Colloidal Silica vs Nano Clay: Polymer Clay Nanocomposite Comparison

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanocomposite Technology Background and Objectives

Nanocomposite technology represents a significant advancement in materials science, emerging in the early 1990s when researchers at Toyota Central Research developed the first polymer-clay nanocomposites. This breakthrough demonstrated remarkable improvements in mechanical properties, thermal stability, and barrier characteristics with minimal filler content. Since then, the field has expanded exponentially, with global research efforts focused on optimizing the integration of nanoscale fillers within polymer matrices.

The evolution of nanocomposite technology has followed several distinct phases. Initially, research concentrated on fundamental understanding of nanofiller dispersion mechanisms. This was followed by exploration of various nanofiller types, including layered silicates, carbon nanotubes, graphene, and metal oxide nanoparticles. The current phase emphasizes tailored functionality and sustainable production methods, reflecting broader industry trends toward environmentally responsible manufacturing.

Colloidal silica and nanoclay represent two prominent categories of nanofillers with distinct characteristics and applications. Colloidal silica consists of amorphous silicon dioxide particles suspended in a liquid medium, typically ranging from 5-100 nm in diameter. These spherical particles offer high surface area and excellent dispersibility in polar systems. Nanoclay, conversely, comprises layered silicate minerals with platelet structures, most commonly montmorillonite, which can be exfoliated to nanometer thickness while maintaining high aspect ratios.

The comparative analysis of these materials within polymer matrices addresses critical technological needs across multiple industries. Enhanced mechanical properties, improved barrier characteristics, flame retardancy, and reduced material weight all contribute to performance advantages in automotive, packaging, construction, and consumer goods applications. Additionally, these nanocomposites potentially enable reduced material consumption through more efficient use of resources.

The primary technical objective of this investigation is to establish comprehensive performance benchmarks between colloidal silica and nanoclay as polymer reinforcement agents. This includes quantitative assessment of mechanical properties, thermal stability, barrier performance, and processing characteristics across various polymer systems. Secondary objectives include identifying optimal processing parameters for each nanofiller type and evaluating their economic and environmental impacts throughout the product lifecycle.

Understanding the fundamental differences between these nanofiller types will guide future material development strategies and enable more targeted application of nanocomposite technology. As sustainability concerns increasingly drive materials selection decisions, the comparative environmental footprints of these technologies will become increasingly relevant to commercial implementation strategies.

The evolution of nanocomposite technology has followed several distinct phases. Initially, research concentrated on fundamental understanding of nanofiller dispersion mechanisms. This was followed by exploration of various nanofiller types, including layered silicates, carbon nanotubes, graphene, and metal oxide nanoparticles. The current phase emphasizes tailored functionality and sustainable production methods, reflecting broader industry trends toward environmentally responsible manufacturing.

Colloidal silica and nanoclay represent two prominent categories of nanofillers with distinct characteristics and applications. Colloidal silica consists of amorphous silicon dioxide particles suspended in a liquid medium, typically ranging from 5-100 nm in diameter. These spherical particles offer high surface area and excellent dispersibility in polar systems. Nanoclay, conversely, comprises layered silicate minerals with platelet structures, most commonly montmorillonite, which can be exfoliated to nanometer thickness while maintaining high aspect ratios.

The comparative analysis of these materials within polymer matrices addresses critical technological needs across multiple industries. Enhanced mechanical properties, improved barrier characteristics, flame retardancy, and reduced material weight all contribute to performance advantages in automotive, packaging, construction, and consumer goods applications. Additionally, these nanocomposites potentially enable reduced material consumption through more efficient use of resources.

The primary technical objective of this investigation is to establish comprehensive performance benchmarks between colloidal silica and nanoclay as polymer reinforcement agents. This includes quantitative assessment of mechanical properties, thermal stability, barrier performance, and processing characteristics across various polymer systems. Secondary objectives include identifying optimal processing parameters for each nanofiller type and evaluating their economic and environmental impacts throughout the product lifecycle.

Understanding the fundamental differences between these nanofiller types will guide future material development strategies and enable more targeted application of nanocomposite technology. As sustainability concerns increasingly drive materials selection decisions, the comparative environmental footprints of these technologies will become increasingly relevant to commercial implementation strategies.

