Comparative Analysis of 2JZ-GTE vs 2JZ-GE in Performance

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2JZ Engine Evolution

The 2JZ engine series, developed by Toyota, represents a significant milestone in automotive engineering. This inline-six engine family, introduced in 1991, quickly gained recognition for its robust design and exceptional performance potential. The evolution of the 2JZ engine can be traced through two primary variants: the 2JZ-GE and the 2JZ-GTE.

The 2JZ-GE, the naturally aspirated version, was first introduced in the 1991 Toyota Arista. It featured a cast-iron block, aluminum cylinder head, and four valves per cylinder. This engine was designed to balance performance with fuel efficiency, making it suitable for a wide range of vehicles. Over time, Toyota made incremental improvements to the 2JZ-GE, enhancing its power output and efficiency through refinements in valve timing and fuel injection systems.

The 2JZ-GTE, the turbocharged variant, debuted in 1991 in the Toyota Aristo V300. This engine shared the same basic architecture as the 2JZ-GE but incorporated twin turbochargers, significantly boosting its performance capabilities. The 2JZ-GTE quickly became renowned for its ability to handle high levels of boost pressure without compromising reliability, making it a favorite among performance enthusiasts and tuners.

Throughout its production run, the 2JZ-GTE underwent several iterations. Notable improvements included the adoption of VVT-i (Variable Valve Timing with intelligence) in later models, which enhanced both power output and fuel efficiency. The engine's robust design, featuring a closed deck block and forged internals, allowed it to withstand substantial power increases with minimal modifications.

The evolution of both 2JZ variants was driven by Toyota's commitment to continuous improvement and the changing demands of the automotive market. As emissions regulations became stricter, Toyota engineers focused on enhancing fuel efficiency and reducing emissions without sacrificing performance. This led to the development of more advanced fuel injection systems and engine management technologies.

By the early 2000s, the 2JZ engine had cemented its status as a legendary powerplant. Its ability to produce high power outputs reliably made it a popular choice for both street and racing applications. The engine's versatility was demonstrated by its use in a variety of Toyota and Lexus models, from luxury sedans to sports cars.

The legacy of the 2JZ engine continues to influence modern engine design. Its overbuilt nature and tuning potential set a benchmark for durability and performance that many manufacturers still strive to match. The lessons learned from the 2JZ's development have been applied to subsequent Toyota engines, contributing to the company's reputation for building reliable and capable powerplants.

The 2JZ-GE, the naturally aspirated version, was first introduced in the 1991 Toyota Arista. It featured a cast-iron block, aluminum cylinder head, and four valves per cylinder. This engine was designed to balance performance with fuel efficiency, making it suitable for a wide range of vehicles. Over time, Toyota made incremental improvements to the 2JZ-GE, enhancing its power output and efficiency through refinements in valve timing and fuel injection systems.

The 2JZ-GTE, the turbocharged variant, debuted in 1991 in the Toyota Aristo V300. This engine shared the same basic architecture as the 2JZ-GE but incorporated twin turbochargers, significantly boosting its performance capabilities. The 2JZ-GTE quickly became renowned for its ability to handle high levels of boost pressure without compromising reliability, making it a favorite among performance enthusiasts and tuners.

Throughout its production run, the 2JZ-GTE underwent several iterations. Notable improvements included the adoption of VVT-i (Variable Valve Timing with intelligence) in later models, which enhanced both power output and fuel efficiency. The engine's robust design, featuring a closed deck block and forged internals, allowed it to withstand substantial power increases with minimal modifications.

The evolution of both 2JZ variants was driven by Toyota's commitment to continuous improvement and the changing demands of the automotive market. As emissions regulations became stricter, Toyota engineers focused on enhancing fuel efficiency and reducing emissions without sacrificing performance. This led to the development of more advanced fuel injection systems and engine management technologies.

By the early 2000s, the 2JZ engine had cemented its status as a legendary powerplant. Its ability to produce high power outputs reliably made it a popular choice for both street and racing applications. The engine's versatility was demonstrated by its use in a variety of Toyota and Lexus models, from luxury sedans to sports cars.

The legacy of the 2JZ engine continues to influence modern engine design. Its overbuilt nature and tuning potential set a benchmark for durability and performance that many manufacturers still strive to match. The lessons learned from the 2JZ's development have been applied to subsequent Toyota engines, contributing to the company's reputation for building reliable and capable powerplants.

Market Demand Analysis

The market demand for high-performance engines like the 2JZ-GTE and 2JZ-GE remains strong, driven by enthusiasts, motorsport applications, and the tuning community. These engines, particularly the 2JZ-GTE, have achieved legendary status among car enthusiasts for their robustness and tuning potential.

In the aftermarket sector, there is a consistent demand for both engines, with the 2JZ-GTE being more sought after due to its higher performance capabilities. This demand is reflected in the pricing of used engines and complete vehicle models equipped with these powerplants. The 2JZ-GTE, being the more powerful variant, commands a premium in the market.

