Comparative Environmental Footprint: DLE Vs Evaporation Pond Methods

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) technology represents a significant evolution in lithium production methodologies, emerging as an alternative to traditional evaporation pond techniques that have dominated the industry for decades. The development of DLE can be traced back to the early 2000s, with substantial advancements occurring in the 2010s as global demand for lithium accelerated due to the electric vehicle revolution and expanding energy storage applications.

DLE encompasses a family of technologies designed to selectively extract lithium from brine resources using various mechanisms including adsorption, ion exchange, solvent extraction, and membrane processes. These approaches aim to address the fundamental limitations of evaporation ponds, which require extensive land use, consume significant water resources, and operate on lengthy production timelines of 18-24 months.

The technological evolution of DLE has been driven by increasing environmental concerns, water scarcity issues in lithium-rich regions, and the need for more efficient extraction methods to meet surging global demand. Industry projections suggest lithium demand could increase by 400-500% by 2030, necessitating more sustainable and scalable production methods.

The primary objectives of DLE technology development include reducing the environmental footprint of lithium production, particularly regarding water consumption and land use. While evaporation ponds typically require 2,000 liters of water per kilogram of lithium carbonate equivalent (LCE), advanced DLE systems aim to reduce this figure by 50-90%, representing a transformative improvement in resource efficiency.

Additionally, DLE technologies target significant reductions in production timeframes, with many systems capable of extracting lithium in hours or days rather than months. This acceleration addresses critical supply chain concerns as battery manufacturers and automakers seek reliable lithium sources to support electrification goals.

Another key objective is improving lithium recovery rates. Traditional evaporation methods typically recover only 40-50% of available lithium, whereas leading DLE technologies demonstrate potential recovery rates of 70-90%, substantially improving resource utilization efficiency and economic viability.

The technology also aims to enable lithium extraction from unconventional and lower-grade resources that would be uneconomical using traditional methods, potentially expanding the global lithium resource base by accessing previously untapped sources including geothermal brines, oilfield brines, and lower-concentration salt lake deposits.

As environmental regulations tighten globally and ESG considerations become increasingly important to investors and consumers, DLE represents a critical pathway toward more sustainable lithium production aligned with circular economy principles and reduced carbon intensity across the battery supply chain.

DLE encompasses a family of technologies designed to selectively extract lithium from brine resources using various mechanisms including adsorption, ion exchange, solvent extraction, and membrane processes. These approaches aim to address the fundamental limitations of evaporation ponds, which require extensive land use, consume significant water resources, and operate on lengthy production timelines of 18-24 months.

The technological evolution of DLE has been driven by increasing environmental concerns, water scarcity issues in lithium-rich regions, and the need for more efficient extraction methods to meet surging global demand. Industry projections suggest lithium demand could increase by 400-500% by 2030, necessitating more sustainable and scalable production methods.

The primary objectives of DLE technology development include reducing the environmental footprint of lithium production, particularly regarding water consumption and land use. While evaporation ponds typically require 2,000 liters of water per kilogram of lithium carbonate equivalent (LCE), advanced DLE systems aim to reduce this figure by 50-90%, representing a transformative improvement in resource efficiency.

Additionally, DLE technologies target significant reductions in production timeframes, with many systems capable of extracting lithium in hours or days rather than months. This acceleration addresses critical supply chain concerns as battery manufacturers and automakers seek reliable lithium sources to support electrification goals.

Another key objective is improving lithium recovery rates. Traditional evaporation methods typically recover only 40-50% of available lithium, whereas leading DLE technologies demonstrate potential recovery rates of 70-90%, substantially improving resource utilization efficiency and economic viability.

The technology also aims to enable lithium extraction from unconventional and lower-grade resources that would be uneconomical using traditional methods, potentially expanding the global lithium resource base by accessing previously untapped sources including geothermal brines, oilfield brines, and lower-concentration salt lake deposits.

As environmental regulations tighten globally and ESG considerations become increasingly important to investors and consumers, DLE represents a critical pathway toward more sustainable lithium production aligned with circular economy principles and reduced carbon intensity across the battery supply chain.