Market Analysis of Polymer Clay Nanocomposites

The polymer clay nanocomposite market has experienced significant growth over the past decade, driven by increasing demand for advanced materials with enhanced properties across multiple industries. The global market for polymer nanocomposites was valued at approximately 4.1 billion USD in 2022 and is projected to reach 8.5 billion USD by 2028, representing a compound annual growth rate of 12.8%.

Within this broader market, colloidal silica and nano clay-based polymer composites represent two dominant segments with distinct market dynamics. Nano clay composites currently hold the larger market share, accounting for roughly 38% of the polymer nanocomposite market due to their earlier commercial adoption and established supply chains. Colloidal silica composites, while representing a smaller segment at approximately 21%, are demonstrating faster growth rates of 14.2% annually compared to nano clay's 11.3%.

The automotive and aerospace industries remain the largest consumers of these materials, collectively accounting for 43% of market demand. These sectors primarily utilize these nanocomposites for lightweight structural components, where the mechanical reinforcement properties are particularly valuable. The packaging industry follows closely at 18% market share, leveraging the barrier properties of both materials to develop high-performance food packaging solutions.

Regional analysis reveals Asia-Pacific as the dominant market, representing 42% of global consumption, with China and Japan leading production and consumption. North America and Europe follow at 28% and 24% respectively, with these regions focusing more on high-value applications in medical devices and specialized industrial equipment.

Price sensitivity varies significantly across application sectors. While construction and general consumer goods industries remain highly price-sensitive, aerospace and electronics sectors demonstrate willingness to pay premium prices for performance advantages. The average price point for nano clay composites ranges from 3.2-5.8 USD/kg, while colloidal silica composites typically command 4.5-7.2 USD/kg due to more complex processing requirements.

Market forecasts indicate that environmental regulations will increasingly influence market dynamics, with bio-based polymer nanocomposites expected to gain market share. Additionally, the growing focus on circular economy principles is driving research into recyclability of these materials, potentially reshaping competitive positioning between colloidal silica and nano clay systems based on their end-of-life characteristics.

Consumer trends show increasing preference for materials with demonstrable sustainability credentials, creating new market opportunities for manufacturers who can effectively communicate the environmental benefits of their specific nanocomposite technology.

Within this broader market, colloidal silica and nano clay-based polymer composites represent two dominant segments with distinct market dynamics. Nano clay composites currently hold the larger market share, accounting for roughly 38% of the polymer nanocomposite market due to their earlier commercial adoption and established supply chains. Colloidal silica composites, while representing a smaller segment at approximately 21%, are demonstrating faster growth rates of 14.2% annually compared to nano clay's 11.3%.

The automotive and aerospace industries remain the largest consumers of these materials, collectively accounting for 43% of market demand. These sectors primarily utilize these nanocomposites for lightweight structural components, where the mechanical reinforcement properties are particularly valuable. The packaging industry follows closely at 18% market share, leveraging the barrier properties of both materials to develop high-performance food packaging solutions.

Regional analysis reveals Asia-Pacific as the dominant market, representing 42% of global consumption, with China and Japan leading production and consumption. North America and Europe follow at 28% and 24% respectively, with these regions focusing more on high-value applications in medical devices and specialized industrial equipment.

Price sensitivity varies significantly across application sectors. While construction and general consumer goods industries remain highly price-sensitive, aerospace and electronics sectors demonstrate willingness to pay premium prices for performance advantages. The average price point for nano clay composites ranges from 3.2-5.8 USD/kg, while colloidal silica composites typically command 4.5-7.2 USD/kg due to more complex processing requirements.

Market forecasts indicate that environmental regulations will increasingly influence market dynamics, with bio-based polymer nanocomposites expected to gain market share. Additionally, the growing focus on circular economy principles is driving research into recyclability of these materials, potentially reshaping competitive positioning between colloidal silica and nano clay systems based on their end-of-life characteristics.

Consumer trends show increasing preference for materials with demonstrable sustainability credentials, creating new market opportunities for manufacturers who can effectively communicate the environmental benefits of their specific nanocomposite technology.

Current Challenges in Colloidal Silica and Nano Clay Technologies

Despite significant advancements in both colloidal silica and nano clay technologies for polymer nanocomposites, several critical challenges persist that impede their widespread industrial adoption and optimal performance. These challenges span across synthesis, processing, characterization, and application domains.

For colloidal silica, dispersion stability remains a primary concern. The inherent tendency of silica nanoparticles to agglomerate due to strong hydrogen bonding significantly reduces their effectiveness as reinforcement agents. Current stabilization methods using surfactants or surface modifications often introduce compatibility issues with polymer matrices or diminish the thermal properties of the resulting composites.

