Coil Whine in Electric Vehicles: Challenges and Solutions

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EV Coil Whine Background and Objectives

Coil whine in electric vehicles (EVs) has emerged as a significant challenge in the automotive industry, particularly as the global market shifts towards electrification. This high-frequency noise, typically ranging from 2 kHz to 20 kHz, is produced by electromagnetic forces acting on the windings of electric motors and power electronics components. The phenomenon has gained attention due to its potential impact on passenger comfort and overall vehicle quality perception.

The evolution of EV technology has brought coil whine to the forefront of engineering concerns. As electric powertrains have become more powerful and efficient, the issue of electromagnetic noise has become more pronounced. This is partly due to the higher switching frequencies in modern power electronics and the increased power density in electric motors. The problem is further exacerbated by the absence of masking noise from internal combustion engines, making even subtle electromagnetic sounds more noticeable in the quiet cabin of an EV.

The primary objective in addressing coil whine is to enhance the acoustic comfort of electric vehicles without compromising their performance or efficiency. This goal aligns with the broader industry trend towards creating a superior user experience in EVs, which is crucial for widespread adoption. Manufacturers are increasingly recognizing that the unique sound profile of electric vehicles, including the mitigation of coil whine, is an important differentiator in the competitive automotive market.

From a technical perspective, the objectives of coil whine research and development include identifying the root causes of the phenomenon, developing effective mitigation strategies, and implementing solutions that are both cost-effective and scalable for mass production. This involves a multidisciplinary approach, combining expertise from electrical engineering, materials science, and acoustic engineering.

The automotive industry is also exploring the potential of using advanced materials and innovative design techniques to address coil whine at its source. This includes the development of new winding technologies, improved insulation materials, and optimized motor and inverter designs. Additionally, there is a growing interest in active noise control systems that can dynamically counteract electromagnetic noise in real-time.

As the EV market continues to expand, the importance of solving the coil whine issue becomes increasingly critical. It is not merely a matter of comfort but also relates to safety, as excessive noise can lead to driver fatigue and reduced awareness. Furthermore, regulatory bodies are beginning to consider noise emissions from electric vehicles, including high-frequency sounds, in their standards and guidelines.

The evolution of EV technology has brought coil whine to the forefront of engineering concerns. As electric powertrains have become more powerful and efficient, the issue of electromagnetic noise has become more pronounced. This is partly due to the higher switching frequencies in modern power electronics and the increased power density in electric motors. The problem is further exacerbated by the absence of masking noise from internal combustion engines, making even subtle electromagnetic sounds more noticeable in the quiet cabin of an EV.

The primary objective in addressing coil whine is to enhance the acoustic comfort of electric vehicles without compromising their performance or efficiency. This goal aligns with the broader industry trend towards creating a superior user experience in EVs, which is crucial for widespread adoption. Manufacturers are increasingly recognizing that the unique sound profile of electric vehicles, including the mitigation of coil whine, is an important differentiator in the competitive automotive market.

From a technical perspective, the objectives of coil whine research and development include identifying the root causes of the phenomenon, developing effective mitigation strategies, and implementing solutions that are both cost-effective and scalable for mass production. This involves a multidisciplinary approach, combining expertise from electrical engineering, materials science, and acoustic engineering.

The automotive industry is also exploring the potential of using advanced materials and innovative design techniques to address coil whine at its source. This includes the development of new winding technologies, improved insulation materials, and optimized motor and inverter designs. Additionally, there is a growing interest in active noise control systems that can dynamically counteract electromagnetic noise in real-time.

As the EV market continues to expand, the importance of solving the coil whine issue becomes increasingly critical. It is not merely a matter of comfort but also relates to safety, as excessive noise can lead to driver fatigue and reduced awareness. Furthermore, regulatory bodies are beginning to consider noise emissions from electric vehicles, including high-frequency sounds, in their standards and guidelines.