Market Analysis for Lithium Extraction Solutions

The global lithium extraction market is experiencing unprecedented growth, driven primarily by the expanding electric vehicle (EV) industry and renewable energy storage systems. Current market valuations place the lithium extraction sector at approximately $4 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 12-15% through 2030, potentially reaching $10-12 billion by decade's end. This remarkable expansion reflects the critical role lithium plays in the global transition toward sustainable energy solutions.

Direct Lithium Extraction (DLE) technologies are gaining significant market traction against traditional evaporation pond methods. While evaporation ponds currently dominate with roughly 80% of global production capacity, DLE solutions are expected to capture 25-30% of market share by 2030. This shift is particularly evident in North America and Europe, where environmental regulations and water conservation concerns are driving adoption of more sustainable extraction methodologies.

Customer segmentation within the lithium extraction market reveals three primary buyer categories: established mining corporations seeking to modernize operations, battery manufacturers pursuing vertical integration strategies, and emerging green technology companies prioritizing environmentally responsible supply chains. Each segment demonstrates distinct purchasing behaviors and technology adoption timelines, with green technology companies showing the highest willingness to invest in premium DLE solutions despite higher initial capital expenditures.

Regional market analysis indicates that while South America (particularly the "Lithium Triangle" of Chile, Argentina, and Bolivia) continues to dominate production volume, North America is emerging as the fastest-growing market for advanced extraction technologies. China maintains its position as the largest processor of lithium compounds, though recent geopolitical tensions have accelerated efforts to develop processing capacity in other regions.

Pricing trends reveal a significant premium for lithium extracted using environmentally responsible methods. Battery-grade lithium carbonate produced via DLE commands a 15-20% price premium in certain markets, particularly among European and North American buyers with stringent ESG (Environmental, Social, and Governance) requirements. This price differential is expected to narrow as DLE technologies achieve greater economies of scale, potentially reaching parity with traditional methods by 2028-2030.

Market barriers for DLE adoption include high capital expenditure requirements, technological maturity concerns, and integration challenges with existing processing infrastructure. However, these barriers are progressively diminishing as technology providers demonstrate successful commercial-scale implementations and operational cost reductions through process optimization and energy efficiency improvements.

Direct Lithium Extraction (DLE) technologies are gaining significant market traction against traditional evaporation pond methods. While evaporation ponds currently dominate with roughly 80% of global production capacity, DLE solutions are expected to capture 25-30% of market share by 2030. This shift is particularly evident in North America and Europe, where environmental regulations and water conservation concerns are driving adoption of more sustainable extraction methodologies.

Customer segmentation within the lithium extraction market reveals three primary buyer categories: established mining corporations seeking to modernize operations, battery manufacturers pursuing vertical integration strategies, and emerging green technology companies prioritizing environmentally responsible supply chains. Each segment demonstrates distinct purchasing behaviors and technology adoption timelines, with green technology companies showing the highest willingness to invest in premium DLE solutions despite higher initial capital expenditures.

Regional market analysis indicates that while South America (particularly the "Lithium Triangle" of Chile, Argentina, and Bolivia) continues to dominate production volume, North America is emerging as the fastest-growing market for advanced extraction technologies. China maintains its position as the largest processor of lithium compounds, though recent geopolitical tensions have accelerated efforts to develop processing capacity in other regions.

Pricing trends reveal a significant premium for lithium extracted using environmentally responsible methods. Battery-grade lithium carbonate produced via DLE commands a 15-20% price premium in certain markets, particularly among European and North American buyers with stringent ESG (Environmental, Social, and Governance) requirements. This price differential is expected to narrow as DLE technologies achieve greater economies of scale, potentially reaching parity with traditional methods by 2028-2030.

Market barriers for DLE adoption include high capital expenditure requirements, technological maturity concerns, and integration challenges with existing processing infrastructure. However, these barriers are progressively diminishing as technology providers demonstrate successful commercial-scale implementations and operational cost reductions through process optimization and energy efficiency improvements.

Current State and Challenges of Lithium Extraction Methods

Lithium extraction methodologies have evolved significantly over the past decades, with two primary approaches dominating the industry: traditional evaporation pond methods and the emerging Direct Lithium Extraction (DLE) technologies. The conventional evaporation pond technique, which has been the industry standard for over 50 years, relies on solar evaporation of brine in large ponds over 12-24 months to concentrate lithium before chemical processing. This method currently accounts for approximately 80% of global lithium production, primarily in the "Lithium Triangle" of Chile, Argentina, and Bolivia.

