Chemicals, and DAK Americas. These companies are investing heavily in research and development to enhance the moisture resistance properties of PETG films while maintaining their other desirable characteristics.

Looking ahead, the market for moisture-resistant PETG films is projected to continue its growth trajectory. Factors such as urbanization, changing lifestyles, and the increasing adoption of convenient packaging solutions are expected to drive demand. Additionally, the push towards sustainable and recyclable materials presents both challenges and opportunities for innovation in this space.

The packaging industry represents the largest market segment for moisture-resistant PETG films. With the rise of e-commerce and the need for robust packaging solutions, there is a growing demand for films that can withstand varying humidity conditions during storage and transportation. The food and beverage sector, in particular, requires packaging materials that maintain their integrity and prevent moisture ingress, preserving product quality and extending shelf life.

In the electronics industry, moisture-resistant PETG films are gaining traction for protecting sensitive components and printed circuit boards. As electronic devices become more compact and sophisticated, the need for reliable moisture barriers has intensified. This trend is further amplified by the expansion of the Internet of Things (IoT) and the increasing use of electronics in harsh environments.

The medical and pharmaceutical sectors also present significant market opportunities for moisture-resistant PETG films. These industries require packaging materials that can maintain sterility and protect drugs and medical devices from moisture contamination. The ongoing global health concerns have further accelerated the demand for high-performance packaging solutions in these sectors.

Geographically, Asia-Pacific is expected to be the fastest-growing market for moisture-resistant PETG films, driven by rapid industrialization, increasing disposable incomes, and changing consumer preferences. North America and Europe remain significant markets, with a focus on innovative and sustainable packaging solutions.

The market is characterized by intense competition among key players, including Eastman Chemical Company, SK Chemicals, and DAK Americas. These companies are investing heavily in research and development to enhance the moisture resistance properties of PETG films while maintaining their other desirable characteristics.

Looking ahead, the market for moisture-resistant PETG films is projected to continue its growth trajectory. Factors such as urbanization, changing lifestyles, and the increasing adoption of convenient packaging solutions are expected to drive demand. Additionally, the push towards sustainable and recyclable materials presents both challenges and opportunities for innovation in this space.

Current Challenges in PETG Film Moisture Management

The management of moisture in PETG (Polyethylene Terephthalate Glycol-modified) film production and application presents several significant challenges. One of the primary issues is the hygroscopic nature of PETG, which makes it susceptible to moisture absorption from the environment. This absorption can lead to dimensional instability, affecting the film's performance and quality in various applications.

A major challenge lies in maintaining consistent moisture levels throughout the manufacturing process. PETG films are particularly sensitive to humidity fluctuations during extrusion, cooling, and storage phases. Even small variations in moisture content can result in uneven film thickness, surface defects, and reduced optical clarity. These issues are especially problematic in industries requiring high-precision films, such as packaging and electronics.

Another significant hurdle is the difficulty in accurately measuring and controlling moisture content in real-time during production. Current moisture measurement techniques often lack the precision and speed required for continuous, high-volume manufacturing processes. This limitation can lead to quality inconsistencies and increased production waste.

The expansion of PETG films due to moisture absorption poses challenges in applications where dimensional stability is crucial. For instance, in flexible electronics or medical device packaging, even slight changes in film dimensions can compromise product integrity or functionality. Developing effective strategies to mitigate moisture-induced expansion while maintaining the film's desirable properties remains a complex task.

Furthermore, the interaction between moisture and other environmental factors, such as temperature and UV exposure, complicates the prediction and control of PETG film behavior. These interactions can accelerate degradation processes, affecting the film's long-term performance and shelf life. Understanding and managing these complex relationships is essential for improving product reliability and durability.

The recycling and reprocessing of PETG films present additional moisture-related challenges. Residual moisture in recycled materials can lead to processing difficulties and quality issues in subsequent production cycles. Developing efficient drying techniques that do not compromise the material's properties is an ongoing area of research and development.