Market Impact Analysis

The impact of coil whine in electric vehicles (EVs) on the automotive market is significant and multifaceted. As consumers increasingly adopt EVs, their expectations for a quiet and comfortable driving experience have risen. Coil whine, a high-frequency noise produced by electromagnetic components, poses a challenge to meeting these expectations and can potentially influence purchasing decisions.

The presence of coil whine in EVs has led to increased warranty claims and customer complaints, affecting brand reputation and customer satisfaction. This issue has prompted automotive manufacturers to allocate additional resources to research and development, focusing on noise reduction technologies and improved component design. The need for specialized acoustic engineering in EV development has created new job opportunities and expanded the skill sets required in the automotive industry.

Coil whine has also impacted the supply chain dynamics within the EV market. Component suppliers are under pressure to develop and produce quieter electrical systems, inverters, and motors. This has led to increased competition among suppliers, driving innovation in materials and manufacturing processes. The demand for noise-reducing components has created new market segments and business opportunities for specialized suppliers.

The issue of coil whine has influenced regulatory discussions and the development of new standards for EV noise emissions. As governments and industry bodies work to establish guidelines for acceptable noise levels in EVs, manufacturers are compelled to invest in noise reduction technologies to ensure compliance. This regulatory pressure has accelerated the pace of innovation in acoustic management for EVs.

From a competitive standpoint, the ability to effectively address coil whine has become a differentiating factor among EV manufacturers. Companies that successfully minimize or eliminate coil whine in their vehicles gain a competitive edge, potentially capturing a larger market share and commanding premium prices for their quieter, more refined products.

The market for aftermarket solutions addressing coil whine has also emerged, offering noise reduction kits and services for existing EVs. This has created additional revenue streams for automotive service providers and aftermarket parts manufacturers, further expanding the economic impact of the coil whine issue.

In conclusion, the challenges posed by coil whine in EVs have rippled through various aspects of the automotive market, influencing product development, supply chain dynamics, regulatory landscapes, and consumer preferences. As the EV market continues to grow, the ability to effectively manage and mitigate coil whine will remain a crucial factor in shaping market trends and competitive positioning.

The presence of coil whine in EVs has led to increased warranty claims and customer complaints, affecting brand reputation and customer satisfaction. This issue has prompted automotive manufacturers to allocate additional resources to research and development, focusing on noise reduction technologies and improved component design. The need for specialized acoustic engineering in EV development has created new job opportunities and expanded the skill sets required in the automotive industry.

Coil whine has also impacted the supply chain dynamics within the EV market. Component suppliers are under pressure to develop and produce quieter electrical systems, inverters, and motors. This has led to increased competition among suppliers, driving innovation in materials and manufacturing processes. The demand for noise-reducing components has created new market segments and business opportunities for specialized suppliers.

The issue of coil whine has influenced regulatory discussions and the development of new standards for EV noise emissions. As governments and industry bodies work to establish guidelines for acceptable noise levels in EVs, manufacturers are compelled to invest in noise reduction technologies to ensure compliance. This regulatory pressure has accelerated the pace of innovation in acoustic management for EVs.

From a competitive standpoint, the ability to effectively address coil whine has become a differentiating factor among EV manufacturers. Companies that successfully minimize or eliminate coil whine in their vehicles gain a competitive edge, potentially capturing a larger market share and commanding premium prices for their quieter, more refined products.

The market for aftermarket solutions addressing coil whine has also emerged, offering noise reduction kits and services for existing EVs. This has created additional revenue streams for automotive service providers and aftermarket parts manufacturers, further expanding the economic impact of the coil whine issue.

In conclusion, the challenges posed by coil whine in EVs have rippled through various aspects of the automotive market, influencing product development, supply chain dynamics, regulatory landscapes, and consumer preferences. As the EV market continues to grow, the ability to effectively manage and mitigate coil whine will remain a crucial factor in shaping market trends and competitive positioning.