Despite its widespread use, evaporation pond technology faces substantial challenges. The method is highly water-intensive, consuming an estimated 500,000 gallons of water per ton of lithium produced in arid regions where water scarcity is already a critical issue. Additionally, the process is characterized by low recovery rates of 30-50%, significant land use requirements of 2,000-4,000 acres per operation, and vulnerability to weather fluctuations that can disrupt production schedules.

In contrast, DLE technologies represent a paradigm shift in lithium extraction. These methods utilize selective adsorption, ion exchange membranes, or solvent extraction to directly separate lithium from brine solutions. While still evolving, DLE approaches demonstrate promising advantages, including dramatically reduced water consumption (potentially 90% less than evaporation methods), significantly smaller land footprints (50-100 acres), and substantially higher recovery rates of 70-90%.

However, DLE technologies face their own set of challenges. Energy requirements are considerably higher than traditional methods, with estimates suggesting 15-40 kWh per kilogram of lithium carbonate equivalent (LCE) compared to 5-15 kWh for evaporation ponds. The technology also struggles with brine chemistry variability across different deposits, requiring customized solutions for each location. Additionally, the management of chemical reagents and waste streams presents environmental concerns that require careful consideration.

The geographical distribution of lithium extraction technologies shows interesting patterns. South American operations predominantly utilize evaporation ponds due to favorable climatic conditions, while North American and European projects increasingly favor DLE approaches to address stricter environmental regulations and different geological contexts. Chinese extraction operations employ a mix of both methodologies, with growing investment in DLE research.

The industry currently stands at a critical inflection point, with mounting pressure from automotive and battery manufacturers for more environmentally sustainable lithium sources. This demand, coupled with regulatory trends favoring reduced environmental impacts, is accelerating the transition toward DLE technologies despite their current technical and economic limitations.

Despite its widespread use, evaporation pond technology faces substantial challenges. The method is highly water-intensive, consuming an estimated 500,000 gallons of water per ton of lithium produced in arid regions where water scarcity is already a critical issue. Additionally, the process is characterized by low recovery rates of 30-50%, significant land use requirements of 2,000-4,000 acres per operation, and vulnerability to weather fluctuations that can disrupt production schedules.

In contrast, DLE technologies represent a paradigm shift in lithium extraction. These methods utilize selective adsorption, ion exchange membranes, or solvent extraction to directly separate lithium from brine solutions. While still evolving, DLE approaches demonstrate promising advantages, including dramatically reduced water consumption (potentially 90% less than evaporation methods), significantly smaller land footprints (50-100 acres), and substantially higher recovery rates of 70-90%.

However, DLE technologies face their own set of challenges. Energy requirements are considerably higher than traditional methods, with estimates suggesting 15-40 kWh per kilogram of lithium carbonate equivalent (LCE) compared to 5-15 kWh for evaporation ponds. The technology also struggles with brine chemistry variability across different deposits, requiring customized solutions for each location. Additionally, the management of chemical reagents and waste streams presents environmental concerns that require careful consideration.

The geographical distribution of lithium extraction technologies shows interesting patterns. South American operations predominantly utilize evaporation ponds due to favorable climatic conditions, while North American and European projects increasingly favor DLE approaches to address stricter environmental regulations and different geological contexts. Chinese extraction operations employ a mix of both methodologies, with growing investment in DLE research.

The industry currently stands at a critical inflection point, with mounting pressure from automotive and battery manufacturers for more environmentally sustainable lithium sources. This demand, coupled with regulatory trends favoring reduced environmental impacts, is accelerating the transition toward DLE technologies despite their current technical and economic limitations.