Processing challenges for colloidal silica include achieving uniform distribution throughout polymer matrices, particularly at higher loading levels where viscosity increases dramatically. The hydrophilic nature of silica surfaces creates interfacial compatibility issues with hydrophobic polymers, necessitating complex surface treatments that add cost and complexity to manufacturing processes.

Nano clay technologies face parallel but distinct challenges. The complete exfoliation of clay platelets, critical for maximizing the surface area interaction with polymer matrices, remains difficult to achieve consistently at industrial scales. Partial exfoliation or intercalation results in suboptimal mechanical and barrier properties in the final nanocomposites.

The high aspect ratio of nano clays, while beneficial for properties like gas barrier performance, creates processing difficulties including increased viscosity and potential orientation issues during molding or extrusion. This can lead to anisotropic properties in the final product, which may be undesirable for certain applications.

Both technologies suffer from characterization limitations. Current analytical methods struggle to accurately quantify dispersion quality, exfoliation degree, and interfacial interactions in situ. This hampers systematic optimization efforts and quality control in production environments.

Environmental and health concerns present additional challenges. The potential toxicity of nanoparticles, particularly those with dimensions below 100 nm, raises regulatory questions and safety concerns for workers and end-users. Sustainable production methods and end-of-life considerations for these nanocomposites remain underdeveloped.

Cost-effectiveness represents another significant barrier. The specialized processing equipment, complex modification procedures, and quality control requirements increase production costs substantially compared to conventional composites. This cost premium limits market penetration to high-value applications where performance benefits clearly justify the additional expense.

Scalability challenges persist for both technologies, with laboratory-scale successes often proving difficult to translate to industrial production volumes while maintaining consistent quality and performance characteristics.

For colloidal silica, dispersion stability remains a primary concern. The inherent tendency of silica nanoparticles to agglomerate due to strong hydrogen bonding significantly reduces their effectiveness as reinforcement agents. Current stabilization methods using surfactants or surface modifications often introduce compatibility issues with polymer matrices or diminish the thermal properties of the resulting composites.

Processing challenges for colloidal silica include achieving uniform distribution throughout polymer matrices, particularly at higher loading levels where viscosity increases dramatically. The hydrophilic nature of silica surfaces creates interfacial compatibility issues with hydrophobic polymers, necessitating complex surface treatments that add cost and complexity to manufacturing processes.

Nano clay technologies face parallel but distinct challenges. The complete exfoliation of clay platelets, critical for maximizing the surface area interaction with polymer matrices, remains difficult to achieve consistently at industrial scales. Partial exfoliation or intercalation results in suboptimal mechanical and barrier properties in the final nanocomposites.

The high aspect ratio of nano clays, while beneficial for properties like gas barrier performance, creates processing difficulties including increased viscosity and potential orientation issues during molding or extrusion. This can lead to anisotropic properties in the final product, which may be undesirable for certain applications.

Both technologies suffer from characterization limitations. Current analytical methods struggle to accurately quantify dispersion quality, exfoliation degree, and interfacial interactions in situ. This hampers systematic optimization efforts and quality control in production environments.

Environmental and health concerns present additional challenges. The potential toxicity of nanoparticles, particularly those with dimensions below 100 nm, raises regulatory questions and safety concerns for workers and end-users. Sustainable production methods and end-of-life considerations for these nanocomposites remain underdeveloped.

Cost-effectiveness represents another significant barrier. The specialized processing equipment, complex modification procedures, and quality control requirements increase production costs substantially compared to conventional composites. This cost premium limits market penetration to high-value applications where performance benefits clearly justify the additional expense.

Scalability challenges persist for both technologies, with laboratory-scale successes often proving difficult to translate to industrial production volumes while maintaining consistent quality and performance characteristics.