The automotive industry has seen a shift towards smaller displacement, turbocharged engines in recent years due to emissions regulations and fuel efficiency requirements. However, this trend has paradoxically increased the value and desirability of older, larger displacement engines like the 2JZ series, which are known for their reliability and tuning potential.

The market for these engines extends beyond their original application in Toyota and Lexus vehicles. Engine swaps using 2JZ engines are popular in various platforms, from drift cars to drag racers, indicating a broad market appeal. This versatility contributes to sustained demand across different motorsport disciplines and custom car building sectors.

Geographically, the demand for 2JZ engines is global, with strong markets in Japan, the United States, Europe, and Australia. In regions with a strong car culture and less stringent emissions regulations for modified vehicles, the demand tends to be higher. This global appeal has led to a robust international trade in both complete engines and parts.

The aftermarket parts industry supporting these engines is substantial, with numerous companies offering performance upgrades, replacement parts, and tuning solutions. This ecosystem around the 2JZ engines further reinforces their market demand and longevity in the performance sector.

While new production of these engines has ceased, the market for remanufactured and rebuilt 2JZ engines remains active. This indicates a long-term demand projection, as enthusiasts and builders continue to seek these engines for their projects, despite the engines being out of production for several years.

In the aftermarket sector, there is a consistent demand for both engines, with the 2JZ-GTE being more sought after due to its higher performance capabilities. This demand is reflected in the pricing of used engines and complete vehicle models equipped with these powerplants. The 2JZ-GTE, being the more powerful variant, commands a premium in the market.

The automotive industry has seen a shift towards smaller displacement, turbocharged engines in recent years due to emissions regulations and fuel efficiency requirements. However, this trend has paradoxically increased the value and desirability of older, larger displacement engines like the 2JZ series, which are known for their reliability and tuning potential.

The market for these engines extends beyond their original application in Toyota and Lexus vehicles. Engine swaps using 2JZ engines are popular in various platforms, from drift cars to drag racers, indicating a broad market appeal. This versatility contributes to sustained demand across different motorsport disciplines and custom car building sectors.

Geographically, the demand for 2JZ engines is global, with strong markets in Japan, the United States, Europe, and Australia. In regions with a strong car culture and less stringent emissions regulations for modified vehicles, the demand tends to be higher. This global appeal has led to a robust international trade in both complete engines and parts.

The aftermarket parts industry supporting these engines is substantial, with numerous companies offering performance upgrades, replacement parts, and tuning solutions. This ecosystem around the 2JZ engines further reinforces their market demand and longevity in the performance sector.

While new production of these engines has ceased, the market for remanufactured and rebuilt 2JZ engines remains active. This indicates a long-term demand projection, as enthusiasts and builders continue to seek these engines for their projects, despite the engines being out of production for several years.

Technical Specifications

The 2JZ-GTE and 2JZ-GE engines, both part of Toyota's renowned JZ engine family, share many similarities but differ significantly in their performance characteristics. The 2JZ-GTE, being the twin-turbocharged variant, boasts superior power output and torque figures compared to its naturally aspirated counterpart, the 2JZ-GE.

The 2JZ-GTE features a displacement of 2,997 cc, with a bore and stroke of 86 mm × 86 mm. It utilizes a dual overhead camshaft (DOHC) configuration with four valves per cylinder. The engine's compression ratio is set at 8.5:1, lower than the 2JZ-GE to accommodate forced induction. Two CT20 turbochargers work in parallel to deliver a maximum boost pressure of 0.8 bar (11.6 psi).

In contrast, the 2JZ-GE shares the same displacement and bore/stroke dimensions but operates with a higher compression ratio of 10.0:1. It also employs a DOHC setup with four valves per cylinder but lacks forced induction. This naturally aspirated design results in a more linear power delivery compared to its turbocharged sibling.

Power output figures highlight the performance gap between these engines. The 2JZ-GTE produces an impressive 280 horsepower at 5,600 rpm and 320 lb-ft of torque at 4,000 rpm in its standard form. However, it's worth noting that these figures were often underrated due to the "Gentlemen's Agreement" among Japanese automakers. In reality, the engine was capable of producing over 320 horsepower.

The 2JZ-GE, while less powerful, still delivers respectable performance with 220 horsepower at 5,800 rpm and 210 lb-ft of torque at 4,800 rpm. This naturally aspirated version offers a more gradual power curve, making it more suitable for daily driving and applications where immediate throttle response is preferred over peak power.

Both engines feature cast-iron blocks known for their durability and ability to withstand high internal pressures. This robust construction contributes to the legendary status of the 2JZ series, particularly in tuning circles. The cylinder heads are made of aluminum alloy, incorporating pent-roof combustion chambers and squish areas to enhance fuel mixture and combustion efficiency.