Technical Challenges and Constraints

Coil whine in electric vehicles presents significant technical challenges and constraints that require innovative solutions. The primary issue stems from the high-frequency electromagnetic oscillations in the vehicle's power electronics, particularly in the inverter and motor systems. These oscillations can produce audible noise, ranging from 1 kHz to 20 kHz, which is often perceived as an annoying whine by vehicle occupants.

One of the main technical challenges is the complex interplay between electrical, mechanical, and acoustic phenomena. The electromagnetic forces generated by alternating currents in the motor windings and power electronics components cause minute physical vibrations in these components. These vibrations, in turn, produce sound waves that propagate through the vehicle structure, resulting in audible noise inside the cabin.

Another significant constraint is the limited space available for implementing noise reduction solutions in electric vehicles. The compact design of modern EVs leaves little room for additional insulation or vibration damping materials without compromising vehicle weight or performance. This spatial limitation necessitates the development of highly efficient and compact noise mitigation techniques.

The high power density of electric vehicle powertrains also contributes to the coil whine problem. As manufacturers strive to increase the power output and efficiency of electric motors and inverters, the electromagnetic forces and resulting vibrations tend to intensify. This creates a challenging trade-off between performance optimization and noise reduction.

Temperature variations pose another technical hurdle in addressing coil whine. The acoustic properties of materials and the behavior of electromagnetic components can change significantly across the wide temperature range experienced by electric vehicles. This variability complicates the design of effective noise reduction solutions that must perform consistently under diverse operating conditions.

The need for cost-effective solutions presents an additional constraint. While high-end luxury electric vehicles may incorporate expensive noise reduction technologies, mass-market EVs require more economical approaches to remain competitive. This economic factor limits the range of viable technical solutions and necessitates innovative, cost-efficient designs.

Regulatory requirements and consumer expectations for vehicle noise levels add further complexity to the coil whine challenge. As electric vehicles become more prevalent, noise regulations are evolving to address their unique acoustic characteristics. Meeting these standards while maintaining vehicle performance and affordability requires a delicate balance of engineering trade-offs.

One of the main technical challenges is the complex interplay between electrical, mechanical, and acoustic phenomena. The electromagnetic forces generated by alternating currents in the motor windings and power electronics components cause minute physical vibrations in these components. These vibrations, in turn, produce sound waves that propagate through the vehicle structure, resulting in audible noise inside the cabin.

Another significant constraint is the limited space available for implementing noise reduction solutions in electric vehicles. The compact design of modern EVs leaves little room for additional insulation or vibration damping materials without compromising vehicle weight or performance. This spatial limitation necessitates the development of highly efficient and compact noise mitigation techniques.

The high power density of electric vehicle powertrains also contributes to the coil whine problem. As manufacturers strive to increase the power output and efficiency of electric motors and inverters, the electromagnetic forces and resulting vibrations tend to intensify. This creates a challenging trade-off between performance optimization and noise reduction.

Temperature variations pose another technical hurdle in addressing coil whine. The acoustic properties of materials and the behavior of electromagnetic components can change significantly across the wide temperature range experienced by electric vehicles. This variability complicates the design of effective noise reduction solutions that must perform consistently under diverse operating conditions.

The need for cost-effective solutions presents an additional constraint. While high-end luxury electric vehicles may incorporate expensive noise reduction technologies, mass-market EVs require more economical approaches to remain competitive. This economic factor limits the range of viable technical solutions and necessitates innovative, cost-efficient designs.

Regulatory requirements and consumer expectations for vehicle noise levels add further complexity to the coil whine challenge. As electric vehicles become more prevalent, noise regulations are evolving to address their unique acoustic characteristics. Meeting these standards while maintaining vehicle performance and affordability requires a delicate balance of engineering trade-offs.

Current Coil Whine Mitigation Strategies

01 Noise reduction techniques for electronic devices

Various methods are employed to reduce coil whine noise in electronic devices. These techniques include using specialized materials, optimizing circuit design, and implementing noise cancellation technologies. By addressing the root causes of coil whine, such as electromagnetic vibrations, these approaches aim to minimize or eliminate the audible noise produced by electronic components.- Noise reduction techniques for electronic devices: Various methods are employed to reduce coil whine noise in electronic devices. These techniques include using specialized materials, optimizing circuit design, and implementing noise cancellation technologies. By addressing the root causes of coil whine, such as electromagnetic vibrations, these approaches aim to minimize or eliminate the audible noise produced by electronic components.