Comparative Assessment of Colloidal Silica and Nano Clay Solutions

01 Preparation methods of polymer clay nanocomposites

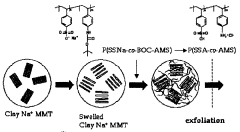

Various methods can be employed to prepare polymer clay nanocomposites, including in-situ polymerization, melt intercalation, and solution blending. These techniques facilitate the dispersion of nanoclay particles within the polymer matrix, enhancing the interfacial interaction between the organic polymer and inorganic clay. The processing conditions, such as temperature, shear rate, and mixing time, significantly influence the final structure and properties of the nanocomposites.- Preparation methods of polymer clay nanocomposites: Various methods can be employed to prepare polymer clay nanocomposites, including in-situ polymerization, melt intercalation, and solution blending. These techniques facilitate the dispersion of nano clay and colloidal silica within the polymer matrix, enhancing the interfacial interaction between the organic polymer and inorganic nanoparticles. The processing conditions, such as temperature, shear rate, and mixing time, significantly influence the final structure and properties of the nanocomposites.

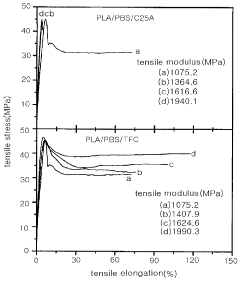

- Mechanical property enhancement in polymer nanocomposites: The incorporation of nano clay and colloidal silica into polymer matrices significantly improves mechanical properties such as tensile strength, modulus, and impact resistance. The nanoscale dispersion of these fillers creates a large interfacial area between the polymer and nanoparticles, leading to effective stress transfer. The layered structure of nano clays provides reinforcement through platelet orientation, while colloidal silica particles enhance hardness and abrasion resistance, resulting in superior mechanical performance compared to conventional composites.

- Barrier and thermal properties of clay-silica nanocomposites: Polymer nanocomposites containing nano clay and colloidal silica exhibit enhanced barrier properties against gases, moisture, and chemicals. The layered silicate structure of nano clays creates a tortuous path for permeating molecules, while colloidal silica particles fill interstitial spaces. These nanocomposites also demonstrate improved thermal stability and flame retardancy due to the formation of a protective char layer during combustion and the high thermal resistance of silica. The synergistic effect of combining both nano clay and colloidal silica results in superior barrier and thermal performance.

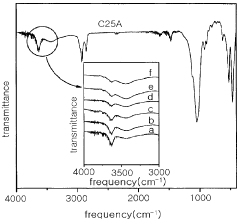

- Surface modification of nanoparticles for improved compatibility: Surface modification of nano clay and colloidal silica is crucial for achieving good dispersion in polymer matrices. Organic modifiers such as quaternary ammonium compounds for nano clays and silane coupling agents for colloidal silica enhance the compatibility between the hydrophilic nanoparticles and hydrophobic polymer matrices. These surface treatments reduce particle agglomeration, improve interfacial adhesion, and facilitate better exfoliation of clay platelets, resulting in nanocomposites with more uniform properties and enhanced performance.

- Applications of polymer clay-silica nanocomposites: Polymer nanocomposites incorporating nano clay and colloidal silica find applications across various industries. In automotive and aerospace sectors, they are used for lightweight structural components with high strength and impact resistance. In packaging, they provide enhanced barrier properties for food preservation. These materials are also utilized in electronics as insulating materials with improved thermal stability, in construction as durable coatings and adhesives, and in biomedical fields for drug delivery systems and tissue engineering scaffolds due to their biocompatibility and controlled degradation properties.

02 Incorporation of colloidal silica in polymer nanocomposites

Colloidal silica particles can be incorporated into polymer matrices to form nanocomposites with enhanced mechanical, thermal, and barrier properties. The silica nanoparticles, typically ranging from 5-100 nm in diameter, can be surface-modified to improve compatibility with the polymer matrix. The uniform dispersion of colloidal silica within the polymer results in materials with improved stiffness, strength, and dimensional stability while maintaining transparency in many applications.Expand Specific Solutions03 Nanoclay modification and functionalization

Nanoclays, particularly montmorillonite and other layered silicates, can be chemically modified to enhance their compatibility with polymer matrices. Surface modification typically involves ion exchange reactions with organic surfactants such as quaternary ammonium compounds. This functionalization transforms the hydrophilic clay surface to organophilic, facilitating better dispersion in hydrophobic polymer matrices and improving the intercalation or exfoliation of clay layers, which is crucial for achieving optimal property enhancements.Expand Specific Solutions04 Mechanical and thermal properties of polymer clay nanocomposites

The incorporation of nanoclays and colloidal silica into polymer matrices significantly enhances mechanical properties such as tensile strength, modulus, and impact resistance. These nanocomposites also exhibit improved thermal stability, with higher glass transition temperatures and decomposition temperatures compared to neat polymers. The property enhancements are attributed to the high aspect ratio of clay platelets, the large interfacial area between the nanoparticles and polymer matrix, and the restricted mobility of polymer chains in the vicinity of nanoparticles.Expand Specific Solutions05 Applications of polymer clay nanocomposites

