Thermal Integration: Using Geothermal Heat To Improve DLE Efficiency

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Geothermal-DLE Integration Background and Objectives

Direct Lithium Extraction (DLE) has emerged as a promising alternative to traditional lithium extraction methods, offering reduced environmental impact and potentially higher recovery rates. However, DLE processes typically require significant energy inputs, particularly for heating brines to optimal processing temperatures. This energy requirement represents both a substantial operational cost and a potential environmental concern if powered by fossil fuels.

Geothermal resources present a unique opportunity for integration with DLE operations. Geothermal energy has been utilized for electricity generation and direct heating applications for decades, with technological advancements steadily improving efficiency and expanding viable deployment scenarios. The natural synergy between geothermal resources and lithium-rich brines creates a compelling case for combined systems.

The evolution of this integrated approach can be traced back to early observations of lithium content in geothermal brines, particularly in locations such as the Salton Sea in California. Initial focus was primarily on the geothermal electricity generation, with mineral recovery considered a secondary benefit. However, as global demand for lithium has surged due to the electric vehicle revolution and renewable energy storage requirements, the strategic value of co-located lithium extraction has gained prominence.

Recent technological developments have enabled more efficient heat exchange systems and membrane technologies that can operate effectively at the temperature ranges typical of geothermal resources. These advancements have created new possibilities for thermal integration between geothermal systems and DLE processes, potentially addressing one of DLE's key limitations.

The primary technical objective of geothermal-DLE integration is to leverage naturally occurring heat from geothermal resources to power the thermal requirements of DLE processes, thereby reducing operational costs and improving the overall energy efficiency of lithium production. Secondary objectives include minimizing the carbon footprint of lithium extraction, maximizing resource utilization from a single brine source, and developing scalable systems that can be deployed across various geothermal resource types.

Additional goals include optimizing heat transfer mechanisms between geothermal and DLE systems, developing temperature management strategies for various DLE technologies, and creating closed-loop systems that minimize water consumption and waste generation. The ultimate aim is to establish a sustainable, economically viable pathway for lithium production that can help meet growing global demand while minimizing environmental impacts.

This integration represents a potential paradigm shift in critical mineral extraction, moving toward more sustainable practices that align with global decarbonization efforts while addressing supply chain concerns for materials essential to the clean energy transition.

Geothermal resources present a unique opportunity for integration with DLE operations. Geothermal energy has been utilized for electricity generation and direct heating applications for decades, with technological advancements steadily improving efficiency and expanding viable deployment scenarios. The natural synergy between geothermal resources and lithium-rich brines creates a compelling case for combined systems.

The evolution of this integrated approach can be traced back to early observations of lithium content in geothermal brines, particularly in locations such as the Salton Sea in California. Initial focus was primarily on the geothermal electricity generation, with mineral recovery considered a secondary benefit. However, as global demand for lithium has surged due to the electric vehicle revolution and renewable energy storage requirements, the strategic value of co-located lithium extraction has gained prominence.

Recent technological developments have enabled more efficient heat exchange systems and membrane technologies that can operate effectively at the temperature ranges typical of geothermal resources. These advancements have created new possibilities for thermal integration between geothermal systems and DLE processes, potentially addressing one of DLE's key limitations.

The primary technical objective of geothermal-DLE integration is to leverage naturally occurring heat from geothermal resources to power the thermal requirements of DLE processes, thereby reducing operational costs and improving the overall energy efficiency of lithium production. Secondary objectives include minimizing the carbon footprint of lithium extraction, maximizing resource utilization from a single brine source, and developing scalable systems that can be deployed across various geothermal resource types.

Additional goals include optimizing heat transfer mechanisms between geothermal and DLE systems, developing temperature management strategies for various DLE technologies, and creating closed-loop systems that minimize water consumption and waste generation. The ultimate aim is to establish a sustainable, economically viable pathway for lithium production that can help meet growing global demand while minimizing environmental impacts.

This integration represents a potential paradigm shift in critical mineral extraction, moving toward more sustainable practices that align with global decarbonization efforts while addressing supply chain concerns for materials essential to the clean energy transition.

Market Analysis for Thermal-Enhanced DLE

The Direct Lithium Extraction (DLE) market is experiencing significant growth as global demand for lithium continues to surge, driven primarily by the electric vehicle and energy storage sectors. Current market projections indicate that the global lithium market is expected to reach $8.2 billion by 2028, with DLE technologies potentially capturing a substantial portion of this growth due to their environmental and efficiency advantages over traditional extraction methods.