Fuel delivery systems differ between the two variants. The 2JZ-GTE employs a sequential electronic fuel injection system with larger fuel injectors to accommodate the increased fuel demands of forced induction. The 2JZ-GE utilizes a simpler electronic fuel injection system, adequate for its naturally aspirated operation.

The 2JZ-GTE features a displacement of 2,997 cc, with a bore and stroke of 86 mm × 86 mm. It utilizes a dual overhead camshaft (DOHC) configuration with four valves per cylinder. The engine's compression ratio is set at 8.5:1, lower than the 2JZ-GE to accommodate forced induction. Two CT20 turbochargers work in parallel to deliver a maximum boost pressure of 0.8 bar (11.6 psi).

In contrast, the 2JZ-GE shares the same displacement and bore/stroke dimensions but operates with a higher compression ratio of 10.0:1. It also employs a DOHC setup with four valves per cylinder but lacks forced induction. This naturally aspirated design results in a more linear power delivery compared to its turbocharged sibling.

Power output figures highlight the performance gap between these engines. The 2JZ-GTE produces an impressive 280 horsepower at 5,600 rpm and 320 lb-ft of torque at 4,000 rpm in its standard form. However, it's worth noting that these figures were often underrated due to the "Gentlemen's Agreement" among Japanese automakers. In reality, the engine was capable of producing over 320 horsepower.

The 2JZ-GE, while less powerful, still delivers respectable performance with 220 horsepower at 5,800 rpm and 210 lb-ft of torque at 4,800 rpm. This naturally aspirated version offers a more gradual power curve, making it more suitable for daily driving and applications where immediate throttle response is preferred over peak power.

Both engines feature cast-iron blocks known for their durability and ability to withstand high internal pressures. This robust construction contributes to the legendary status of the 2JZ series, particularly in tuning circles. The cylinder heads are made of aluminum alloy, incorporating pent-roof combustion chambers and squish areas to enhance fuel mixture and combustion efficiency.

Fuel delivery systems differ between the two variants. The 2JZ-GTE employs a sequential electronic fuel injection system with larger fuel injectors to accommodate the increased fuel demands of forced induction. The 2JZ-GE utilizes a simpler electronic fuel injection system, adequate for its naturally aspirated operation.

Tuning Potential

01 Engine performance enhancement

Various methods are employed to enhance the performance of 2JZ-GTE and 2JZ-GE engines. These include modifications to improve power output, fuel efficiency, and overall engine responsiveness. Techniques may involve optimizing fuel injection systems, upgrading turbochargers, and fine-tuning engine management systems.- Engine performance enhancement: Various methods are employed to enhance the performance of 2JZ-GTE and 2JZ-GE engines. These include modifications to improve power output, fuel efficiency, and overall engine responsiveness. Techniques may involve optimizing fuel injection systems, upgrading turbochargers, and fine-tuning engine management systems.

- Cooling system improvements: Enhancements to the cooling systems of 2JZ-GTE and 2JZ-GE engines are crucial for maintaining optimal performance. This includes redesigning radiators, implementing advanced coolant formulations, and improving coolant flow to manage engine temperatures more effectively, especially under high-performance conditions.

- Exhaust system optimization: Optimizing the exhaust system is a key factor in improving the performance of 2JZ-GTE and 2JZ-GE engines. This involves designing more efficient exhaust manifolds, upgrading catalytic converters, and implementing variable exhaust systems to reduce back pressure and increase power output across different RPM ranges.

- Intake system modifications: Modifications to the intake system can significantly enhance the performance of 2JZ-GTE and 2JZ-GE engines. This includes redesigning air intake pathways, implementing larger throttle bodies, and utilizing advanced air filtration systems to improve airflow and combustion efficiency.

- Engine internals upgrades: Upgrading internal engine components is crucial for maximizing the performance potential of 2JZ-GTE and 2JZ-GE engines. This involves using stronger pistons, connecting rods, and crankshafts, as well as implementing advanced valve train systems to withstand higher RPMs and increased power output.

02 Cooling system improvements

Enhancements to the cooling systems of 2JZ-GTE and 2JZ-GE engines are crucial for maintaining optimal performance. This includes redesigning radiators, implementing advanced coolant formulations, and improving heat dissipation mechanisms to prevent overheating during high-performance operations.Expand Specific Solutions03 Exhaust system optimization

Optimizing the exhaust system is a key factor in improving the performance of 2JZ-GTE and 2JZ-GE engines. This involves designing more efficient exhaust manifolds, upgrading catalytic converters, and implementing variable exhaust systems to enhance engine breathing and reduce back pressure.Expand Specific Solutions04 Intake system modifications

Modifications to the intake system can significantly boost the performance of 2JZ-GTE and 2JZ-GE engines. This includes redesigning air intake pathways, implementing cold air intake systems, and optimizing intake manifold geometry to improve airflow and volumetric efficiency.Expand Specific Solutions05 Engine internals upgrades