Technical Comparison of DLE and Evaporation Pond Methods

01 Environmental impact comparison between DLE and evaporation pond methods

Direct Lithium Extraction (DLE) methods generally have a smaller environmental footprint compared to traditional evaporation pond techniques. DLE requires less land area, reduces water consumption, and minimizes habitat disruption. Evaporation ponds, while established technology, require large land areas, significant water usage, and can impact local ecosystems. The comparative analysis of these methods shows that DLE technologies offer more sustainable approaches to lithium extraction with reduced environmental consequences.- Environmental impact comparison between DLE and evaporation pond methods: Direct Lithium Extraction (DLE) methods generally have a smaller environmental footprint compared to traditional evaporation pond techniques. DLE requires significantly less land area, reduces water consumption by up to 90%, and minimizes habitat disruption. Evaporation ponds, while established technology, require large land areas, consume substantial water through evaporation, and can potentially contaminate surrounding ecosystems through leakage of brine solutions containing various salts and chemicals.

- Water usage and conservation in lithium extraction: Water usage represents a critical environmental concern in lithium extraction processes. Traditional evaporation pond methods consume vast quantities of water through evaporation, particularly problematic in arid regions where lithium brine deposits are commonly found. Advanced DLE technologies incorporate water recycling systems that can recover and reuse up to 90% of process water. Some innovations include closed-loop water systems, brine reinjection techniques, and water treatment processes that minimize freshwater consumption and reduce pressure on local water resources.

- Energy consumption and carbon footprint reduction: Energy requirements differ significantly between lithium extraction methods, affecting their overall carbon footprint. Evaporation ponds rely primarily on solar energy for evaporation but require energy-intensive processing of concentrated brine afterward. DLE technologies typically require more upfront energy for operation but can be powered by renewable sources. Innovations in energy-efficient DLE processes include heat recovery systems, optimized extraction cycles, and integration with renewable energy sources such as geothermal, solar, or wind power to create more sustainable extraction operations with reduced greenhouse gas emissions.

- Land use and habitat preservation strategies: Land disturbance varies dramatically between lithium extraction methods. Evaporation ponds require extensive surface area, often 10-20 square kilometers of land per operation, significantly altering natural landscapes and wildlife habitats. DLE technologies operate with a much smaller physical footprint, sometimes requiring less than 10% of the land area compared to evaporation ponds. Advanced approaches incorporate habitat restoration plans, wildlife corridors, and minimally invasive infrastructure designs to reduce ecological disruption while maintaining extraction efficiency.

- Chemical usage and waste management innovations: Chemical management represents a significant environmental consideration in lithium extraction. Evaporation ponds typically use fewer chemicals but generate large volumes of salt waste and potentially harmful byproducts. DLE methods often employ selective sorbents, solvents, or membranes that require careful handling but can be designed for regeneration and reuse. Recent innovations focus on biodegradable extraction agents, closed-loop chemical systems, and beneficial repurposing of extraction byproducts. Advanced waste management approaches include selective precipitation of valuable byproducts like magnesium and potassium compounds, reducing overall waste while creating additional revenue streams.

02 Water usage and conservation in lithium extraction processes

Water consumption is a critical environmental concern in lithium extraction. Traditional evaporation pond methods require substantial water resources, often in water-scarce regions, leading to depletion of groundwater and affecting local communities. DLE technologies offer significant water conservation benefits, with some methods enabling water recycling and reduced freshwater requirements. Advanced water management systems integrated with extraction processes can further minimize the hydrological impact of lithium production operations.Expand Specific Solutions03 Energy consumption and carbon footprint considerations

Energy requirements differ significantly between lithium extraction methods, affecting their overall carbon footprint. DLE technologies often require more energy input for operation but over shorter timeframes compared to evaporation ponds. Innovations in renewable energy integration with extraction facilities can substantially reduce greenhouse gas emissions associated with lithium production. Some advanced DLE systems incorporate energy recovery mechanisms to improve efficiency and minimize environmental impact, making them more sustainable despite higher initial energy demands.Expand Specific Solutions04 Land use and ecosystem disruption

The land footprint of lithium extraction varies significantly between methods. Evaporation ponds require extensive surface area, often disrupting natural habitats and ecosystems. DLE technologies operate with substantially smaller land requirements, reducing habitat fragmentation and preserving biodiversity. Restoration and reclamation strategies for extraction sites can mitigate long-term environmental damage, with some innovative approaches incorporating ecosystem services into operational planning to minimize disruption to local flora and fauna.Expand Specific Solutions05 Chemical usage and waste management