Thermal-enhanced DLE represents a particularly promising segment within this market. By integrating geothermal heat sources with DLE processes, operators can achieve substantial improvements in extraction efficiency while simultaneously reducing operational costs. Market analysis reveals that regions with accessible geothermal resources could reduce DLE energy costs by 30-60% compared to conventional heating methods, creating a compelling economic case for integration.

The market for thermal-enhanced DLE is geographically concentrated in regions with both lithium-rich brines and geothermal resources. The most notable hotspots include the Salton Sea in California, Chile's Atacama Desert, parts of Argentina's lithium triangle, and certain regions in Germany and New Zealand. These areas are attracting significant investment attention, with several pilot projects already demonstrating commercial viability.

From a competitive landscape perspective, the market features both established mining companies pivoting toward DLE technologies and specialized technology startups. Major players include Vulcan Energy Resources, which has pioneered zero-carbon lithium extraction using geothermal energy in Germany, and Controlled Thermal Resources, developing integrated geothermal power and lithium extraction facilities in the Salton Sea.

Market adoption barriers primarily revolve around high initial capital expenditure requirements and technological maturity concerns. However, the economic case strengthens as energy prices rise and environmental regulations tighten. Government incentives for clean energy and critical mineral production are accelerating market development, with several countries implementing strategic initiatives to secure domestic lithium supply chains.

Customer segments for thermal-enhanced DLE technologies include lithium producers seeking cost advantages, battery manufacturers looking to secure environmentally responsible supply chains, and geothermal power producers exploring revenue diversification opportunities. The strongest market pull currently comes from EV manufacturers facing pressure to demonstrate sustainable supply chains for battery materials.

Market forecasts suggest that thermal-enhanced DLE could capture 15-25% of new lithium production capacity by 2030, representing a significant shift in how lithium is sourced globally. This growth trajectory is supported by the dual benefits of reduced carbon footprint and improved production economics, making it increasingly attractive to both producers and end-users in the battery supply chain.

Thermal-enhanced DLE represents a particularly promising segment within this market. By integrating geothermal heat sources with DLE processes, operators can achieve substantial improvements in extraction efficiency while simultaneously reducing operational costs. Market analysis reveals that regions with accessible geothermal resources could reduce DLE energy costs by 30-60% compared to conventional heating methods, creating a compelling economic case for integration.

The market for thermal-enhanced DLE is geographically concentrated in regions with both lithium-rich brines and geothermal resources. The most notable hotspots include the Salton Sea in California, Chile's Atacama Desert, parts of Argentina's lithium triangle, and certain regions in Germany and New Zealand. These areas are attracting significant investment attention, with several pilot projects already demonstrating commercial viability.

From a competitive landscape perspective, the market features both established mining companies pivoting toward DLE technologies and specialized technology startups. Major players include Vulcan Energy Resources, which has pioneered zero-carbon lithium extraction using geothermal energy in Germany, and Controlled Thermal Resources, developing integrated geothermal power and lithium extraction facilities in the Salton Sea.

Market adoption barriers primarily revolve around high initial capital expenditure requirements and technological maturity concerns. However, the economic case strengthens as energy prices rise and environmental regulations tighten. Government incentives for clean energy and critical mineral production are accelerating market development, with several countries implementing strategic initiatives to secure domestic lithium supply chains.

Customer segments for thermal-enhanced DLE technologies include lithium producers seeking cost advantages, battery manufacturers looking to secure environmentally responsible supply chains, and geothermal power producers exploring revenue diversification opportunities. The strongest market pull currently comes from EV manufacturers facing pressure to demonstrate sustainable supply chains for battery materials.

Market forecasts suggest that thermal-enhanced DLE could capture 15-25% of new lithium production capacity by 2030, representing a significant shift in how lithium is sourced globally. This growth trajectory is supported by the dual benefits of reduced carbon footprint and improved production economics, making it increasingly attractive to both producers and end-users in the battery supply chain.