- Coil design and construction for minimizing whine: Innovative coil designs and construction methods are developed to minimize whine noise. These include using specialized winding techniques, selecting appropriate core materials, and implementing damping mechanisms. By optimizing the physical structure of coils, manufacturers can reduce the likelihood of vibrations that lead to audible whine.

- Power supply and voltage regulation improvements: Enhancements in power supply design and voltage regulation contribute to reducing coil whine. These improvements focus on stabilizing voltage levels, filtering out electromagnetic interference, and optimizing power delivery to components. By ensuring a clean and stable power supply, the occurrence of coil whine can be significantly reduced in various electronic devices.

- Acoustic isolation and dampening solutions: Acoustic isolation and dampening techniques are employed to minimize the propagation of coil whine noise. These solutions involve using sound-absorbing materials, implementing vibration isolation mounts, and designing enclosures that reduce noise transmission. By isolating the source of coil whine and dampening its effects, the overall perceived noise can be significantly reduced.

- Detection and measurement of coil whine: Advanced detection and measurement techniques are developed to identify and quantify coil whine noise. These methods involve using specialized sensors, signal processing algorithms, and acoustic analysis tools. By accurately detecting and measuring coil whine, manufacturers can better understand its characteristics and develop more effective mitigation strategies.

02 Coil design and construction for noise reduction

Innovative coil designs and construction methods are developed to mitigate coil whine noise. These include using specialized winding techniques, incorporating damping materials, and optimizing the physical structure of the coils. By focusing on the coil itself, these approaches aim to reduce vibrations and resonances that contribute to the whine noise.Expand Specific Solutions03 Power supply and voltage regulation for noise reduction

Improvements in power supply design and voltage regulation techniques are implemented to minimize coil whine noise. These methods focus on stabilizing power delivery, reducing electromagnetic interference, and optimizing voltage levels to prevent or reduce the conditions that lead to coil whine in electronic devices.Expand Specific Solutions04 Acoustic isolation and dampening methods

Various acoustic isolation and dampening techniques are employed to reduce the transmission of coil whine noise. These methods include using sound-absorbing materials, implementing vibration isolation systems, and designing enclosures that minimize sound propagation. By focusing on containing and absorbing the noise, these approaches aim to reduce the perceived coil whine in electronic devices.Expand Specific Solutions05 Detection and analysis of coil whine noise

Advanced detection and analysis techniques are developed to identify and characterize coil whine noise in electronic devices. These methods involve using specialized sensors, signal processing algorithms, and acoustic analysis tools to pinpoint the sources and characteristics of the noise. By accurately identifying the problem, these techniques enable more targeted and effective noise reduction strategies.Expand Specific Solutions

Key EV Manufacturers and Suppliers

The coil whine issue in electric vehicles represents a challenging technical problem in an industry transitioning from early adoption to mainstream acceptance. The market for electric vehicles is rapidly expanding, with a projected global market size of $823.75 billion by 2030. However, the technology to address coil whine is still evolving, indicating a moderate level of technological maturity. Companies like Robert Bosch GmbH, ZF Friedrichshafen AG, and DENSO Corp. are at the forefront of developing solutions, leveraging their expertise in automotive electronics and powertrain systems. As the EV market grows, competition among these players and emerging specialists is likely to intensify, driving innovation in noise reduction technologies and enhancing overall vehicle quality.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced noise reduction techniques for electric vehicle powertrains, focusing on minimizing coil whine. Their approach includes innovative winding designs and advanced insulation materials to reduce electromagnetic noise. They have implemented active noise control systems that use counter-phase sound waves to cancel out coil whine[1]. Additionally, Bosch has developed specialized software algorithms that optimize the switching frequency of power electronics to minimize audible noise[3]. Their solutions also incorporate mechanical damping and isolation techniques to prevent the transmission of vibrations caused by coil whine to the vehicle body[5].