Lastly, balancing moisture management with other desirable film properties, such as gas barrier performance, mechanical strength, and transparency, remains a significant challenge. Modifications to improve moisture resistance often come at the cost of other critical characteristics, necessitating careful optimization and trade-off analyses.

A major challenge lies in maintaining consistent moisture levels throughout the manufacturing process. PETG films are particularly sensitive to humidity fluctuations during extrusion, cooling, and storage phases. Even small variations in moisture content can result in uneven film thickness, surface defects, and reduced optical clarity. These issues are especially problematic in industries requiring high-precision films, such as packaging and electronics.

Another significant hurdle is the difficulty in accurately measuring and controlling moisture content in real-time during production. Current moisture measurement techniques often lack the precision and speed required for continuous, high-volume manufacturing processes. This limitation can lead to quality inconsistencies and increased production waste.

The expansion of PETG films due to moisture absorption poses challenges in applications where dimensional stability is crucial. For instance, in flexible electronics or medical device packaging, even slight changes in film dimensions can compromise product integrity or functionality. Developing effective strategies to mitigate moisture-induced expansion while maintaining the film's desirable properties remains a complex task.

Furthermore, the interaction between moisture and other environmental factors, such as temperature and UV exposure, complicates the prediction and control of PETG film behavior. These interactions can accelerate degradation processes, affecting the film's long-term performance and shelf life. Understanding and managing these complex relationships is essential for improving product reliability and durability.

The recycling and reprocessing of PETG films present additional moisture-related challenges. Residual moisture in recycled materials can lead to processing difficulties and quality issues in subsequent production cycles. Developing efficient drying techniques that do not compromise the material's properties is an ongoing area of research and development.

Lastly, balancing moisture management with other desirable film properties, such as gas barrier performance, mechanical strength, and transparency, remains a significant challenge. Modifications to improve moisture resistance often come at the cost of other critical characteristics, necessitating careful optimization and trade-off analyses.

Existing Moisture Control Solutions for PETG Films

01 PETG film manufacturing process

The manufacturing process of PETG films involves extrusion, stretching, and heat treatment. The process parameters, such as temperature, pressure, and stretching ratio, are carefully controlled to achieve desired film properties. Various techniques are employed to improve film quality and performance, including biaxial orientation and surface treatment.- PETG film manufacturing process: The manufacturing process of PETG films involves extrusion, stretching, and heat treatment. The process parameters, such as temperature, pressure, and stretching ratio, are carefully controlled to achieve desired film properties. Various techniques are employed to improve film quality, including multi-layer co-extrusion and orientation processes.

- PETG film composition and additives: PETG films can be modified with various additives to enhance their properties. These additives may include stabilizers, plasticizers, and fillers. The composition of the PETG resin and the type and amount of additives used can significantly affect the film's expansion characteristics, mechanical properties, and overall performance.

- PETG film expansion techniques: Various techniques are used to expand PETG films, including biaxial stretching, blow molding, and thermoforming. These processes involve heating the film to its softening point and then applying force to stretch it in one or more directions. The expansion process can be optimized to achieve desired film thickness, uniformity, and mechanical properties.

- Applications of expanded PETG films: Expanded PETG films find applications in various industries, including packaging, electronics, and medical devices. The expanded films offer advantages such as improved insulation properties, reduced weight, and enhanced cushioning. Specific applications include food packaging, protective covers for electronic devices, and medical packaging materials.

- PETG film expansion equipment and machinery: Specialized equipment and machinery are used for PETG film expansion processes. This includes extruders, stretching units, heat treatment chambers, and winding systems. Advanced control systems and sensors are employed to monitor and adjust process parameters in real-time, ensuring consistent film quality and expansion characteristics.