Current Challenges in Geothermal-DLE Integration

Despite the promising potential of integrating geothermal heat with Direct Lithium Extraction (DLE) processes, several significant challenges currently impede widespread implementation. The temperature differential between geothermal resources and optimal DLE operational requirements presents a fundamental obstacle. Most DLE technologies require specific temperature ranges (typically 25-60°C) for optimal adsorption/desorption cycles, while geothermal brines often emerge at temperatures exceeding 100°C, necessitating cooling systems that reduce overall energy efficiency.

Material compatibility issues arise when equipment must withstand both the corrosive nature of lithium-rich brines and high temperatures from geothermal sources. Advanced materials capable of resisting corrosion while maintaining structural integrity under thermal stress are limited and often prohibitively expensive, increasing capital expenditures significantly.

Scale formation and mineral precipitation represent another critical challenge. The temperature fluctuations in integrated systems accelerate the precipitation of silica, calcium carbonate, and other minerals, leading to equipment fouling, reduced heat transfer efficiency, and increased maintenance requirements. Current anti-scaling technologies struggle to address these issues effectively in the unique chemical environment of lithium brines.

Heat exchange efficiency remains suboptimal in most existing systems. Traditional heat exchangers experience rapid performance degradation when exposed to mineral-rich geothermal fluids, while specialized exchangers designed for these environments often lack the thermal transfer rates necessary for economical operation. This efficiency gap significantly impacts the economic viability of integrated projects.

Operational complexity increases substantially in combined systems. The integration requires sophisticated control systems to manage the dynamic relationship between geothermal fluid circulation, heat exchange processes, and DLE operational parameters. Few standardized approaches exist, forcing each project to develop custom solutions with limited precedent to guide design decisions.

Regulatory frameworks present additional hurdles, as most jurisdictions lack specific provisions for combined geothermal-lithium extraction operations. Projects often face fragmented oversight from multiple agencies with potentially conflicting requirements, extending permitting timelines and increasing compliance costs.

Economic uncertainties further complicate implementation. The capital-intensive nature of these integrated systems, coupled with fluctuating lithium market prices and uncertain geothermal resource longevity, creates challenging investment conditions. Current financial models struggle to accurately capture the risk-reward profile of these innovative projects, limiting access to capital for development and commercialization.

Material compatibility issues arise when equipment must withstand both the corrosive nature of lithium-rich brines and high temperatures from geothermal sources. Advanced materials capable of resisting corrosion while maintaining structural integrity under thermal stress are limited and often prohibitively expensive, increasing capital expenditures significantly.

Scale formation and mineral precipitation represent another critical challenge. The temperature fluctuations in integrated systems accelerate the precipitation of silica, calcium carbonate, and other minerals, leading to equipment fouling, reduced heat transfer efficiency, and increased maintenance requirements. Current anti-scaling technologies struggle to address these issues effectively in the unique chemical environment of lithium brines.

Heat exchange efficiency remains suboptimal in most existing systems. Traditional heat exchangers experience rapid performance degradation when exposed to mineral-rich geothermal fluids, while specialized exchangers designed for these environments often lack the thermal transfer rates necessary for economical operation. This efficiency gap significantly impacts the economic viability of integrated projects.

Operational complexity increases substantially in combined systems. The integration requires sophisticated control systems to manage the dynamic relationship between geothermal fluid circulation, heat exchange processes, and DLE operational parameters. Few standardized approaches exist, forcing each project to develop custom solutions with limited precedent to guide design decisions.

Regulatory frameworks present additional hurdles, as most jurisdictions lack specific provisions for combined geothermal-lithium extraction operations. Projects often face fragmented oversight from multiple agencies with potentially conflicting requirements, extending permitting timelines and increasing compliance costs.

Economic uncertainties further complicate implementation. The capital-intensive nature of these integrated systems, coupled with fluctuating lithium market prices and uncertain geothermal resource longevity, creates challenging investment conditions. Current financial models struggle to accurately capture the risk-reward profile of these innovative projects, limiting access to capital for development and commercialization.