Strengths: Comprehensive approach combining hardware and software solutions, extensive experience in automotive systems. Weaknesses: Potential increased cost and complexity of implementation.

TDK Corp.

Technical Solution: TDK has focused on developing advanced materials and components to address coil whine in electric vehicles. They have created specialized magnetic cores with optimized geometries and material compositions that significantly reduce electromagnetic noise[2]. TDK's approach also includes the use of nanocrystalline soft magnetic materials in power inductors, which offer high permeability and low core losses, resulting in reduced coil whine[4]. Furthermore, they have developed noise suppression filters specifically designed for high-frequency noise in EV powertrains, effectively mitigating coil whine issues[6].

Strengths: Expertise in materials science and component design, solutions applicable across various EV systems. Weaknesses: May require integration efforts with other vehicle systems.

Innovative Noise Reduction Technologies

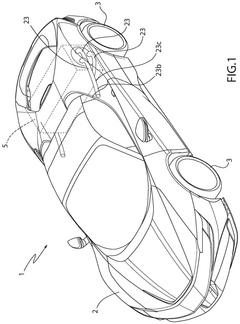

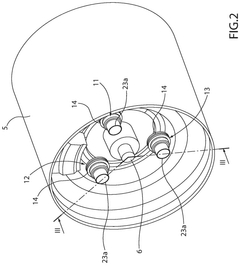

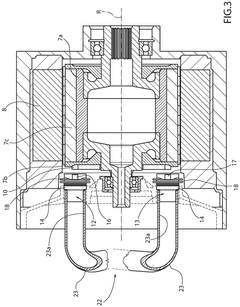

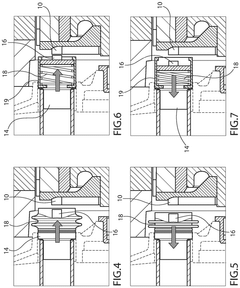

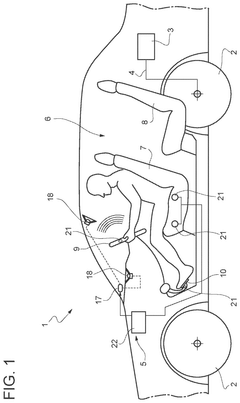

Electric propulsion apparatus for a motor vehicle with generation of sounds depending on the operation thereof

PatentPendingEP4539038A1

Innovation

- Incorporating harmonic oscillators with magnets and elastic elements into the propulsion apparatus, which oscillate in response to the rotating magnetic field generated by the electric motor, producing sound pressure waves that mimic the sounds of a conventional internal combustion engine.

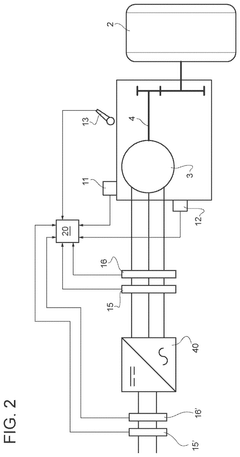

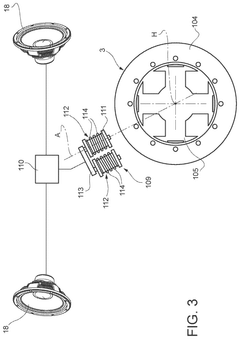

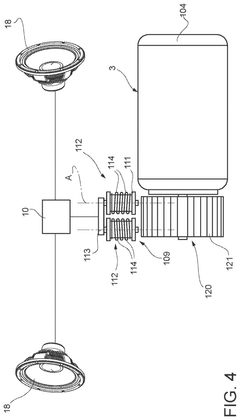

Motor vehicle with a sound generation assembly

PatentPendingUS20240351518A1

Innovation

- A motor vehicle equipped with sensors to detect vibrational and electromagnetic responses from the electric axle, processing these signals to generate characteristic sounds through a pitch-shifting technique, which are then emitted to enhance driver awareness and pleasure by transforming undesirable frequencies into a more pleasant acoustic range.