02 PETG film composition and additives

PETG films can be modified with various additives to enhance their properties. These additives may include stabilizers, plasticizers, and functional fillers. The composition of the PETG resin and the type and amount of additives used can significantly affect the film's performance, such as its mechanical strength, thermal stability, and optical properties.Expand Specific Solutions03 PETG film applications

PETG films find applications in various industries due to their unique properties. They are used in packaging, electronics, medical devices, and automotive sectors. The films can be tailored for specific applications by adjusting their thickness, surface properties, and other characteristics to meet the requirements of different end-uses.Expand Specific Solutions04 PETG film expansion techniques

Various techniques are employed to expand PETG films, including thermal expansion, mechanical stretching, and gas-assisted expansion. These methods can be used to create expanded or foamed PETG films with reduced density and improved insulation properties. The expansion process can be controlled to achieve specific pore structures and densities.Expand Specific Solutions05 PETG film surface modification

Surface modification techniques are applied to PETG films to enhance their properties or functionalities. These may include plasma treatment, chemical etching, or coating applications. Surface modifications can improve adhesion, printability, barrier properties, or introduce specific functionalities such as antimicrobial or antistatic properties to the PETG film surface.Expand Specific Solutions

Key PETG Film Manufacturers and Suppliers

The characterization of moisture impact on PETG film expansion is currently in an early development stage, with a growing market driven by increasing demand for sustainable packaging solutions. The global PETG film market is expected to expand significantly in the coming years, fueled by applications in food packaging, pharmaceuticals, and consumer goods. Technologically, the field is evolving rapidly, with companies like Eastman Chemical Co., Toyobo Co., Ltd., and Toray Industries, Inc. leading innovation efforts. These firms are investing in research to improve moisture resistance and dimensional stability of PETG films, aiming to enhance performance in high-humidity environments. Collaboration between industry leaders and academic institutions, such as Sichuan University and the National University of Singapore, is accelerating progress in understanding and mitigating moisture-related challenges in PETG film applications.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed a novel approach to characterizing and mitigating moisture impact on PETG film expansion. Their method involves using advanced spectroscopic techniques to analyze the molecular interactions between water and PETG polymer chains. They have created a predictive model that correlates humidity levels with film expansion rates, allowing for precise control in various applications. Toray has also implemented a surface modification technique that creates a hydrophobic layer on the PETG film, significantly reducing moisture absorption [2][5].

Strengths: Precise characterization and prediction of moisture-induced expansion, improved moisture resistance. Weaknesses: May require specialized equipment for surface modification, potentially increasing production costs.

Eastman Chemical Co.

Technical Solution: Eastman Chemical Co. has developed advanced PETG film formulations with enhanced moisture resistance. Their technology involves incorporating hydrophobic additives and optimizing the polymer structure to reduce water absorption. They have implemented a proprietary drying process that removes residual moisture from the film before packaging, minimizing the risk of expansion during storage and use. Eastman has also developed a multi-layer film structure that includes a moisture barrier layer, effectively reducing the overall moisture sensitivity of the PETG film [1][3].

Strengths: Improved moisture resistance, reduced expansion, and enhanced stability in humid environments. Weaknesses: Potentially higher production costs and complexity in manufacturing multi-layer structures.

Innovative Approaches to PETG Film Moisture Resistance

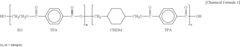

Flame-retardant, glycol-modified polyethylene terephthalate film

PatentInactiveUS20060142454A1

Innovation

- Incorporating a suitable amount of a processing aid, such as an acrylic terpolymer resin, along with a flame retardant and a lubricant into a glycol-modified polyethylene terephthalate (PET-G) film composition to enhance both flame retardancy and processability.

Multilayer optical film having high heat resistance and method for manufacturing the same

PatentInactiveUS9541689B2

Innovation

- A multilayer optical film structure is developed with alternately laminated resin layers, where the first resin layer comprises crystalline naphthalene dicarboxylic-acid polyester and the second resin layer comprises polyethylene terephthalate glycol (PETG) with a glass transition temperature of 100 to 140°C, enhancing heat resistance and optical properties.

Environmental Factors Affecting PETG Film Performance

Environmental factors play a crucial role in the performance of PETG (Polyethylene Terephthalate Glycol-modified) films, particularly in relation to moisture impact and expansion characteristics. The hygroscopic nature of PETG makes it susceptible to moisture absorption, which can significantly affect its dimensional stability and mechanical properties.