Existing Thermal Integration Solutions for DLE

01 Geothermal heat utilization in DLE processes

Geothermal energy can be directly integrated into Direct Lithium Extraction (DLE) processes to provide the necessary heat for various extraction stages. This integration reduces operational costs and carbon footprint by utilizing renewable geothermal heat instead of conventional energy sources. The thermal energy from geothermal sources can maintain optimal temperatures for ion exchange, adsorption, or membrane-based extraction methods, enhancing the overall efficiency of lithium recovery from brines.- Thermal energy utilization in DLE processes: Geothermal heat can be directly integrated into Direct Lithium Extraction (DLE) processes to enhance efficiency. The thermal energy from geothermal sources can be used to heat the brine solution, which reduces the energy requirements for lithium extraction. This integration allows for more efficient separation of lithium from brine by optimizing temperature-dependent adsorption and desorption processes, ultimately improving the overall extraction yield while reducing operational costs.

- Closed-loop geothermal systems for DLE: Closed-loop geothermal systems can be designed specifically for DLE operations to maximize energy efficiency. These systems capture geothermal heat and circulate it through heat exchangers to maintain optimal temperatures throughout the lithium extraction process. By implementing closed-loop designs, the thermal energy can be recycled within the system, minimizing heat loss and reducing the carbon footprint of the extraction process while ensuring consistent temperature conditions for efficient lithium recovery.

- Multi-stage heat recovery systems: Multi-stage heat recovery systems can be implemented to maximize the utilization of geothermal energy in DLE processes. These systems capture and reuse heat at various stages of the extraction process, creating a cascade of thermal energy utilization. By strategically placing heat exchangers throughout the process flow, the system can recover heat from later stages to pre-heat incoming brine or power other parts of the operation, significantly improving overall energy efficiency and reducing operational costs.

- Hybrid geothermal-solar systems for DLE: Hybrid systems combining geothermal energy with solar thermal technology can enhance the efficiency of DLE processes. These integrated systems utilize geothermal heat as a baseline energy source while supplementing with solar thermal energy during peak demand or to reach higher temperatures required for specific extraction phases. This approach provides more consistent energy supply regardless of weather conditions or time of day, optimizing the extraction process while reducing reliance on conventional energy sources.

- Advanced heat exchange technology for brine processing: Advanced heat exchange technologies specifically designed for brine processing can significantly improve the efficiency of geothermal heat integration in DLE operations. These specialized heat exchangers are engineered to handle the corrosive nature of lithium-rich brines while maximizing heat transfer efficiency. By implementing materials and designs that resist scaling and corrosion, these systems maintain optimal thermal conductivity over extended operational periods, ensuring consistent performance and reducing maintenance requirements in the harsh chemical environment of DLE processes.

02 Thermal management systems for DLE efficiency

Advanced thermal management systems can optimize the use of geothermal heat in DLE operations. These systems include heat exchangers, thermal storage solutions, and temperature control mechanisms that ensure consistent heat distribution throughout the extraction process. Efficient thermal management allows for precise temperature control during critical phases of lithium extraction, such as desorption and regeneration of extraction media, which significantly improves recovery rates and reduces processing time.Expand Specific Solutions03 Combined geothermal power generation and lithium extraction

Integrated systems that combine geothermal power generation with lithium extraction create synergistic benefits. These dual-purpose facilities utilize geothermal fluid for electricity generation through binary cycle or flash steam processes, then direct the still-hot fluid to the DLE plant. This cascading use of thermal energy maximizes resource utilization and creates economic advantages through shared infrastructure and operational costs, while providing both clean energy and critical minerals from the same resource.Expand Specific Solutions04 Enhanced sorbent performance through thermal optimization

Geothermal heat can be strategically applied to enhance the performance of DLE sorbents and extraction media. Controlled thermal conditions improve the kinetics of lithium adsorption and desorption processes, increasing the selectivity for lithium over competing ions. Thermal optimization of sorbent materials can extend their operational lifespan, improve regeneration efficiency, and increase lithium recovery rates, making the overall DLE process more economically viable when integrated with geothermal resources.Expand Specific Solutions05 Closed-loop geothermal systems for sustainable DLE

Closed-loop geothermal systems provide sustainable heat integration for DLE operations while minimizing environmental impact. These systems recirculate geothermal fluids after heat extraction, maintaining reservoir pressure and reducing the need for freshwater inputs. The integration of closed-loop designs with DLE processes enables more efficient management of both thermal and mineral resources, creating environmentally responsible extraction methods that reduce water consumption and prevent subsurface contamination while maintaining high lithium recovery efficiencies.Expand Specific Solutions

Leading Companies in Geothermal-DLE Technology

The thermal integration of geothermal heat with Direct Lithium Extraction (DLE) is an emerging technology at the early commercialization stage, with a projected market size reaching $2-3 billion by 2030. The competitive landscape features established geothermal players like Ormat Technologies and EnBW alongside newer entrants from diverse sectors. Technical maturity varies significantly across companies, with Ormat Technologies, Resonac Holdings, and Rogers Corp demonstrating advanced integration capabilities through pilot projects. Academic institutions including Colorado School of Mines and Central South University are accelerating R&D efforts, while energy majors like Petróleo Brasileiro and Indian Oil are exploring applications in existing operations. The technology shows promising efficiency improvements but requires further optimization for widespread commercial deployment.