Acoustic Regulations for EVs

The acoustic regulations for electric vehicles (EVs) have become increasingly important as these vehicles gain popularity worldwide. Governments and regulatory bodies are developing and implementing standards to address the unique noise characteristics of EVs, including the issue of coil whine.

In the European Union, the United Nations Economic Commission for Europe (UNECE) Regulation No. 138 sets requirements for the Acoustic Vehicle Alerting System (AVAS) in EVs. This regulation mandates that EVs must emit a minimum sound level when traveling at low speeds to alert pedestrians and other road users of their presence. The regulation specifies frequency ranges and sound pressure levels that must be met by the AVAS.

The United States has similar regulations under the Federal Motor Vehicle Safety Standard (FMVSS) No. 141, which requires EVs to produce audible noise when traveling at speeds up to 30 km/h (18.6 mph). This standard aims to enhance pedestrian safety by making EVs more detectable in urban environments.

In addition to AVAS regulations, many countries have established limits on interior and exterior noise levels for all vehicles, including EVs. These regulations often reference ISO 5128 for interior noise measurement and ISO 362 for exterior noise measurement. While these standards were initially developed for internal combustion engine vehicles, they are being adapted and applied to EVs as well.

Specific to coil whine, there are currently no explicit regulations addressing this issue in EVs. However, the general vehicle noise regulations indirectly impact coil whine management. For instance, the European Union's Regulation (EU) No 540/2014 on the sound level of motor vehicles sets limits on the overall noise emissions of vehicles, which could potentially encompass coil whine if it contributes significantly to the vehicle's acoustic profile.

As the EV market continues to grow, it is likely that more specific regulations addressing high-frequency noise emissions, including coil whine, will be developed. Some countries, such as Japan and South Korea, are already considering updates to their noise regulations to better address the unique acoustic characteristics of EVs.

Manufacturers must navigate this complex regulatory landscape while developing EVs that meet both performance and acoustic requirements. This often involves a combination of noise reduction techniques, sound design, and careful component selection to ensure compliance with existing regulations and anticipate future standards.

In the European Union, the United Nations Economic Commission for Europe (UNECE) Regulation No. 138 sets requirements for the Acoustic Vehicle Alerting System (AVAS) in EVs. This regulation mandates that EVs must emit a minimum sound level when traveling at low speeds to alert pedestrians and other road users of their presence. The regulation specifies frequency ranges and sound pressure levels that must be met by the AVAS.

The United States has similar regulations under the Federal Motor Vehicle Safety Standard (FMVSS) No. 141, which requires EVs to produce audible noise when traveling at speeds up to 30 km/h (18.6 mph). This standard aims to enhance pedestrian safety by making EVs more detectable in urban environments.

In addition to AVAS regulations, many countries have established limits on interior and exterior noise levels for all vehicles, including EVs. These regulations often reference ISO 5128 for interior noise measurement and ISO 362 for exterior noise measurement. While these standards were initially developed for internal combustion engine vehicles, they are being adapted and applied to EVs as well.

Specific to coil whine, there are currently no explicit regulations addressing this issue in EVs. However, the general vehicle noise regulations indirectly impact coil whine management. For instance, the European Union's Regulation (EU) No 540/2014 on the sound level of motor vehicles sets limits on the overall noise emissions of vehicles, which could potentially encompass coil whine if it contributes significantly to the vehicle's acoustic profile.

As the EV market continues to grow, it is likely that more specific regulations addressing high-frequency noise emissions, including coil whine, will be developed. Some countries, such as Japan and South Korea, are already considering updates to their noise regulations to better address the unique acoustic characteristics of EVs.

Manufacturers must navigate this complex regulatory landscape while developing EVs that meet both performance and acoustic requirements. This often involves a combination of noise reduction techniques, sound design, and careful component selection to ensure compliance with existing regulations and anticipate future standards.