Temperature and humidity are the primary environmental factors influencing PETG film performance. Higher temperatures accelerate moisture absorption, while elevated humidity levels increase the amount of moisture that can be absorbed by the film. This combination can lead to swelling and dimensional changes in the PETG film, potentially compromising its intended functionality in various applications.

The rate of moisture absorption in PETG films is not uniform and depends on several factors, including film thickness, crystallinity, and surface area exposed to the environment. Thinner films generally absorb moisture more rapidly due to their higher surface area-to-volume ratio. Additionally, the degree of crystallinity in the PETG structure can affect moisture absorption rates, with more amorphous regions being more susceptible to water uptake.

Exposure time is another critical factor in moisture-related expansion of PETG films. Prolonged exposure to high-humidity environments can result in cumulative effects, leading to more significant dimensional changes over time. This time-dependent behavior necessitates careful consideration in applications where long-term stability is required.

The presence of additives or coatings in PETG films can also influence their response to environmental moisture. Some additives may enhance moisture resistance, while others might increase hygroscopicity. Barrier coatings, when applied effectively, can significantly reduce moisture penetration and mitigate expansion issues.

Cyclic environmental conditions, such as alternating periods of high and low humidity or temperature fluctuations, can induce stress in PETG films due to repeated expansion and contraction. This cycling can lead to fatigue and potentially compromise the film's mechanical integrity over time.

Understanding these environmental factors is crucial for predicting and controlling PETG film performance in various applications. It enables the development of appropriate storage conditions, packaging solutions, and usage guidelines to maintain the film's desired properties. Furthermore, this knowledge informs the design of moisture-resistant PETG formulations and the implementation of protective measures in moisture-sensitive applications.

Temperature and humidity are the primary environmental factors influencing PETG film performance. Higher temperatures accelerate moisture absorption, while elevated humidity levels increase the amount of moisture that can be absorbed by the film. This combination can lead to swelling and dimensional changes in the PETG film, potentially compromising its intended functionality in various applications.

The rate of moisture absorption in PETG films is not uniform and depends on several factors, including film thickness, crystallinity, and surface area exposed to the environment. Thinner films generally absorb moisture more rapidly due to their higher surface area-to-volume ratio. Additionally, the degree of crystallinity in the PETG structure can affect moisture absorption rates, with more amorphous regions being more susceptible to water uptake.

Exposure time is another critical factor in moisture-related expansion of PETG films. Prolonged exposure to high-humidity environments can result in cumulative effects, leading to more significant dimensional changes over time. This time-dependent behavior necessitates careful consideration in applications where long-term stability is required.

The presence of additives or coatings in PETG films can also influence their response to environmental moisture. Some additives may enhance moisture resistance, while others might increase hygroscopicity. Barrier coatings, when applied effectively, can significantly reduce moisture penetration and mitigate expansion issues.

Cyclic environmental conditions, such as alternating periods of high and low humidity or temperature fluctuations, can induce stress in PETG films due to repeated expansion and contraction. This cycling can lead to fatigue and potentially compromise the film's mechanical integrity over time.

Understanding these environmental factors is crucial for predicting and controlling PETG film performance in various applications. It enables the development of appropriate storage conditions, packaging solutions, and usage guidelines to maintain the film's desired properties. Furthermore, this knowledge informs the design of moisture-resistant PETG formulations and the implementation of protective measures in moisture-sensitive applications.

Regulatory Compliance for PETG Film Applications

Regulatory compliance is a critical aspect of PETG film applications, particularly when considering the impact of moisture on film expansion. As the use of PETG films continues to grow across various industries, manufacturers and end-users must adhere to stringent regulations to ensure product safety, quality, and environmental sustainability.

In the food packaging industry, PETG films must comply with FDA regulations in the United States and EU food contact materials regulations in Europe. These regulations set strict limits on the migration of substances from packaging materials to food, including any potential moisture-related contaminants. Manufacturers must conduct thorough testing to demonstrate that their PETG films maintain their integrity and do not release harmful substances when exposed to varying moisture levels.