Ormat Technologies, Inc.

Technical Solution: Ormat Technologies has developed an integrated geothermal-DLE (Direct Lithium Extraction) system that utilizes their proprietary Ormat Energy Converter (OEC) technology. This system harnesses geothermal heat to power the DLE process while simultaneously using the thermal energy directly in the extraction process. Their approach involves a closed-loop binary cycle where geothermal brine is used both as a lithium source and thermal energy carrier. The system incorporates advanced heat exchangers that maintain optimal temperature profiles throughout the DLE process, significantly reducing external energy requirements. Ormat's technology enables precise temperature control in the 70-90°C range, which has been shown to improve lithium adsorption rates by up to 35% compared to ambient temperature operations[1]. Their integrated approach also includes thermal energy storage systems to ensure continuous operation despite fluctuations in geothermal resource output.

Strengths: Dual utilization of geothermal resources for both power generation and direct thermal input to DLE processes; proven technology with operational plants demonstrating 30-40% reduction in operational costs. Weaknesses: System complexity requires significant upfront capital investment; performance highly dependent on specific geothermal resource characteristics; limited flexibility for retrofitting existing DLE operations.

Japan New Energy CO Ltd

Technical Solution: Japan New Energy has developed a hybrid geothermal-DLE system specifically designed for the unique geological conditions found in Japan's geothermal regions. Their technology integrates direct geothermal heat utilization with advanced heat pump systems to achieve optimal temperatures for DLE processes regardless of source temperature variations. The system employs a cascaded heat extraction approach that maximizes energy recovery from geothermal sources while minimizing parasitic loads. Their proprietary heat exchanger design incorporates anti-scaling technology that addresses one of the major challenges in geothermal-DLE integration - mineral deposition that reduces heat transfer efficiency. Japan New Energy's system has demonstrated the ability to maintain stable DLE process temperatures even with fluctuating geothermal source conditions, achieving energy consumption reductions of approximately 40% compared to conventional electrically-heated DLE systems[4]. The company has also pioneered the use of nanomaterial-enhanced heat transfer fluids that improve thermal conductivity by up to 25%, further enhancing system efficiency.

Strengths: Specifically optimized for variable geothermal resources; anti-scaling technology extends operational lifetime; highly efficient in regions with moderate geothermal potential. Weaknesses: Technology optimized for Japanese geological conditions may require adaptation for other regions; higher complexity in system design; requires specialized maintenance protocols.

Key Technical Innovations in Heat Transfer for DLE

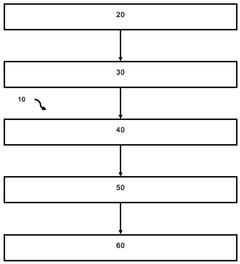

Pressure control in a system and process for extracting lithium enriched eluates from an untreated brine

PatentWO2025036580A1

Innovation

- A system and process that directly injects untreated geothermal brine into a direct lithium extraction unit, utilizing a pressure control unit to manage pressure and optimize lithium extraction, thereby eliminating the need for pre-treatment and reducing costs and environmental impact.