Environmental Impact of Noise Solutions

The environmental impact of noise solutions for coil whine in electric vehicles is a critical consideration in the development of sustainable transportation technologies. As electric vehicles (EVs) gain popularity, addressing noise pollution becomes increasingly important for both urban environments and wildlife habitats.

Traditional noise reduction methods often rely on materials that may have negative environmental consequences. For instance, sound-absorbing foams and insulation materials commonly used in vehicles can contain harmful chemicals or be difficult to recycle. However, innovative approaches are emerging that prioritize eco-friendly solutions.

One promising direction is the use of bio-based materials for noise insulation. These materials, derived from renewable sources such as plant fibers or recycled textiles, offer comparable sound-dampening properties to traditional synthetic materials while reducing the carbon footprint of vehicle production. Additionally, these bio-based solutions are often biodegradable or more easily recyclable at the end of the vehicle's life cycle.

Active noise control systems, which use sound waves to cancel out unwanted noise, present another environmentally friendly option. These systems require minimal additional materials and can be implemented through software updates, reducing the need for physical components that may impact the environment.

The development of more efficient electric motors and power electronics can also contribute to reducing coil whine at the source. By optimizing the design and materials used in these components, manufacturers can minimize noise generation without relying heavily on additional insulation materials.

Furthermore, the implementation of noise reduction solutions can have positive environmental effects beyond the immediate vehicle. By creating quieter EVs, cities may experience reduced overall noise pollution, potentially leading to improved quality of life for residents and less disruption to local ecosystems.

However, it is essential to consider the full life cycle impact of any noise reduction solution. This includes the environmental costs of production, use, and disposal. Manufacturers must balance the immediate benefits of noise reduction with long-term environmental sustainability.

In conclusion, the environmental impact of noise solutions for coil whine in EVs is a multifaceted issue. While some traditional methods may pose environmental challenges, emerging technologies and materials offer promising alternatives that align with the broader goals of sustainable transportation. As the EV industry continues to evolve, prioritizing eco-friendly noise reduction strategies will be crucial in minimizing the environmental footprint of these vehicles.

Traditional noise reduction methods often rely on materials that may have negative environmental consequences. For instance, sound-absorbing foams and insulation materials commonly used in vehicles can contain harmful chemicals or be difficult to recycle. However, innovative approaches are emerging that prioritize eco-friendly solutions.

One promising direction is the use of bio-based materials for noise insulation. These materials, derived from renewable sources such as plant fibers or recycled textiles, offer comparable sound-dampening properties to traditional synthetic materials while reducing the carbon footprint of vehicle production. Additionally, these bio-based solutions are often biodegradable or more easily recyclable at the end of the vehicle's life cycle.

Active noise control systems, which use sound waves to cancel out unwanted noise, present another environmentally friendly option. These systems require minimal additional materials and can be implemented through software updates, reducing the need for physical components that may impact the environment.

The development of more efficient electric motors and power electronics can also contribute to reducing coil whine at the source. By optimizing the design and materials used in these components, manufacturers can minimize noise generation without relying heavily on additional insulation materials.

Furthermore, the implementation of noise reduction solutions can have positive environmental effects beyond the immediate vehicle. By creating quieter EVs, cities may experience reduced overall noise pollution, potentially leading to improved quality of life for residents and less disruption to local ecosystems.

However, it is essential to consider the full life cycle impact of any noise reduction solution. This includes the environmental costs of production, use, and disposal. Manufacturers must balance the immediate benefits of noise reduction with long-term environmental sustainability.

In conclusion, the environmental impact of noise solutions for coil whine in EVs is a multifaceted issue. While some traditional methods may pose environmental challenges, emerging technologies and materials offer promising alternatives that align with the broader goals of sustainable transportation. As the EV industry continues to evolve, prioritizing eco-friendly noise reduction strategies will be crucial in minimizing the environmental footprint of these vehicles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!