Upgrading internal engine components is crucial for enhancing the performance and durability of 2JZ-GTE and 2JZ-GE engines. This may involve using stronger pistons, connecting rods, and crankshafts, as well as implementing advanced materials and coatings to reduce friction and improve heat resistance.Expand Specific Solutions

Key Manufacturers

The comparative analysis of 2JZ-GTE vs 2JZ-GE performance is in a mature stage of development within the automotive industry. The market for these engines, primarily in aftermarket and performance applications, remains significant due to their enduring popularity. Technologically, both engines are well-established, with the 2JZ-GTE being more advanced due to its turbocharging. Companies like Toyota, the original manufacturer, and aftermarket specialists have extensively refined these engines over the years, leading to a high level of technical maturity. The ongoing interest in these engines for performance upgrades and engine swaps indicates a stable, though niche, market segment within the automotive performance industry.

Sony Group Corp.

Technical Solution: Sony, as a leading automotive technology provider, has developed advanced engine management systems that can be applied to both 2JZ-GTE and 2JZ-GE engines. Their system utilizes high-precision sensors and adaptive control algorithms to optimize fuel injection, ignition timing, and boost pressure (for the 2JZ-GTE). This technology allows for real-time adjustments based on driving conditions, enhancing performance and efficiency. Sony's system also incorporates machine learning capabilities to continuously improve engine performance over time, adapting to individual driving styles and environmental factors[1][3].

Strengths: Advanced sensor technology, adaptive algorithms, and machine learning integration. Weaknesses: Potentially higher cost and complexity compared to simpler engine management systems.

Analog Devices International Unlimited Co.

Technical Solution: Analog Devices has developed precision analog and mixed-signal solutions specifically tailored for automotive engine control systems. Their technology includes high-accuracy sensors for measuring various engine parameters such as temperature, pressure, and air flow. For the 2JZ-GTE, they offer specialized boost pressure sensors and wastegate control systems. Their solutions for the 2JZ-GE focus on optimizing air-fuel mixture and ignition timing. Analog Devices' advanced signal processing capabilities enable more precise engine control, resulting in improved performance and fuel efficiency for both engine variants[5][6].

Strengths: High-precision sensing technology, specialized solutions for turbocharged and naturally aspirated engines. Weaknesses: May require integration with other systems for complete engine management.