Chemical additives and waste management represent significant environmental considerations in lithium extraction. Evaporation ponds typically use fewer chemicals but generate substantial waste brine that can contaminate soil and water sources. DLE methods may utilize more specialized chemicals but often feature closed-loop systems that minimize waste discharge. Advanced treatment technologies for process residues and spent materials can reduce the environmental liability of extraction operations, with some innovations focusing on recovery of valuable by-products from waste streams to improve overall sustainability.Expand Specific Solutions

Key Industry Players in Lithium Extraction

The Direct Lithium Extraction (DLE) versus Evaporation Pond methods competition is currently in a transitional phase, with the lithium extraction market expanding rapidly due to growing electric vehicle demand. While traditional evaporation ponds dominate current production, DLE technologies are gaining momentum as more environmentally sustainable alternatives. Companies like International Battery Metals, Evove, and Cemvita Factory are advancing DLE innovations, while established players such as Shell, Eni, and ConocoPhillips are investing in research. Academic institutions including King Fahd University and Lanzhou University are contributing significant research to improve technical feasibility. The technology is approaching commercial viability, though challenges in scaling and process optimization remain before widespread adoption can occur.

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has developed a comprehensive DLE technology platform that integrates selective ion exchange materials with advanced separation processes. Their system employs proprietary adsorbents that selectively extract lithium from brine resources with minimal co-extraction of impurities. The process operates in continuous flow mode, allowing for consistent lithium recovery while minimizing reagent consumption and waste generation. Koch's technology incorporates sophisticated water management systems that recycle up to 95% of process water, dramatically reducing the water footprint compared to evaporation ponds. Their approach includes modular process units that can be configured to accommodate varying brine compositions and production capacities. The technology also features advanced process control systems that optimize energy usage and chemical consumption based on real-time monitoring of process parameters and environmental conditions.

Strengths: Highly selective lithium extraction with minimal impurities; substantial water conservation through closed-loop recycling; reduced chemical consumption compared to conventional methods; scalable modular design. Weaknesses: Higher energy intensity than passive evaporation; requires more complex operational management; higher initial capital costs; technology still being optimized for certain brine chemistries.

Shell Oil Co.

Technical Solution: Shell Oil has developed an innovative DLE technology that utilizes novel solvent extraction techniques combined with membrane separation processes. Their approach employs proprietary solvents that selectively bind with lithium ions in brine solutions, enabling efficient separation from other elements. The extracted lithium is then recovered through a stripping process that regenerates the solvent for reuse. Shell's system operates in a continuous closed-loop configuration that minimizes water consumption and waste generation. Their technology incorporates advanced heat integration strategies that recover and reuse thermal energy throughout the process, reducing overall energy requirements by up to 40% compared to conventional methods. The system's compact design requires approximately 85% less land area than traditional evaporation ponds while achieving comparable production rates. Shell has also implemented comprehensive environmental monitoring protocols that track water usage, emissions, and energy consumption throughout the extraction process.

Strengths: Dramatically reduced land footprint compared to evaporation ponds; significantly lower water consumption through closed-loop processing; faster extraction timeframe (days vs. months); advanced energy recovery systems reducing overall consumption. Weaknesses: Higher operational complexity requiring specialized expertise; greater initial capital investment; technology still being optimized for commercial-scale implementation; requires reliable infrastructure support.

Environmental Impact Assessment Methodologies

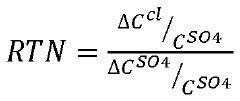

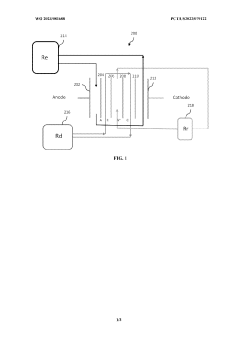

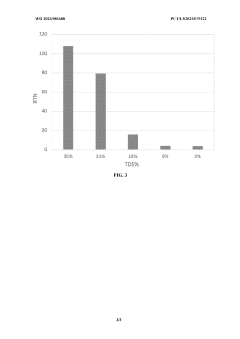

Monovalent anion selective membrane enabled by high concentration brine

PatentWO2023081688A1

Innovation

- A monovalent anion selective membrane enabled by high concentration brine solutions is developed, utilizing an anion exchange membrane that enhances selectivity for monovalent anions, allowing for effective separation of lithium from divalent ions like Mg2+ and sulfate, thereby reducing lithium losses and improving recovery rates.