Polymer clay nanocomposites find applications across various industries due to their enhanced properties. They are used in automotive components for weight reduction and improved mechanical performance, in packaging materials for enhanced barrier properties against gases and moisture, in flame-retardant materials due to their improved thermal stability, and in coatings and adhesives for improved durability and performance. The combination of colloidal silica and nanoclays in polymer matrices offers synergistic effects that can be tailored for specific application requirements.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The polymer clay nanocomposite market is in a growth phase, with increasing applications across automotive, packaging, and construction sectors. The global market size is estimated to reach $5.3 billion by 2025, growing at a CAGR of 7.2%. Technologically, colloidal silica and nano clay additives represent different approaches to enhancing polymer properties, with nano clay showing greater commercial adoption. Leading companies like Dow Global Technologies, DuPont, and ExxonMobil Chemical have established strong patent portfolios in polymer nanocomposites, while academic institutions such as Northwestern University and South China University of Technology are advancing fundamental research. Chinese players including Sinopec are rapidly expanding their market presence through increased R&D investments and manufacturing capacity.

Dow Global Technologies LLC

Technical Solution: Dow has developed proprietary polymer clay nanocomposite technologies that utilize both colloidal silica and nanoclay reinforcements. Their approach involves surface modification of colloidal silica particles (10-100 nm) with silane coupling agents to improve dispersion and compatibility with polymer matrices. For nanoclay composites, Dow employs organically modified montmorillonite clays with quaternary ammonium compounds to enhance exfoliation. Their patented melt-intercalation process achieves superior dispersion of nanoclays compared to conventional methods, resulting in nanocomposites with up to 40% improvement in mechanical properties at low filler loadings (3-5 wt%). Dow's comparative studies demonstrate that while nanoclay provides better barrier properties and flame retardancy, colloidal silica offers superior transparency and abrasion resistance in polymer systems.

Strengths: Extensive intellectual property portfolio in both technologies; established manufacturing infrastructure; proprietary surface modification techniques. Weaknesses: Nanoclay composites show higher tendency for agglomeration during processing; colloidal silica systems require more complex surface treatments to achieve optimal polymer compatibility.

Rohm & Haas Co.

Technical Solution: Rohm & Haas (now part of Dow) has developed specialized polymer nanocomposite technologies comparing colloidal silica and nanoclay reinforcements, particularly for acrylic and coating applications. Their colloidal silica approach utilizes proprietary aqueous and solvent-based silica dispersions (10-30 nm particles) with tailored surface modifications for polymer compatibility. For nanoclay systems, they employ organically modified layered silicates with their patented in-situ emulsion polymerization technique. Their comparative studies demonstrate that colloidal silica nanocomposites provide superior scratch resistance (up to 3H pencil hardness improvement) and weatherability (>90% gloss retention after 2000 hours QUV exposure), while their nanoclay composites offer enhanced barrier properties (40-50% reduction in water vapor transmission) and improved rheological control. Rohm & Haas has successfully commercialized these technologies in architectural coatings, adhesives, and specialty polymer applications.

Strengths: Extensive expertise in waterborne systems; advanced characterization capabilities; strong formulation knowledge for specific performance attributes. Weaknesses: More limited application in engineering thermoplastics; colloidal silica systems show greater sensitivity to pH and electrolyte conditions in aqueous formulations.

Key Patents and Scientific Breakthroughs in Nanocomposite Materials

A exfoliated NANO-composite from polyaniline graft copolymer/clay

PatentWO2005068551A1

Innovation

- A method involving the preparation of tert-butoxycarbonyl-aninostyrene, followed by reaction with sodium styrenesulfonate to form a copolymer that is then penetrated into clay layers swollen in an aqueous solution, allowing for the creation of self-doped, exfoliated polyaniline/clay nano-composites without organic treatment.

Modification of platelet-shaped silica clay

PatentWO2005113660A1

Innovation

- A method involving the sequential reaction of layered silica clay with an organic amine compound followed by a silane compound, which increases hydrophobicity and introduces functional groups that enhance the bonding strength between the clay and polymer, thereby improving the mechanical properties of the nanocomposite.