For medical device applications, PETG films are subject to regulations such as ISO 10993 for biocompatibility and USP Class VI for plastics. These standards require extensive testing to ensure that the material remains stable and safe for use in medical environments, even when exposed to moisture. Manufacturers must provide documentation proving that their PETG films meet these requirements, including data on moisture absorption and its impact on film properties.

In the automotive and aerospace industries, PETG films must comply with regulations related to flammability and off-gassing. Standards such as FAR 25.853 for aircraft interiors and FMVSS 302 for automotive applications set specific requirements for material performance under various environmental conditions, including exposure to moisture. Manufacturers must demonstrate that their PETG films maintain their flame-retardant properties and do not release harmful gases when subjected to moisture-induced expansion.

Environmental regulations also play a significant role in PETG film applications. Many regions have implemented restrictions on single-use plastics and require manufacturers to provide recyclable or biodegradable alternatives. PETG films must meet these sustainability requirements while still maintaining their performance characteristics under varying moisture conditions. Compliance with regulations such as the EU's Packaging and Packaging Waste Directive is essential for manufacturers operating in the European market.

To ensure regulatory compliance, manufacturers must implement robust quality control processes and maintain detailed documentation of their testing procedures and results. This includes regular monitoring of moisture-related parameters during production and storage, as well as long-term stability studies to assess the impact of moisture on PETG film properties over time. Third-party certification and regular audits may also be required to demonstrate ongoing compliance with relevant regulations.

As regulations continue to evolve, manufacturers must stay informed about changes in compliance requirements across different regions and industries. This may involve investing in research and development to improve moisture resistance and develop new formulations that meet increasingly stringent regulatory standards. By prioritizing regulatory compliance in their approach to characterizing moisture impact on PETG film expansion, manufacturers can ensure the continued success and market acceptance of their products in a highly regulated global marketplace.

In the food packaging industry, PETG films must comply with FDA regulations in the United States and EU food contact materials regulations in Europe. These regulations set strict limits on the migration of substances from packaging materials to food, including any potential moisture-related contaminants. Manufacturers must conduct thorough testing to demonstrate that their PETG films maintain their integrity and do not release harmful substances when exposed to varying moisture levels.

For medical device applications, PETG films are subject to regulations such as ISO 10993 for biocompatibility and USP Class VI for plastics. These standards require extensive testing to ensure that the material remains stable and safe for use in medical environments, even when exposed to moisture. Manufacturers must provide documentation proving that their PETG films meet these requirements, including data on moisture absorption and its impact on film properties.

In the automotive and aerospace industries, PETG films must comply with regulations related to flammability and off-gassing. Standards such as FAR 25.853 for aircraft interiors and FMVSS 302 for automotive applications set specific requirements for material performance under various environmental conditions, including exposure to moisture. Manufacturers must demonstrate that their PETG films maintain their flame-retardant properties and do not release harmful gases when subjected to moisture-induced expansion.

Environmental regulations also play a significant role in PETG film applications. Many regions have implemented restrictions on single-use plastics and require manufacturers to provide recyclable or biodegradable alternatives. PETG films must meet these sustainability requirements while still maintaining their performance characteristics under varying moisture conditions. Compliance with regulations such as the EU's Packaging and Packaging Waste Directive is essential for manufacturers operating in the European market.

To ensure regulatory compliance, manufacturers must implement robust quality control processes and maintain detailed documentation of their testing procedures and results. This includes regular monitoring of moisture-related parameters during production and storage, as well as long-term stability studies to assess the impact of moisture on PETG film properties over time. Third-party certification and regular audits may also be required to demonstrate ongoing compliance with relevant regulations.

As regulations continue to evolve, manufacturers must stay informed about changes in compliance requirements across different regions and industries. This may involve investing in research and development to improve moisture resistance and develop new formulations that meet increasingly stringent regulatory standards. By prioritizing regulatory compliance in their approach to characterizing moisture impact on PETG film expansion, manufacturers can ensure the continued success and market acceptance of their products in a highly regulated global marketplace.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!