Innovative Features

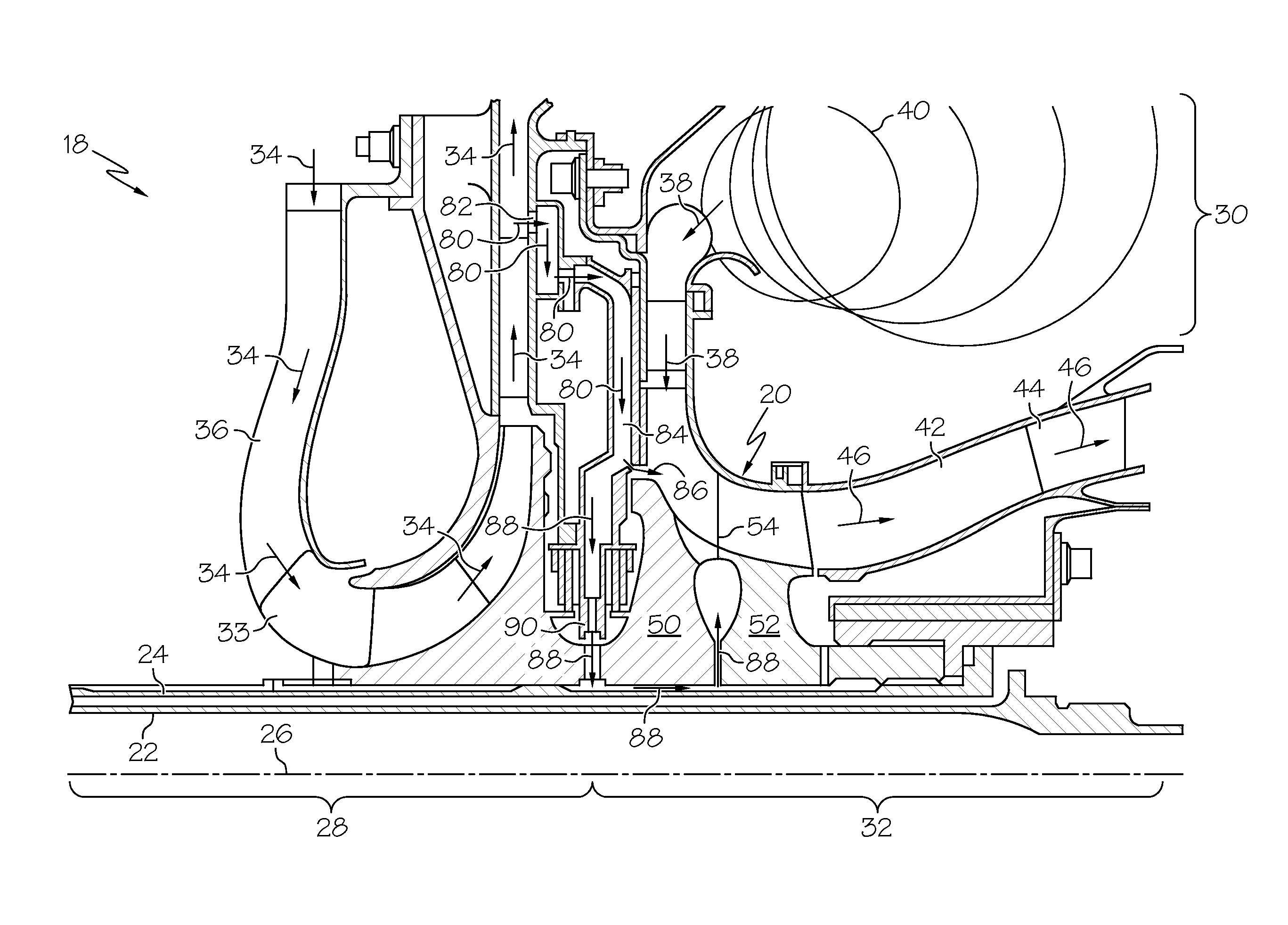

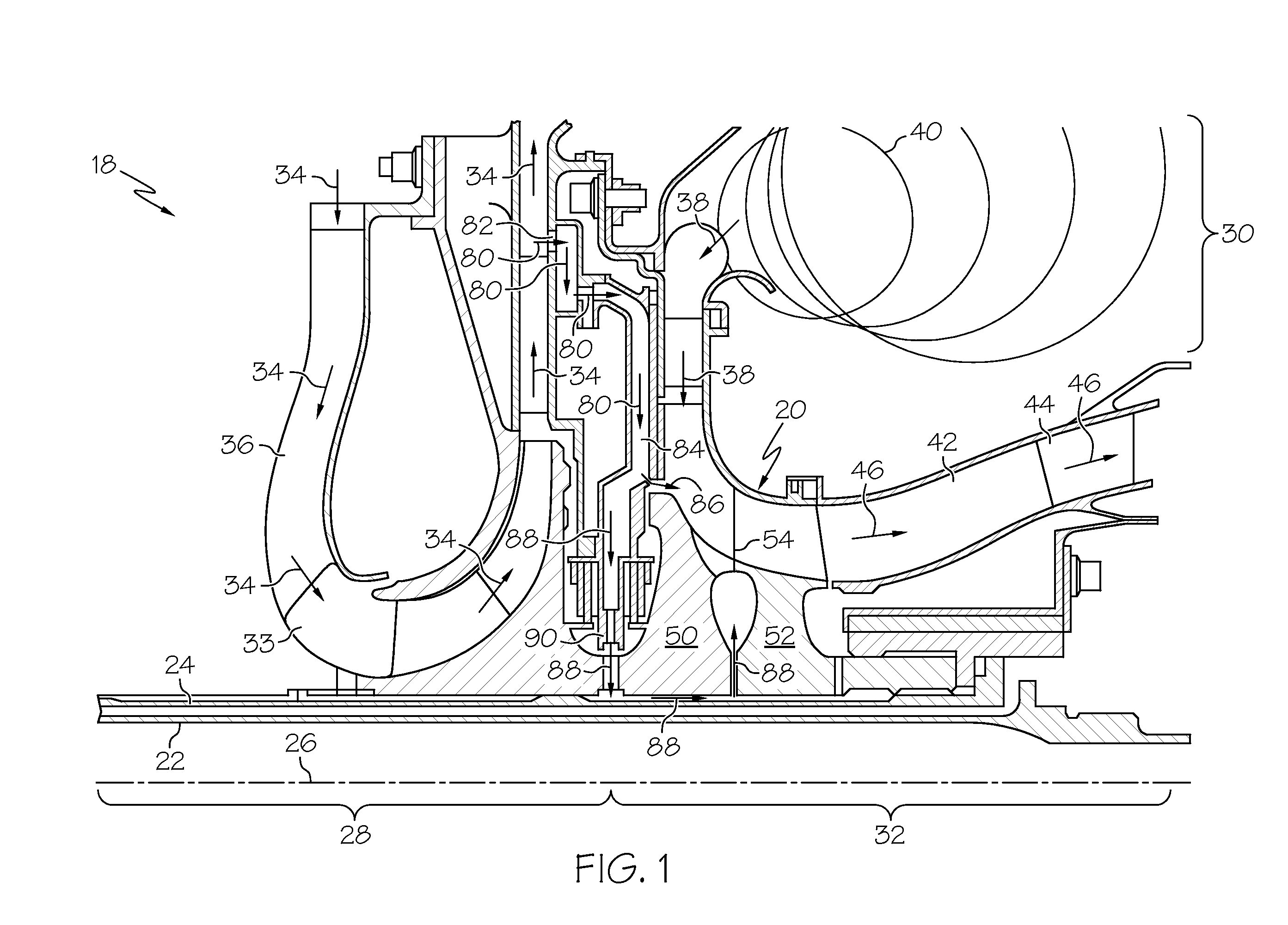

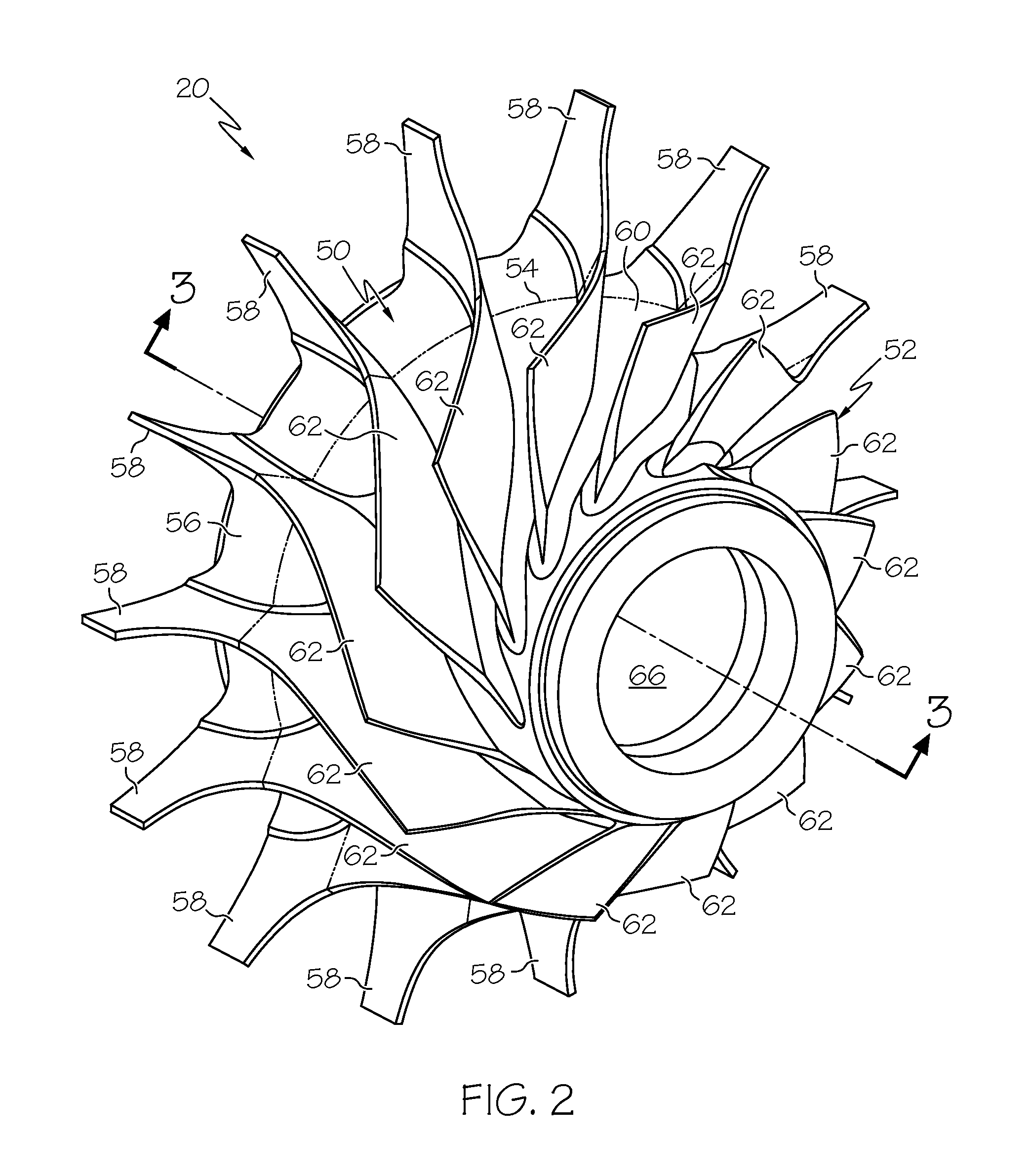

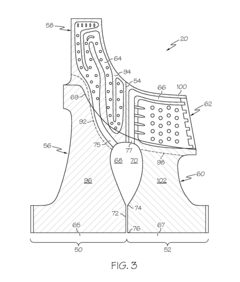

Axially-split radial turbines and methods for the manufacture thereof

PatentInactiveUS20130272882A1

Innovation

- An axially-split radial turbine design is developed, where a forward bladed ring and aft turbine rotor are metallurgically bonded to form a monolithic structure with internal cooling passages, allowing for the use of disparate alloys tailored to specific operating conditions, and a method involving directed thermal growth bonding and separate casting of bladed pieces to form a monolithic bladed ring.