Environmental Impact and Sustainability Considerations

The environmental impact of polymer nanocomposites represents a critical consideration in material selection and development. When comparing colloidal silica and nano clay as reinforcement materials, several sustainability factors emerge as significant differentiators. Colloidal silica production typically involves alkaline extraction from sand or chemical synthesis methods, which can be energy-intensive but generally utilizes abundant raw materials. The extraction process may involve significant water usage and chemical treatments, though modern production facilities have implemented closed-loop systems to minimize environmental discharge.

Nano clay, predominantly derived from naturally occurring minerals like montmorillonite, requires mining operations that can lead to habitat disruption and land degradation. However, the relatively low processing requirements post-extraction provide nano clay with certain environmental advantages. The purification and modification processes for nano clays typically consume less energy than the synthesis of colloidal silica, though they may involve organic modifiers that present their own environmental considerations.

Lifecycle assessment studies indicate that polymer nanocomposites incorporating either material can significantly reduce the overall environmental footprint of final products through weight reduction, extended service life, and improved performance. The enhanced mechanical properties enable material reduction strategies, with some applications achieving 20-30% less polymer usage while maintaining equivalent performance specifications.

End-of-life management presents distinct challenges for both systems. Colloidal silica-based nanocomposites generally demonstrate better compatibility with existing recycling streams, as silica remains relatively inert during reprocessing. Nano clay composites may present challenges in conventional recycling processes due to potential agglomeration during reprocessing, though research indicates minimal impact on recycled material properties at typical loading levels below 5%.

Biodegradability assessments reveal that neither reinforcement significantly accelerates polymer degradation in natural environments, though nano clay may offer slight advantages in certain biodegradable polymer matrices by creating tortuous paths that control moisture penetration rates. This property has shown promise in controlled-release agricultural applications where gradual degradation is desirable.

Regulatory frameworks increasingly emphasize nanomaterial safety throughout the product lifecycle. Both materials have established safety profiles when properly bound in polymer matrices, though occupational exposure during manufacturing requires appropriate controls. Recent studies suggest minimal leaching of nanoparticles from properly formulated composites under normal use conditions, addressing concerns about potential environmental accumulation.

Nano clay, predominantly derived from naturally occurring minerals like montmorillonite, requires mining operations that can lead to habitat disruption and land degradation. However, the relatively low processing requirements post-extraction provide nano clay with certain environmental advantages. The purification and modification processes for nano clays typically consume less energy than the synthesis of colloidal silica, though they may involve organic modifiers that present their own environmental considerations.

Lifecycle assessment studies indicate that polymer nanocomposites incorporating either material can significantly reduce the overall environmental footprint of final products through weight reduction, extended service life, and improved performance. The enhanced mechanical properties enable material reduction strategies, with some applications achieving 20-30% less polymer usage while maintaining equivalent performance specifications.

End-of-life management presents distinct challenges for both systems. Colloidal silica-based nanocomposites generally demonstrate better compatibility with existing recycling streams, as silica remains relatively inert during reprocessing. Nano clay composites may present challenges in conventional recycling processes due to potential agglomeration during reprocessing, though research indicates minimal impact on recycled material properties at typical loading levels below 5%.

Biodegradability assessments reveal that neither reinforcement significantly accelerates polymer degradation in natural environments, though nano clay may offer slight advantages in certain biodegradable polymer matrices by creating tortuous paths that control moisture penetration rates. This property has shown promise in controlled-release agricultural applications where gradual degradation is desirable.

Regulatory frameworks increasingly emphasize nanomaterial safety throughout the product lifecycle. Both materials have established safety profiles when properly bound in polymer matrices, though occupational exposure during manufacturing requires appropriate controls. Recent studies suggest minimal leaching of nanoparticles from properly formulated composites under normal use conditions, addressing concerns about potential environmental accumulation.

Performance Metrics and Testing Methodologies

Comprehensive performance evaluation of polymer clay nanocomposites requires standardized testing methodologies to ensure reliable comparison between colloidal silica and nano clay reinforcements. The mechanical property assessment typically includes tensile strength testing (ASTM D638), which measures the maximum stress a material can withstand while being stretched before breaking. Flexural strength testing (ASTM D790) evaluates the material's ability to resist deformation under load, while impact resistance testing (ASTM D256) determines the energy required to break a specimen under high-speed loading conditions.