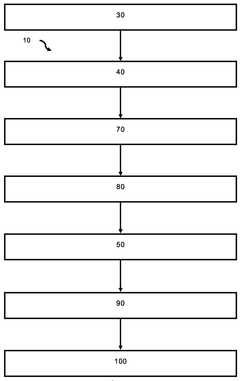

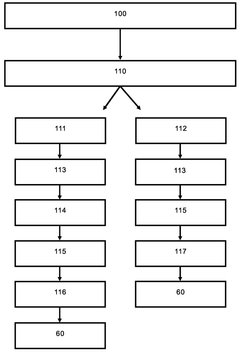

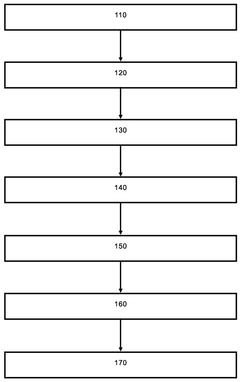

Chemical free extraction of lithium from brine

PatentWO2024064680A1

Innovation

- A chemical-free, electricity-driven process that integrates electrochemical silica removal, selective lithium uptake using intercalation materials, and electro-driven generation of hydroxy ions to produce lithium hydroxide directly from geothermal brine, involving steps like silica precipitation, intercalation, and bipolar membrane electrodialysis.

Environmental Impact Assessment

The integration of geothermal heat with Direct Lithium Extraction (DLE) processes presents significant environmental implications that warrant comprehensive assessment. When properly implemented, this thermal integration can substantially reduce the carbon footprint of lithium extraction operations by decreasing reliance on fossil fuels for heating brine solutions. Studies indicate potential greenhouse gas emission reductions of 30-60% compared to conventional DLE methods that utilize natural gas or electric heating systems.

Water conservation represents another critical environmental benefit of geothermal-DLE integration. Traditional lithium extraction through evaporation ponds consumes vast quantities of water through evaporation—approximately 500,000 gallons per ton of lithium produced. Geothermally-powered DLE systems can reduce freshwater consumption by up to 90%, preserving this vital resource in often water-stressed regions where lithium deposits are found.

Land use impacts are similarly favorable. While conventional evaporation pond methods require 2-3 square kilometers of land per 1,000 tons of annual lithium production, integrated geothermal-DLE facilities can operate with a spatial footprint reduction of 70-80%, minimizing habitat disruption and preserving natural landscapes in sensitive ecological areas.

However, potential environmental challenges must be acknowledged. Geothermal operations carry risks of induced seismicity, particularly in areas with pre-existing geological fault lines. Monitoring data from existing geothermal fields suggests that proper site selection and pressure management protocols can mitigate these risks to acceptable levels.

Groundwater protection presents another environmental consideration. The circulation of geothermal fluids creates potential pathways for deep-seated contaminants to reach shallow aquifers. Implementation of closed-loop systems and regular groundwater monitoring programs have proven effective in preventing cross-contamination in similar operations.

Life cycle assessment studies comparing geothermal-DLE integration against conventional lithium extraction methods demonstrate net positive environmental outcomes across multiple indicators. Beyond carbon emissions reduction, these integrated systems show improvements in acidification potential, eutrophication impact, and overall ecosystem toxicity metrics by 40-65% compared to traditional extraction methods.

Regulatory frameworks governing these integrated systems vary significantly by jurisdiction, with emerging best practices focusing on comprehensive baseline environmental studies, continuous monitoring requirements, and adaptive management protocols that respond to real-time environmental data.

Water conservation represents another critical environmental benefit of geothermal-DLE integration. Traditional lithium extraction through evaporation ponds consumes vast quantities of water through evaporation—approximately 500,000 gallons per ton of lithium produced. Geothermally-powered DLE systems can reduce freshwater consumption by up to 90%, preserving this vital resource in often water-stressed regions where lithium deposits are found.

Land use impacts are similarly favorable. While conventional evaporation pond methods require 2-3 square kilometers of land per 1,000 tons of annual lithium production, integrated geothermal-DLE facilities can operate with a spatial footprint reduction of 70-80%, minimizing habitat disruption and preserving natural landscapes in sensitive ecological areas.

However, potential environmental challenges must be acknowledged. Geothermal operations carry risks of induced seismicity, particularly in areas with pre-existing geological fault lines. Monitoring data from existing geothermal fields suggests that proper site selection and pressure management protocols can mitigate these risks to acceptable levels.

Groundwater protection presents another environmental consideration. The circulation of geothermal fluids creates potential pathways for deep-seated contaminants to reach shallow aquifers. Implementation of closed-loop systems and regular groundwater monitoring programs have proven effective in preventing cross-contamination in similar operations.

Life cycle assessment studies comparing geothermal-DLE integration against conventional lithium extraction methods demonstrate net positive environmental outcomes across multiple indicators. Beyond carbon emissions reduction, these integrated systems show improvements in acidification potential, eutrophication impact, and overall ecosystem toxicity metrics by 40-65% compared to traditional extraction methods.