Emissions Regulations

Emissions regulations play a crucial role in the comparative analysis of the 2JZ-GTE and 2JZ-GE engines, particularly in terms of their performance characteristics. These regulations have significantly influenced the design, development, and implementation of both engine variants, shaping their respective performance profiles and market positioning.

The 2JZ-GTE, being a twin-turbocharged engine, faces more stringent emissions challenges compared to its naturally aspirated counterpart, the 2JZ-GE. This is primarily due to the increased fuel consumption and higher combustion temperatures associated with forced induction systems. As a result, manufacturers have had to implement advanced emission control technologies to ensure compliance with increasingly strict environmental standards.

One of the key differences between the two engines in terms of emissions compliance lies in their fuel injection systems. The 2JZ-GTE typically employs a more sophisticated sequential multi-port fuel injection system, which allows for more precise fuel metering and better control over the air-fuel mixture. This enhanced control contributes to improved emissions performance, particularly in terms of reducing unburned hydrocarbons and carbon monoxide emissions.

Conversely, the 2JZ-GE, while still utilizing fuel injection technology, may not require the same level of complexity in its fuel delivery system. This can potentially result in a simpler and more cost-effective emissions control strategy, albeit with some trade-offs in terms of overall performance and efficiency.

The exhaust gas recirculation (EGR) systems employed in both engines also play a crucial role in meeting emissions standards. The 2JZ-GTE, due to its higher output and increased thermal load, may require a more robust EGR system to effectively reduce nitrogen oxide (NOx) emissions. This can include larger EGR coolers and more precise EGR valve control, which can impact the engine's overall performance characteristics.

Catalytic converter technology is another area where emissions regulations have influenced the design and performance of both engines. The 2JZ-GTE, with its higher exhaust gas temperatures and flow rates, typically requires more advanced and heat-resistant catalytic converters. These high-performance catalysts are designed to efficiently convert harmful emissions even under the more demanding conditions created by the turbocharged engine.

As emissions standards have evolved over time, both the 2JZ-GTE and 2JZ-GE have undergone various modifications to maintain compliance. This has led to the development of more advanced engine management systems, improved materials for exhaust components, and the integration of additional sensors for more precise emissions monitoring and control.

In conclusion, while both the 2JZ-GTE and 2JZ-GE engines have been subject to emissions regulations, the turbocharged nature of the GTE variant has necessitated more complex and potentially performance-impacting emissions control strategies. This has resulted in a delicate balance between achieving high performance outputs and meeting stringent environmental standards, influencing the overall characteristics and capabilities of each engine variant.

The 2JZ-GTE, being a twin-turbocharged engine, faces more stringent emissions challenges compared to its naturally aspirated counterpart, the 2JZ-GE. This is primarily due to the increased fuel consumption and higher combustion temperatures associated with forced induction systems. As a result, manufacturers have had to implement advanced emission control technologies to ensure compliance with increasingly strict environmental standards.

One of the key differences between the two engines in terms of emissions compliance lies in their fuel injection systems. The 2JZ-GTE typically employs a more sophisticated sequential multi-port fuel injection system, which allows for more precise fuel metering and better control over the air-fuel mixture. This enhanced control contributes to improved emissions performance, particularly in terms of reducing unburned hydrocarbons and carbon monoxide emissions.

Conversely, the 2JZ-GE, while still utilizing fuel injection technology, may not require the same level of complexity in its fuel delivery system. This can potentially result in a simpler and more cost-effective emissions control strategy, albeit with some trade-offs in terms of overall performance and efficiency.

The exhaust gas recirculation (EGR) systems employed in both engines also play a crucial role in meeting emissions standards. The 2JZ-GTE, due to its higher output and increased thermal load, may require a more robust EGR system to effectively reduce nitrogen oxide (NOx) emissions. This can include larger EGR coolers and more precise EGR valve control, which can impact the engine's overall performance characteristics.

Catalytic converter technology is another area where emissions regulations have influenced the design and performance of both engines. The 2JZ-GTE, with its higher exhaust gas temperatures and flow rates, typically requires more advanced and heat-resistant catalytic converters. These high-performance catalysts are designed to efficiently convert harmful emissions even under the more demanding conditions created by the turbocharged engine.

As emissions standards have evolved over time, both the 2JZ-GTE and 2JZ-GE have undergone various modifications to maintain compliance. This has led to the development of more advanced engine management systems, improved materials for exhaust components, and the integration of additional sensors for more precise emissions monitoring and control.

In conclusion, while both the 2JZ-GTE and 2JZ-GE engines have been subject to emissions regulations, the turbocharged nature of the GTE variant has necessitated more complex and potentially performance-impacting emissions control strategies. This has resulted in a delicate balance between achieving high performance outputs and meeting stringent environmental standards, influencing the overall characteristics and capabilities of each engine variant.