Thermal stability metrics are equally important, with Thermogravimetric Analysis (TGA) measuring weight loss as a function of temperature to determine decomposition points and thermal degradation profiles. Differential Scanning Calorimetry (DSC) provides insights into glass transition temperature, crystallization behavior, and melting characteristics. Dynamic Mechanical Analysis (DMA) evaluates viscoelastic properties across temperature ranges, revealing how material stiffness changes with temperature.

Barrier properties assessment includes oxygen transmission rate (OTR) and water vapor transmission rate (WVTR) tests, critical for packaging applications. Gas permeability measurements follow ASTM D1434 standards, while moisture barrier properties are evaluated using ASTM E96 protocols. These tests determine how effectively the nanocomposites prevent gas and moisture penetration.

Rheological characterization employs rotational rheometers to measure viscosity, yield stress, and thixotropic behavior. Melt flow index testing (ASTM D1238) quantifies how easily the material flows when melted, providing insights into processability during manufacturing. Capillary rheometry offers additional data on shear-dependent viscosity at processing conditions.

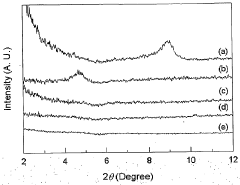

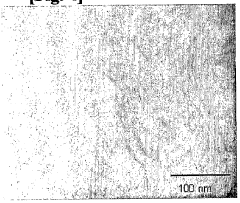

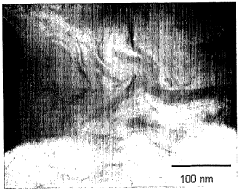

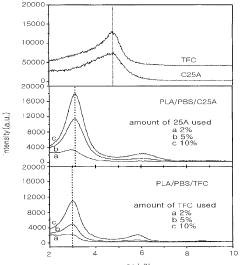

Morphological analysis utilizes Scanning Electron Microscopy (SEM) to visualize dispersion quality at micro-scale, while Transmission Electron Microscopy (TEM) provides nano-scale visualization of particle distribution. X-ray Diffraction (XRD) characterizes crystalline structures and intercalation/exfoliation states of nano clay. Atomic Force Microscopy (AFM) offers surface topography information and mechanical property mapping at nanometer resolution.

Long-term performance testing includes accelerated aging protocols (ASTM G154 for UV exposure, ASTM D1183 for humidity aging) to predict service life. Creep testing evaluates deformation under constant load over time, while fatigue testing assesses performance under cyclic loading conditions. These methodologies collectively provide a comprehensive framework for comparing colloidal silica and nano clay reinforcements in polymer nanocomposites across multiple performance dimensions.

Thermal stability metrics are equally important, with Thermogravimetric Analysis (TGA) measuring weight loss as a function of temperature to determine decomposition points and thermal degradation profiles. Differential Scanning Calorimetry (DSC) provides insights into glass transition temperature, crystallization behavior, and melting characteristics. Dynamic Mechanical Analysis (DMA) evaluates viscoelastic properties across temperature ranges, revealing how material stiffness changes with temperature.

Barrier properties assessment includes oxygen transmission rate (OTR) and water vapor transmission rate (WVTR) tests, critical for packaging applications. Gas permeability measurements follow ASTM D1434 standards, while moisture barrier properties are evaluated using ASTM E96 protocols. These tests determine how effectively the nanocomposites prevent gas and moisture penetration.

Rheological characterization employs rotational rheometers to measure viscosity, yield stress, and thixotropic behavior. Melt flow index testing (ASTM D1238) quantifies how easily the material flows when melted, providing insights into processability during manufacturing. Capillary rheometry offers additional data on shear-dependent viscosity at processing conditions.

Morphological analysis utilizes Scanning Electron Microscopy (SEM) to visualize dispersion quality at micro-scale, while Transmission Electron Microscopy (TEM) provides nano-scale visualization of particle distribution. X-ray Diffraction (XRD) characterizes crystalline structures and intercalation/exfoliation states of nano clay. Atomic Force Microscopy (AFM) offers surface topography information and mechanical property mapping at nanometer resolution.

Long-term performance testing includes accelerated aging protocols (ASTM G154 for UV exposure, ASTM D1183 for humidity aging) to predict service life. Creep testing evaluates deformation under constant load over time, while fatigue testing assesses performance under cyclic loading conditions. These methodologies collectively provide a comprehensive framework for comparing colloidal silica and nano clay reinforcements in polymer nanocomposites across multiple performance dimensions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!