Process and product

PatentPendingUS20250161879A1

Innovation

- The process involves contacting an aqueous lithium solution with a lithium sorbent to absorb lithium, followed by separation of the loaded sorbent and depleted solution, and subsequent treatment to regenerate the sorbent. This process utilizes pH control to maintain the lithium depleted solution at a pH of about 3 to 7 and employs ultrafiltration or nanofiltration membranes for separation.

Regulatory Framework for Lithium Extraction Operations

The regulatory landscape governing lithium extraction operations varies significantly across jurisdictions, with increasing scrutiny on environmental impacts driving more stringent requirements. At the international level, frameworks such as the UN Framework Convention on Climate Change and the Paris Agreement indirectly influence lithium extraction by promoting sustainable resource management and reduced carbon emissions. These agreements have prompted countries with lithium reserves to develop more environmentally conscious extraction policies.

In the United States, lithium extraction is regulated through multiple federal agencies including the Bureau of Land Management (BLM), Environmental Protection Agency (EPA), and the Department of Energy. The National Environmental Policy Act (NEPA) requires environmental impact assessments for major extraction projects, while the Clean Water Act and Safe Drinking Water Act impose strict limitations on water usage and potential contamination—factors particularly relevant when comparing DLE to evaporation pond methods.

The European Union has established the European Battery Alliance and the European Raw Materials Alliance, which promote sustainable lithium extraction practices through voluntary standards and potential future regulations. The EU Taxonomy for Sustainable Activities specifically addresses mining operations, creating financial incentives for companies employing environmentally superior extraction technologies like DLE.

Chile, Argentina, and Bolivia—comprising the "Lithium Triangle"—have developed country-specific regulatory frameworks. Chile's regulations are particularly noteworthy, requiring companies to limit water consumption and implement environmental management plans. Recent amendments have begun to favor DLE methods by offering expedited permitting processes for technologies demonstrating reduced water usage and environmental impact.

Australia, another major lithium producer, regulates extraction through state-level mining acts and the Environment Protection and Biodiversity Conservation Act, with increasing pressure to adopt more sustainable practices. China, as both a producer and major consumer of lithium, has implemented its Mineral Resources Law with recent amendments focusing on resource efficiency and environmental protection.

Emerging regulatory trends include carbon footprint disclosure requirements, water usage restrictions, and indigenous rights considerations. Several jurisdictions are developing specific lithium extraction regulations that differentiate between traditional evaporation methods and newer DLE technologies, with the latter often receiving preferential treatment due to their reduced environmental footprint. These regulatory frameworks increasingly incorporate lifecycle assessment requirements, pushing companies to document and minimize environmental impacts across the entire extraction process.

In the United States, lithium extraction is regulated through multiple federal agencies including the Bureau of Land Management (BLM), Environmental Protection Agency (EPA), and the Department of Energy. The National Environmental Policy Act (NEPA) requires environmental impact assessments for major extraction projects, while the Clean Water Act and Safe Drinking Water Act impose strict limitations on water usage and potential contamination—factors particularly relevant when comparing DLE to evaporation pond methods.

The European Union has established the European Battery Alliance and the European Raw Materials Alliance, which promote sustainable lithium extraction practices through voluntary standards and potential future regulations. The EU Taxonomy for Sustainable Activities specifically addresses mining operations, creating financial incentives for companies employing environmentally superior extraction technologies like DLE.

Chile, Argentina, and Bolivia—comprising the "Lithium Triangle"—have developed country-specific regulatory frameworks. Chile's regulations are particularly noteworthy, requiring companies to limit water consumption and implement environmental management plans. Recent amendments have begun to favor DLE methods by offering expedited permitting processes for technologies demonstrating reduced water usage and environmental impact.

Australia, another major lithium producer, regulates extraction through state-level mining acts and the Environment Protection and Biodiversity Conservation Act, with increasing pressure to adopt more sustainable practices. China, as both a producer and major consumer of lithium, has implemented its Mineral Resources Law with recent amendments focusing on resource efficiency and environmental protection.