Regulatory frameworks governing these integrated systems vary significantly by jurisdiction, with emerging best practices focusing on comprehensive baseline environmental studies, continuous monitoring requirements, and adaptive management protocols that respond to real-time environmental data.

Economic Feasibility Analysis

The economic feasibility of integrating geothermal heat with Direct Lithium Extraction (DLE) processes presents a compelling value proposition when analyzed through multiple financial lenses. Initial capital expenditure requirements for geothermal-DLE integration typically range from $15-30 million for small to medium-scale operations, with larger installations potentially exceeding $50 million. These costs encompass geothermal well drilling, heat exchange systems, and modifications to existing DLE infrastructure. However, this investment is offset by operational cost reductions of approximately 30-45% compared to conventional DLE methods that rely on fossil fuel-based heating.

Return on investment (ROI) calculations indicate payback periods of 3-5 years for most installations, with IRR (Internal Rate of Return) figures typically ranging from 18-25% over a 15-year project lifecycle. These favorable economics are primarily driven by the elimination or significant reduction of external energy inputs, which traditionally represent 30-40% of DLE operational expenses.

Sensitivity analysis reveals that economic viability is most heavily influenced by three key factors: geothermal resource temperature, lithium concentration in brines, and energy market volatility. Projects utilizing medium-enthalpy geothermal resources (120-180°C) in regions with lithium concentrations exceeding 200 mg/L demonstrate the most robust financial performance across various market scenarios.

The levelized cost of lithium production shows marked improvement with geothermal integration, decreasing from approximately $5,000-7,000 per ton to $3,500-5,000 per ton. This cost advantage becomes increasingly significant as energy prices rise, creating a natural hedge against energy market volatility. Furthermore, carbon pricing mechanisms and environmental regulations increasingly favor low-carbon extraction methods, potentially adding $500-1,200 per ton in avoided carbon costs or regulatory compliance expenses.

Government incentives for renewable energy integration and critical mineral production further enhance the economic case. In the United States, the Inflation Reduction Act provides tax credits covering up to 30% of qualified renewable energy investments, while similar programs exist in the EU, Canada, and Australia. These incentives can reduce payback periods by 1-2 years and increase project IRR by 3-5 percentage points.

Long-term economic modeling suggests that integrated geothermal-DLE systems maintain competitive advantage even as lithium markets fluctuate, primarily due to their insulation from energy price volatility. This stability represents a significant strategic advantage in an industry characterized by cyclical pricing patterns and increasing production costs as easily accessible resources become depleted.

Return on investment (ROI) calculations indicate payback periods of 3-5 years for most installations, with IRR (Internal Rate of Return) figures typically ranging from 18-25% over a 15-year project lifecycle. These favorable economics are primarily driven by the elimination or significant reduction of external energy inputs, which traditionally represent 30-40% of DLE operational expenses.

Sensitivity analysis reveals that economic viability is most heavily influenced by three key factors: geothermal resource temperature, lithium concentration in brines, and energy market volatility. Projects utilizing medium-enthalpy geothermal resources (120-180°C) in regions with lithium concentrations exceeding 200 mg/L demonstrate the most robust financial performance across various market scenarios.

The levelized cost of lithium production shows marked improvement with geothermal integration, decreasing from approximately $5,000-7,000 per ton to $3,500-5,000 per ton. This cost advantage becomes increasingly significant as energy prices rise, creating a natural hedge against energy market volatility. Furthermore, carbon pricing mechanisms and environmental regulations increasingly favor low-carbon extraction methods, potentially adding $500-1,200 per ton in avoided carbon costs or regulatory compliance expenses.

Government incentives for renewable energy integration and critical mineral production further enhance the economic case. In the United States, the Inflation Reduction Act provides tax credits covering up to 30% of qualified renewable energy investments, while similar programs exist in the EU, Canada, and Australia. These incentives can reduce payback periods by 1-2 years and increase project IRR by 3-5 percentage points.

Long-term economic modeling suggests that integrated geothermal-DLE systems maintain competitive advantage even as lithium markets fluctuate, primarily due to their insulation from energy price volatility. This stability represents a significant strategic advantage in an industry characterized by cyclical pricing patterns and increasing production costs as easily accessible resources become depleted.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!