Cost-Benefit Analysis

When comparing the 2JZ-GTE and 2JZ-GE engines in terms of performance, it is crucial to consider the cost-benefit analysis to determine the overall value proposition of each engine variant. The 2JZ-GTE, being the turbocharged version, offers significantly higher performance potential but comes at a premium cost compared to its naturally aspirated counterpart, the 2JZ-GE.

The initial cost difference between the two engines is substantial. The 2JZ-GTE typically commands a higher price in the market due to its advanced turbocharging system and associated components. This price premium can range from 30% to 50% higher than the 2JZ-GE, depending on the condition and source of the engine.

In terms of performance benefits, the 2JZ-GTE offers a considerable advantage. Stock power output for the 2JZ-GTE ranges from 276 to 320 horsepower, while the 2JZ-GE produces around 220 to 230 horsepower. This power difference translates to significantly improved acceleration and overall performance, which can be particularly valuable for enthusiasts and competitive applications.

Fuel efficiency is another factor to consider. The turbocharged 2JZ-GTE, despite its higher power output, can be more fuel-efficient when driven conservatively due to its ability to produce power at lower RPMs. However, under heavy load or aggressive driving, fuel consumption can increase dramatically compared to the 2JZ-GE.

Maintenance costs also play a role in the long-term cost-benefit analysis. The 2JZ-GTE's turbocharging system introduces additional components that require maintenance and potential replacement over time. This includes turbochargers, intercoolers, and associated plumbing, which are not present in the simpler 2JZ-GE setup.

Reliability is a key consideration. Both engines are renowned for their robustness, but the 2JZ-GE's simpler naturally aspirated design may offer slightly better long-term reliability with less potential for costly turbo-related issues.

Resale value is another important aspect. The 2JZ-GTE, due to its higher performance potential and desirability among enthusiasts, tends to hold its value better over time. This can partially offset the higher initial investment when considering long-term ownership.

For performance enthusiasts, the 2JZ-GTE's ability to handle significant power increases with relatively minor modifications provides excellent value. The engine can support power outputs well beyond 1000 horsepower with appropriate upgrades, offering a cost-effective platform for high-performance builds compared to achieving similar power levels with a modified 2JZ-GE.

In conclusion, the cost-benefit analysis between the 2JZ-GTE and 2JZ-GE largely depends on the intended use and priorities of the owner. For those seeking maximum performance potential and willing to invest in higher initial and maintenance costs, the 2JZ-GTE offers superior value. For users prioritizing simplicity, lower costs, and adequate performance for daily driving, the 2JZ-GE presents a more economical choice while still providing the legendary reliability associated with the 2JZ platform.

The initial cost difference between the two engines is substantial. The 2JZ-GTE typically commands a higher price in the market due to its advanced turbocharging system and associated components. This price premium can range from 30% to 50% higher than the 2JZ-GE, depending on the condition and source of the engine.

In terms of performance benefits, the 2JZ-GTE offers a considerable advantage. Stock power output for the 2JZ-GTE ranges from 276 to 320 horsepower, while the 2JZ-GE produces around 220 to 230 horsepower. This power difference translates to significantly improved acceleration and overall performance, which can be particularly valuable for enthusiasts and competitive applications.

Fuel efficiency is another factor to consider. The turbocharged 2JZ-GTE, despite its higher power output, can be more fuel-efficient when driven conservatively due to its ability to produce power at lower RPMs. However, under heavy load or aggressive driving, fuel consumption can increase dramatically compared to the 2JZ-GE.

Maintenance costs also play a role in the long-term cost-benefit analysis. The 2JZ-GTE's turbocharging system introduces additional components that require maintenance and potential replacement over time. This includes turbochargers, intercoolers, and associated plumbing, which are not present in the simpler 2JZ-GE setup.

Reliability is a key consideration. Both engines are renowned for their robustness, but the 2JZ-GE's simpler naturally aspirated design may offer slightly better long-term reliability with less potential for costly turbo-related issues.

Resale value is another important aspect. The 2JZ-GTE, due to its higher performance potential and desirability among enthusiasts, tends to hold its value better over time. This can partially offset the higher initial investment when considering long-term ownership.

For performance enthusiasts, the 2JZ-GTE's ability to handle significant power increases with relatively minor modifications provides excellent value. The engine can support power outputs well beyond 1000 horsepower with appropriate upgrades, offering a cost-effective platform for high-performance builds compared to achieving similar power levels with a modified 2JZ-GE.

In conclusion, the cost-benefit analysis between the 2JZ-GTE and 2JZ-GE largely depends on the intended use and priorities of the owner. For those seeking maximum performance potential and willing to invest in higher initial and maintenance costs, the 2JZ-GTE offers superior value. For users prioritizing simplicity, lower costs, and adequate performance for daily driving, the 2JZ-GE presents a more economical choice while still providing the legendary reliability associated with the 2JZ platform.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!