Emerging regulatory trends include carbon footprint disclosure requirements, water usage restrictions, and indigenous rights considerations. Several jurisdictions are developing specific lithium extraction regulations that differentiate between traditional evaporation methods and newer DLE technologies, with the latter often receiving preferential treatment due to their reduced environmental footprint. These regulatory frameworks increasingly incorporate lifecycle assessment requirements, pushing companies to document and minimize environmental impacts across the entire extraction process.

Water Resource Management in Lithium Production

Water resource management represents a critical aspect of lithium production, particularly when comparing Direct Lithium Extraction (DLE) and traditional evaporation pond methods. The stark contrast between these two approaches primarily centers on water consumption, conservation, and environmental impact.

Traditional evaporation pond methods require substantial water resources, with estimates suggesting that producing one ton of lithium carbonate can consume approximately 500,000 gallons of water. This process relies on natural evaporation in arid regions, where lithium-rich brine is pumped from underground aquifers into large ponds and left to evaporate for 12-18 months. The significant water loss through evaporation creates considerable strain on local water tables, often in regions already experiencing water scarcity.

In contrast, DLE technologies demonstrate promising water efficiency advantages. Most DLE methods can recover up to 90% of the water used in the extraction process, allowing it to be returned to the original aquifer or repurposed. This closed-loop system significantly reduces the net water consumption compared to evaporation ponds, with some advanced DLE systems claiming to use less than 50,000 gallons per ton of lithium produced – a 90% reduction.

The geographical implications of these different water management approaches are substantial. Evaporation ponds are primarily viable in arid regions with high evaporation rates, such as the "Lithium Triangle" spanning Chile, Argentina, and Bolivia. These areas often face competing demands for limited water resources from local communities, agriculture, and other industries. Several documented cases show declining water tables and diminished access to freshwater for indigenous communities near large-scale evaporation operations.

DLE methods offer greater flexibility in terms of geographical deployment, as they are less dependent on specific climatic conditions. This allows for lithium production in regions with more abundant water resources, potentially alleviating pressure on water-stressed areas. Additionally, the faster processing time of DLE (hours or days versus months) means less water is tied up in the production process at any given time.

From a regulatory perspective, water management in lithium production faces increasing scrutiny. Several countries are implementing stricter water usage regulations for mining operations, with particular attention to the lithium sector. Companies employing water-efficient DLE technologies may gain competitive advantages in securing permits and maintaining social licenses to operate in communities concerned about water security.

Traditional evaporation pond methods require substantial water resources, with estimates suggesting that producing one ton of lithium carbonate can consume approximately 500,000 gallons of water. This process relies on natural evaporation in arid regions, where lithium-rich brine is pumped from underground aquifers into large ponds and left to evaporate for 12-18 months. The significant water loss through evaporation creates considerable strain on local water tables, often in regions already experiencing water scarcity.

In contrast, DLE technologies demonstrate promising water efficiency advantages. Most DLE methods can recover up to 90% of the water used in the extraction process, allowing it to be returned to the original aquifer or repurposed. This closed-loop system significantly reduces the net water consumption compared to evaporation ponds, with some advanced DLE systems claiming to use less than 50,000 gallons per ton of lithium produced – a 90% reduction.

The geographical implications of these different water management approaches are substantial. Evaporation ponds are primarily viable in arid regions with high evaporation rates, such as the "Lithium Triangle" spanning Chile, Argentina, and Bolivia. These areas often face competing demands for limited water resources from local communities, agriculture, and other industries. Several documented cases show declining water tables and diminished access to freshwater for indigenous communities near large-scale evaporation operations.

DLE methods offer greater flexibility in terms of geographical deployment, as they are less dependent on specific climatic conditions. This allows for lithium production in regions with more abundant water resources, potentially alleviating pressure on water-stressed areas. Additionally, the faster processing time of DLE (hours or days versus months) means less water is tied up in the production process at any given time.

From a regulatory perspective, water management in lithium production faces increasing scrutiny. Several countries are implementing stricter water usage regulations for mining operations, with particular attention to the lithium sector. Companies employing water-efficient DLE technologies may gain competitive advantages in securing permits and maintaining social licenses to operate in communities concerned about water security.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!